Professional Documents

Culture Documents

PQR With-Pwht

Uploaded by

KarthikOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PQR With-Pwht

Uploaded by

KarthikCopyright:

Available Formats

Page 1 of 2

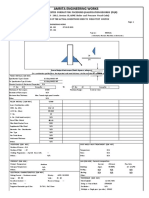

QW-482 SUGGESTED FORMAT FOR

PROCEDURE QUALIFICATION RECORD

(See QW-201.1,Section IX,ASME Boiler

and Pressure Vessel Code) DOCUMENT NO PIN LI-CQA-213-F-02

Procedure Qualification Record No: PQR/L&T/UAIL/P-02 Date : 11.08.2019

WPS No : WPS/L&T/UAIL/P-04 Rev No.0 Date : 01.07.2019

Welding Process(s) :GTAW+SMAW

Type (s)(Manual\Automatic\Semi-automatic : Manual

JOINTS: (QW-402)

Joint Design: Single-V

Root Spacing: As per Sketch

Backing : GTAW(With/Without)+SMAW(With)

Backing Material ( Type) Weld Metal

Joint Sketch

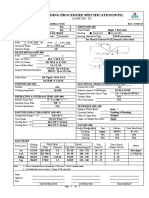

BASE METALS (QW-403) POST WELD HEAT TREATMENT (QW-407)

Material specification: A106 GR.B/A53GR.B/API-5LGR.B Temperature Range: 620⁰C ± 20⁰C

Type of Grade Or UNS number: A106 GR.B/A53GR.B/API-5LGR.B Time Range: 2.4 min/mm

P.NO:01 Group No.01 to P.NO.01 Group NO.01 Others: N.A

Thickness of Test Coupon: 10.97MM

Diameter of the test coupon: DN150 (OD:168.30MM)

Maximum Pass thickness: 1.5 mm ≤ t ≤ 6mm (GTAW) & 4 mm ≤

t ≤ 20 mm (SMAW)

FILLER METALS (QW-404): GAS (QW-408)

Layers(combination welding) 1.GTAW 2.SMAW Percentage composition

SFA specification: 5.18 5.1 Gases Mixture Flow rate

AWS Classification: ER-70S2 E-7018 Shielding Argon 99.995% 6 to 10 LPM

Filler metal F No: 6 4 Trailing N.A N.A N.A

Weld Metal analysis A. No: 1 1 Backing N.A N.A N.A

Size of Filler metal : 2mm & 2.4mm 2.5,3.15 & 4mm

Filler metal product form: SOLID N.A ELECTRICAL CHARACTERISTICS (QW-409)

Electrode flux class: N.A N.A Current: DC

Flux type: N.A N.A Polarity: DCEN-GTAW & DCEP-SMAW

Flux trade name: N.A N.A Amps: 80-130 Volts: 20-30

Weld metal thickness: N.A N.A Tungsten Electrode size: 2.0 & 2.4mm 2 % Thoriated

Transfer Mode for GMAW (FCAW): N.A

Others: N.A

Page 2 of 2

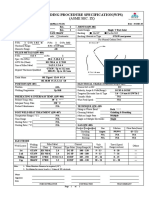

POSITION (QW-405) TECHNIQUE ( QW-410)

Position(s) of Groove 6G Travel Speed: GTAW - 60-75mm/min & SMAW-90-

Welding Progression UPHILL 12mm/min

Position(s) of Fillet ALL String Or Weave Bead : Both

Other N.A Oscillation: String / Weave not more than 3 times the

PREHEAT (QW-406) electrode diameter

Preheat Temperature, Minimum : 10⁰C Multi pass or Single pass (Per side): Multi Pass

Inter pass Temperature, Maximum : 250⁰C Single or Multiple electrodes: Single

Others: N.A Others: N.A

QW-483 (BACK)

Tensile test (QW-150)

Ultimate unit

Specimen Width Thickness Area Ultimate Total Type of failure and

stress

Number (MM) (MM) (MM2) Load (N) location

(PSI or MPA)

