Professional Documents

Culture Documents

SILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18

Uploaded by

Abdulmecit YetisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18

Uploaded by

Abdulmecit YetisCopyright:

Available Formats

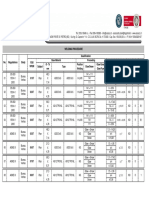

WELDING PROCEDURE SPECIFICATION (WPS)

(ASME Section IX , API 650 13th Ed. 2021)

Project reference:

WPS No SILVER-WPS-GESA-01 Supporting PQR No PQR-0063-W-18.Rev01

Revision No 00 Welding Process(es) SMAW

Revision Date 02.12.2021 Type(s) Manual

Page: 1/2

JOINTS (QW-402)

Joint Design Butt & Lap Joint Root Spacing Min. 5 mm

Backing YES

Backing Material (Type) X Metal Non Fusing Metal Non Metallic Other

BASE METALS (QW-403)

P-No. 1 Group No. - to P-No. 1 Group No. -

Or

ASTM A516 Gr 60 , ASTM A516 Gr ASTM A516 Gr 60 , ASTM A516 Gr 70

Specification type and grade 70 A36 To specification type and grade A36

Or

Chem. Analysis and Mech. Prop. - To Chem. Analysis and Mech. Prop. -

Thickness range:

Base Metal: Groove : 5 < T < 32 mm Fillet : All

Maximum Pass Thickness ≤ 1/2 in. (13 mm) X Yes No

Other

FILLER METALS (QW-404) Root Hot,Fill & CAP : SMAW : SAW

Spec. No. (SFA) 5.1

AWS No. (Class) E7018-1 H4 or Equivalent

Trade Name BOHLER FOX S EV 50-1 or Equivalent

F-No. 4

A-No. 1

Size of Filler Metals Dia 2.5 mm. , 3.2 mm., 4 mm.

Filler Metal Product Form

Supplemental Filler Metal

Weld Metal

Thickness Range

Groove Up to 32 mm

Fillet All

Electrode-Flux (Class) N/A

Flux Type N/A

Flux Trade Name N/A

Consumable Insert N/A

Other

PREPARED BY CHECKED BY OWNER / PMC

APPROVED BY TR

CONSTRUCTION ORGANIZATION REPRESENTATIVE

NAME: Abdulmecit YETİŞ NAME: NAME: NAME:

SIGNATURE: SIGNATURE: SIGNATURE: SIGNATURE:

Date: 06.12.2021 Date: Date: Date:

Yayınlanma Tarihi / Publish Date Doküman No / Document No 1/2

02.12.2021 F.IM.13/00.EK-1

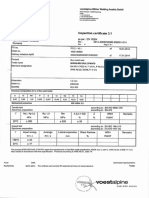

WELDING PROCEDURE SPECIFICATION (WPS)

(ASME Section IX , API 650 13th Ed. 2021)

WPS No: SILVER-WPS-GESA-01 Rev. No : 00 Revision Date : 02.12.2021 Supporting PQR No : PQR-0063 Page : 2/2

POSITIONS (QW-405) POSTWELD HEAT TREATMENT (QW-407)

Position(s) of Groove 1G & 2F Temperature Range N/A

Welding Progression: Forward Time Range N/A

Position(s) of Fillet All Other

Other - GAS (QW-408)

PREHEAT (QW-406) Percent Composition

Preheat Temp. Min. 80C Gas(es) (Mixture) Flow Rate

Interpass Temp. Max. 80C - 125C Shielding N/A N/A N/A

Preheat Maintenance N/A Trailing N/A N/A N/A

Other Backing N/A N/A N/A

(Continuous or special heating where applicable should be recorded) Other

ELECTRICAL CHARACTERISTICS (QW-409)

Filler Metal Travel

Current Ampere Wire Feed Energy or Volt

Speed Heat Input

Weld Pass(es) Process Dia. Type and (Range) Speed Power (Range)

Class Range (Kj/mm)

(mm) Polarity (A) (Range) (Range) (V)

(mm/min)

Root SMAW E7018-1H4 2.5 DCEP 70-90 N/A N/A 21 - 23 50-70 1.97-2.30

Hot SMAW E7018-1H4 2.5 or 3.2 DCEP 80-125 N/A N/A 24 - 26 60-80 1.69-1.93

Fill SMAW E7018-1H4 3.2 or 4 DCEP 120 - 140 N/A N/A 2 2- 26 60-130 2.34-2.76

CAP SMAW E7018-1H4 2.5 or 3.2 DCEP 110-125 N/A N/A 22 - 24 60-80 2.20-2.60

Pulsing Current / Polarity SMAW – DCEP ( + )

