Professional Documents

Culture Documents

Process Audit VDA-6 3-2010 - en

Uploaded by

Rohini GadhaweOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Audit VDA-6 3-2010 - en

Uploaded by

Rohini GadhaweCopyright:

Available Formats

477471139.

xlsx

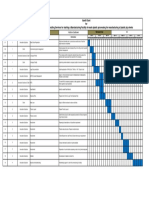

Audit Contract VDA 6.3-2010

Client: (z.B. management,person responsible for the product, person responsible for the auditprogramme)

Audited Party: (z.B. internal department, supplier)

Reason for Audit:

Audit Objective:

Audit Variant:

Internal Audit Potential Analysis

External Audit Special Audit

Audit Location:

Internal Audit external

Audit Team:

Lead Auditor: Process Specialist(s):

Auditors:

Audit Extent:

Prosesses: Products:

Manufacturing

Locations: Interfaces:

Outside Processes:

Audit Date

Desired Date: Shifts:

Auditperiod:

Date of Contract

Essential Documents (test/inspections regulations, contracts, important agreements, cost stipulations, etc.)

History (complaints, rejects, delivery performance, project status)

Remarks (background information)

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 1 von 40

477471139.xlsx

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 2 von 40

477471139.xlsx

VDA 6.3-2010 Audit Report: Assessment of Quality Cabability

Supplier: Client: Date:

Supplier No.: Reason for contract: Contract No.:

Location:

Assess-ment

Process/Product index Achieved Classified Findings / requirements

Overall Process P2 bis P7 EG 60% Highlights

befor SOP ED 60%

after SOP EP nb

Product Group*

Product group 1 EPN nb

Product group 2 EPN nb

Product group 3 EPN nb

Product group 4 EPN nb

Product group 5 EPN nb Areas of improvement

* Values automaticly taken from Assessment Matrix

Classification scale: A: 90-100% (Q-cabable); B: >= 80-90% (conditionally Q-cabable); C: <80% (not Q-capable)

Audit history / Certificates

Audit Basis Date Carried out Result

Participants: Distribution to:

Timing for improvement plan:

For actions see 'Improvement program' and/or 'Immediate actions'

Lead Auditor Co-Auditor signed for Organisation

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 3 von 40

477471139.xlsx

Explanations

Supplier: Client: Date:

The improvement program was discussed in the final meeting on site and handed over as a draft.. The audited Organisaion is asked to define sustainable corrective actions for the identified weak points and to

implement them rapidly.

We point out that within the audit the processes only can be checked randomly. Other weak points and / or potentials for imprevement may be possible.

It is the responsibility of the audited parties to expand the investigation and necessary measures to similar areas / issues.

Participants: Auditor:

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 4 von 40

477471139.xlsx

VDA 6.3-2010 Audit Report: Assessment of Quality Cabability

Supplier: Client: Date:

Assessment Elements / Process Stages Assessment after Process Analysis (mean value, process stage E 1 - n) and

generic baseline

Target Target

Minimum requirement 80 90 Minimum requirement 80 90

per assessment element per assessment element

60 70 80 90 100 60 70 80 90 100

Erfüllungsgrad Erfüllungsgrad

Assignment to

Assessment elements / pre-

Assessment elements / pre

Product group Process stages audit actual Process stages audit actual

Process input

Project Management

P2 60.0% EU 1 nb

Planning Product/Process Process sequence

P3 nb EU 2 nb

Carrying out Personnel support

Product/Process

P4 nb EU 3 nb

Supplier Management Material resources

Produktgruppe 1

Produktgruppe 2

Produktgruppe 3

Produktgruppe 4

Produktgruppe 5

P5 nb EU 4 nb

Prozess Analysis Proces effectiveness level

P6 nb EU 5 nb

Customer Satisfaction Process result

P7 nb EU 6 nb

Transport / parts handling

Process Name 1 E1 nb / storage EU 7 nb

Process Name 2 E2 nb Generic Baseline

Process Name 3 E3 nb Process responsiblity PR nb

Process Name 4 E4 nb Target orientation TO nb

Process Name 5 E5 nb Communication CO 60.0%

Process Name 6 E6 nb Risk orientation RI 60.0%

Process Name 7 E7 nb

Process Name 8 E8 nb Overall Compliance EG 60.0%

Process Name 9 E9 nb Befor SOP ED 60.0%

Process Name 10 E 10 nb After SOP EP nb

Comment: Please input values Pre-Audit yourself

Values of actual audit will be automaticly entered

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 5 von 40

477471139.xlsx

VDA 6.3-2010 Assessment Matrix including Product Groups Notes:

Supplier: Client: Date: Generic Baseline

A Development

P 2 Project Management Entry: only following values are allowed Achivement level % G1 G2 G3 G4

nb not assessed

2.1 2.2* 2.3 2.4 2.5* 2.6 2.7* 10 Requirements fully satisfied PR TO CO RI

8 Requirements mainly satisfied

nb 6 nb nb nb nb nb

6 Requirements partly satisfied

4 Requirements inadequately satisfied EPM 60% nb nb 6 6 Note: Entry "n.b." = Question not answered

0 Requirements not satisfied

P 3 Planning Product/Process Development Note: Entry "n.a." = Question not applicable

Product Process

3.1 3.2* 3.3 3.4 3.5 3.1 3.2* 3.3 3.4 3.5

nb nb nb nb nb EPdP nb nb nb nb nb nb EPzP nb E PP nb nb nb nb nb 3.1.

nb Green fields for entering

P 4 Carrying out Product/Process Development Blue writing -> example entry

Product Process

4.1 4.2 4.3 4.4 4.5* 4.6 4.7 4.8 4.9 4.1 4.2 4.3 4.4 4.5* 4.6 4.7 4.8 4.9

nb nb nb nb nb nb nb nb nb EPdR nb nb nb nb nb nb nb nb nb nb EPzR nb EPR nb nb nb nb nb nb nb nb nb

Automatic Calculation of the

B Full Production grey, blue, yellow and red fields

5.1* 5.2 5.3 5.4* 5.5* 5.6 5.7

P 5 Supplier Management nb nb nb nb nb nb nb ELM nb nb nb nb nb

P 6 Process Analysis Serial Production

1 Process Input 2 Work Content / Process Sequences 3 Personnel Support 4 Material Ressources 5 Process Effectiveness Level 6 Process Result / Output

7 Transport and Part Handling Generic Baseline

6.1.1* 6.1.2 6.1.3 6.1.4 6.1.5 6.2.1* 6.2.2 6.2.3* 6.2.4* 6.2.5 6.2.6 6.3.1 6.3.2* 6.3.3 6.4.1 6.4.2* 6.4.3 6.4.4 6.5.1 6.5.2 6.5.3* 6.5.4* 6.6.1* 6.6.2 6.6.3 6.6.4 6.1.2 6.1.3 6.1.4 6.2.5 6.2.6 6.4.4 6.6.2 6.6.3 G1 G2 G3 G4

Process step 1: Process Name 1 PR TO CO RI

nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb E1 nb nb nb nb nb nb nb nb nb nb nb nb nb

Process step 2: Process Name 2

nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb E2 nb nb nb nb nb nb nb nb nb nb nb nb nb

Process step 3: Process Name 3

nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb E3 nb nb nb nb nb nb nb nb nb nb nb nb nb

Process step 4: Process Name 4

nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb E4 nb nb nb nb nb nb nb nb nb nb nb nb nb Reasons for downgrading

Process step 5: Process Name 5

nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb E5 nb nb nb nb nb nb nb nb nb nb nb nb nb Down-grading from A to B despite an

Process step 6: Process Name 6 achievement level of EG>= 90%

nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb E6 nb nb nb nb nb nb nb nb nb nb nb nb nb > At least one process elements P2-P7 or

process stage E1-En assessed <80 %.

Process step 7: Process Name 7

nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb E7 nb nb nb nb nb nb nb nb nb nb nb nb nb

> Level of achievement of the sub-elements of

Process step 8: Process Name 8 P6 (EU1-EU7) assessed <80 %.

nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb E8 nb nb nb nb nb nb nb nb nb nb nb nb nb

Farbcode

Process step 9: Process Name 9 > At least one *-question awarded with 4

E9 points.

nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb

Process step 10: Process Name 10 > At least one question from process audit

E10 awarded with 0 points.

nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb

> Assessments from generic baseline assessed

Assessment of Subelements of the Process analysis (mean value step 1 - n)

<70 %.