1 20.20 MM 10.84 MM 218.96 105000 N 480 MPA Broken at outside of weld

6 20.12 MM 10.87 MM 218.70 106000 N 485 MPA Broken at outside of weld

Guided Bend Tests (QW-160)

Type and Figure No Results

Root Bend-2 (QW 462.3) Root Bend found Satisfactory at 180⁰ (4t)

Root Bend-4 (QW 462.3) Root Bend found Satisfactory at 180⁰ (4t)

Face Bend-3 (QW 462.3) Face Bend found Satisfactory at 180⁰ (4t)

Face Bend-5 (QW 462.3) Face Bend found Satisfactory at 180⁰ (4t)

Toughness tests (QW-170)

Notch Specimen Test Impact Values Drop wt. break

Specimen Number

Location size Temperature Ft-lb or J % Shear Mils or mm ( Yes\No)

Not Not

Not prepared NA NA NA NA NO

prepared prepared

Fillet weld test (QW-180)

Results Satisfactory: Yes √ No Penetration into parent metal Yes: N.A No: N.A

Macro-Results: N.A

Other Tests

Type of test: Radiography Examination (Report No: SNT/RT/09) Date: 25-07-2019

Deposit Analysis: N.A

Others: N.A

Welders Name: MR.GOUTAM BEMAL Stamp No. LT/PIPING/GTAW/SMAW/W-09

Test Conducted by: IRC INDUSTRIAL RESEARCH & CONSULTANCY) Lab Test Report No: IRC/M/1416/19-20

Date: 09.08.2019

We certify that the statement in this record is correct and that the test coupons were prepared welded and

tested in accordance with the requirements of Section IX of ASME Code.

Contractor: M/S LARSEN & TOUBRO-LIMITED

Date ___________________________ Certified /Approved by: ____________________________________

You might also like

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoNo ratings yet

- Amrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Document3 pagesAmrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Balkishan DyavanapellyNo ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- PQR TipsDocument4 pagesPQR TipsWaqas WaqasNo ratings yet

- Super Duplex Stainless SteelDocument1 pageSuper Duplex Stainless SteelUma Shankar100% (2)

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- Aws 001Document1 pageAws 001akshay sarfareNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- Wps For Steel RodsDocument5 pagesWps For Steel RodsHamid MansouriNo ratings yet

- Wps & PQR For Valve Installation - XLSX Fix TerbaruDocument20 pagesWps & PQR For Valve Installation - XLSX Fix TerbarufebriNo ratings yet

- Form Wps JBL09-2011Document2 pagesForm Wps JBL09-2011fawad aliNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- WPS 19Document15 pagesWPS 19Avishek Gupta100% (1)

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNo ratings yet

- Welding Procedure Specification (WPS) : Page: 1/1Document5 pagesWelding Procedure Specification (WPS) : Page: 1/1Walid BdeirNo ratings yet

- Graycor WPS 19 SampleDocument5 pagesGraycor WPS 19 SampleRaul SebastiamNo ratings yet

- Clad PQRDocument5 pagesClad PQRRinshadNo ratings yet

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Document2 pagesWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabNo ratings yet

- Qualified Welder List Valid Until - 03-12-2019Document2 pagesQualified Welder List Valid Until - 03-12-2019csolanki6586100% (1)

- ASME Section IX Welding Procedure Qualification: Antonius P. BramonoDocument50 pagesASME Section IX Welding Procedure Qualification: Antonius P. BramonoHAKANNo ratings yet

- Weld Repair Rate - MFJO542Document2 pagesWeld Repair Rate - MFJO542Salahuddin Farooqui100% (1)

- QW-483 BlankDocument2 pagesQW-483 BlankCraftyBob100% (1)

- WPS PQR 12Document9 pagesWPS PQR 12Ranjan KumarNo ratings yet

- Welding Procecure SpecificationDocument9 pagesWelding Procecure SpecificationNwoha PeterNo ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFAhmad Daniel100% (1)

