Professional Documents

Culture Documents

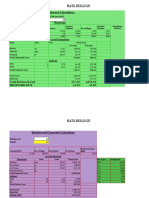

Oil & Grease Test

Uploaded by

Rohini GadhaweCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oil & Grease Test

Uploaded by

Rohini GadhaweCopyright:

Available Formats

Oil and Grease, LLE, 10056

Oil and Grease DOC316.53.01187

USEPA1 Hexane Extractable Gravimetric Method Method 10056

15 to 3000 mg/L HEM and SGT-HEM

Scope and Application: For water and wastewater

1 Equivalent to USEPA Method 1664. Adapted from Standard Methods for the Examination of Water and Wastewater, Section 5520B.

Test preparation

Before starting the test:

Determine a blank value (350 mL) of distilled or deionized water) with each new lot of reagents. If the blank result is greater

than 5 mg, resolve the source of error or remove interferences before performing this procedure. Use the equivalent amount

of acid to determine the blank and all samples from each sampling source.

The sample must be at room temperature before analyzing.

Do not use plastic tubing to transfer the solvent between containers.

Do not pre-rinse the collecting vessel with sample.

Anhydrous sodium sulfate is used to remove traces of water from the hexane extraction layer. Dry the sodium sulfate at 200

to 250 °C for 24 hours for best performance.

Spilled reagent will affect test accuracy and is hazardous to skin and other materials.

If determining both the HEM and the SGT-HEM, clean and dry two distillation flasks (one for each procedure) in advance.

• HEM = n-hexane extractable materials

• SGT-HEM = Silica Gel Treated n-hexane extractable materials

Oil and Grease

Page 1 of 16

Oil and Grease

Hexane Extractable Gravimetric Method

1. Collect 350 mL of 2. Using a pipette and 3. Using an analytical 4. Add 20 mL of

sample in a clean 500-mL pipette filler, add 4 mL of balance, weigh a n-hexane to the

separatory funnel. 1:1 Hydrochloric Acid previously dried and separatory funnel.

If the sample is not solution to the separatory cleaned 125-mL distillation If the sample was

collected in the separatory funnel. Mix well. The pH flask containing 3–5 collected in a separate

funnel, set the empty must be ≤ 2 to hydrolyze boiling chips to the nearest container or if repeating

container and lid aside for oils and grease and 0.1 mg. Record the weight this step, rinse the

use in step 4. prevent a sodium sulfate of the flask. collecting vessel/

interference. volumetric flask which

Check sample pH after contained the sample/

acid addition by dipping a water layer with 20 mL of

glass rod into the sample n-hexane, then add the

and allowing a few drops 20-mL n-hexane rinse to

to touch the pH paper. Do the separatory funnel.

not dip the pH paper into

the sample. Rinse the

glass rod with a small

portion of hexane back

into the separatory funnel

to remove any grease/oil

on the rod.

Oil and Grease

Page 2 of 16

Oil and Grease

Hexane Extractable Gravimetric Method (continued)

5. Stopper the funnel. 6. Let the funnel stand 7. Slowly drain the lower 8. Set up the filtering

Invert the funnel and undisturbed for at least 10 water layer from the funnel. Put the glass

release the gases through minutes to ensure separatory flask into the funnel in the neck of the

the stopcock. Then, separation of the lower original sample container distillation flask. Place a

vigorously shake the water layer and the upper or 500-mL volumetric folded 12.5 cm filter paper

funnel for two minutes. solvent layer. flask. This should take in the funnel. Add 10 g of

To release gases from the The solvent layer may be about 3–4 minutes. Save anhydrous sodium sulfate

separatory funnel, invert it brown if a colored oil is the water layer for step 10. to the filter paper. Rinse

and shake it once very present. To ensure that water is not the sodium sulfate with a

hard (support the stopper transferred in step 9, allow small amount of the

If you repeat this step the hexane. Discard the

with your hand). Under a third time and the water several drops of solvent

hood, point the delivery layer to drain into the hexane properly.

layer is cloudy, allow the

tube in a safe direction separatory funnel to stand water layer until the Use the same filter, funnel

and slowly open the undisturbed for 20 minutes solvent layer is visible on and sodium sulfate when

stopcock to release any for better separation of the top of the water. repeating this step for the

gas. Close the stopcock. water and solvent layers. If the water layer drains second and third

Repeat the venting too quickly, excess water extractions. Remove large,

procedure until you no will be present in the hard sodium sulfate

longer hear the release of solvent layer. This causes chunks between

gases. sodium sulfate and water extractions to reduce

interference. sodium sulfate

contamination.

Oil and Grease

Page 3 of 16

Oil and Grease

Hexane Extractable Gravimetric Method (continued)

Repeat

Steps 4–10

9. Drip-drain the solvent 10. Return the water layer 11. Repeat step 4 through 12. Rinse the separatory

layer into the pre-weighed to the separatory funnel. step 10 two more times. funnel with three separate

boiling flask through a Use the same glass funnel After the third extraction, 5-mL aliquots of fresh

funnel containing filter for the second and third discard the water layer. n-hexane to remove any

paper and 10 g anhydrous extraction (referred to in There may be small oil film left on the funnel

sodium sulfate. Gently stir step 11). amounts of acetone and/or walls. Drain each aliquot

the sodium sulfate with a n-hexane in the water through the funnel

glass stirring rod while the To reduce spillage, a containing the sodium

second funnel can be layer.

solvent layer is draining. sulfate into the distillation

Be careful not to rip the used when pouring the Refer to your local waste flask.

filter paper. water layer into the disposal procedure for

separatory funnel. proper disposal

Any spillage will cause instructions.

inaccurate results. To

reduce spillage, use a

glass rod to guide the

sample solution into the

filter.