1.1 1.2 1.3 1.4 1.5 2.1 2.2 2.3 2.4 2.5 2.6 3.1 3.2 3.3 4.1 4.2 4.3 4.4 5.1 5.2 5.3 5.4 6.1 6.2 6.3 6.4 6.1.2 6.1.3 6.1.4 6.2.5 6.2.6 6.4.4 6.6.2 6.6.3

nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb nb EPG nb nb nb nb nb nb nb nb nb

EU1 nb EU2 nb EU3 nb EU4 nb EU5 nb EU6 nb Transport, Part Handling EU7 nb for down-grading to C despite an achievement

G1 G2 G3 G4 level of ≥ 80 %

7.1* 7.2 7.3* 7.4 7.5 7.6 PR TO CO RI > At least one process elements P2-P7 or

P 7 Customer Support / Customer Satisfaction / Services nb nb nb nb nb nb EK nb nb nb nb nb

process stage E1-En assessed <70 %.

Farbcode

Achivement level [%] for PR TO Co RI > Level of achievement of the sub-elements of

P6 (EU1-EU7) assessed <70 %.

Achivement level EPG by Product Groups Element P6[%] (mean value Ex-En)

Overall Achivement Level EPN [%] by Generic Baseline nb nb 60% 60%

Product group 1 Product group 2 Product group 3 Product group 4 Product group 5 Product Groups > At least one *-question awarded with 0

Product Group points.

Process Steps Product EPN [%] Classification

Group

EPGN [%] Overall Achivement Level EG [%]:

nb

Classi- Achivement Description of

Classified fication Level EG[%] Classification

nb

Achivement Level Classification A EG > 90 Quality cabable

ED [%] 60% nb

60%

before SOP (Part A) 80 ≥ EG ≥ 90 Conditionally quality-

B

capable

nb

EG < 80 Not

C

quality-capable

after SOP (Part B) EP [%] nb nb Classification results (A, B, C) must be entered manually, by taking into

account the downgrading rule!

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 6 von 40

477471139.xlsx

Questionaire VDA 6.3-2010 Date:

Supplier:

Client:

Question

Pos.

Quest

Nr. Points Comments / Assesment Remarks

A Development

P 2 Project Management

2.1 Is the project organisation (project management)

established and are tasks & authorities specified for the nb

team leader and team members?

###

2.2* Are the resources required for the project

development planned and available and are all changes 6

displayed?

2.3 Is there a project plan and has this been agreed with

the customer? nb

2.4 Is change management in the project ensured by the

project organisation? nb

2.5* Are the responsible personnel within the organisation

and in the customer's company involved in the change nb

control system?

2.6 Is there a QM plan for the project? Is this implemented

and monitored regularly for compliance? nb

2.7* Is there an established escalation process and is this

implemented effectively? nb

P 3 Planning Product/Process Development

Product

3.1 Are the product-specific requirements laid down?

nb

3.2* Has manufacturing feasibility been assessed in a cross-

functional manner, based on the requirements which

have been determined for product & process? nb

3.3 Are there plans for the product and process

development? nb

3.4 Have the necessary resources been taken into account

for the product and process development? nb

3.5 Is QM planning arranged for sourcing bought-in

products and services? nb

Process

3.1 Are the process-specific requirements laid down?

nb

3.2* Has manufacturing feasibility been assessed in a cross-

functional manner, based on the requirements which

have been determined for product & process? nb

3.3 Are there plans for the product and process

development? nb

3.4 Have the necessary resources been taken into account

for the product and process development? nb

3.5 Is QM planning arranged for sourcing bought-in

products and services? nb

P 4 Carrying out Product/Process Development

Product

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 7 von 40

477471139.xlsx

Questionaire VDA 6.3-2010 Date:

Supplier:

Client:

Question

Pos.

Quest

Nr. Points Comments / Assesment Remarks

4.1 Have the Product FMEA / Process FMEA been drawn

up? Are they up-dated as the project progresses and

are corrective actions laid down? nb

4.2 Are the stipulations arising from the plans for product

and process development put into effect? nb

4.3 Are the personnel resources in place and qualified?

nb

4.4 Is the infrastructure in place and appropriate? nb

4.5* Based on the requirements, are the necessary evidence

and releases available for the various phases? nb

4.8 Are the planning activities associated with sourcing

outside products and services implemented effectively? nb

4.9 Is the transfer of the project to production controlled in

order to secure the product launch? nb

Process

4.1 Have the Product FMEA / Process FMEA been drawn

up? Are they up-dated as the project progresses and

are corrective actions laid down? nb

4.2 Are the stipulations arising from the plans for product

and process development put into effect?

nb

4.3 Are the personnel resources in place and qualified?

nb

4.4 Is the infrastructure in place and appropriate? nb

4.5* Based on the requirements, are the necessary evidence

and releases available for the various phases? nb

4.6 Are the productions control plans used for the various

phases and are production, test and inspection nb

documents derived from them?

4.7 Has a pre-production run been carried out under serial

production conditions to obtain production approval / nb

release?

4.8 Are the planning activities associated with sourcing

outside products and services implemented effectively? nb

4.9 Is the transfer of the project to production controlled in

order to secure the product launch? nb

B Full Production

P 5 Supplier Management

5.1* Are only approved/released and quality-capable

suppliers selected? nb

5.2 Are the customer's requirements taken into account in

the supply chain? nb

5.3 Have target agreements for delivery performance been

agreed with suppliers and put into operation? nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 8 von 40

477471139.xlsx

Questionaire VDA 6.3-2010 Date:

Supplier:

Client:

Question

Pos.

Quest

Nr. Points Comments / Assesment Remarks

5.4* Are the necessary approvals/releases available for the

out-sourced products and services? nb

5.5* Is the quality of the out-sourced products and services

ensured? nb

5.6 Are incoming goods stored appropriately? nb

5.7 Are personnel qualified for the various tasks and are

responsibilities defined? nb

P 6 Process Analysis Serial Production

Process step 1: Process Name 1

1 Process Input

6.1.1* Has the project been transferred from development to

serial production? nb

6.1.2 Are the necessary quantities / production batch sizes of

incoming materials available at the right time and at

the right place (stores; work-station)? nb

6.1.3 Are incoming materials stored appropriately and are

transport facilities / packing arrangements suitable for

the special characteristics of the incoming materials? nb

6.1.4 Are the necessary identifications / records / approvals

available and allocated appropriately to the incoming nb

materials?

6.1.5 Are changes to the product or process in the course of

serial production tracked and documented? nb

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and

test/inspection documents, based on the production nb

control plan?

6.2.2 Are production operations checked / approved and are

setting data logged? nb

6.2.3* Can the customer's specific product requirements be

satisfied with the production facilities used? nb

6.2.4* Are significant characteristics controlled in production?

nb

6.2.5 Are scrap, rework and setting parts kept separate and

identified? nb

6.2.6 Is the flow of materials and parts secured against

mixing / wrong items? nb

3 Personnel Support

6.3.1 Are operators given responsibility and authority to

monitor the quality of product and process? nb

6.3.2* Are the operators able to carry out their allotted tasks

and are their qualifications kept up-to-date? nb

6.3.3 Is there a personnel employment plan? nb

4 Material Ressources

6.4.1 How are the maintenance and overhaul of production

facilities / tools controlled? nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 9 von 40

477471139.xlsx

Questionaire VDA 6.3-2010 Date:

Supplier:

Client:

Question

Pos.

Quest

Nr. Points Comments / Assesment Remarks

6.4.2* Can the quality requirements be monitored effectively

with the test, inspection and measurement facilities nb

employed?

6.4.3 Are the work-stations and test/inspection areas

suitable for requirements? nb

6.4.4 Are tools, equipment and test/inspection facilities

stored correctly? nb

5 Process Effectiveness Level

6.5.1 Are target requirements set for product and process?

nb

6.5.2 Are quality and process data logged in such a way that

they can be assessed? nb

6.5.3* In the case of deviations from product and process

requirements, are the causes analysed and the

corrective actions checked for effectiveness? nb

6.5.4* Are processes and products audited regularly? nb

6 Process Result / Output

6.6.1* Are the customer's requirements met in terms of

product and process? nb

6.6.2 Are quantities / production batch sizes aligned with

requirements and are they forwarded to the next nb

process stage in a targeted manner?

6.6.3 Are products / components stored in an appropriate

manner and are transport facilities / packing

arrangements suitable for the special characteristics of

the products / components? nb

6.6.4 Are the necessary records / releases carried out and

stored appropriately? nb

Process step 2:

Process Name 2

1 Process Input

6.1.1* Has the project been transferred from development to

serial production? nb

6.1.2 Are the necessary quantities / production batch sizes of

incoming materials available at the right time and at nb

the right place (stores; work-station)?

