Professional Documents

Culture Documents

Weld Procedure Specification (WPS)

Uploaded by

Senthil Kumaran0%(1)0% found this document useful (1 vote)

485 views2 pagesWPS is a Written document gives instruction to the welder. Welding document. GTAW and SAW Combination welding in SS Material

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWPS is a Written document gives instruction to the welder. Welding document. GTAW and SAW Combination welding in SS Material

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0%(1)0% found this document useful (1 vote)

485 views2 pagesWeld Procedure Specification (WPS)

Uploaded by

Senthil KumaranWPS is a Written document gives instruction to the welder. Welding document. GTAW and SAW Combination welding in SS Material

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

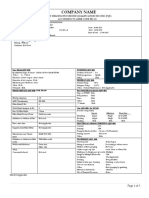

COMPANY NAME

QW-482. WELDING PROCEDURE SPECIFICATIONS (WPS)

ACCORDING TO ASME CODE SEC-IX

Company Name : XXXXXXXXXXXXXX

WPS No : XXXXXXXXXXXX Rev.No: 0 Date : 18.04.2017

Supporting PQR : XXXXX /PQR/004 PQR Date : 18.04.2017

Welding Process : GTAW

Types(Manual, Automatic, semiautomatic) : Manual

Joints :((QW-402))

All Joint Design

Joint Design : All as per approved fabrication drawing

Baking : With or Without

Baking Metal : Base metal or Weld metal

Retainer : Not to be Used

Base Metals(QW-403) POSITION (QW-405)

P.No.1 to P.No.8 Position of Groove : All

Group No: All to Group No: All Fillet : All

specification Type & Grade : _____________________ Weld progression : Uphill

specification Type & Grade : ________________________ Other : N/A

Thickness Range PREHEAT (QW-406)

Base metal : Groove : 1.5 mm - 16 mm Preheat Temp. : 16˚C Min

Fillet : All Interpass Temp. : 160°C Max

Other : N/A Other Preheat Maintenance : Not Applicable

FILLER METALS (QW-404) Post Weld Heat treatment (QW-407)

SFA Specification 5.9 Type of PWHT : Not Applicable

AWS Classification ER 309L Temperature : Not Applicable

Filler Metal F-No. 6 Time : Not Applicable

Other : Not Applicable

‘T’ Limits : Not Applicable

Weld Metal Analysis A-No. 8 Gas (QW-408) For GTAW

Size Of Filler Metal 2.5mm Percent Composition

Filler Metal Product Form Solid bare wire Gas(es) (Mixture) Flow Rate

Addition or deletion of None Shielding : Argon single 10-15 LPM

Flux Backing : Argon single 20-25 LPM

Trailing : N/A N/A N/A

Flux / wire class Not Applicable ELECTRICAL CHARACTERISTICS (QW-409)

Current : DC

Supplemental Filler Metal Not Applicable

Polarity : EN

Manufacture and Brand All approved brand names Tungsten Electrode Size : 2.4 mm ( Thoriated 2% )

name Pulsing Current : None

Heat input : N/A

Other : None

Addition or deletion for With filler metal TECHNIQUE (QW -410)

filler metal String or weave Bead : Root string & others weave

Weld metal thickness Multi pass to Single pass (per side) : Multiple

Groove : 16 mm MAX Single to Multiple Electrodes : None

Fillet : All Peening : Not Permitted

Other Orifice Cup Size : 6mm,8mm or 10mm

Consumable Insert : Initial or Interpass cleaning : Grinding & Wire brushing

None

Method of back gauge : Grinding(Where

applicable)and back chip

sound metal

Oscillation : N/A

Close to out chamber : None

Other : N/A

Manual or Automatic : Manual

Use of Thermal Processes : None

N/A- NOT APPLICABLE

Page 1 of 2

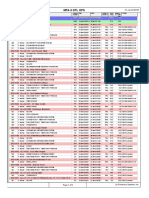

COMPANY NAME

QW-482. WELDING PROCEDURE SPECIFICATIONS (WPS)