Tungsten Electrode Size and Type N/A

Mode of Metal Transfer for GMAW (FCAW) N/A

Heat Input (Max.) 2.76

Other

TECHNIQUE (QW-410) SMAW SAW

String or Weave Bead String / Weave

Orifice, Nozzle, or Gas Cup Size N/A

Initial and Interpass Cleaning Chipping , Grinding , Wire Brushing

Method of Back Gouging Grinding / Gouging

Oscillation Max. 3 times of Electrode core diameter

Contact Tube to Work Distance N/A

Multiple or Single Pass (per side) Multiple

Multiple or Single Electrodes Single

Electrode Spacing N/A

Peening None

Other

PREPARED BY CHECKED BY OWNER / PMC

APPROVED BY TR

CONSTRUCTION ORGANIZATION REPRESENTATIVE

NAME: Abdulmecit YETİŞ NAME: NAME: NAME:

SIGNATURE: SIGNATURE: SIGNATURE: SIGNATURE:

Date: 06.12.2021 Date: Date: Date:

Yayınlanma Tarihi / Publish Date Doküman No / Document No 2/2

02.12.2021 F.IM.13/00.EK-1

You might also like

- 90 Qd60 F 205 - 0 Welding Control ProcedureDocument43 pages90 Qd60 F 205 - 0 Welding Control ProcedureErkan Horasan100% (1)

- List Applicable WPS StructureDocument7 pagesList Applicable WPS StructureFerdie OSNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Abdulmecit YetisNo ratings yet

- GMAW (Solid Wire) vs. FCAW (Flux-Cored Wire)Document3 pagesGMAW (Solid Wire) vs. FCAW (Flux-Cored Wire)momoitachiNo ratings yet

- HistoryDocument20 pagesHistoryAlexandru RomînuNo ratings yet

- A-Method Statement Painting and Touch-Up Painting For Furnace-CDocument20 pagesA-Method Statement Painting and Touch-Up Painting For Furnace-CTrương Đông HưngNo ratings yet

- Familiarization With Apparatus and Equipment Used in Testing of MaterialsDocument5 pagesFamiliarization With Apparatus and Equipment Used in Testing of MaterialsEmanoAce33% (6)

- Pilot StudyDocument11 pagesPilot StudySatya Prakash80% (5)

- Welding ProcedureDocument3 pagesWelding ProcedureDuverlyOrlandoMattaVásquezNo ratings yet

- PWHT Procedure for Berri Increment ProjectDocument36 pagesPWHT Procedure for Berri Increment ProjectRizwan.descon DesconNo ratings yet

- Fabrication Procedure for Hasbah Offshore Gas Facilities Tie-In PlatformDocument50 pagesFabrication Procedure for Hasbah Offshore Gas Facilities Tie-In PlatformBashir AlamNo ratings yet

- ALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and InspectionDocument31 pagesALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and Inspectionahmed.njahNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalpravinNo ratings yet

- Welding Coordinator WeldMap Weld Data Sheet PDFDocument1 pageWelding Coordinator WeldMap Weld Data Sheet PDFAzhar AhmadNo ratings yet

- Weld Book - Flare KOD - Structure Rev ADocument169 pagesWeld Book - Flare KOD - Structure Rev ARajesh K PillaiNo ratings yet

- Piping Pre - Fabrication Erection & Non Destructive TestingDocument39 pagesPiping Pre - Fabrication Erection & Non Destructive TestingStanley Alex100% (1)

- Science Grade 7Document8 pagesScience Grade 7Lacus ClyneNo ratings yet

- WPS Steel Structure Welding ProcedureDocument1 pageWPS Steel Structure Welding ProcedureadiNo ratings yet

- Form Wps JBL09-2011Document2 pagesForm Wps JBL09-2011fawad aliNo ratings yet

- Wps & PQR and Weld Map and Test PlanDocument67 pagesWps & PQR and Weld Map and Test PlanmarghoobNo ratings yet

- Ejc-M13 - FN953205Document203 pagesEjc-M13 - FN953205JoséNo ratings yet

- Inspection & Test Plan: For Non Slam Check Valve (Axial Type)Document4 pagesInspection & Test Plan: For Non Slam Check Valve (Axial Type)Jeroan AyamNo ratings yet

- MOG-HSEQ-P-139 Rev A1 HSEQ-S Minimum Requiremnets For Contractors & Suppliers ActivitiesDocument47 pagesMOG-HSEQ-P-139 Rev A1 HSEQ-S Minimum Requiremnets For Contractors & Suppliers ActivitiesSalim MuftahNo ratings yet