6.1.3 Are incoming materials stored appropriately and are

transport facilities / packing arrangements suitable for

the special characteristics of the incoming materials? nb

6.1.4 Are the necessary identifications / records / approvals

available and allocated appropriately to the incoming nb

materials?

6.1.5 Are changes to the product or process in the course of

serial production tracked and documented? nb

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and

test/inspection documents, based on the production nb

control plan?

6.2.2 Are production operations checked / approved and are

setting data logged? nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 10 von 40

477471139.xlsx

Questionaire VDA 6.3-2010 Date:

Supplier:

Client:

Question

Pos.

Quest

Nr. Points Comments / Assesment Remarks

6.2.3* Can the customer's specific product requirements be

satisfied with the production facilities used? nb

6.2.4* Are significant characteristics controlled in production?

nb

6.2.5 Are scrap, rework and setting parts kept separate and

identified? nb

6.2.6 Is the flow of materials and parts secured against

mixing / wrong items? nb

3 Personnel Support

6.3.1 Are operators given responsibility and authority to

monitor the quality of product and process? nb

6.3.2* Are the operators able to carry out their allotted tasks

and are their qualifications kept up-to-date? nb

6.3.3 Is there a personnel employment plan? nb

4 Material Ressources

6.4.1 How are the maintenance and overhaul of production

facilities / tools controlled? nb

6.4.2* Can the quality requirements be monitored effectively

with the test, inspection and measurement facilities nb

employed?

6.4.3 Are the work-stations and test/inspection areas

suitable for requirements? nb

6.4.4 Are tools, equipment and test/inspection facilities

stored correctly? nb

5 Process Effectiveness Level

6.5.1 Are target requirements set for product and process?

nb

6.5.2 Are quality and process data logged in such a way that

they can be assessed? nb

6.5.3* In the case of deviations from product and process

requirements, are the causes analysed and the

corrective actions checked for effectiveness? nb

6.5.4* Are processes and products audited regularly? nb

6 Process Result / Output

6.6.1* Are the customer's requirements met in terms of

product and process? nb

6.6.2 Are quantities / production batch sizes aligned with

requirements and are they forwarded to the next nb

process stage in a targeted manner?

6.6.3 Are products / components stored in an appropriate

manner and are transport facilities / packing

arrangements suitable for the special characteristics of nb

the products / components?

6.6.4 Are the necessary records / releases carried out and

stored appropriately? nb

Process step 3:

Process Name 3

1 Process Input

6.1.1* Has the project been transferred from development to

serial production? nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 11 von 40

477471139.xlsx

Questionaire VDA 6.3-2010 Date:

Supplier:

Client:

Question

Pos.

Quest

Nr. Points Comments / Assesment Remarks

6.1.2 Are the necessary quantities / production batch sizes of

incoming materials available at the right time and at nb

the right place (stores; work-station)?

6.1.3 Are incoming materials stored appropriately and are

transport facilities / packing arrangements suitable for

the special characteristics of the incoming materials? nb

6.1.4 Are the necessary identifications / records / approvals

available and allocated appropriately to the incoming nb

materials?

6.1.5 Are changes to the product or process in the course of

serial production tracked and documented? nb

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and

test/inspection documents, based on the production nb

control plan?

6.2.2 Are production operations checked / approved and are

setting data logged? nb

6.2.3* Can the customer's specific product requirements be

satisfied with the production facilities used? nb

6.2.4* Are significant characteristics controlled in production?

nb

6.2.5 Are scrap, rework and setting parts kept separate and

identified? nb

6.2.6 Is the flow of materials and parts secured against

mixing / wrong items? nb

3 Personnel Support

6.3.1 Are operators given responsibility and authority to

monitor the quality of product and process? nb

6.3.2* Are the operators able to carry out their allotted tasks

and are their qualifications kept up-to-date? nb

6.3.3 Is there a personnel employment plan? nb

4 Material Ressources

6.4.1 How are the maintenance and overhaul of production

facilities / tools controlled? nb

6.4.2* Can the quality requirements be monitored effectively

with the test, inspection and measurement facilities nb

employed?

6.4.3 Are the work-stations and test/inspection areas

suitable for requirements? nb

6.4.4 Are tools, equipment and test/inspection facilities

stored correctly? nb

5 Process Effectiveness Level

6.5.1 Are target requirements set for product and process?

nb

6.5.2 Are quality and process data logged in such a way that

they can be assessed? nb

6.5.3* In the case of deviations from product and process

requirements, are the causes analysed and the

corrective actions checked for effectiveness? nb

6.5.4* Are processes and products audited regularly? nb

6 Process Result / Output

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 12 von 40

477471139.xlsx

Questionaire VDA 6.3-2010 Date:

Supplier:

Client:

Question

Pos.

Quest

Nr. Points Comments / Assesment Remarks

6.6.1* Are the customer's requirements met in terms of

product and process? nb

6.6.2 Are quantities / production batch sizes aligned with

requirements and are they forwarded to the next nb

process stage in a targeted manner?

6.6.3 Are products / components stored in an appropriate

manner and are transport facilities / packing

arrangements suitable for the special characteristics of nb

the products / components?

6.6.4 Are the necessary records / releases carried out and

stored appropriately? nb

Process step 4:

Process Name 4

1 Process Input

6.1.1* Has the project been transferred from development to

serial production? nb

6.1.2 Are the necessary quantities / production batch sizes of

incoming materials available at the right time and at nb

the right place (stores; work-station)?

6.1.3 Are incoming materials stored appropriately and are

transport facilities / packing arrangements suitable for

the special characteristics of the incoming materials? nb

6.1.4 Are the necessary identifications / records / approvals

available and allocated appropriately to the incoming nb

materials?

6.1.5 Are changes to the product or process in the course of

serial production tracked and documented? nb

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and

test/inspection documents, based on the production nb

control plan?

6.2.2 Are production operations checked / approved and are

setting data logged? nb

6.2.3* Can the customer's specific product requirements be

satisfied with the production facilities used? nb

6.2.4* Are significant characteristics controlled in production?

nb

6.2.5 Are scrap, rework and setting parts kept separate and

identified? nb

6.2.6 Is the flow of materials and parts secured against

mixing / wrong items? nb

3 Personnel Support

6.3.1 Are operators given responsibility and authority to

monitor the quality of product and process? nb

6.3.2* Are the operators able to carry out their allotted tasks

and are their qualifications kept up-to-date? nb

6.3.3 Is there a personnel employment plan? nb

4 Material Ressources

6.4.1 How are the maintenance and overhaul of production

facilities / tools controlled? nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 13 von 40

477471139.xlsx

Questionaire VDA 6.3-2010 Date:

Supplier:

Client:

Question

Pos.

Quest

Nr. Points Comments / Assesment Remarks

6.4.2* Can the quality requirements be monitored effectively

with the test, inspection and measurement facilities nb

employed?

6.4.3 Are the work-stations and test/inspection areas

suitable for requirements? nb

6.4.4 Are tools, equipment and test/inspection facilities

stored correctly? nb

5 Process Effectiveness Level

6.5.1 Are target requirements set for product and process?

nb

6.5.2 Are quality and process data logged in such a way that

they can be assessed? nb

6.5.3* In the case of deviations from product and process

requirements, are the causes analysed and the

corrective actions checked for effectiveness? nb

6.5.4* Are processes and products audited regularly? nb

6 Process Result / Output

6.6.1* Are the customer's requirements met in terms of

product and process? nb

6.6.2 Are quantities / production batch sizes aligned with

requirements and are they forwarded to the next nb

process stage in a targeted manner?

6.6.3 Are products / components stored in an appropriate

manner and are transport facilities / packing

arrangements suitable for the special characteristics of nb

the products / components?

6.6.4 Are the necessary records / releases carried out and

stored appropriately? nb

Process step 5:

Process Name 5

1 Process Input

6.1.1* Has the project been transferred from development to

serial production? nb

6.1.2 Are the necessary quantities / production batch sizes of

incoming materials available at the right time and at nb

the right place (stores; work-station)?

6.1.3 Are incoming materials stored appropriately and are

transport facilities / packing arrangements suitable for

the special characteristics of the incoming materials? nb

6.1.4 Are the necessary identifications / records / approvals

available and allocated appropriately to the incoming nb

materials?

6.1.5 Are changes to the product or process in the course of

serial production tracked and documented? nb

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and

test/inspection documents, based on the production nb

control plan?

6.2.2 Are production operations checked / approved and are

setting data logged? nb

6.2.3* Can the customer's specific product requirements be

satisfied with the production facilities used? nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 14 von 40

477471139.xlsx

Questionaire VDA 6.3-2010 Date:

Supplier:

Client:

Question

Pos.