ACCORDING TO ASME CODE SEC-IX

Pass No. Process Filler metal Size (mm) Current Volts TRAVEL SPEED Polarity

class (A) (V) (mm/min)

Root GTAW ER- 309L 2.5 90-110 12-16 - DCEN

Subsequent GTAW ER- 309L 2.5 90-125 12-15 - DCEN

Pass

PREPARED BY APPROVED BY REVIEWED BY AI / CLIENT

SIGN :

NAME:

DATE:

Page 2 of 2

You might also like

- C-11, C-13 Dissassembly - Assembly 2006 PDFDocument80 pagesC-11, C-13 Dissassembly - Assembly 2006 PDFAhmer Camdzic100% (2)

- Welding Procedure Specification for Stainless SteelDocument5 pagesWelding Procedure Specification for Stainless SteelVarun Malhotra100% (5)

- Storage Tank Fabrication & Erection ProcedureDocument15 pagesStorage Tank Fabrication & Erection ProcedureSenthil Kumaran100% (9)

- Inspection and Test Plan - Pressure Vessel Fabrication (ITP)Document9 pagesInspection and Test Plan - Pressure Vessel Fabrication (ITP)Senthil Kumaran100% (2)

- Blasting & Painting Report - FormatDocument2 pagesBlasting & Painting Report - FormatSenthil Kumaran100% (6)

- QC Welding Inspector InterviewDocument286 pagesQC Welding Inspector InterviewNDT CTC100% (7)

- Welding Repair ProcedureDocument6 pagesWelding Repair ProcedureSenthil Kumaran100% (2)

- Procedure For Post Weld Heat Treatment (PWHT PROCEDURE)Document10 pagesProcedure For Post Weld Heat Treatment (PWHT PROCEDURE)Senthil Kumaran100% (2)

- D0117 RB XEO Service ManualDocument217 pagesD0117 RB XEO Service ManualYuriko MartinezNo ratings yet

- Dimensional Inspection Report TemplateDocument1 pageDimensional Inspection Report TemplateAlfian ImaduddinNo ratings yet

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocument3 pagesWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanNo ratings yet

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- PT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSDocument1 pagePT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSBudi Setia RahmanNo ratings yet

- AES-W-016 welding filler metalsDocument2 pagesAES-W-016 welding filler metalsmalika_00No ratings yet

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- Wps For Smaw06-001 (Pipe 6g CS)Document10 pagesWps For Smaw06-001 (Pipe 6g CS)walitedisonNo ratings yet

- Wps FormatDocument12 pagesWps FormatGohilakrishnan ThiagarajanNo ratings yet

- Liquid Penetrant Testing Report SummaryDocument1 pageLiquid Penetrant Testing Report SummaryAbdul NaveedNo ratings yet

- Essential and Non-Essential Variables For WPS - PQRDocument4 pagesEssential and Non-Essential Variables For WPS - PQRNatarajan MurugesanNo ratings yet

- WPS 2014-002 006 - 6G PipeDocument3 pagesWPS 2014-002 006 - 6G PipejeswinNo ratings yet

- Preparation and Control of WeldingDocument3 pagesPreparation and Control of Weldingbalakumar rajaramNo ratings yet

- WPS for Welding SA-335 P11 to SA-234 WP11Document3 pagesWPS for Welding SA-335 P11 to SA-234 WP11Ganesh rohitNo ratings yet

- GTAW Welding ParametersDocument1 pageGTAW Welding ParameterssahadNo ratings yet

- WPS for 304 Stainless Steel Welding ProcedureDocument2 pagesWPS for 304 Stainless Steel Welding ProcedureAsad Bin Ala QatariNo ratings yet

- Attachment 22 - (SECL-PIP026) Welding Consumable Issue SlipDocument5 pagesAttachment 22 - (SECL-PIP026) Welding Consumable Issue SlipRjeb mohamedNo ratings yet