Oil and Grease

Page 4 of 16

Oil and Grease

Hexane Extractable Gravimetric Method (continued)

See See

Go to

Figure 1 Figure 1

Step 15

13. Rinse the tip of the 14. If HEM is to be 15. Using the distillation 16. Disconnect the

glass funnel with 5 mL of determined, go to step 15. assembly shown in condenser/connector

n-hexane while removing it If only the SGT-HEM is to Figure 13, distill off the portion of the distillation

from the distillation flask. be determined and the n-hexane. Distillation is assembly at the pinch

Check for sodium sulfate HEM is known, go to complete when there are clamp and remove the

contamination. step 21. no boiling bubbles or the distillation flask from the

Sodium sulfate distillation flask appears heat source with an

If only the SGT-HEM is to dry. anti-lint cloth or tongs.

contamination will appear be analyzed, the HEM is

as cubic crystals at the needed in order to Use a steam bath or a hot The distilled n-hexane

bottom of the distillation determine the amount of plate to maintain a water may be re-used in future

flask. If present, re-filter silica gel needed for the bath at the proper HEM extractions, but is not

the solvent layer through SGT-HEM. For each group temperature for the recommended for

filter paper without sodium of samples from a distillation. Do not place SGT-HEM due to the

sulfate. You must re-clean, discharge, determine the the flask directly on a hot potential increased water

dry and weigh the boiling HEM before the plate. This will cause low content of the solvent.

flask and boiling chips; or SGT-HEM. results and is dangerous

have an extra flask ready because n-hexane is

in case this is necessary. volatile.

Evaporation will be faster if

the long vertical arm of the

connector is wrapped with

insulation (paper towel,

cloth or asbestos

insulating tape). The

distillation should take less

than 30 minutes.

Oil and Grease

Page 5 of 16

Oil and Grease

Hexane Extractable Gravimetric Method (continued)

17. Remove the remaining 18. Place the flask in a 19. Using an analytical 20. Calculate the test

solvent vapors from the desiccator for 30 minutes balance, weigh the flask to results:

distillation flask by (or longer if necessary) the nearest 0.1 mg. A – B × 1000 = mg/L HEM

attaching the vacuum until it cools to room Record this weight. Do not

connector/gas inlet temperature. touch the flask after A= Weight (mg) of residue

adapter to the flask. Apply If the silica gel indicator weighing; fingerprints will B= Weight (mg) of flask

a vacuum for 1–2 minutes has turned red, replace the add weight. with boiling chips (step 3).

or until all n-hexane silica gel. Always use a tong or a

solvent vapors have been Example:

lint-free wipe when

removed. handling the flask. A = 92.4659 g

Crystals on the bottom of Precise weighing is B = 92.4206 g

the flask indicate that necessary for accurate Sample volume = 0.350 L

sodium sulfate may have results; multiple weight (350 mL)

been dissolved in the measurements are

extraction steps. Re- recommended. Re-wipe 92.4659 – 92.4206

dissolve the extract in n- the flask before each ------------------------------------------------- =

0.350

hexane, filter into another measurement to ensure all

pre-weighed flask and 129.4 mg/L

contaminants are

repeat steps 14–16. This removed. Record each If yield is less than

is not necessarily true for weight; use the lowest 15 mg/L and additional

the “standard” extraction repeatable value for precision is needed, use a

since stearic acid is calculations. 1-liter sample.

crystalline below 69 °C

(156 °F). If sodium sulfate

is present in the standard,

big cubical crystals (not

the flattened stearic acid

crystals) will be visible.

Also, an unusually high

yield compared to the

expected value will result.

Oil and Grease

Page 6 of 16

Oil and Grease

Hexane Extractable Gravimetric Method (continued)

21. If only calculating the 22. For a 350-mL water 23. Put a magnetic stir bar 24. Stir solution on a

HEM, stop here. sample, dilution is and the correct amount of magnetic stirrer for five

If continuing with necessary if the HEM is silica gel (based on the minutes (minimum).

SGT-HEM, re-dissolve above 2850 mg/L (for a equation below) into the

residue with approximately 1-liter sample, dilute if the flask with the solvent/

85 mL of fresh n-hexane. HEM is greater than product from step 22.

Heat slightly to ensure 1000 mg/L). 3 × mg/L HEM

-------------------------------------- =

re-dissolving of all HEM To dilute to a 1000 mg/L 100

materials. sample, pour the silica gel (g ± 0.3)

re-dissolved HEM into a

100-mL volumetric flask.

Rinse the distillation flask

3–4 times with 2–3 mL of

n-hexane. Fill the

volumetric flask to volume

with n-hexane. Mix well.

Into a 100-mL beaker,

volumetrically pipet the

amount (Va) determined

by this equation:

10000

V a = ----------------

Wh

where:

Va = Volume of aliquot to

be withdrawn (mL) to get

1000 mg of HEM.

Wh = Weight of HEM (mg)

(A –B x 1000 in step 19

(mg)). Dilute to about

100 mL with n-hexane.

Oil and Grease

Page 7 of 16

Oil and Grease

Hexane Extractable Gravimetric Method (continued)

Perform

Steps 15—20.