Quest

Nr. Points Comments / Assesment Remarks

6.2.4* Are significant characteristics controlled in production?

nb

6.2.5 Are scrap, rework and setting parts kept separate and

identified? nb

6.2.6 Is the flow of materials and parts secured against

mixing / wrong items? nb

3 Personnel Support

6.3.1 Are operators given responsibility and authority to

monitor the quality of product and process? nb

6.3.2* Are the operators able to carry out their allotted tasks

and are their qualifications kept up-to-date? nb

6.3.3 Is there a personnel employment plan? nb

4 Material Ressources

6.4.1 How are the maintenance and overhaul of production

facilities / tools controlled? nb

6.4.2* Can the quality requirements be monitored effectively

with the test, inspection and measurement facilities nb

employed?

6.4.3 Are the work-stations and test/inspection areas

suitable for requirements? nb

6.4.4 Are tools, equipment and test/inspection facilities

stored correctly? nb

5 Process Effectiveness Level

6.5.1 Are target requirements set for product and process?

nb

6.5.2 Are quality and process data logged in such a way that

they can be assessed? nb

6.5.3* In the case of deviations from product and process

requirements, are the causes analysed and the

corrective actions checked for effectiveness? nb

6.5.4* Are processes and products audited regularly? nb

6 Process Result / Output

6.6.1* Are the customer's requirements met in terms of

product and process? nb

6.6.2 Are quantities / production batch sizes aligned with

requirements and are they forwarded to the next nb

process stage in a targeted manner?

6.6.3 Are products / components stored in an appropriate

manner and are transport facilities / packing

arrangements suitable for the special characteristics of nb

the products / components?

6.6.4 Are the necessary records / releases carried out and

stored appropriately? nb

Process step 6:

Process Name 6

1 Process Input

6.1.1* Has the project been transferred from development to

serial production? nb

6.1.2 Are the necessary quantities / production batch sizes of

incoming materials available at the right time and at nb

the right place (stores; work-station)?

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 15 von 40

477471139.xlsx

Questionaire VDA 6.3-2010 Date:

Supplier:

Client:

Question

Pos.

Quest

Nr. Points Comments / Assesment Remarks

6.1.3 Are incoming materials stored appropriately and are

transport facilities / packing arrangements suitable for

the special characteristics of the incoming materials? nb

6.1.4 Are the necessary identifications / records / approvals

available and allocated appropriately to the incoming nb

materials?

6.1.5 Are changes to the product or process in the course of

serial production tracked and documented? nb

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and

test/inspection documents, based on the production nb

control plan?

6.2.2 Are production operations checked / approved and are

setting data logged? nb

6.2.3* Can the customer's specific product requirements be

satisfied with the production facilities used? nb

6.2.4* Are significant characteristics controlled in production?

nb

6.2.5 Are scrap, rework and setting parts kept separate and

identified? nb

6.2.6 Is the flow of materials and parts secured against

mixing / wrong items? nb

3 Personnel Support

6.3.1 Are operators given responsibility and authority to

monitor the quality of product and process? nb

6.3.2* Are the operators able to carry out their allotted tasks

and are their qualifications kept up-to-date? nb

6.3.3 Is there a personnel employment plan? nb

4 Material Ressources

6.4.1 How are the maintenance and overhaul of production

facilities / tools controlled? nb

6.4.2* Can the quality requirements be monitored effectively

with the test, inspection and measurement facilities nb

employed?

6.4.3 Are the work-stations and test/inspection areas

suitable for requirements? nb

6.4.4 Are tools, equipment and test/inspection facilities

stored correctly? nb

5 Process Effectiveness Level

6.5.1 Are target requirements set for product and process?

nb

6.5.2 Are quality and process data logged in such a way that

they can be assessed? nb

6.5.3* In the case of deviations from product and process

requirements, are the causes analysed and the

corrective actions checked for effectiveness? nb

6.5.4* Are processes and products audited regularly? nb

6 Process Result / Output

6.6.1* Are the customer's requirements met in terms of

product and process? nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 16 von 40

477471139.xlsx

Questionaire VDA 6.3-2010 Date:

Supplier:

Client:

Question

Pos.

Quest

Nr. Points Comments / Assesment Remarks

6.6.2 Are quantities / production batch sizes aligned with

requirements and are they forwarded to the next nb

process stage in a targeted manner?

6.6.3 Are products / components stored in an appropriate

manner and are transport facilities / packing

arrangements suitable for the special characteristics of nb

the products / components?

6.6.4 Are the necessary records / releases carried out and

stored appropriately? nb

Process step 7:

Process Name 7

1 Process Input

6.1.1* Has the project been transferred from development to

serial production? nb

6.1.2 Are the necessary quantities / production batch sizes of

incoming materials available at the right time and at nb

the right place (stores; work-station)?

6.1.3 Are incoming materials stored appropriately and are

transport facilities / packing arrangements suitable for

the special characteristics of the incoming materials? nb

6.1.4 Are the necessary identifications / records / approvals

available and allocated appropriately to the incoming nb

materials?

6.1.5 Are changes to the product or process in the course of

serial production tracked and documented? nb

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and

test/inspection documents, based on the production nb

control plan?

6.2.2 Are production operations checked / approved and are

setting data logged? nb

6.2.3* Can the customer's specific product requirements be

satisfied with the production facilities used? nb

6.2.4* Are significant characteristics controlled in production?

nb

6.2.5 Are scrap, rework and setting parts kept separate and

identified? nb

6.2.6 Is the flow of materials and parts secured against

mixing / wrong items? nb

3 Personnel Support

6.3.1 Are operators given responsibility and authority to

monitor the quality of product and process? nb

6.3.2* Are the operators able to carry out their allotted tasks

and are their qualifications kept up-to-date? nb

6.3.3 Is there a personnel employment plan? nb

4 Material Ressources

6.4.1 How are the maintenance and overhaul of production

facilities / tools controlled? nb

6.4.2* Can the quality requirements be monitored effectively

with the test, inspection and measurement facilities nb

employed?

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 17 von 40

477471139.xlsx

Questionaire VDA 6.3-2010 Date:

Supplier:

Client:

Question

Pos.

Quest

Nr. Points Comments / Assesment Remarks

6.4.3 Are the work-stations and test/inspection areas

suitable for requirements? nb

6.4.4 Are tools, equipment and test/inspection facilities

stored correctly? nb

5 Process Effectiveness Level

6.5.1 Are target requirements set for product and process?

nb

6.5.2 Are quality and process data logged in such a way that

they can be assessed? nb

6.5.3* In the case of deviations from product and process

requirements, are the causes analysed and the

corrective actions checked for effectiveness? nb

6.5.4* Are processes and products audited regularly? nb

6 Process Result / Output

6.6.1* Are the customer's requirements met in terms of

product and process? nb

6.6.2 Are quantities / production batch sizes aligned with

requirements and are they forwarded to the next nb

process stage in a targeted manner?

6.6.3 Are products / components stored in an appropriate

manner and are transport facilities / packing

arrangements suitable for the special characteristics of nb

the products / components?

6.6.4 Are the necessary records / releases carried out and

stored appropriately? nb

Process step 8:

Process Name 8

1 Process Input

6.1.1* Has the project been transferred from development to

serial production? nb

6.1.2 Are the necessary quantities / production batch sizes of

incoming materials available at the right time and at nb

the right place (stores; work-station)?

6.1.3 Are incoming materials stored appropriately and are

transport facilities / packing arrangements suitable for

the special characteristics of the incoming materials? nb

6.1.4 Are the necessary identifications / records / approvals

available and allocated appropriately to the incoming nb

materials?

6.1.5 Are changes to the product or process in the course of

serial production tracked and documented? nb

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and

test/inspection documents, based on the production nb

control plan?

6.2.2 Are production operations checked / approved and are

setting data logged? nb

6.2.3* Can the customer's specific product requirements be

satisfied with the production facilities used? nb

6.2.4* Are significant characteristics controlled in production?

nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 18 von 40

477471139.xlsx

Questionaire VDA 6.3-2010 Date:

Supplier:

Client:

Question

Pos.

Quest

Nr. Points Comments / Assesment Remarks

6.2.5 Are scrap, rework and setting parts kept separate and

identified? nb

6.2.6 Is the flow of materials and parts secured against

mixing / wrong items? nb

3 Personnel Support

6.3.1 Are operators given responsibility and authority to

monitor the quality of product and process? nb

6.3.2* Are the operators able to carry out their allotted tasks

and are their qualifications kept up-to-date? nb

6.3.3 Is there a personnel employment plan? nb

4 Material Ressources

6.4.1 How are the maintenance and overhaul of production

facilities / tools controlled? nb

6.4.2* Can the quality requirements be monitored effectively

with the test, inspection and measurement facilities nb

employed?