- WPS FormatDocument2 pagesWPS FormatAmit SarkarNo ratings yet

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Document17 pagesWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizNo ratings yet

- Welder'S Work Record Log Sheet Welder's Name: S.M.W. Membership#Document1 pageWelder'S Work Record Log Sheet Welder's Name: S.M.W. Membership#satnamNo ratings yet

- Preheat and Interpass TempDocument2 pagesPreheat and Interpass TempUche UrchNo ratings yet

- Welding terminology guideDocument18 pagesWelding terminology guidemahi1437100% (1)

- ASME P NumbersDocument3 pagesASME P Numbersrajesh100% (1)

- Welding Repair Procedure for PT. Juhdi Sakti EngineeringDocument4 pagesWelding Repair Procedure for PT. Juhdi Sakti EngineeringRiky SumantriNo ratings yet

- July weld repair rate reportDocument2 pagesJuly weld repair rate reportSalahuddin Farooqui100% (1)

- WPS PQR As Per IsDocument3 pagesWPS PQR As Per Istarun kaushalNo ratings yet

- Request for Welding Procedure ApprovalDocument10 pagesRequest for Welding Procedure ApprovalAlam MD SazidNo ratings yet

- WPQR Welding Procedure QualificationDocument3 pagesWPQR Welding Procedure QualificationThanasis KyrgiazoglouNo ratings yet

- Acceptable Grade of Plate Material (API 650)Document1 pageAcceptable Grade of Plate Material (API 650)juantamad02No ratings yet

- MTH - Spec Cross-Ref Chartr1Document1 pageMTH - Spec Cross-Ref Chartr1RamuAlagappanNo ratings yet

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNo ratings yet

- QW-451 Procedure Qualification Thickness Limits and Test SpecimensDocument2 pagesQW-451 Procedure Qualification Thickness Limits and Test SpecimensmiteshNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw - OverlayDocument1 pageWPS Format For Asme Ix - Wps - Gtaw - OverlayThe Welding Inspections Community100% (1)

- Butt JointsDocument21 pagesButt JointsRaj1-23No ratings yet

- Welding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesWelding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)ngonphanhoangNo ratings yet

- ASME P NumbersDocument1 pageASME P NumbersFahri Risfa ZulfiNo ratings yet

- Piping Inspection 22.01.2020Document72 pagesPiping Inspection 22.01.2020KarthikNo ratings yet

- Welded Tube Joint SpecDocument8 pagesWelded Tube Joint SpecAvinash ShuklaNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- Lesson 14 WelderQuals - New2Document80 pagesLesson 14 WelderQuals - New2Mohd Syafiq100% (1)

- WPS Format For Asme Ix - Wps - Gtaw SawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityNo ratings yet

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- Name:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWDocument2 pagesName:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWSabit CirdiNo ratings yet

- BPV IX-16-3 QW-283 - ButteringDocument1 pageBPV IX-16-3 QW-283 - ButteringyutweldingNo ratings yet

- Weld RepairDocument2 pagesWeld RepairAnurag YadavNo ratings yet

- ASTM Grades Explained for Pipes, Fittings, Flanges & MoreDocument4 pagesASTM Grades Explained for Pipes, Fittings, Flanges & Moremohan babuNo ratings yet

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- NRP QapDocument10 pagesNRP QapKevin Mathew100% (1)

- Fit Up Welding Visual Inspection ReportDocument2 pagesFit Up Welding Visual Inspection Reportgst ajah100% (1)

- Sample WPS 1Document13 pagesSample WPS 1waqas pirachaNo ratings yet

- Report No. TA-V-1456Document2 pagesReport No. TA-V-1456u04ajf3No ratings yet

- Madina Group W.L.L. Procedure Qualification Record 152Document38 pagesMadina Group W.L.L. Procedure Qualification Record 152MAT-LIONNo ratings yet