25. Place a funnel on a 26. Follow step 15–

clean, dry distillation flask step 20. Weigh the

with 3–5 boiling chips in it. product remaining in the

Place a 12.5-cm filter bottom of the flask and

paper in the funnel. calculate the results using

Pre-moisten the filter the equation below:

paper with fresh n-hexane. A–B

Filter the solution through ------------------------------------------ =

Sample Volume

filter paper. mg/L SGT – HEM

Rinse the beaker

containing remaining silica where:

gel 3 times with 5-mL A = Weight (mg) of residue

aliquots of fresh n-hexane

B = Weight (mg) of flask

and pour the aliquots into

with boiling chips.

the distillation flask.

Oil and Grease

Page 8 of 16

Oil and Grease

Figure 13 Distillation assembly

1. Pinch Clamp 8. Water Bath

2. J-Shaped Connector 9. Hot Plate

3. Clamp, 3-Prong 10. Receiving Flask

4. Condenser 11. Water In

5. Pinch Clamp 12. Clamp Holders

6. Clamp, 3-Prong 13. Water Out

7. Distillation Flask 14. Support Stand and Rod Assembly

Oil and Grease

Page 9 of 16

Oil and Grease

Interferences

Substances extracted from samples will vary from source to source, depending upon the diversity

of the site being sampled. Some samples may contain high amounts of detergents or particulates

that can interfere with the extraction procedure. For these samples, it may be necessary to use a

350-mL sample rather than 1-liter (which is an option). In this circumstance, the 350-mL sample is

EPA accepted for reporting. Wash all glassware in hot water with detergent, rinse with tap and

distilled water and rinse with n-hexane or acetone.

If an emulsion forms between the two phases (at step 6) and is greater than one-third the volume

of the solvent layer, filter the emulsion and solvent layer through a funnel with glass wool in it. If an

emulsion still exists, other possible solutions include: stirring the solvent and emulsion layer with a

stir bar, using solvent phase separation paper, centrifugation, using an ultrasonic bath with ice,

adding NaCl or other physical methods. (Solid phase or other extraction techniques would fall

under performance based modifications.)

A milky solvent/product layer in the distillation flask indicates water in the solvent layer. Let the

flask stand one hour to allow the water to settle. Re-filter the solvent layer through sodium sulfate

to remove remaining water.

Extremely low yields could mean a poor extraction (step 5 through step 8) and a high yield could

indicate a problem in the solvent drying (step 8). Follow step 5 through step 8 very carefully and

run your blank before you run samples in order to identify any possible interference due to these

steps. If your blank indicates a yield above 1 mg per test, you should identify the source of

contamination before continuing; likely sources are sodium sulfate contamination and improperly

rinsed glassware.

Sample collection, preservation and storage

• Collect samples in wide-mouth glass bottles or directly in the separatory funnel for immediate

analysis.

• Collection of sample may be done directly into the separatory funnel. Measure 350 mL of

water with a graduated cylinder.

• Pour this into the separatory funnel. Use a laboratory pen to mark the 350-mL level. Fill with

sample to this mark.

• Do not pre-rinse the bottle or separatory funnel with the sample.

• If analysis is delayed for more than a few hours, add 6 mL of 1:1 Hydrochloric Acid Solution for

each liter or quart of sample.

• Check the pH to ensure it is 2 or less. Do not place the pH paper directly into the sample, but

dip a glass rod into the sample and touch the pH paper with a drop of sample.

• Rinse the rod with n-hexane directly back into sample container after the pH has been

determined to make sure that no product has adhered to the glass rod.

• If necessary, add more acid to bring pH below 2.

• Store the sample between 0–4 °C (32–39 °F). Preserved samples can be stored for 28 days.

Handling glassware

Before analysis, careful cleaning and drying of the glassware and boiling chips is necessary. Clean

the chips and distillation flask by washing with hot water and detergent, rinsing with distilled water

and then rinsing with acetone or n-hexane. Place the cleaned flask and boiling chips in a drying

oven at 105–115 °C (220–240 °F) for 2 hours. Cool to room temperature in a desiccator for at least

30 minutes. Store in the desiccator until needed.

To eliminate errors, always handle the flask with tongs or an anti-lint wipe. If the same flasks are

used repeatedly, record their weights after drying in the oven without boiling chips. The drying step

Oil and Grease

Page 10 of 16

Oil and Grease

may be skipped if the flasks weigh the same after the acetone or n-hexane rinse as it does after

drying. Boiling chips will vary in weight; their weight should be added to the flask weight.

Definition of HEM and SGT-HEM

Oil and grease is the conventional term used to define pollutants of this nature. The new term

n-Hexane Extractable Materials (HEM) indicates this method may be applied to materials other

than oils and greases.

Likewise, the term Total Petroleum Hydrocarbons (TPH) was traditionally used to classify aliphatic

hydrocarbon materials. The new term Silica Gel Treated n-Hexane Extractable Material

(SGT-HEM), indicates that this method may be applied to materials other than aliphatic petroleum

hydrocarbons that are not adsorbed by silica gel.

Detection limit

This method is not applicable to measurements of materials that volatilize at temperatures below

approximately 85 °C (185 °F). Petroleum fuels from gasoline through #2 fuel oil may be partially

lost in the solvent removal operation. Some crude oils and heavy fuel oils contain a significant

percentage of materials that are not soluble in n-hexane. Recoveries of these materials may

be low.

The method is capable of measuring HEM and SGT-HEM in the range of 15 to 3000 mg/L when

using a 350-mL sample and may be decreased to as low as 5 mg/L if a 1-liter sample is used.

When using the 1-liter sample volume, use the amount of reagents listed for the 1-liter size in EPA

monitoring, testing procedures and modifications.

