Professional Documents

Culture Documents

Name: Nihat First Name (S) : WPQ N°: TUR-19-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QW

Uploaded by

Sabit Cirdi0 ratings0% found this document useful (0 votes)

48 views2 pagesOriginal Title

welding certificate

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

48 views2 pagesName: Nihat First Name (S) : WPQ N°: TUR-19-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QW

Uploaded by

Sabit CirdiCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

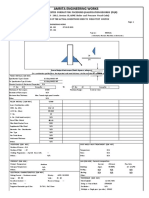

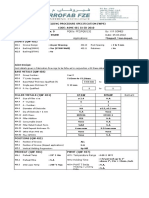

WELDERS - PERFORMANCE - QUALIFICATION

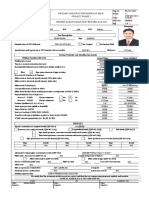

Name: Nihat First Name (s): KÖKEN WPQ n°: TUR-19-A-931

Registration number :

Production weld WPS used N°: TÜMAY-WPS-

Stamp: N/A

Test coupon Rev. 18-002

Essential Variables (QW -350) Actual Values Qualified Ranges

QW Type (manual;semi-auto) 1: Semi-auto 2: N/A 1: Semi-auto 2: N/A

352-356 Welding Process(es) 1: GMAW 2: N/A 1: GMAW 2: N/A

Info. onl. Base Material(s) specification EN 10025-2 S355JR to EN 10025-2 S355JR

402.4 Backing (with/without) 1: YES NO Backing

402.7 Backing (with/without) (OFW) 1: YES NO N/A

403.2 Plate Thickness (mm) or Fillet : Maximum to be welded

14 mm

403.16 Pipe outside dia. (mm) Butt Weld : O.D ≥ 73 mm

403.18 P-No. to P-No. N/A to N/A N/A

Info. onl. Filler metal or electrode specification(s) 1: AWS A5.18:05 2: N/A

(SFA)

Info. onl. Filler metal or electrode classification (s) 1: ER 70 S-6 2: N/A

404.14 Filler (GTAW, PAW, OFW ) with without N/A

404.15 Filler metal F-Number(s) 1: F No:6 2: N/A 1: F No:6 2: N/A

404.22 Consumable Insert (GTAW or PAW) with without N/A

404.23 Filler metal product forms (GTAW,PAW) 1: Bare 2: N/A 1: Bare 2: N/A

t: Weld metal deposit 1: 14 mm 2: N/A

404.30 1:Max. to be welded 2: N/A

3 layers minimum Yes No Yes No

404.31 t: Weld metal deposit (OFW) 1: N/A 1: N/A

a) T<1/2“(13mm): N/A a) 1.1 x T : MAX

404.32 t: Limit (GMAW Short Circ.)

b) T≥1/2“(13mm): N/A b) 2T: MAX

405.1 Position qualified 1: 1G 2: N/A 1: Ø >24" F, ≤24" F 2: N/A

405.3 Vertical progression (uphil or downhill) 1: Uphill 2: N/A 1: Uphill 2: N/A

408.7 Type of fuel gas (OFW) 1: N/A 1: N/A

408.8 Inert gas backing(GTAW,PAW,GMAW) 1: with without 1: N/A

Transfer. Mode (Spray, Puls.Globular

409.2

Short Circ.) (GMAW, FCAW)

1: Spray 1: Spray

409.4 AC - DC (GTAW only) 1: N/A 1: N/A

QW-161 GUIDED BEND TEST

Type QW-462.3 (a) (b) Results: Type QW-462.2 Results:

N/A (Face Bend) N/A Side Bend-1-2 (Side Bend) Acc.

N/A (Root Bend) N/A Side Bend-3-4 (Side Bend) Acc.

QW-191.2 ULTRASONIC TEST

UT-Personnel (Name): Mehmet SAGIROGLU Level: II ASNT TC1A

Results: Acc. Report N°: MANUT-0500

QW-181.2 FILLET WELD TEST QW-462.4 (b) or (c)

Location of track or tear:

Length: % Results:

QW-184 MACRO EXAMINATION QW-462.4 (b)

Length of indication: Concavity: Convexity:

Fillet leg size: Results:

OTHER

Visual examination results (QW-302.4): KA/TÜM/VT/231119

Welding test conducted by: Y. KENAN ARSLANTAY BVT 297

Mechanical / radiographic tests conducted by: Laboratory test no.:

We certify that the statements in this record are correct and that the test coupons were prepared welded and tested in accordance with the requirements of Section IX of the ASME (ED

2018) Boiler and Pressure Vessel Code.

