Professional Documents

Culture Documents

Slamet WPQR

Uploaded by

Chandra Bintang W.POriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Slamet WPQR

Uploaded by

Chandra Bintang W.PCopyright:

Available Formats

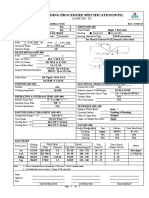

FS-751-03-002R0

QW.484 MANUFACTURER RECORD OF WELDER OR WELDING OPERATOR

QUALIFICATION TEST

Report No. : W03/REI/WPQR/2022

Welder Name : SLAMET M Stamp. No. : W- 8

Using WPS : Date : 02 Desember 2022

the above welder is qualified for the following ranges

Variable Record Actual Values Qualification Range

Used in Qualification

Process GMAW GMAW

Process Type Manual Manual

Backing (metal, weld metal, flux, etc (QW-402) weld metal backing With / Without

Base metal P.no. To P.No. SS 400/ ASTM A36 P.No.1 Gr 1 to P.No.1 Gr 1

√ Plate Pipe (enter diameter if pipe or tube) Plate t = 5 mm atau 6 mm 3 mm - 24 mm

Filler metal of electrode specification ( SFA ) AWS A5.18 --

Filler metal of electrode clasification ER 70S --

Filler metal F. No. 6 all F no 6

Consumable insert ( GTAW or Paw ) - -

Filler metal product form ( solid/metal or flux cored/powder )

GTAW or PAW ) - -

Deposit thickness for each process - -

process 1 GMAW 1 Layer Min. Yes No 3 mm Maximum to be welded

Process 2 1 Layer Min. Yes No - -

plate & pipe over 610mm ( F,V ) pipe <

Position Qualified 3G

610mm ( F )Fillet (F,H,V)

Weld Progression (QW-410) Up Hill Up Hill

Type of fuel gas (OFW) - -

Inert Gas backing (GTAW,PAW,GMAW) -- --

transfer mode (spray/globular or pulse to short circuit-GMAW) - -

Electrical Characteristics (QW-409)

- Current DC DC / AC

- Polarity EP EP / EN

Result

Visual Inspection Result : REJECT

Transverse face and root bends ( QW 462.3a) Longitudinal bends (QW 462.3b ) Side bends

Pipe bend specimen, corrosion resistant weld metal overlay (QW462.5c)

Plate bend specimen, corrosion resistant weld metal overlay (QW462.5d)

Pipe specimen macro test for fusion Plate specimen macro test for fusion

Type Result Type Result Type Result

N/A N/A N/A N/A N/A N/A

N/A N/A N/A N/A N/A N/A

Alternative volumetric Examination Result ( QW 191) : RT or PT √ ( check one )

√ Fillet Weld fracture test (QW 462.4b) Fillet Weld in pipe (QW462..4c)

Macro Examination QW 184 - Fillet Weld ( in ) - X - Cocavity/covexity ( in ) -

Other Test -

Film or specimens evaluated by - Company -

Mechanical test conducted by -

Welding supervised by PT. REXLINE ENGINEERING INDONESIA Laboratory test no -

We certify that statement in this record are correct and the test coupons were prepared, welded, and tested in accordance with the

requirements ASME Section IX. 2010 Edition , 2011 Add.

Prepared by, Approved by,

CHANDRA BINTANG

Date : 02 Desember 2022 Date :

Note : Any essential variables in addition to those above shall be record.

You might also like

- 170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQDocument4 pages170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- Cert Piping W54.5Document2 pagesCert Piping W54.5SANU0% (1)

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)ventas ventasNo ratings yet

- Format WPQDocument2 pagesFormat WPQAkash Singh TomarNo ratings yet

- WPQ Certificates Klis14Document8 pagesWPQ Certificates Klis14AdhicharanNo ratings yet

- 385 2 Internal Gtaw+SmawDocument2 pages385 2 Internal Gtaw+Smawsubash1688No ratings yet

- Val Caraig WPQTDocument1 pageVal Caraig WPQTMark Jason M. BrualNo ratings yet

- Abdul Muhid WPQRDocument1 pageAbdul Muhid WPQRChandra Bintang W.PNo ratings yet

- Pt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionDocument1 pagePt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionHaryanto RNo ratings yet

- WPQ Formats NEWDocument4 pagesWPQ Formats NEWMANABENDRA MAITRANo ratings yet

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- VLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmDocument3 pagesVLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmTuTuy AnNo ratings yet

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNo ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- WPQDocument10 pagesWPQayoki100% (3)