6.4.3 Are the work-stations and test/inspection areas

suitable for requirements? nb

6.4.4 Are tools, equipment and test/inspection facilities

stored correctly? nb

5 Process Effectiveness Level

6.5.1 Are target requirements set for product and process?

nb

6.5.2 Are quality and process data logged in such a way that

they can be assessed? nb

6.5.3* In the case of deviations from product and process

requirements, are the causes analysed and the

corrective actions checked for effectiveness? nb

6.5.4* Are processes and products audited regularly? nb

6 Process Result / Output

6.6.1* Are the customer's requirements met in terms of

product and process? nb

6.6.2 Are quantities / production batch sizes aligned with

requirements and are they forwarded to the next nb

process stage in a targeted manner?

6.6.3 Are products / components stored in an appropriate

manner and are transport facilities / packing

arrangements suitable for the special characteristics of nb

the products / components?

6.6.4 Are the necessary records / releases carried out and

stored appropriately? nb

Process step 9:

Process Name 9

1 Process Input

6.1.1* Has the project been transferred from development to

serial production? nb

6.1.2 Are the necessary quantities / production batch sizes of

incoming materials available at the right time and at nb

the right place (stores; work-station)?

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 19 von 40

477471139.xlsx

Questionaire VDA 6.3-2010 Date:

Supplier:

Client:

Question

Pos.

Quest

Nr. Points Comments / Assesment Remarks

6.1.3 Are incoming materials stored appropriately and are

transport facilities / packing arrangements suitable for

the special characteristics of the incoming materials? nb

6.1.4 Are the necessary identifications / records / approvals

available and allocated appropriately to the incoming nb

materials?

6.1.5 Are changes to the product or process in the course of

serial production tracked and documented? nb

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and

test/inspection documents, based on the production nb

control plan?

6.2.2 Are production operations checked / approved and are

setting data logged? nb

6.2.3* Can the customer's specific product requirements be

satisfied with the production facilities used? nb

6.2.4* Are significant characteristics controlled in production?

nb

6.2.5 Are scrap, rework and setting parts kept separate and

identified? nb

6.2.6 Is the flow of materials and parts secured against

mixing / wrong items? nb

3 Personnel Support

6.3.1 Are operators given responsibility and authority to

monitor the quality of product and process? nb

6.3.2* Are the operators able to carry out their allotted tasks

and are their qualifications kept up-to-date? nb

6.3.3 Is there a personnel employment plan? nb

4 Material Ressources

6.4.1 How are the maintenance and overhaul of production

facilities / tools controlled? nb

6.4.2* Can the quality requirements be monitored effectively

with the test, inspection and measurement facilities nb

employed?

6.4.3 Are the work-stations and test/inspection areas

suitable for requirements? nb

6.4.4 Are tools, equipment and test/inspection facilities

stored correctly? nb

5 Process Effectiveness Level

6.5.1 Are target requirements set for product and process?

nb

6.5.2 Are quality and process data logged in such a way that

they can be assessed? nb

6.5.3* In the case of deviations from product and process

requirements, are the causes analysed and the

corrective actions checked for effectiveness? nb

6.5.4* Are processes and products audited regularly? nb

6 Process Result / Output

6.6.1* Are the customer's requirements met in terms of

product and process? nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 20 von 40

477471139.xlsx

Questionaire VDA 6.3-2010 Date:

Supplier:

Client:

Question

Pos.

Quest

Nr. Points Comments / Assesment Remarks

6.6.2 Are quantities / production batch sizes aligned with

requirements and are they forwarded to the next nb

process stage in a targeted manner?

6.6.3 Are products / components stored in an appropriate

manner and are transport facilities / packing

arrangements suitable for the special characteristics of nb

the products / components?

6.6.4 Are the necessary records / releases carried out and

stored appropriately? nb

Process step 10:

Process Name 10

1 Process Input

6.1.1* Has the project been transferred from development to

serial production? nb

6.1.2 Are the necessary quantities / production batch sizes of

incoming materials available at the right time and at nb

the right place (stores; work-station)?

6.1.3 Are incoming materials stored appropriately and are

transport facilities / packing arrangements suitable for

the special characteristics of the incoming materials? nb

6.1.4 Are the necessary identifications / records / approvals

available and allocated appropriately to the incoming nb

materials?

6.1.5 Are changes to the product or process in the course of

serial production tracked and documented? nb

2 Work Content / Process Sequences

6.2.1* Are all the relevant details listed in the production and

test/inspection documents, based on the production nb

control plan?

6.2.2 Are production operations checked / approved and are

setting data logged? nb

6.2.3* Can the customer's specific product requirements be

satisfied with the production facilities used? nb

6.2.4* Are significant characteristics controlled in production?

nb

6.2.5 Are scrap, rework and setting parts kept separate and

identified? nb

6.2.6 Is the flow of materials and parts secured against

mixing / wrong items? nb

3 Personnel Support

6.3.1 Are operators given responsibility and authority to

monitor the quality of product and process? nb

6.3.2* Are the operators able to carry out their allotted tasks

and are their qualifications kept up-to-date? nb

6.3.3 Is there a personnel employment plan? nb

4 Material Ressources

6.4.1 How are the maintenance and overhaul of production

facilities / tools controlled? nb

6.4.2* Can the quality requirements be monitored effectively

with the test, inspection and measurement facilities nb

employed?

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 21 von 40

477471139.xlsx

Questionaire VDA 6.3-2010 Date:

Supplier:

Client:

Question

Pos.

Quest

Nr. Points Comments / Assesment Remarks

6.4.3 Are the work-stations and test/inspection areas

suitable for requirements? nb

6.4.4 Are tools, equipment and test/inspection facilities

stored correctly? nb

5 Process Effectiveness Level

6.5.1 Are target requirements set for product and process?

nb

6.5.2 Are quality and process data logged in such a way that

they can be assessed? nb

6.5.3* In the case of deviations from product and process

requirements, are the causes analysed and the

corrective actions checked for effectiveness? nb

6.5.4* Are processes and products audited regularly? nb

6 Process Result / Output

6.6.1* Are the customer's requirements met in terms of

product and process? nb

6.6.2 Are quantities / production batch sizes aligned with

requirements and are they forwarded to the next nb

process stage in a targeted manner?

6.6.3 Are products / components stored in an appropriate

manner and are transport facilities / packing

arrangements suitable for the special characteristics of nb

the products / components?

6.6.4 Are the necessary records / releases carried out and

stored appropriately? nb

P 7 Customer Support / Customer Satisfaction / Services

7.1* Are the customer's requirements satisfied regarding

QM system, product (on delivery) and process? nb

7.2 Is customer support ensured? nb

7.3* Is the supply of parts ensured? nb

7.4 If there are deviations from quality requirements, are

failure analyses carried out and corrective actions

implemented effectively? nb

7.5 Is there a process which ensures that analysis of

defective parts is carried out? nb

7.6 Are personnel qualified for the various tasks and are

responsibilities defined? nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 22 von 40

477471139.xlsx

Improvement Program VDA 6.3-2010 Date:

Supplier: Client:

To be filled by auditor to be filled by audited party

Quest Weaknesses, recommended actions, Actions and cause analysis by the Respon-

Pos.

Points Timing Effectiveness

No. findings organisation sibles

A Development

P 2 Project Management

6 nb

2.1

2.2* 6

2.3 nb

2.4 nb

2.5* nb

2.6 nb

2.7* nb

P 3 Planning Product/Process Development

Product

3.1 nb

3.2* nb

3.3 nb

3.4 nb

3.5 nb

Process

3.1 nb

3.2* nb

3.3 nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 23 von 40

477471139.xlsx

To be filled by auditor to be filled by audited party

Quest Weaknesses, recommended actions, Actions and cause analysis by the Respon-

Pos.

Points Timing Effectiveness

No. findings organisation sibles

3.4 nb

3.5 nb

P 4 Carrying out Product/Process Development

Product

4.1 nb

4.2 nb

4.3 nb

4.4 nb

4.5* nb

4.8 nb

4.9 nb

Process

4.1 nb

4.2 nb

4.3 nb

4.4 nb

4.5* nb

4.6 nb

4.7 nb

4.8 nb

4.9 nb

B Full Production

P 5 Supplier Management

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 24 von 40

477471139.xlsx

To be filled by auditor to be filled by audited party

Quest Weaknesses, recommended actions, Actions and cause analysis by the Respon-

Pos.