- EFR-190719-PQR-01 - Shell Vertical-Horizontal PDFDocument11 pagesEFR-190719-PQR-01 - Shell Vertical-Horizontal PDFIonut FloricaNo ratings yet

- IRN - 18.07.2019 - Harshad Panchal - Revision-0 - Furnace Fabrica - JNK - PORVAIR - RIL PDFDocument3 pagesIRN - 18.07.2019 - Harshad Panchal - Revision-0 - Furnace Fabrica - JNK - PORVAIR - RIL PDFsaptarshi jashNo ratings yet

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPS-PQR ListDocument1 pageWPS-PQR ListSandra SandersNo ratings yet

- WPS SampleDocument182 pagesWPS Sampleaymenfr23No ratings yet

- Limak - Sawaed WpsDocument1 pageLimak - Sawaed WpsAlam MD SazidNo ratings yet

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Document1 pageWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- Pull Off Test Report RefinaryDocument3 pagesPull Off Test Report RefinaryZaid Raslan AyoubNo ratings yet

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNo ratings yet

- WPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmDocument1 pageWPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmufomski100% (1)

- WeldDocs WPSDocument2 pagesWeldDocs WPSMDSIKKU_2005No ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Document4 pagesProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabNo ratings yet

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouNo ratings yet

- PWPS WPS CAP 039 PQR 035Document15 pagesPWPS WPS CAP 039 PQR 035GOPINATH KRISHNAN NAIRNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- BPV IX-16-3 QW-283 - ButteringDocument1 pageBPV IX-16-3 QW-283 - ButteringyutweldingNo ratings yet

- Smaw PQR FinalDocument3 pagesSmaw PQR Finalsheikmoin100% (1)

- QW 483 - PQR (Gtaw+smaw) 04.01.17Document8 pagesQW 483 - PQR (Gtaw+smaw) 04.01.17Srikant GanjiNo ratings yet

- PQR GmawDocument4 pagesPQR GmawEr Sumant Kumar Singh0% (1)

- Base Metals (Qw-403) Postweld Heat Treatment (Qw-407)Document2 pagesBase Metals (Qw-403) Postweld Heat Treatment (Qw-407)beyNo ratings yet

- Procedure Qualification RecordDocument6 pagesProcedure Qualification RecordGaurang PandyaNo ratings yet

- QW-482 Welding Procedure Specification: Section IX, ASME Boiler & Pressure Vessel CodeDocument2 pagesQW-482 Welding Procedure Specification: Section IX, ASME Boiler & Pressure Vessel CodeRamzi ZoghlamiNo ratings yet

- Cert Piping W54.5Document2 pagesCert Piping W54.5SANU0% (1)

- Welding Procedure Specification (WPS) : Supporting PQR 01Document2 pagesWelding Procedure Specification (WPS) : Supporting PQR 01duyanhNo ratings yet

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (5)

- Weld Map-IBR Piping FinalDocument3 pagesWeld Map-IBR Piping FinalKarthikNo ratings yet

- MD-216-4400-QD-IX-ITP-1001-A07 Inspection Test Plan For Earthwork in Tailing Management Facility-4400 PDFDocument7 pagesMD-216-4400-QD-IX-ITP-1001-A07 Inspection Test Plan For Earthwork in Tailing Management Facility-4400 PDFKarthikNo ratings yet

- PO/Contract Number: 25875-000-POA-PS02-00001 Supplier/Contractor Name: Document Title: Material Traceability and Identification ProcedureDocument11 pagesPO/Contract Number: 25875-000-POA-PS02-00001 Supplier/Contractor Name: Document Title: Material Traceability and Identification ProcedureKarthikNo ratings yet

- Md-216-1000-Eg-Ix-Itp-1006-A01 Inspection and Test Plan Ball Mill Shell - DischargeDocument5 pagesMd-216-1000-Eg-Ix-Itp-1006-A01 Inspection and Test Plan Ball Mill Shell - DischargeKarthikNo ratings yet