- WD946-EZ300-00009 Procedure For Painting Rev 0Document21 pagesWD946-EZ300-00009 Procedure For Painting Rev 0Manuel BurdilesNo ratings yet

- MODEC Group confidential flange repair documentDocument11 pagesMODEC Group confidential flange repair documentDenny AgusNo ratings yet

- Saudi Aramco WPS Procedure ApprovalDocument7 pagesSaudi Aramco WPS Procedure ApprovalAkansha SharmaNo ratings yet

- Welding Consumable Storage and Handling ProceduresDocument27 pagesWelding Consumable Storage and Handling ProceduresKannan MurugesanNo ratings yet

- Utoc Preliminary Wps Shell Project 270807 PDFDocument55 pagesUtoc Preliminary Wps Shell Project 270807 PDFErick HoganNo ratings yet

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- Daily Report-018 (Su Jinlong)Document10 pagesDaily Report-018 (Su Jinlong)sujinlongNo ratings yet

- Welding Procedure Qualification Record (WPQR)Document8 pagesWelding Procedure Qualification Record (WPQR)Belin InversoNo ratings yet

- Passenger Handling Presentation 2020Document305 pagesPassenger Handling Presentation 2020Elshaikh100% (1)

- Historical Background of The SchoolDocument2 pagesHistorical Background of The SchoolJoel Daen50% (2)

- PT Alphacon's Single V Butt Joint WPSDocument20 pagesPT Alphacon's Single V Butt Joint WPScrys0% (1)

- 6 Contractor QC Resume Review ChecklistDocument1 page6 Contractor QC Resume Review ChecklistMudabbir HussainNo ratings yet

- Welding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldDocument2 pagesWelding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldAbdulmecit YetisNo ratings yet

- Final Welding Inspection ReportDocument1 pageFinal Welding Inspection ReportKish Shan S SubediNo ratings yet

- Method Statement: Pt. Duta Graha Indah TBK Welding Procedure (Preparation)Document4 pagesMethod Statement: Pt. Duta Graha Indah TBK Welding Procedure (Preparation)Nigin Parambath50% (2)

- Pr-w-1102.21-4012-004 Rev A Welder Qualification Testing For Steel Structure (WQT) - SWDocument18 pagesPr-w-1102.21-4012-004 Rev A Welder Qualification Testing For Steel Structure (WQT) - SWMehmet Soysal100% (1)

- Idc-000-Mgp-Onp-Pro-005518en-01 Weld NumberingDocument18 pagesIdc-000-Mgp-Onp-Pro-005518en-01 Weld NumberingJovan Poznan100% (1)

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Document2 pagesLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNo ratings yet

- Saudi Aramco welding reportDocument2 pagesSaudi Aramco welding reportsmdriyazbashaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- SAIC-W-2039 Welder & Operator Certification Review Issuance of JCC (Job Clearance Card) & Review Performance - PipelinesDocument9 pagesSAIC-W-2039 Welder & Operator Certification Review Issuance of JCC (Job Clearance Card) & Review Performance - PipelinesilliasuddinNo ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- Procedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherDocument2 pagesProcedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherPanneer SelvamNo ratings yet

- Yanbu WPS 201Document1 pageYanbu WPS 201Prem DixitNo ratings yet

- Control flow diagram for GACC's new welder qualification processDocument1 pageControl flow diagram for GACC's new welder qualification processSiddiqui Abdul KhaliqNo ratings yet

- Fitup (2019!06!01) Report-91 OfficialDocument2 pagesFitup (2019!06!01) Report-91 OfficialCarlosNo ratings yet

- Welding Log DW-CWDocument12 pagesWelding Log DW-CWhasan shahriarNo ratings yet

- Wps Mig PDF FreeDocument3 pagesWps Mig PDF Freehanz bermejoNo ratings yet

- Nde Map & Nde Procedure (Sudah Di Revisi)Document4 pagesNde Map & Nde Procedure (Sudah Di Revisi)Hardika SambilangNo ratings yet

- Sarma Tub Inox Certificat PDFDocument1 pageSarma Tub Inox Certificat PDFJacob HarrisNo ratings yet

- Aws N-1 WPS-PQR FormDocument2 pagesAws N-1 WPS-PQR FormEdwin MariacaNo ratings yet

- JIMT Visual Inspection ReportDocument1,913 pagesJIMT Visual Inspection Reportgomathyselvi100% (1)