Standard preparation

1. Transfer 400 ±4 mg stearic acid and 400 ±4 mg hexadecane into a 100-mL volumetric flask.

2. Pour 75 mL of acetone into the flask. Cover with a small beaker and stir gently. Heat slightly

until all material is in solution. Over-heating with the lid on causes pressure build up.

3. Fill to volume with acetone. Cover. Allow to equilibrate to room temperature and continue to fill

to volume until solution is at stable volume.

4. Using a volumetric pipet, transfer 5 mL of the solution from step 3 into 350 mL of deionized

reagent water. This standard solution should be 114.3-mg/L HEM or 57.1-mg/L SGT-HEM. If

using a 1-liter water sample, 5 mL gives concentrations of 40 mg/L HEM and 20 mg/L

SGT-HEM. To verify the concentration, pipette 5 mL of the solution from step 3 in a

pre-weighed flask, place in hood and allow acetone to evaporate off. Weigh the flask. Verify

that the weight difference before and after solution addition is 40 (±1) mg.

EPA monitoring, testing procedures and modifications

If the Oil and Grease tests are used for compliance reporting to the USEPA, make the following

changes to the procedure:

1. Use a 1-liter sample in a 2000-mL separatory funnel rather than a 350-mL sample in a 500-mL

separatory funnel (step 1).

2. Use 6 mL (instead of 4 mL) of 1:1 hydrochloric acid to bring the pH below 2 (step 2) and 30 mL

of n-hexane instead of 20 mL of n-hexane for the extraction (step 4).

Before testing real samples for oil and grease, you must be able to obtain a MDL (Minimum

Detection Limit) less than or equal to the EPA reported MDL and to report an IPR (Initial Precision

and Recovery). Before attempting the MDL and IPR, it is highly recommended to run

laboratory reagent water blanks to eliminate all interference.

Oil and Grease

Page 11 of 16

Oil and Grease

MDL: The USEPA-documented MDL is extremely difficult to reproduce if the slightest sodium

sulfate contamination occurs. EPA Method 1664 requires the MDL to be ≤ 1.4 mg/L for HEM and

≤ 1.6 mg/L for SGT-HEM. This is calculated by determining the standard deviation of seven

standard samples for HEM or seven standards for SGT-HEM and multiplying their respective

standard deviations by 3.143 (Student’s t test).

The recommended standard concentration for determining the MDL is about 5 mg/L. To prepare

the standard for HEM follow steps 1–3 in Standard preparation, but change step 1 to transfer

100 (± 4) mg stearic acid and 100 (± 4) mg hexadecane to a 250-mL volumetric flask. To prepare

the SGT-HEM standard, transfer 200 (± 4) mg of decahexane only into a 250-mL volumetric flask.

Transfer 5 mL of either standard into 1-liter of reagent water. Analysis of the standard should give

5 mg/L for either HEM or SGT-HEM.

IPR: Follow the procedure for HEM and SGT-HEM, using deionized water (void of any oil and

grease) as the blank. Perform the procedure four separate times using 5 mL of the standard

(40 mg/L 1:1 stearic acid/hexadecane) diluted into 1 liter of demineralized water. Report the

average percent recovery (X) and the standard deviation of the percent recovery(s) for both HEM

and SGT-HEM. X and s should fall within these parameters:

• HEM: Precision(s) ≤ 10%; Recovery(X) 83–101%

• SGT-HEM: Precision(s) ≤ 13%; Recovery(X) 83–116%

If not within these ranges, correct the problem and repeat IPR.

Once the MDL and IPR have been established, keep records for EPA verification or for future

reference.

Oil and grease reporting to EPA

To report the HEM and/or SGT-HEM, include the following data for each set of up to ten samples.

1. BLANK: Must be less than 5.0 mg/L for HEM and SGT-HEM.

Note: For compliance monitoring, it may be necessary to use a standard that either matches the

regulatory concentration limit or is 1 to 5 times higher than the concentration of the sample (B),

whichever is greater. The concentration of the spike (T) needs to be divided by 2 for SGT-HEM if

using the standard (40 mg/L 1:1 stearic acid/hexadecane).

2. OPR (Ongoing Precision and Recovery): Determine the amount of analyte in a one liter

sample containing 5 mL of the standard (40 mg/L 1:1 stearic acid/hexadecane). Continue on if

the HEM recovery is 70–114% and the SGT-HEM recovery is 66–114%. If recovery is lower,

an interference may be present or analysis technique may be faulty. Identify the cause and

repeat OPR until within range.

3. MS and MSD (matrix spike and matrix spike duplicate): Determine the background

concentration (B) of your sample by running HEM and SGT-HEM for the discharge water.

Spike two 1-liter discharge water samples with 5 mL of standard and measure the

concentration of the analyte after spiking (A).

Determine the Percent Recovery (P) as follows:

100 × ( A – B )

P HEM(40 mg/L) = -----------------------------------

T

100 × ( A – B )

P SGT – HEM = -----------------------------------

T⁄2

If HEM Recovery is 79–114% and SGT-HEM Recovery is 66–114%, then calculate the

Relative Percent Difference (RPD). If recovery is lower, an interference may be present.

Identify and correct the interference, then repeat MS and MSD.

Conc MS – Conc MSD

RPD = ---------------------------------------------------- × 200

Conc MS + Conc MSD

Oil and Grease

Page 12 of 16

Oil and Grease

If RPD for HEM ≤ 18 and RPD for SGT-HEM ≤ 24, then continue with step 4.

If recovery is lower, an interference may be present. Identify and correct the interference, then

repeat MS and MSD.

After every five MS/MSD tests, compute the average percent recovery (Pa) and standard

deviation of the percent recovery (sp). Record these numbers as Pa ±2sp.