Manufacturer / contractor Examiner : Signature Decision Maker : Signature Day Month Year

Y. KENAN ARSLANTAY ALİ TAYLAN ÖZTÜRK 23.11.2019

BVT 297

WE 016-TR.Rev 04 1/2 30/11/ 2019

r

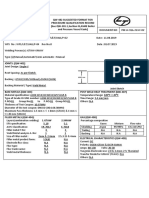

Certificate N : TUR-18-A-931

WELDER APPROVAL TEST CERTIFICATE Page 2 / 2

Registration number :

Prolongation for approval by Employer or the welding Coordinator for the following 6 months

Date Signature Name – Position or Title

WE 016-TR.Rev 04 2/2 30/11/2018

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Name:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWDocument2 pagesName:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWSabit CirdiNo ratings yet

- Welders Qualified for Semi-Auto GMAWDocument2 pagesWelders Qualified for Semi-Auto GMAWSabit CirdiNo ratings yet

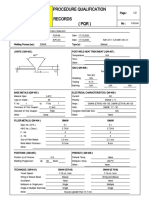

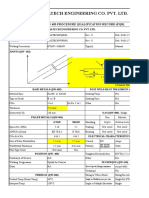

- Aic Asf PQR 133Document3 pagesAic Asf PQR 133AHMED MEDANYNo ratings yet

- PQRDocument2 pagesPQRHoangNo ratings yet

- AMRITA ENGINEERING WORKS PQRDocument3 pagesAMRITA ENGINEERING WORKS PQRBalkishan DyavanapellyNo ratings yet

- Welding Procedure Specification for Vertical Storage TanksDocument6 pagesWelding Procedure Specification for Vertical Storage TanksYASH BARDHAN SinghNo ratings yet

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- PT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSDocument1 pagePT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSBudi Setia RahmanNo ratings yet

- WPS Gtaw+smawDocument2 pagesWPS Gtaw+smawAnand GNo ratings yet

- Form No. 101 - 401 Bharat Heavy Electricals Limited Tiruchirappalli-620014 Welding Technology Centre Page 1 of 2Document10 pagesForm No. 101 - 401 Bharat Heavy Electricals Limited Tiruchirappalli-620014 Welding Technology Centre Page 1 of 2JithinAbrahamNo ratings yet

- WPQ FormatDocument8 pagesWPQ FormatsanjaykumarmauryaNo ratings yet

- WPS Dissimilar 11.08 MM Max.Document4 pagesWPS Dissimilar 11.08 MM Max.Sripathy50% (2)

- Welding Procedure Specification for Stainless SteelDocument5 pagesWelding Procedure Specification for Stainless SteelVarun Malhotra100% (5)

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- WQT Record for Pipeline Welder QualificationDocument99 pagesWQT Record for Pipeline Welder QualificationVivek Jadhav100% (1)

- Astm 537 CL.1 WPSDocument2 pagesAstm 537 CL.1 WPSaudiihussain67% (3)

- GTAW Welding Process ParametersDocument12 pagesGTAW Welding Process Parametersmiteshpatel191No ratings yet

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- Procedure Qualification Record PQRDocument2 pagesProcedure Qualification Record PQRWalid BdeirNo ratings yet

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- QW 482 WPS (Gtaw+smaw) 04.01.2015Document8 pagesQW 482 WPS (Gtaw+smaw) 04.01.2015Srikant GanjiNo ratings yet

- CALTECH ENGINEERING PQR PROCEDUREDocument8 pagesCALTECH ENGINEERING PQR PROCEDURESrikant GanjiNo ratings yet

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocument1 pageWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- WELDING PROCEDURE SPECIFICATION FOR GTAW+FCAW+GTAW-SA928Document2 pagesWELDING PROCEDURE SPECIFICATION FOR GTAW+FCAW+GTAW-SA928duyanhNo ratings yet

- PQR 03 2014Document2 pagesPQR 03 2014vinuNo ratings yet

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocument3 pagesWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanNo ratings yet

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 pagesBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarNo ratings yet

- WELDER QUALIFICATION REPORTDocument2 pagesWELDER QUALIFICATION REPORTAkash Singh TomarNo ratings yet

- Slamet WPQRDocument1 pageSlamet WPQRChandra Bintang W.PNo ratings yet

- S 001 Link 2Document1 pageS 001 Link 2wael badawiNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Aic Asf PQR 0121Document2 pagesAic Asf PQR 0121AHMED MEDANYNo ratings yet

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- 1 WPS 132Document2 pages1 WPS 132VishnuGK100% (1)

- Aic Asf PQR 0122Document2 pagesAic Asf PQR 0122AHMED MEDANYNo ratings yet

- Gtaw - Inox - 6g Julio Arriagada Gallegos Constructora Laja Mayo 2023Document1 pageGtaw - Inox - 6g Julio Arriagada Gallegos Constructora Laja Mayo 2023elevacerchileNo ratings yet

- Final PQRDocument130 pagesFinal PQRAhamed Naufal CaNo ratings yet

- Abdul Muhid WPQRDocument1 pageAbdul Muhid WPQRChandra Bintang W.PNo ratings yet