- Welding Qualification: by Hema SantoshDocument45 pagesWelding Qualification: by Hema Santoshravi00098No ratings yet

- Company Logo Added to QAP DocumentDocument4 pagesCompany Logo Added to QAP Documentmanoj thakkar100% (1)

- RFI-3458 - Daily Fit Up Inspection Report-OKDocument24 pagesRFI-3458 - Daily Fit Up Inspection Report-OKnguyennamxmNo ratings yet

- Quality Assurance Plan: High Frequency Electric Resistance Welded PipeDocument15 pagesQuality Assurance Plan: High Frequency Electric Resistance Welded PipeSachin KumarNo ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- Wps Pip Gtaw - ArabianDocument1 pageWps Pip Gtaw - ArabianIshack MohammedNo ratings yet

- Class P6A6Document24 pagesClass P6A6SalimNo ratings yet

- Welder Qualification Register 01Document3 pagesWelder Qualification Register 01Andrei UrsacheNo ratings yet

- MSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryDocument1 pageMSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryMohd SaffririzalNo ratings yet

- SILVER-WPS-GESA-07 8mm To 16mm SAW LW P1.2 TO P1.2 - PQR-0036-W-21Document2 pagesSILVER-WPS-GESA-07 8mm To 16mm SAW LW P1.2 TO P1.2 - PQR-0036-W-21Abdulmecit YetisNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)MALABAR TIMESNo ratings yet

- Recipe of Medical AirDocument13 pagesRecipe of Medical AirMd. Rokib ChowdhuryNo ratings yet

- 3M NLP White PaperDocument12 pages3M NLP White PaperJayampathi SamarasingheNo ratings yet

- WEEK 7 ICPS - and - ICSSDocument31 pagesWEEK 7 ICPS - and - ICSScikguhafidzuddinNo ratings yet

- Food, Family, and FriendshipsDocument256 pagesFood, Family, and FriendshipsBianca PradoNo ratings yet

- Korean Enthusiasm and PatriotismDocument68 pagesKorean Enthusiasm and PatriotismYukino Hera100% (1)

- Fundamentals Deep Learning Activation Functions When To Use ThemDocument15 pagesFundamentals Deep Learning Activation Functions When To Use ThemfaisalNo ratings yet

- BISE Sukkur HSC Part 2 Results 2015Document12 pagesBISE Sukkur HSC Part 2 Results 2015ajayNo ratings yet

- DGN ExamDocument5 pagesDGN ExamMaiga Ayub HusseinNo ratings yet

- WholeDocument397 pagesWholedelbot01No ratings yet

- Lesson 2 - Procedures in Cleaning Utensils and EquipmentDocument26 pagesLesson 2 - Procedures in Cleaning Utensils and EquipmentReizel TulauanNo ratings yet

- React Rich Text EditorDocument3 pagesReact Rich Text Editordhirendrapratapsingh398No ratings yet

- v16 n3Document219 pagesv16 n3Mark ReinhardtNo ratings yet

- Eddy Current Testing Exam Questions Assignment2Document1 pageEddy Current Testing Exam Questions Assignment2Narotam Kumar GupteshwarNo ratings yet

- Belotero Intense LidocaineDocument7 pagesBelotero Intense LidocaineAnnaNo ratings yet

- Axial Centrifugal FansDocument15 pagesAxial Centrifugal FansAhsan JavedNo ratings yet

- Forcepoint Email Security Configuration Information v8.5Document64 pagesForcepoint Email Security Configuration Information v8.5ajay chaudharyNo ratings yet

- MSDS Slideway Oil Iso VG 68 - 031115Document6 pagesMSDS Slideway Oil Iso VG 68 - 031115Rini SiskayantiNo ratings yet

- B1 UDO Trace LogDocument14 pagesB1 UDO Trace LogCh M KashifNo ratings yet

- MF ISIN CodeDocument49 pagesMF ISIN CodeshriramNo ratings yet

- PIRA - 2022 - ESTIMATED FMV As of October 2022Document48 pagesPIRA - 2022 - ESTIMATED FMV As of October 2022Aggy ReynadoNo ratings yet

- Clinical Presentation of Ectopic Pregnancy Turned Out to Be Ectopic PregnancyDocument33 pagesClinical Presentation of Ectopic Pregnancy Turned Out to Be Ectopic PregnancyRosiNo ratings yet

- Complete Tds CourseDocument32 pagesComplete Tds CourseAMLANNo ratings yet

- Meta Hids by eBPFDocument27 pagesMeta Hids by eBPFninggou.yangNo ratings yet