4. Calibrate your analytical balance at 2 mg and 1000 mg using class “S” weights to ensure

calibration within ±10%.

5. Analyze up to 10 samples from the source used in the MS and MSD before starting back at

step 1. For every 10 samples you must determine a new blank, OPR, RPD, MS and MSD.

Summary

Each laboratory must first verify the MDL and IPR and ensure they are within proper parameters

before reporting oil and grease test results to the EPA. Once this is established for a laboratory, it

does not need to be done again.

For every 10 samples per discharge source, one must calibrate the balance, report one blank, one

OPR, one MS and one MSD. Logs must be kept on percent recovery and relative percent

differences for MS/MSD tests. For every five MS/MSD test, calculate and record the average

percent recovery and standard deviation.

Summary of method

Oil and Grease & Total Petroleum Hydrocarbons (TPH) include any material that may be

recovered as a substance that is soluble in the n-hexane extractant. These include substances

such as relatively non-volatile hydrocarbons, vegetable oils, animal fats, waxes, soaps, greases

and related materials. When measuring oil and grease (HEM) gravimetrically, the substances are

extracted from the sample with n-hexane, then the n-hexane is evaporated. The residue left is

weighed to determine the concentration of oil and grease materials in mg/L.

When measuring Total Petroleum Hydrocarbons (SGT-HEM) gravimetrically, the substances are

extracted from the sample with n-hexane, then mixed with silica gel to absorb non-TPH

components. Then the n-hexane is evaporated. Like the HEM, the residue left is weighed to

determine the concentration of total petroleum hydrocarbons.

Note: Careful technique is required to obtain accurate and precise results.

Consumables and replacement items

Required reagents

Description Quantity/Test Unit Catalog number

Hydrochloric Acid Standard Solution, 1:1 (6N) 4 mL 500 mL 88449

Hexane, ACS grade 100–200 mL 500 mL 1447849

pH Paper, 0–14 pH units varies 100/pkg 2601300

Silica Gel with indicator (for desiccator) varies 454 g 1426901

Silica Gel, 100–200 mesh 1–30 g 500 g 2665034

Sodium sulfate, anhydrous 10 g 113 g 709914

Oil and Grease

Page 13 of 16

Oil and Grease

Required apparatus

Description Quantity/Test Unit Catalog number

Adapter, vacuum connector/gas inlet, 28/15 1 each 1433900

Aspirator, vacuum 1 each 213100

Balance, Analytical, 115 VAC 60 Hz. 1 each 2936801

Boiling Chips 3–10 500 g 2055734

Clamp, 3-prong 2 each 42200

Clamp, holder 2 each 32600

Clamp, pinch type, No. 28, F/Glass Joints 2 each 1433800

Condenser, reflux, w/ground glass joints, 28/15 1 each 1433700

Cylinder, graduated, 500-mL 1 each 2088549

Cylinder, graduated, 50-mL 1 each 50841

Desiccator 1 each 2088800

Desiccator Plate 1 each 1428400

Filter Funnel, 65-mm, short stem 1 each 2664700

Filter Paper, 12.5-cm, folded, pore size 8 to 12 µm 1 100/pkg 69257

Flask, Erlenmeyer, 125-mL 1 each 50543

Flask, Erlenmeyer, 125-mL, w/ground glass joint 28/15 2 each 1434000

Funnel, separatory, 500-mL 1 each 52049

Marker, Laboratory 1 each 2092000

Oven, drying, 120 VAC, 50 Hz 1 each 1428900

Pipette filler, safety bulb 1 each 1465100

Pipette, serological, 5-mL 1 each 53237

Ring Support, 4-inch 1 each 580-01

Rod, glass 1 3/pkg 177001

Steam bath, 8-inch, 5-ring 1 each 2347900

Hot Plate/Stirrer, 7.25 x 7.25", 120 VAC 1 each 2881600

Stir Bar, 22.2 x 7.9 mm 1 each 2095350

Support stand 2 each 56300

Tongs, crucible, 9-inch 1 each 56900

Tube, connecting, J-shaped, w/ground glass joint, 28/15 1 each 1814300

Tubing, black rubber, 7.9 X 2.4 mm 1 3.6 m 56019

Recommended standards

Description Unit Catalog number

Hexadecane, 99%, 400 mg 100 mL 2664842

Stearic Acid, 400 mg 500 g 2664934

Oil and Grease

Page 14 of 16

Oil and Grease

Optional reagents and apparatus

Description Unit Catalog number

Acetone, ACS 500 mL 1442949

Separatory funnel, 2-liters each 52054

Beaker, 50 mL each 50041H

Balance, Weight Set each 2617601

Hotplate/Stirrer 7.25 x 7.25 in., 220–240 VAC each 2881602

Ring Support, 4.5 in. each 2656300

Furnace, Muffle, 120 VAC each 1429600

Pipet, Volumetric 5.0 mL each 14515-37

Flask, Volumetric 100 mL 14574-452

Cylinder, graduated, 100 mL each 508-42

Oil and Grease

Page 15 of 16

FOR TECHNICAL ASSISTANCE, PRICE INFORMATION AND ORDERING: HACH COMPANY

In the U.S.A. – Call toll-free 800-227-4224 WORLD HEADQUARTERS

Outside the U.S.A. – Contact the HACH office or distributor serving you. Telephone: (970) 669-3050

On the Worldwide Web – www.hach.com; E-mail – techhelp@hach.com FAX: (970) 669-2932

© Hach Company, 2007, 2010, 2012. All rights reserved. Printed in the U.S.A. Edition 7