- Aws 001Document1 pageAws 001akshay sarfareNo ratings yet

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- Asme Ix - WPS - Gtaw Fcaw Gmaw PDFDocument1 pageAsme Ix - WPS - Gtaw Fcaw Gmaw PDFThe Welding Inspections CommunityNo ratings yet

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Document3 pagesHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnNo ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- 188-Gmaw-Zug-Asme (Rivaldy Hendrawan-3g) - WPQDocument1 page188-Gmaw-Zug-Asme (Rivaldy Hendrawan-3g) - WPQMuhammad Fitransyah Syamsuar Putra100% (1)

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- SMAW DuniDocument4 pagesSMAW DuniMuhammad Fitransyah Syamsuar PutraNo ratings yet

- EFR-190719-PQR-01 - Shell Vertical-Horizontal PDFDocument11 pagesEFR-190719-PQR-01 - Shell Vertical-Horizontal PDFIonut FloricaNo ratings yet

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusNo ratings yet

- WPS 19Document15 pagesWPS 19Avishek Gupta100% (1)

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Welding Procedure Qualification Record: Shipyard LogoDocument4 pagesWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- Welding Procedure Specification (WPS) : Supporting PQR 01Document2 pagesWelding Procedure Specification (WPS) : Supporting PQR 01duyanhNo ratings yet

- PWPS Fillet WeldDocument2 pagesPWPS Fillet WeldUgonnaNo ratings yet

- PQR A106 HAL-1Document1 pagePQR A106 HAL-1Budi Setia RahmanNo ratings yet

- P-WPS 135 - MAG (GR 316)Document9 pagesP-WPS 135 - MAG (GR 316)Tarun PatelNo ratings yet

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Document2 pagesWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (2)

- WPS Ernicu 7 R1 3 6 PDFDocument4 pagesWPS Ernicu 7 R1 3 6 PDFandresNo ratings yet

- Welding Procedure Specification According To EN ISO 15609, 2004Document2 pagesWelding Procedure Specification According To EN ISO 15609, 2004Dimitris NikouNo ratings yet

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocument3 pagesWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanNo ratings yet

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Document1 pageWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- P WPSDocument3 pagesP WPSAnilkumar G NairNo ratings yet

- Graycor WPS 19 SampleDocument5 pagesGraycor WPS 19 SampleRaul SebastiamNo ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- 1036330-23-350 Al 465 BX Nam Smaw+fcaw Iso 9606 CS 6G (H-L045)Document2 pages1036330-23-350 Al 465 BX Nam Smaw+fcaw Iso 9606 CS 6G (H-L045)Nguyen Thanh Binh0% (1)

- 161 Gmaw Zug Asme (Beni Kantona 3g) WPQDocument2 pages161 Gmaw Zug Asme (Beni Kantona 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPS Api 1104Document3 pagesWPS Api 1104miguelNo ratings yet

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- Sembcorp Marine Integrated Yard PteDocument3 pagesSembcorp Marine Integrated Yard PteMd. Mizanur Rahaman100% (1)

- Gtaw 106Document2 pagesGtaw 106ganeshkumarg_1No ratings yet

- Registro de Calificacion Del Procedimiento (PQR) : JOINTS (QW-402)Document2 pagesRegistro de Calificacion Del Procedimiento (PQR) : JOINTS (QW-402)Anonymous Xa5rkMZm9ZNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocument1 pageWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- WPQ 006Document1 pageWPQ 006vinuNo ratings yet

- Daily Report 210623 Repair CrusherDocument2 pagesDaily Report 210623 Repair CrusherChandra Bintang W.PNo ratings yet

- So 00297 Idler Conveyor System - Sulut 1 CFSPP - UbeDocument2 pagesSo 00297 Idler Conveyor System - Sulut 1 CFSPP - UbeChandra Bintang W.PNo ratings yet

- Checklist Record - PT. MEI - SO-00328-PT. Rexline MEI-220786Document1 pageChecklist Record - PT. MEI - SO-00328-PT. Rexline MEI-220786Chandra Bintang W.PNo ratings yet

- WO 340 Rubber Linning PT. PAL INDONESIADocument6 pagesWO 340 Rubber Linning PT. PAL INDONESIAChandra Bintang W.PNo ratings yet

- List Not Yet Mill CertificateDocument2 pagesList Not Yet Mill CertificateChandra Bintang W.PNo ratings yet

- Abdul Muhid WPQRDocument1 pageAbdul Muhid WPQRChandra Bintang W.PNo ratings yet