Points Timing Effectiveness

No. findings organisation sibles

5.1* nb

5.2 nb

5.3 nb

5.4* nb

5.5* nb

5.6 nb

5.7 nb

P 6 Process Analysis Serial Production

Process step 1: Process Name 1

1 Process Input

6.1.1* nb

6.1.2 nb

6.1.3 nb

6.1.4 nb

6.1.5 nb

2 Work Content / Process Sequences

6.2.1* nb

6.2.2 nb

6.2.3* nb

6.2.4* nb

6.2.5 nb

6.2.6 nb

3 Personnel Support

6.3.1 nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 25 von 40

477471139.xlsx

To be filled by auditor to be filled by audited party

Quest Weaknesses, recommended actions, Actions and cause analysis by the Respon-

Pos.

Points Timing Effectiveness

No. findings organisation sibles

6.3.2* nb

6.3.3 nb

4 Material Ressources

6.4.1 nb

6.4.2* nb

6.4.3 nb

6.4.4 nb

5 Process Effectiveness Level

6.5.1 nb

6.5.2 nb

6.5.3* nb

6.5.4* nb

6 Process Result / Output

6.6.1* nb

6.6.2 nb

6.6.3 nb

6.6.4 nb

Process step 2: Process Name 2

1 Process Input

6.1.1* nb

6.1.2 nb

6.1.3 nb

6.1.4 nb

6.1.5 nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 26 von 40

477471139.xlsx

To be filled by auditor to be filled by audited party

Quest Weaknesses, recommended actions, Actions and cause analysis by the Respon-

Pos.

Points Timing Effectiveness

No. findings organisation sibles

2 Work Content / Process Sequences

6.2.1* nb

6.2.2 nb

6.2.3* nb

6.2.4* nb

6.2.5 nb

6.2.6 nb

3 Personnel Support

6.3.1 nb

6.3.2* nb

6.3.3 nb

4 Material Ressources

6.4.1 nb

6.4.2* nb

6.4.3 nb

6.4.4 nb

5 Process Effectiveness Level

6.5.1 nb

6.5.2 nb

6.5.3* nb

6.5.4* nb

6 Process Result / Output

6.6.1* nb

6.6.2 nb

6.6.3 nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 27 von 40

477471139.xlsx

To be filled by auditor to be filled by audited party

Quest Weaknesses, recommended actions, Actions and cause analysis by the Respon-

Pos.

Points Timing Effectiveness

No. findings organisation sibles

6.6.4 nb

Process step 3: Process Name 3

1 Process Input

6.1.1* nb

6.1.2 nb

6.1.3 nb

6.1.4 nb

6.1.5 nb

2 Work Content / Process Sequences

6.2.1* nb

6.2.2 nb

6.2.3* nb

6.2.4* nb

6.2.5 nb

6.2.6 nb

3 Personnel Support

6.3.1 nb

6.3.2* nb

6.3.3 nb

4 Material Ressources

6.4.1 nb

6.4.2* nb

6.4.3 nb

6.4.4 nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 28 von 40

477471139.xlsx

To be filled by auditor to be filled by audited party

Quest Weaknesses, recommended actions, Actions and cause analysis by the Respon-

Pos.

Points Timing Effectiveness

No. findings organisation sibles

5 Process Effectiveness Level

6.5.1 nb

6.5.2 nb

6.5.3* nb

6.5.4* nb

6 Process Result / Output

6.6.1* nb

6.6.2 nb

6.6.3 nb

6.6.4 nb

Process step 4: Process Name 4

1 Process Input

6.1.1* nb

6.1.2 nb

6.1.3 nb

6.1.4 nb

6.1.5 nb

2 Work Content / Process Sequences

6.2.1* nb

6.2.2 nb

6.2.3* nb

6.2.4* nb

6.2.5 nb

6.2.6 nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 29 von 40

477471139.xlsx

To be filled by auditor to be filled by audited party

Quest Weaknesses, recommended actions, Actions and cause analysis by the Respon-

Pos.

Points Timing Effectiveness

No. findings organisation sibles

3 Personnel Support

6.3.1 nb

6.3.2* nb

6.3.3 nb

4 Material Ressources

6.4.1 nb

6.4.2* nb

6.4.3 nb

6.4.4 nb

5 Process Effectiveness Level

6.5.1 nb

6.5.2 nb

6.5.3* nb

6.5.4* nb

6 Process Result / Output

6.6.1* nb

6.6.2 nb

6.6.3 nb

6.6.4 nb

Process step 5: Process Name 5

1 Process Input

6.1.1* nb

6.1.2 nb

6.1.3 nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 30 von 40

477471139.xlsx

To be filled by auditor to be filled by audited party

Quest Weaknesses, recommended actions, Actions and cause analysis by the Respon-

Pos.

Points Timing Effectiveness

No. findings organisation sibles

6.1.4 nb

6.1.5 nb

2 Work Content / Process Sequences

6.2.1* nb

6.2.2 nb

6.2.3* nb

6.2.4* nb

6.2.5 nb

6.2.6 nb

3 Personnel Support

6.3.1 nb

6.3.2* nb

6.3.3 nb

4 Material Ressources

6.4.1 nb

6.4.2* nb

6.4.3 nb

6.4.4 nb

5 Process Effectiveness Level

6.5.1 nb

6.5.2 nb

6.5.3* nb

y 6.5.4* nb

6 Process Result / Output

6.6.1* nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 31 von 40

477471139.xlsx

To be filled by auditor to be filled by audited party

Quest Weaknesses, recommended actions, Actions and cause analysis by the Respon-

Pos.

Points Timing Effectiveness

No. findings organisation sibles

6.6.2 nb

6.6.3 nb

6.6.4 nb

Process step 6: Process Name 6

1 Process Input

6.1.1* nb

6.1.2 nb

6.1.3 nb

6.1.4 nb

6.1.5 nb

2 Work Content / Process Sequences

6.2.1* nb

6.2.2 nb

6.2.3* nb

6.2.4* nb

6.2.5 nb

6.2.6 nb

3 Personnel Support

6.3.1 nb

6.3.2* nb

6.3.3 nb

4 Material Ressources

6.4.1 nb

6.4.2* nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 32 von 40

477471139.xlsx

To be filled by auditor to be filled by audited party

Quest Weaknesses, recommended actions, Actions and cause analysis by the Respon-

Pos.

Points Timing Effectiveness

No. findings organisation sibles

6.4.3 nb

6.4.4 nb

5 Process Effectiveness Level

6.5.1 nb

6.5.2 nb

6.5.3* nb

6.5.4* nb

6 Process Result / Output

6.6.1* nb

6.6.2 nb

6.6.3 nb

6.6.4 nb

Process step 7: Process Name 7

1 Process Input

6.1.1* nb

6.1.2 nb

6.1.3 nb

6.1.4 nb

6.1.5 nb

2 Work Content / Process Sequences

6.2.1* nb

6.2.2 nb

6.2.3* nb

6.2.4* nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 33 von 40

477471139.xlsx

To be filled by auditor to be filled by audited party

Quest Weaknesses, recommended actions, Actions and cause analysis by the Respon-

Pos.

Points Timing Effectiveness

No. findings organisation sibles

6.2.5 nb

6.2.6 nb

3 Personnel Support

6.3.1 nb

6.3.2* nb

6.3.3 nb

4 Material Ressources

6.4.1 nb

6.4.2* nb

6.4.3 nb

6.4.4 nb

5 Process Effectiveness Level

6.5.1 nb

6.5.2 nb

6.5.3* nb

6.5.4* nb

6 Process Result / Output

6.6.1* nb

6.6.2 nb

6.6.3 nb

6.6.4 nb

Process step 8: Process Name 8

1 Process Input

6.1.1* nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 34 von 40

477471139.xlsx

To be filled by auditor to be filled by audited party

Quest Weaknesses, recommended actions, Actions and cause analysis by the Respon-

Pos.

Points Timing Effectiveness

No. findings organisation sibles

6.1.2 nb

6.1.3 nb

6.1.4 nb

6.1.5 nb

2 Work Content / Process Sequences

6.2.1* nb

6.2.2 nb

6.2.3* nb

6.2.4* nb

6.2.5 nb

6.2.6 nb

3 Personnel Support

6.3.1 nb

6.3.2* nb

6.3.3 nb

4 Material Ressources

6.4.1 nb

6.4.2* nb

6.4.3 nb

6.4.4 nb

5 Process Effectiveness Level

6.5.1 nb

6.5.2 nb

6.5.3* nb

6.5.4* nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 35 von 40

477471139.xlsx

To be filled by auditor to be filled by audited party

Quest Weaknesses, recommended actions, Actions and cause analysis by the Respon-

Pos.