You might also like

- Manual of Formulas - Recipes, Methods & Secret ProcessesFrom EverandManual of Formulas - Recipes, Methods & Secret ProcessesRating: 4.5 out of 5 stars4.5/5 (2)

- Steam Distillation ExperimentDocument4 pagesSteam Distillation ExperimentibnyasseenNo ratings yet

- Practical Physical Pharmaceutics 2012Document33 pagesPractical Physical Pharmaceutics 2012sam100% (2)

- ISO 13485 Gantt Chart - May 2020Document4 pagesISO 13485 Gantt Chart - May 2020Rohini Gadhawe100% (4)

- Kash's A - B Mescaline Extraction - DMT-Nexus WikiDocument6 pagesKash's A - B Mescaline Extraction - DMT-Nexus WikiDanyLarocqueNo ratings yet

- MWBE List For Mill Creek Peaks Branch State-Thomas Drainage TunnelDocument332 pagesMWBE List For Mill Creek Peaks Branch State-Thomas Drainage TunnelRohanNo ratings yet

- Production Scheduling OptimizationDocument9 pagesProduction Scheduling OptimizationRohini GadhaweNo ratings yet

- Project Gantt Chart PDFDocument1 pageProject Gantt Chart PDFRohini GadhaweNo ratings yet

- SALTS of FATTY ACIDS Identification and Purity TestsDocument9 pagesSALTS of FATTY ACIDS Identification and Purity TestsFermi Dio AlfatyNo ratings yet

- Refractory Science Refractories - : 1.1 Composition and StructureDocument14 pagesRefractory Science Refractories - : 1.1 Composition and StructureNikki AlbiosNo ratings yet

- Wall Wash Test ProceduresDocument5 pagesWall Wash Test Proceduresrabi4457No ratings yet

- 13-Saponification PDFDocument6 pages13-Saponification PDFChelsea Reyna Tolentino0% (2)

- Turbidity Suspended SolidsDocument6 pagesTurbidity Suspended SolidsStrazdas100% (1)

- 01 Vetotop CL530 - 141221 JODocument2 pages01 Vetotop CL530 - 141221 JOassala HaddadNo ratings yet

- Industrial Arts 6: Week 1Document9 pagesIndustrial Arts 6: Week 1arielle domingoNo ratings yet

- Supercritical Power Generation-Experiences, Issues & ChallengesDocument85 pagesSupercritical Power Generation-Experiences, Issues & ChallengesVeda SiddharthNo ratings yet

- Plant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterFrom EverandPlant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterNo ratings yet

- Renault Group CSR For IATF 169494Document10 pagesRenault Group CSR For IATF 169494nkrish21856No ratings yet

- Size Press Efficiency Factors (Breaks, Strength, MoistureDocument2 pagesSize Press Efficiency Factors (Breaks, Strength, Moisturetsvmpm1765No ratings yet

- Metodo XenosepDocument12 pagesMetodo XenosepJenny Chavez AlarconNo ratings yet

- JECFA - Mineral Oil - Monograph 2013Document2 pagesJECFA - Mineral Oil - Monograph 2013elenitabastosNo ratings yet

- Crystallization Is Used To Purify A Solid. The Process Requires A Suitable Solvent. ADocument8 pagesCrystallization Is Used To Purify A Solid. The Process Requires A Suitable Solvent. ARift UrrahmanNo ratings yet

- TrimyristinDocument3 pagesTrimyristindinna_dinunNo ratings yet

- Nickel Experiment XWDocument4 pagesNickel Experiment XWKhairul Anwar Abd HamidNo ratings yet

- 2.1 Separation of Acidic and Neutral SubstancesDocument5 pages2.1 Separation of Acidic and Neutral SubstancesHoong50% (2)

- GRAM STAIN ProcedureDocument1 pageGRAM STAIN ProcedureJona JonaNo ratings yet

- Cotton, Absorbent: Lanugo Gossypii AbsorbensDocument2 pagesCotton, Absorbent: Lanugo Gossypii AbsorbensHamed GholamiNo ratings yet

- Laboratory Exercise 4Document2 pagesLaboratory Exercise 4Ivy RetuyaNo ratings yet

- 24 AspirinDocument4 pages24 AspirinAyoeYoeRamndaniNo ratings yet

- Laboratory Manual For Determining Oil and Grease For Raw and Treated EffluentDocument3 pagesLaboratory Manual For Determining Oil and Grease For Raw and Treated EffluentAnas YuzairiNo ratings yet

- Separation Techniques Student Sheet: Intended Lesson OutcomesDocument19 pagesSeparation Techniques Student Sheet: Intended Lesson Outcomeslianchen251110No ratings yet

- Benzoic Acid LabDocument3 pagesBenzoic Acid LabnonononowayNo ratings yet

- Risk AssessmentDocument2 pagesRisk AssessmentfrancescoNo ratings yet

- EUROPEAN PHARMACOPOEIA 5.0: Cotton, absorbentDocument2 pagesEUROPEAN PHARMACOPOEIA 5.0: Cotton, absorbentluca_sergiuNo ratings yet

- Separate Mixture of Benzoic Acid, Naphthalene and AnilineDocument8 pagesSeparate Mixture of Benzoic Acid, Naphthalene and Anilinejarissa bannerNo ratings yet

- Determination of Oil and GreaseDocument5 pagesDetermination of Oil and GreaseobliviategibiNo ratings yet

- EPA 413.1 Grasas y AceitesDocument3 pagesEPA 413.1 Grasas y AceitesdcardonasterNo ratings yet