- May Nong Unibell PDFDocument332 pagesMay Nong Unibell PDFhuuquocNo ratings yet

- Instruction Manual Fisher 4194ha HB HC Differential Pressure Indicating Controllers en 123990Document92 pagesInstruction Manual Fisher 4194ha HB HC Differential Pressure Indicating Controllers en 123990Zts MksNo ratings yet

- Heat Tracing Long Pipelines PDFDocument9 pagesHeat Tracing Long Pipelines PDFHotnCrispy CrispyNo ratings yet

- ASME B31.4 Design Minimum Wall ThicknessDocument6 pagesASME B31.4 Design Minimum Wall ThicknessAlfredo BravoNo ratings yet

- LBYCVW2 - Experiment 2Document11 pagesLBYCVW2 - Experiment 2Shean Berwin GonzalesNo ratings yet

- ANEXO B Customer Enquiry & Project Engineering Requirements FormDocument4 pagesANEXO B Customer Enquiry & Project Engineering Requirements FormOscar MoraNo ratings yet

- DeepWater Nu-Bolt OrderDocument1 pageDeepWater Nu-Bolt OrderPaulNo ratings yet

- 31 62 13 Bored Concrete PilesDocument20 pages31 62 13 Bored Concrete PilesWidiyanto WidiyantiNo ratings yet

- Biral NBDocument48 pagesBiral NBkamal arabNo ratings yet

- Catalogo de Co2Document310 pagesCatalogo de Co2danilolabreNo ratings yet

- Oil Pipe LinesDocument9 pagesOil Pipe LinesshjahsjanshaNo ratings yet

- Full Line Catalog 1020Document148 pagesFull Line Catalog 1020Freeman MorganNo ratings yet

- PROK - Quality Conveyor EquipmentDocument30 pagesPROK - Quality Conveyor EquipmentDiego AndradeNo ratings yet

- Sanitaire, Silver Series ManualDocument62 pagesSanitaire, Silver Series ManualSaber Abdel MoreidNo ratings yet

- Asset Integrity - RBI EngineerDocument8 pagesAsset Integrity - RBI EngineerOwais MalikNo ratings yet

- Gs Ep Cor 772 Rev02 2019Document67 pagesGs Ep Cor 772 Rev02 2019Alioune CamaraNo ratings yet

- Uso E Manutenzione: Macchine Caffè Espresso - Serie 95Document29 pagesUso E Manutenzione: Macchine Caffè Espresso - Serie 95Yoatzin VegaNo ratings yet

- 8795 PDFDocument22 pages8795 PDFGaneshNo ratings yet

- 2016 Top 900 PricelistDocument19 pages2016 Top 900 Pricelistapi-317879840No ratings yet

- Peb Technical SpecificationDocument4 pagesPeb Technical Specificationalankar ambwadeNo ratings yet

- Ducting KatalogDocument24 pagesDucting Katalogadi utomoNo ratings yet

- Piedmont StyleDDocument1 pagePiedmont StyleDBenjamin MillerNo ratings yet

- Presentation - Indian Pipe IndustryDocument24 pagesPresentation - Indian Pipe IndustryAmit Jain100% (6)

- Rs Concrete Pumping Risk Assessment 2015Document3 pagesRs Concrete Pumping Risk Assessment 2015api-301780442100% (1)

- Vinod Patel Company Profile - June - 2017Document20 pagesVinod Patel Company Profile - June - 2017finance bnbmNo ratings yet

- General Specifi Cations: ADMAG TI Series AXG Magnetic FlowmeterDocument74 pagesGeneral Specifi Cations: ADMAG TI Series AXG Magnetic FlowmeterSteve WanNo ratings yet

- Accident Prevention Manual For Business & Industry:: Engineering & Technology 13th EditionDocument55 pagesAccident Prevention Manual For Business & Industry:: Engineering & Technology 13th EditionUmmy AbbyNo ratings yet

- std118 - 2 Pub Review DraftDocument48 pagesstd118 - 2 Pub Review DraftLizbeth de la CruzNo ratings yet

- GB-Cat Supply Systems PDFDocument232 pagesGB-Cat Supply Systems PDFzoran cukovicNo ratings yet

- 05 - Non-Intrusive Leak Detection in Large Diameter, Low-Pressure Non-Metallic Pipes-Are We Close To Finding The Perfect SolutionDocument9 pages05 - Non-Intrusive Leak Detection in Large Diameter, Low-Pressure Non-Metallic Pipes-Are We Close To Finding The Perfect SolutionPraveen Kesavan NairNo ratings yet