- WPQRDocument1 pageWPQRangelito bernalNo ratings yet

- WPQ 09Document1 pageWPQ 09Budi HahnNo ratings yet

- Weld Procedure Specification (WPS)Document2 pagesWeld Procedure Specification (WPS)Senthil Kumaran0% (1)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- Smaw Wps FinalDocument3 pagesSmaw Wps FinalsheikmoinNo ratings yet

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- PQR With-PwhtDocument2 pagesPQR With-PwhtKarthikNo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- WPS, PQR, WPQ PoojaDocument10 pagesWPS, PQR, WPQ PoojaRajmahesh Dakhore100% (1)

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04Document9 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04BIIS QAQC Babu SivaNo ratings yet

- PWPS 102 - CopyDocument2 pagesPWPS 102 - CopyCyril J PadiyathNo ratings yet

- Raoult's law and colligative propertiesDocument27 pagesRaoult's law and colligative propertiesGøbindNo ratings yet

- Training Report PRASADDocument32 pagesTraining Report PRASADshekharazad_suman85% (13)

- 2024 Yoga Vidya Training FormDocument8 pages2024 Yoga Vidya Training FormJohnNo ratings yet

- Ndeb Bned Reference Texts 2019 PDFDocument11 pagesNdeb Bned Reference Texts 2019 PDFnavroop bajwaNo ratings yet

- FINANCIAL REPORTSDocument34 pagesFINANCIAL REPORTSToni111123No ratings yet

- Quick Reference To Psychotropic Medications: AntidepressantsDocument2 pagesQuick Reference To Psychotropic Medications: AntidepressantsNaiana PaulaNo ratings yet

- FSA&V Case StudyDocument10 pagesFSA&V Case StudyAl Qur'anNo ratings yet

- Sample Prayer For Final Thesis DefenseDocument6 pagesSample Prayer For Final Thesis Defensefjfyj90y100% (2)

- A. Lesson Preview / Review: This Document Is The Property of PHINMA EDUCATIONDocument11 pagesA. Lesson Preview / Review: This Document Is The Property of PHINMA EDUCATIONTherese Anne ArmamentoNo ratings yet

- CENELEC RA STANDARDS CATALOGUEDocument17 pagesCENELEC RA STANDARDS CATALOGUEHamed AhmadnejadNo ratings yet

- CS Sample Paper 1Document10 pagesCS Sample Paper 1SpreadSheetsNo ratings yet

- Bioprocess Engineering QuestionsDocument13 pagesBioprocess Engineering QuestionsPalanisamy Selvamani100% (1)

- Teaching English as a Second Language in Four PhasesDocument18 pagesTeaching English as a Second Language in Four PhasesVia Johnson100% (1)

- Drainage Manual: State of Florida Department of TransportationDocument78 pagesDrainage Manual: State of Florida Department of TransportationghoyarbideNo ratings yet

- Course 4Document3 pagesCourse 4Ibrahim SalahudinNo ratings yet

- Distillation Lab ReportDocument6 pagesDistillation Lab ReportSNo ratings yet

- Python operators and data types quizDocument34 pagesPython operators and data types quizATUL SHARMANo ratings yet

- Hercules Segers - Painter EtchterDocument4 pagesHercules Segers - Painter EtchterArtdataNo ratings yet

- Chapter 08-Borrowing Costs-Tutorial AnswersDocument4 pagesChapter 08-Borrowing Costs-Tutorial AnswersMayomi JayasooriyaNo ratings yet

- Đáp Án K Năng NóiDocument6 pagesĐáp Án K Năng NóiSói ConNo ratings yet

- Too Early! by Anton Pavlovich ChekhovDocument4 pagesToo Early! by Anton Pavlovich Chekhovapi-19787590No ratings yet

- CotomDocument8 pagesCotommuangawaNo ratings yet

- Arnica The Miracle Remedy - Case RecordsDocument4 pagesArnica The Miracle Remedy - Case Recordskaravi schiniasNo ratings yet

- Day3 PESTLE AnalysisDocument13 pagesDay3 PESTLE AnalysisAmit AgrawalNo ratings yet

- Fruit-Gathering by Tagore, Rabindranath, 1861-1941Document46 pagesFruit-Gathering by Tagore, Rabindranath, 1861-1941Gutenberg.orgNo ratings yet

- DMG48480F021 01WN DataSheetDocument16 pagesDMG48480F021 01WN DataSheeteminkiranNo ratings yet

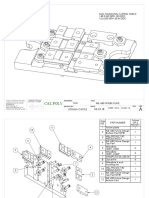

- Fixture Design ProjectDocument4 pagesFixture Design ProjectJosh CastleNo ratings yet

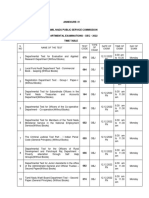

- ANNEXURE IV Dec 2022 enDocument17 pagesANNEXURE IV Dec 2022 enadvocacyindyaNo ratings yet

- Chapter 2 Research and DesignDocument24 pagesChapter 2 Research and Designalvin salesNo ratings yet

- Lesson Plan in ESPDocument4 pagesLesson Plan in ESPkaren daculaNo ratings yet