- 2410 Lab PolystyreneDocument1 page2410 Lab PolystyreneTotok Iswanto100% (1)

- Additive 384Document2 pagesAdditive 384Enrico WibowoNo ratings yet

- lipids by TLC method.Document3 pageslipids by TLC method.shazeen shoaibNo ratings yet

- Saponification of Methyl Salicylate 1Document2 pagesSaponification of Methyl Salicylate 1goyal8974No ratings yet

- International Olive Council Method for Determining StigmastadienesDocument12 pagesInternational Olive Council Method for Determining StigmastadienesSlaw Ben AissaNo ratings yet

- 8 OTTO Biologicals - Notes (B PHarm III) - Thur 21st at 0800Hrs - (Absorbent Cotton) - Oct 2021Document4 pages8 OTTO Biologicals - Notes (B PHarm III) - Thur 21st at 0800Hrs - (Absorbent Cotton) - Oct 2021Bigabwa BernardNo ratings yet

- Ed1c00940 Si 002Document6 pagesEd1c00940 Si 002snhmaitlaNo ratings yet

- Gravimetric Analysis of An Unknown Sulfate: ObjectivesDocument4 pagesGravimetric Analysis of An Unknown Sulfate: ObjectivesScar ShadowNo ratings yet

- Synthesis of Benzoic AcidDocument6 pagesSynthesis of Benzoic AcidHakdogNo ratings yet

- Scope: CautionDocument7 pagesScope: CautionJavier Oswaldo Gonzalez AceroNo ratings yet

- Isolation of Cardioactive GlycosidesDocument8 pagesIsolation of Cardioactive GlycosidesHaider RaheemNo ratings yet

- SteamDistDocument4 pagesSteamDistgnaequiNo ratings yet

- List of Reagents and Instruments: EquipmentDocument2 pagesList of Reagents and Instruments: EquipmentCSS aspirantNo ratings yet

- Feldspar Staining 4Document2 pagesFeldspar Staining 4Gokhan FurtanaNo ratings yet

- Wet-Column ChromatographyDocument8 pagesWet-Column ChromatographyEvelin PalenciaNo ratings yet

- Exp 3 - F23Document4 pagesExp 3 - F23s127886No ratings yet

- Separating The Components of Panacetin PrelabDocument5 pagesSeparating The Components of Panacetin PrelabAmy LaPointe100% (2)

- SAPONIFICATIONDocument4 pagesSAPONIFICATIONMuhammad ShaffizNo ratings yet

- Column ChromDocument4 pagesColumn Chromharunaheer02No ratings yet

- Sap On inDocument4 pagesSap On inkmilagan07No ratings yet

- 6 Properties of Soap PrelabDocument7 pages6 Properties of Soap PrelabRio SurNo ratings yet

- Experiment 6 Thin Layer Chromatographic Separation and Identification of Amino AcidsDocument4 pagesExperiment 6 Thin Layer Chromatographic Separation and Identification of Amino Acidsprathaps1987No ratings yet

- CHEM2054 B9 FlowchartDocument4 pagesCHEM2054 B9 FlowchartBowie ChongNo ratings yet

- Gravimetric Analysis of An Unknown Sulfate: ObjectivesDocument3 pagesGravimetric Analysis of An Unknown Sulfate: ObjectivesGezem GigantoNo ratings yet

- Paraffin, Light Liquid and Paraffin, Liquid - EPDocument2 pagesParaffin, Light Liquid and Paraffin, Liquid - EPelenitabastosNo ratings yet

- Toningformulaein 00 LampDocument16 pagesToningformulaein 00 LampJuan Francisco Martín MárquezNo ratings yet

- RS DextranDocument8 pagesRS DextranelgaNo ratings yet

- Organic vs Inorganic Compounds ExperimentDocument9 pagesOrganic vs Inorganic Compounds ExperimentSandra MacatangayNo ratings yet

- Cool Chemistry Activities for GirlsFrom EverandCool Chemistry Activities for GirlsRating: 5 out of 5 stars5/5 (2)

- Sop AirDocument24 pagesSop AirRohini GadhaweNo ratings yet

- Waste Water Treatment Process Operations Training CourseDocument1 pageWaste Water Treatment Process Operations Training CourseRohini GadhaweNo ratings yet

- Reclaimed Water ManagementDocument1 pageReclaimed Water ManagementRohini GadhaweNo ratings yet

- TBK Vendor Registration FormDocument4 pagesTBK Vendor Registration FormRohini Gadhawe100% (1)

- Introduction To On-Site Wastewater Treatment and Land Application SystemsDocument1 pageIntroduction To On-Site Wastewater Treatment and Land Application SystemsRohini GadhaweNo ratings yet

- About Us Standing Orders Consent M Anagement Notices Download Rti EmailDocument2 pagesAbout Us Standing Orders Consent M Anagement Notices Download Rti EmailRohini GadhaweNo ratings yet

- Water Testing Charges of MPCBDocument3 pagesWater Testing Charges of MPCBRohini GadhaweNo ratings yet

- H.W SopDocument17 pagesH.W SopRohini GadhaweNo ratings yet

- Unit 1 Fish Tale Word ProblemDocument13 pagesUnit 1 Fish Tale Word ProblemRohini GadhaweNo ratings yet

- Customer Specific Requirements of DAG September 2017Document8 pagesCustomer Specific Requirements of DAG September 2017DLNo ratings yet

- Daimler India Special Terms 2017 UpdatesDocument30 pagesDaimler India Special Terms 2017 UpdatesRohini GadhaweNo ratings yet