- 25875-000-V1A-PS02-00004 - Rev.003-With ApprovalDocument11 pages25875-000-V1A-PS02-00004 - Rev.003-With ApprovalKarthikNo ratings yet

- MD-216-4400-QD-IX-ITP-1002-A03 Inspection and Test Plan For Liner Installation in Tailing Management Facility-4400 PDFDocument11 pagesMD-216-4400-QD-IX-ITP-1002-A03 Inspection and Test Plan For Liner Installation in Tailing Management Facility-4400 PDFKarthikNo ratings yet

- Md-216-1000-Eg-Ix-Itp-1005-A01 Inspection and Test Plan Ball Mill Shell - MiddleDocument5 pagesMd-216-1000-Eg-Ix-Itp-1005-A01 Inspection and Test Plan Ball Mill Shell - MiddleKarthik0% (1)

- RF Pad Test ReportDocument1 pageRF Pad Test ReportKarthikNo ratings yet

- Request For Inspection: QC Rfi No.Document1 pageRequest For Inspection: QC Rfi No.KarthikNo ratings yet

- Pressure Test Report: Observation Inspection Checked Reviewed Cleared ResultsDocument1 pagePressure Test Report: Observation Inspection Checked Reviewed Cleared ResultsKarthikNo ratings yet

- Test Pack Clearance FormatDocument2 pagesTest Pack Clearance FormatKarthikNo ratings yet

- Line Designation TableDocument2 pagesLine Designation TableKarthikNo ratings yet

- RF Pad Test ReportDocument1 pageRF Pad Test ReportKarthik100% (1)

- Sample Format: Sensitivity: LNT Construction Internal UseDocument2 pagesSample Format: Sensitivity: LNT Construction Internal UseKarthikNo ratings yet

- PIN LI-CQA-219-F-01 PMI REPORT - UpdatedDocument1 pagePIN LI-CQA-219-F-01 PMI REPORT - UpdatedKarthikNo ratings yet

- Uail - Pin Li-Cqa-213-F-01 WPS FormatDocument2 pagesUail - Pin Li-Cqa-213-F-01 WPS FormatKarthikNo ratings yet

- Data Sheet For PQR or WQT RecordsDocument3 pagesData Sheet For PQR or WQT RecordsKarthikNo ratings yet

- UAIL - PIN LI-CQA-200-F-05 lLINE HISTORY SHEET - UpdatedDocument1 pageUAIL - PIN LI-CQA-200-F-05 lLINE HISTORY SHEET - UpdatedKarthikNo ratings yet

- Portable Oven Verification Report (11 TO 20)Document20 pagesPortable Oven Verification Report (11 TO 20)KarthikNo ratings yet

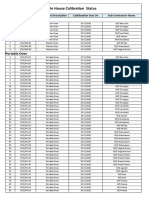

- Oven Calibration StatusDocument3 pagesOven Calibration StatusKarthikNo ratings yet

- The SMP Concept-Based 3D Constitutive Models For Geomaterials - Hajime Matsuoka (Author) - 1, 2006 - CRC Press - 9780415395045 - Anna's ArchiveDocument154 pagesThe SMP Concept-Based 3D Constitutive Models For Geomaterials - Hajime Matsuoka (Author) - 1, 2006 - CRC Press - 9780415395045 - Anna's ArchiveElias Santos SouzaNo ratings yet

- Fosroc Conbextra EP 0211Document4 pagesFosroc Conbextra EP 0211Tri SuhartantoNo ratings yet

- Ghosh: CHM 112M: Lecture 1Document6 pagesGhosh: CHM 112M: Lecture 1zafuhyziNo ratings yet

- 4 Frontal DisplacementDocument89 pages4 Frontal DisplacementHemant SrivastavaNo ratings yet

- Specsheet Freedom FLB P NJZ LightingDocument9 pagesSpecsheet Freedom FLB P NJZ LightingEugenioNo ratings yet