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- PQR - 152Document3 pagesPQR - 152MAT-LIONNo ratings yet

- Clad PQRDocument5 pagesClad PQRRinshadNo ratings yet

- Procedure Qualification Record (PQR)Document3 pagesProcedure Qualification Record (PQR)Senthil KumaranNo ratings yet

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Aic Asf PQR 0122Document2 pagesAic Asf PQR 0122AHMED MEDANYNo ratings yet

- GTAW Welding Process ParametersDocument12 pagesGTAW Welding Process Parametersmiteshpatel191No ratings yet

- Pvs ReportDocument1 pagePvs ReportSenthil KumaranNo ratings yet

- Welding Engineer: M.E. in Welding TechnologyDocument4 pagesWelding Engineer: M.E. in Welding TechnologySenthil KumaranNo ratings yet

- Minimum Requirements For The Education, Examination and QualificationDocument34 pagesMinimum Requirements For The Education, Examination and QualificationАнтон ХруцкийNo ratings yet

- Resume - QC EngineerDocument4 pagesResume - QC EngineerSenthil Kumaran100% (1)

- IWE11 Online ClassesDocument2 pagesIWE11 Online Classesحبيب الرحمنNo ratings yet

- MTA3 GTL 3 Day Lookahead OperationsDocument9 pagesMTA3 GTL 3 Day Lookahead OperationsSenthil KumaranNo ratings yet

- Faculty Datasheet - Dhanesh.EDocument4 pagesFaculty Datasheet - Dhanesh.ESenthil KumaranNo ratings yet

- BGAS GR 2 - Notes - 2Document46 pagesBGAS GR 2 - Notes - 2Senthil KumaranNo ratings yet

- Welding Consumables ProcedureDocument7 pagesWelding Consumables ProcedureSenthil Kumaran100% (1)

- UT Thickness Gauge ProcedureDocument5 pagesUT Thickness Gauge ProcedureSenthil Kumaran100% (2)

- Written Practice ProcedureDocument20 pagesWritten Practice ProcedureSenthil Kumaran50% (2)

- Painting Report - FormatDocument1 pagePainting Report - FormatSenthil Kumaran100% (1)

- Procedure Qualification Record (PQR)Document3 pagesProcedure Qualification Record (PQR)Senthil KumaranNo ratings yet

- PENETRANT TEST PROCEDURE (PT Procedure)Document9 pagesPENETRANT TEST PROCEDURE (PT Procedure)Senthil Kumaran100% (1)

- Precision Storage Vessels PVT LTD: Pressure Test ReportDocument2 pagesPrecision Storage Vessels PVT LTD: Pressure Test ReportSenthil Kumaran100% (1)

- Weld Inspection Report (Weld Traceability Report)Document3 pagesWeld Inspection Report (Weld Traceability Report)Senthil Kumaran100% (1)

- RADIOGRAPHIC TEST PROCEDURE (RT Procedure)Document17 pagesRADIOGRAPHIC TEST PROCEDURE (RT Procedure)Senthil Kumaran100% (1)

- Topic04 - Recovering Graphics FileDocument44 pagesTopic04 - Recovering Graphics FileHappy Plants BDNo ratings yet

- Labview Ecg AdquisicionDocument6 pagesLabview Ecg AdquisicionBAUTISTA ENCISO LEEVAN YACKIENo ratings yet

- Wing Load Calculation: (Example Document For LSA Applicants - v1 of 08.03.16)Document16 pagesWing Load Calculation: (Example Document For LSA Applicants - v1 of 08.03.16)Leonardo VasconcelosNo ratings yet

- Introduction Mechanics Kleppner Solutions 1mk7aDocument4 pagesIntroduction Mechanics Kleppner Solutions 1mk7aSrinivasa Rao0% (1)

- CMOS Technology and Verilog HDL BasicsDocument11 pagesCMOS Technology and Verilog HDL BasicsUnique ProNo ratings yet