- Process Audit VDA-6 3-2010 - enDocument40 pagesProcess Audit VDA-6 3-2010 - enRohini GadhaweNo ratings yet

- Maintenance Training: Sr. No. TopicDocument6 pagesMaintenance Training: Sr. No. TopicRohini Gadhawe100% (1)

- CA ContactsDocument1 pageCA ContactsRohini GadhaweNo ratings yet

- INDIA Rates - ISO 22000/HACCP-DACDocument6 pagesINDIA Rates - ISO 22000/HACCP-DACRohini GadhaweNo ratings yet

- Unitary MethodDocument7 pagesUnitary MethodRohini GadhaweNo ratings yet

- Enrol 000ST7090825 Icnc 00205 20180814140037Document1 pageEnrol 000ST7090825 Icnc 00205 20180814140037Rohini GadhaweNo ratings yet

- Jyothis Academy Prospectus PDFDocument16 pagesJyothis Academy Prospectus PDFRohini GadhaweNo ratings yet

- Worksheet Word ProblemDocument1 pageWorksheet Word ProblemRohini GadhaweNo ratings yet

- The Institution of Engineers (India) : An ISO 9001:2008 Certified Organisation 8 Gokhale Road, Kolkata 700 020Document7 pagesThe Institution of Engineers (India) : An ISO 9001:2008 Certified Organisation 8 Gokhale Road, Kolkata 700 020Rohini GadhaweNo ratings yet

- Visit ReportDocument10 pagesVisit ReportRohini GadhaweNo ratings yet

- Project Gantt ChartDocument1 pageProject Gantt ChartRohini GadhaweNo ratings yet

- Visit ReportDocument10 pagesVisit ReportRohini GadhaweNo ratings yet

- Training Attendance Sheet: Course Title: Faculty: Course Start Date: Course End Date: Company Name: Course DurationDocument4 pagesTraining Attendance Sheet: Course Title: Faculty: Course Start Date: Course End Date: Company Name: Course DurationRohini GadhaweNo ratings yet

- FAL-MTS-01-00 20MnCr5 1730 PDFDocument3 pagesFAL-MTS-01-00 20MnCr5 1730 PDFAndras StegerNo ratings yet

- Origin and Composition of PetroliumDocument27 pagesOrigin and Composition of PetroliumSirajuddin KhanNo ratings yet

- Wooden Windows CatalogueDocument17 pagesWooden Windows CatalogueVIJAY VATSALNo ratings yet

- 1227 AppG PDFDocument2 pages1227 AppG PDFCecilio MtzNo ratings yet

- BTEC ResultDocument6 pagesBTEC Resultubelal211No ratings yet

- Management Summary Purging of Hydrogen PipesDocument3 pagesManagement Summary Purging of Hydrogen Pipescarpo2003No ratings yet

- Gaskets, O-RingsDocument56 pagesGaskets, O-RingsjaveriaNo ratings yet

- DFL E-25Document13 pagesDFL E-25Lea PesiganNo ratings yet

- Nitrogen, Ammonia, Colorimetry, Salicylate-Hypochlorite, Automated-Segmented FlowDocument8 pagesNitrogen, Ammonia, Colorimetry, Salicylate-Hypochlorite, Automated-Segmented FlowManoleteNo ratings yet

- Material Calculator (Building)Document7 pagesMaterial Calculator (Building)Kumbie MadzekeNo ratings yet

- Masonry (Mas) : Course Descriptions: Career/Technical DisciplinesDocument9 pagesMasonry (Mas) : Course Descriptions: Career/Technical DisciplinesYrolle Lynart AldeNo ratings yet

- W2P Bio Filter MediaDocument1 pageW2P Bio Filter MediaAngirishNo ratings yet

- Advantages of Polypropylene Based CoatingsDocument13 pagesAdvantages of Polypropylene Based CoatingspaimpillyNo ratings yet

- Pa6 GF15 - Basf Ultramid B3eg3Document2 pagesPa6 GF15 - Basf Ultramid B3eg3armandoNo ratings yet

- Rheywell Cables PumpsDocument12 pagesRheywell Cables PumpsMahmoud Al-SherbinyNo ratings yet

- Vesta Keep Compounds Product Brochure 32 PagesDocument32 pagesVesta Keep Compounds Product Brochure 32 PagesMorkizgaNo ratings yet

- Dokumen - Tips - High Performance Waterborne Epoxy Formulation For 2019 03 06 19 Table 1 Epoxy ModifiedDocument3 pagesDokumen - Tips - High Performance Waterborne Epoxy Formulation For 2019 03 06 19 Table 1 Epoxy ModifiedLong An ĐỗNo ratings yet

- Quality of Work Life KesoramDocument76 pagesQuality of Work Life KesoramyourstruelyudayNo ratings yet

- D&FBlocksDocument15 pagesD&FBlocksSLNo ratings yet

- Catalog Sisteme Fixari Speciale Electrice Si Comunicatii SUADocument228 pagesCatalog Sisteme Fixari Speciale Electrice Si Comunicatii SUAGabriel TanaseNo ratings yet

- Corrotherm International Brochure 2019Document8 pagesCorrotherm International Brochure 2019colourhutNo ratings yet

- Chemistry One Liner Questions PDFDocument10 pagesChemistry One Liner Questions PDFHacker Mudu0% (1)

- SANHA - Therm SANHA - Therm Industry - Press Systems in Carbon SteelDocument8 pagesSANHA - Therm SANHA - Therm Industry - Press Systems in Carbon SteelaalbertshuNo ratings yet

- Hysol EA 9396Document4 pagesHysol EA 9396Nasos MasourasNo ratings yet