- 19th Exam P3 BDocument15 pages19th Exam P3 Bगुंजन सिन्हाNo ratings yet

- En 12215Document49 pagesEn 12215YasinYıldızNo ratings yet

- 01.07.01 Flow Diagram 1245 8984Document1 page01.07.01 Flow Diagram 1245 8984周庆卓No ratings yet

- Exercise 1: Spectrochemical Analysis: BE132P Instrumentation in Biological Engineering 1Document7 pagesExercise 1: Spectrochemical Analysis: BE132P Instrumentation in Biological Engineering 1Bernadette Virola CuevasNo ratings yet

- Limit Equilibrium Analysis For Rock Slope Stability Using Basic Hoek-Brown Strength CriterionDocument10 pagesLimit Equilibrium Analysis For Rock Slope Stability Using Basic Hoek-Brown Strength CriterionJuan PerezNo ratings yet

- Temperature, Pressure Measurements Solve Column Operating ProblemsDocument5 pagesTemperature, Pressure Measurements Solve Column Operating ProblemsHari PrasadNo ratings yet

- Fiber Laser Cutting Machine Maintenance ManualDocument5 pagesFiber Laser Cutting Machine Maintenance ManualVlatko GavrilovNo ratings yet

- The Morphological and Optical Properties of Volcanic GlassDocument7 pagesThe Morphological and Optical Properties of Volcanic Glasswsjouri2510No ratings yet

- Nitoproof 600 PF: Pitch Free PU Based Liquid Applied Single Component Elastomeric Waterproofing MembraneDocument3 pagesNitoproof 600 PF: Pitch Free PU Based Liquid Applied Single Component Elastomeric Waterproofing MembraneKishore Nayak kNo ratings yet

- Olea PackagesDocument1 pageOlea Packagesmaha jamoukhaNo ratings yet

- Motor-Cad Smma 2001Document11 pagesMotor-Cad Smma 2001ademirpeNo ratings yet

- Conductive PenDocument2 pagesConductive Penpepper100No ratings yet

- Calorimetry in Pharmaceutical Research PDFDocument13 pagesCalorimetry in Pharmaceutical Research PDFAndré Luís Della VolpeNo ratings yet

- Experiment 3Document8 pagesExperiment 3ashutosh yagyikNo ratings yet

- Welcome YOU: Institute of Welding & Testing TechnologyDocument66 pagesWelcome YOU: Institute of Welding & Testing TechnologyHimanshu MishraNo ratings yet

- Guideline Pump SystemDocument16 pagesGuideline Pump SystemBehroozRaadNo ratings yet

- ASNT CatalogDocument47 pagesASNT Catalogcarlos Leandro100% (1)

- Resistance Seam WeldingDocument16 pagesResistance Seam Weldingkkpkk100% (1)

- Stability Assessment of Hypromellose Acetate Succinate HPMCAS NF For Application in Hot Melt Extrusion HMEDocument8 pagesStability Assessment of Hypromellose Acetate Succinate HPMCAS NF For Application in Hot Melt Extrusion HMEDhirendra KumarNo ratings yet

- Machine DesignDocument26 pagesMachine Designrajasekar21No ratings yet

- Class XI Jee Advanced Paper FinalDocument9 pagesClass XI Jee Advanced Paper Finaldheeraj ShahNo ratings yet

- Hardness TestDocument2 pagesHardness TestjorgekarlosprNo ratings yet

- Tsfluxus F8v1-5en LeuDocument24 pagesTsfluxus F8v1-5en LeuRachid EL AOUINANo ratings yet

- Ex ExpPhys V WS2006 07ENDocument15 pagesEx ExpPhys V WS2006 07ENSatyam AgrahariNo ratings yet

- Application Note E-4: Subject: A Review of Techniques For Electrochemical AnalysisDocument15 pagesApplication Note E-4: Subject: A Review of Techniques For Electrochemical AnalysistehtnicaNo ratings yet