- Alamo - Espiritu 1010 VF PDFDocument4 pagesAlamo - Espiritu 1010 VF PDFRolando DávilaNo ratings yet

- Band Pass Filter - Passive RC Filter TutorialDocument10 pagesBand Pass Filter - Passive RC Filter TutorialGabor VatoNo ratings yet

- Test Plan and DocumentsDocument4 pagesTest Plan and DocumentsvimudhiNo ratings yet

- DevSecOps Lead Job DescriptionDocument2 pagesDevSecOps Lead Job DescriptionjencisoNo ratings yet

- Linking Your Thinking - Idea EmergenceDocument1 pageLinking Your Thinking - Idea EmergenceLee NamNo ratings yet

- Certificate of Candidacy For Member, Sangguniang Bayan: Commission On ElectionsDocument2 pagesCertificate of Candidacy For Member, Sangguniang Bayan: Commission On ElectionsPiagapo Lanao del SurNo ratings yet

- Self-Dehydrating Breather Type SDBDocument39 pagesSelf-Dehydrating Breather Type SDBKHALID98No ratings yet

- Delcam - PowerMILL 2014 R1 Whats New EN - 2013Document137 pagesDelcam - PowerMILL 2014 R1 Whats New EN - 2013phạm minh hùngNo ratings yet

- Instant Neural Graphics Primitives With A Multiresolution Hash EncodingDocument13 pagesInstant Neural Graphics Primitives With A Multiresolution Hash EncodingHieu BuiNo ratings yet

- International Journal of Information Management: Min Yan, Raffaele Filieri, Matthew GortonDocument13 pagesInternational Journal of Information Management: Min Yan, Raffaele Filieri, Matthew GortonmasukujjamanNo ratings yet

- HP ALM Tool Manages App LifecycleDocument13 pagesHP ALM Tool Manages App LifecyclevasundharaNo ratings yet

- FRP 1543494499564 - Grating Brochure - 2018Document6 pagesFRP 1543494499564 - Grating Brochure - 2018Ganesh KumarNo ratings yet

- Ph.D. Entrance Exam Results for Biomedical and Chemical EngineeringDocument25 pagesPh.D. Entrance Exam Results for Biomedical and Chemical Engineeringpatelsandip1989No ratings yet

- Powerpoint Jeopardy Research StatsDocument26 pagesPowerpoint Jeopardy Research StatsMarccello 'Pasquale PaganoNo ratings yet

- Technology and Society Unit 3Document21 pagesTechnology and Society Unit 3me niksyNo ratings yet

- Challenges and Issues in e GovernanceDocument28 pagesChallenges and Issues in e GovernanceDaniel ReyesNo ratings yet

- Rolleri Catalogue 2016 INT PDFDocument292 pagesRolleri Catalogue 2016 INT PDFAdrian Vargas SanchezNo ratings yet

- Computer-3 1st QuarterDocument5 pagesComputer-3 1st QuarterEdmar John SajoNo ratings yet

- 3.5.7 Lab - Create A Python Unit TestDocument15 pages3.5.7 Lab - Create A Python Unit TestSamuel GarciaNo ratings yet

- About Jordan's PolicyDocument20 pagesAbout Jordan's PolicySaeed Al-SaeedNo ratings yet

- FTTH-ODN - Optical Fiber Networks Fundamentals (Part 3)Document39 pagesFTTH-ODN - Optical Fiber Networks Fundamentals (Part 3)Mohamed ShabanaNo ratings yet

- N Is The Smallest Positive Integer That Has 7 Factors. Quantity ADocument10 pagesN Is The Smallest Positive Integer That Has 7 Factors. Quantity ATeja SreeNo ratings yet

- KX-TGDA20: Additional Digital Cordless HandsetDocument16 pagesKX-TGDA20: Additional Digital Cordless HandsetBrando GarciaNo ratings yet