Points Timing Effectiveness

No. findings organisation sibles

6 Process Result / Output

6.6.1* nb

6.6.2 nb

6.6.3 nb

6.6.4 nb

Process step 9: Process Name 9

1 Process Input

6.1.1* nb

6.1.2 nb

6.1.3 nb

6.1.4 nb

6.1.5 nb

2 Work Content / Process Sequences

6.2.1* nb

6.2.2 nb

6.2.3* nb

6.2.4* nb

6.2.5 nb

6.2.6 nb

3 Personnel Support

6.3.1 nb

6.3.2* nb

6.3.3 nb

4 Material Ressources

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 36 von 40

477471139.xlsx

To be filled by auditor to be filled by audited party

Quest Weaknesses, recommended actions, Actions and cause analysis by the Respon-

Pos.

Points Timing Effectiveness

No. findings organisation sibles

6.4.1 nb

6.4.2* nb

6.4.3 nb

6.4.4 nb

5 Process Effectiveness Level

6.5.1 nb

6.5.2 nb

6.5.3* nb

6.5.4* nb

6 Process Result / Output

6.6.1* nb

6.6.2 nb

6.6.3 nb

6.6.4 nb

Process step 10: Process Name 10

1 Process Input

6.1.1* nb

6.1.2 nb

6.1.3 nb

6.1.4 nb

6.1.5 nb

2 Work Content / Process Sequences

6.2.1* nb

6.2.2 nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 37 von 40

477471139.xlsx

To be filled by auditor to be filled by audited party

Quest Weaknesses, recommended actions, Actions and cause analysis by the Respon-

Pos.

Points Timing Effectiveness

No. findings organisation sibles

6.2.3* nb

6.2.4* nb

6.2.5 nb

6.2.6 nb

3 Personnel Support

6.3.1 nb

6.3.2* nb

6.3.3 nb

4 Material Ressources

6.4.1 nb

6.4.2* nb

6.4.3 nb

6.4.4 nb

5 Process Effectiveness Level

6.5.1 nb

6.5.2 nb

6.5.3* nb

6.5.4* nb

6 Process Result / Output

6.6.1* nb

6.6.2 nb

6.6.3 nb

6.6.4 nb

P 7 Customer Support / Customer Satisfaction / Services

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 38 von 40

477471139.xlsx

To be filled by auditor to be filled by audited party

Quest Weaknesses, recommended actions, Actions and cause analysis by the Respon-

Pos.

Points Timing Effectiveness

No. findings organisation sibles

7.1* nb

7.2 nb

7.3* nb

7.4 nb

7.5 nb

7.6 nb

Erstellt: Rita Demmeler-Wirth Version/Stand: 2.6/07.08.2011 Seite 39 von 40

This template is provided free of charge by ORGAImprove to be

used by interested parties.

The use of this template is within the responsibility of the user

and at users risk only!

ORGAimprove will not take any responsiblity or liability for any

errors e.g. in calculations / evaluations!

There is no right of support or delivery of updates by

ORGAimprove!

You might also like

- VDA 6.3 2010 - enDocument45 pagesVDA 6.3 2010 - enMahender KumarNo ratings yet

- Excel Tool Process Audit Services VDA 6.3 2016 en V1.0Document12 pagesExcel Tool Process Audit Services VDA 6.3 2016 en V1.0Roberto Barbosa100% (1)

- Excel Tool Prozessaudit VDA 6.3 2010 enDocument37 pagesExcel Tool Prozessaudit VDA 6.3 2010 enrodolfo barbosa0% (1)

- (QSP-QA-08) Process For Internal Rejection HandelingDocument4 pages(QSP-QA-08) Process For Internal Rejection HandelingMUNENDRA SHAKYANo ratings yet

- APQP Sample FormatDocument32 pagesAPQP Sample FormatManigandan RNo ratings yet

- Processaudit VDA 6.3 - RecentDocument32 pagesProcessaudit VDA 6.3 - RecentAnkurNo ratings yet

- NC Analysis Report 3L5Y-Blank FormatDocument160 pagesNC Analysis Report 3L5Y-Blank Formatshobha shelarNo ratings yet

- Process Performance Qualification ProtocolDocument7 pagesProcess Performance Qualification Protocolsandeep sharmaNo ratings yet

- Module 13. Voice of The Customer (VOC)Document47 pagesModule 13. Voice of The Customer (VOC)taghavi1347No ratings yet

- Processaudit VDA 6.3 - RecentDocument34 pagesProcessaudit VDA 6.3 - Recentavinash_k007No ratings yet

- 3-DPA Awareness ProgramDocument27 pages3-DPA Awareness ProgramVishal MaliNo ratings yet

- TMP 8216Document14 pagesTMP 8216nithiananthiNo ratings yet

- Certificate Program in Lean Six Sigma: by - Paresh Kariya B.E. (Mech), MBA. Ph.D. Six Sigma, FIVDocument75 pagesCertificate Program in Lean Six Sigma: by - Paresh Kariya B.E. (Mech), MBA. Ph.D. Six Sigma, FIVBhargav Ka.PatelNo ratings yet

- MP EnglishDocument25 pagesMP EnglishDubilio AlfonzoNo ratings yet

- Vendor Assessment - Self AssessmentDocument10 pagesVendor Assessment - Self Assessmentjennice18No ratings yet

- Excel Tool Prozessaudit VDA 6.3 2010 enDocument29 pagesExcel Tool Prozessaudit VDA 6.3 2010 enHokuto No KenNo ratings yet

- APQP FormatosDocument15 pagesAPQP FormatoseddiefloresNo ratings yet

- IATF OER Checklist Along With Attendance Sheet 2021 07 EditionDocument11 pagesIATF OER Checklist Along With Attendance Sheet 2021 07 EditionAshok PanchalNo ratings yet

- Validation of Special ProcessesDocument3 pagesValidation of Special ProcessesJeyakumarNo ratings yet

- VDA Volume 6.3 Chapter 9.1 2016 Process Audit ResultDocument1 pageVDA Volume 6.3 Chapter 9.1 2016 Process Audit ResultYo GoldNo ratings yet

- VDA 6.3 Audit Report - Quality Capability Assessment: Findings / RequirementsDocument4 pagesVDA 6.3 Audit Report - Quality Capability Assessment: Findings / RequirementsrihabNo ratings yet

- CQI-11 Plating System AssessmentDocument31 pagesCQI-11 Plating System AssessmentKULDEEP THAKUR100% (1)

- APQP Final ProcedureDocument9 pagesAPQP Final ProcedurePk NimiwalNo ratings yet

- Formel QAuditDocument19 pagesFormel QAuditthienthantuyetvh2000No ratings yet

- State of Michigan: (Insert System or Project Name Here) (Inset Phase or Product Increment)Document5 pagesState of Michigan: (Insert System or Project Name Here) (Inset Phase or Product Increment)SamNo ratings yet

- Direct Debit - Exclusion of Open Items From The Direct Debit ProcedureDocument7 pagesDirect Debit - Exclusion of Open Items From The Direct Debit ProcedureSunitha GubbalaNo ratings yet

- Internal Audits Procedure - 0Document8 pagesInternal Audits Procedure - 0dahliaNo ratings yet

- PEAR PresentationDocument38 pagesPEAR PresentationMiguel Ramos100% (2)

- TEM-280 Packaging Validation Protocol Template SampleDocument6 pagesTEM-280 Packaging Validation Protocol Template SampleAnonymous BcT42WLn50% (2)

- ANDTBF - 12 Annual Assessment R3Document6 pagesANDTBF - 12 Annual Assessment R3Heidi CoxNo ratings yet

- PS - Copy of Supplier PSODocument11 pagesPS - Copy of Supplier PSODesmond MahadeoNo ratings yet

- Project Management Guidelines: Owners and List of ContactsDocument6 pagesProject Management Guidelines: Owners and List of ContactsVIbhishanNo ratings yet

- John Deere Process Verification Audit - Instructions: BackgroundDocument6 pagesJohn Deere Process Verification Audit - Instructions: BackgroundTAPANNo ratings yet

- APQP Internal Assessment Checklist: Development PhaseDocument3 pagesAPQP Internal Assessment Checklist: Development PhaseRandhir Kanwar100% (1)

- TEM 225 Validation Report Combined OQ PQ SampleDocument2 pagesTEM 225 Validation Report Combined OQ PQ SampleSameh MostafaNo ratings yet

- CTRL Plan TemplateDocument4 pagesCTRL Plan TemplatevishalNo ratings yet

- APQP ProcedureDocument9 pagesAPQP ProcedurePk Nimiwal100% (4)

- 01 Supplier Pre-Qualification AssessmentDocument18 pages01 Supplier Pre-Qualification AssessmentChinh Lê Đình100% (1)

- Quality Manag.Document13 pagesQuality Manag.Ahmed HanyNo ratings yet

- Test Plan 2013 - SoftwareDocument845 pagesTest Plan 2013 - Softwareazzuraluna801320100% (1)

- Apqp PhaseDocument6 pagesApqp PhaseDisha ShahNo ratings yet

- Project Handling ProcedureDocument8 pagesProject Handling ProcedurePk NimiwalNo ratings yet

- Be-Pdp-Fr-07-E Papso Form Roanoke To Sa - j7Document2 pagesBe-Pdp-Fr-07-E Papso Form Roanoke To Sa - j7Ricardo Frank CordeiroNo ratings yet

- 5M CHANGE ProcedureDocument8 pages5M CHANGE ProcedurePk Nimiwal100% (1)

- Site Audit Report - VeoliaDocument2 pagesSite Audit Report - VeoliaBALAKRISHANANNo ratings yet

- GM 1927-16a Leak Test Process AuditDocument20 pagesGM 1927-16a Leak Test Process AudithuangjlNo ratings yet

- DMAIC Project 3rd Sample - V1Document27 pagesDMAIC Project 3rd Sample - V1Abdulaziz AlzahraniNo ratings yet

- Assignment No:-4: Submitted To: Submitted byDocument6 pagesAssignment No:-4: Submitted To: Submitted byAnkur SinghNo ratings yet

- Supplier Audit: Instructions and Criteria For ScoreDocument7 pagesSupplier Audit: Instructions and Criteria For ScoreAmilaLakmalNo ratings yet

- Internal Audits: 1. PurposeDocument4 pagesInternal Audits: 1. PurposesumanNo ratings yet

- Answer For Finding Sorting OD Height (291121)Document16 pagesAnswer For Finding Sorting OD Height (291121)Azlan MustaphaNo ratings yet

- VAL-SV-E0163-P PCBA Depanelization Router Elite Machine Validation Plan - Edy-29 Nov (CK)Document8 pagesVAL-SV-E0163-P PCBA Depanelization Router Elite Machine Validation Plan - Edy-29 Nov (CK)arumNo ratings yet

- Responsibility Rank of Development: D:/APQP Document/ Special Product and Process CharactesticsDocument4 pagesResponsibility Rank of Development: D:/APQP Document/ Special Product and Process CharactesticsAL BARAKAH GRAINS100% (1)

- 01 Internal Auditing Technique Rev. 05 12 09 2018Document40 pages01 Internal Auditing Technique Rev. 05 12 09 2018Syed Maroof AliNo ratings yet

- QADocsDocument5 pagesQADocsapi-3695674No ratings yet

- Docsity Formatos de Apqp para Su Llenado y Aplicado 1Document64 pagesDocsity Formatos de Apqp para Su Llenado y Aplicado 1Alejandro Martinez OrtegaNo ratings yet

- TYP E E - PETRO C VA 004 - 01 Model of Quality Control ProgramDocument6 pagesTYP E E - PETRO C VA 004 - 01 Model of Quality Control ProgramDan BanulNo ratings yet

- Waste Water Treatment Process Operations Training CourseDocument1 pageWaste Water Treatment Process Operations Training CourseRohini GadhaweNo ratings yet

- Introduction To On-Site Wastewater Treatment and Land Application SystemsDocument1 pageIntroduction To On-Site Wastewater Treatment and Land Application SystemsRohini GadhaweNo ratings yet

- About Us Standing Orders Consent M Anagement Notices Download Rti EmailDocument2 pagesAbout Us Standing Orders Consent M Anagement Notices Download Rti EmailRohini GadhaweNo ratings yet

- Reclaimed Water ManagementDocument1 pageReclaimed Water ManagementRohini GadhaweNo ratings yet

- Oil & Grease TestDocument16 pagesOil & Grease TestRohini GadhaweNo ratings yet

- TBK Vendor Registration FormDocument4 pagesTBK Vendor Registration FormRohini Gadhawe100% (1)

- Water Testing Charges of MPCBDocument3 pagesWater Testing Charges of MPCBRohini GadhaweNo ratings yet

- Sop AirDocument24 pagesSop AirRohini GadhaweNo ratings yet

- Customer Specific Requirements of DAG September 2017Document8 pagesCustomer Specific Requirements of DAG September 2017DLNo ratings yet

- Maintenance Training: Sr. No. TopicDocument6 pagesMaintenance Training: Sr. No. TopicRohini Gadhawe100% (1)

- H.W SopDocument17 pagesH.W SopRohini GadhaweNo ratings yet

- Daimler India Special Terms 2017Document30 pagesDaimler India Special Terms 2017Rohini GadhaweNo ratings yet

- Renault Group CSR For IATF 169494Document10 pagesRenault Group CSR For IATF 169494nkrish21856No ratings yet

- 14 - P11 Production Scheduling and Planning Process-May'17Document9 pages14 - P11 Production Scheduling and Planning Process-May'17Rohini GadhaweNo ratings yet

- Enrol 000ST7090825 Icnc 00205 20180814140037Document1 pageEnrol 000ST7090825 Icnc 00205 20180814140037Rohini GadhaweNo ratings yet

- ISO 13485 Gantt Chart - May 2020Document4 pagesISO 13485 Gantt Chart - May 2020Rohini Gadhawe100% (4)

- Unit 1 Fish Tale Word ProblemDocument13 pagesUnit 1 Fish Tale Word ProblemRohini GadhaweNo ratings yet

- Unitary MethodDocument7 pagesUnitary MethodRohini GadhaweNo ratings yet

- Project Gantt Chart PDFDocument1 pageProject Gantt Chart PDFRohini GadhaweNo ratings yet

- CA ContactsDocument1 pageCA ContactsRohini GadhaweNo ratings yet

- Worksheet Word ProblemDocument1 pageWorksheet Word ProblemRohini GadhaweNo ratings yet

- Jyothis Academy Prospectus PDFDocument16 pagesJyothis Academy Prospectus PDFRohini GadhaweNo ratings yet

- Project Gantt ChartDocument1 pageProject Gantt ChartRohini GadhaweNo ratings yet

- The Institution of Engineers (India) : An ISO 9001:2008 Certified Organisation 8 Gokhale Road, Kolkata 700 020Document7 pagesThe Institution of Engineers (India) : An ISO 9001:2008 Certified Organisation 8 Gokhale Road, Kolkata 700 020Rohini GadhaweNo ratings yet

- Visit ReportDocument10 pagesVisit ReportRohini GadhaweNo ratings yet

- Training Attendance Sheet: Course Title: Faculty: Course Start Date: Course End Date: Company Name: Course DurationDocument4 pagesTraining Attendance Sheet: Course Title: Faculty: Course Start Date: Course End Date: Company Name: Course DurationRohini GadhaweNo ratings yet

- Visit ReportDocument10 pagesVisit ReportRohini GadhaweNo ratings yet

- INDIA Rates - ISO 22000/HACCP-DACDocument6 pagesINDIA Rates - ISO 22000/HACCP-DACRohini GadhaweNo ratings yet

- Sample Statement of Purpose - Business Management Ph.D. Example EssayDocument6 pagesSample Statement of Purpose - Business Management Ph.D. Example EssayakshayNo ratings yet

- Manjunath RathodDocument15 pagesManjunath RathodAnonymous 7a0LzlAyRDNo ratings yet

- Last Mile Connectivity: Sponsored byDocument29 pagesLast Mile Connectivity: Sponsored byVinod ChakaravarthyNo ratings yet

- Porter's Five Force AnalysisDocument24 pagesPorter's Five Force AnalysisAman Oza R100% (1)

- Balance Scorecard - PPT IIIDocument25 pagesBalance Scorecard - PPT IIINeeraj SharmaNo ratings yet

- TQM Practices in TVS Motors - Activity 1Document11 pagesTQM Practices in TVS Motors - Activity 1Pradeep RajNo ratings yet

- Ch. 8 - Malhotra 6th EditionDocument12 pagesCh. 8 - Malhotra 6th EditionCarlos Andres RodriguezNo ratings yet

- Honors Students JAN Returnees To Graduate 2021Document6 pagesHonors Students JAN Returnees To Graduate 2021sharon sharmaNo ratings yet

- 21PDM102L GA Worksheet1Document15 pages21PDM102L GA Worksheet1Yuvan Krishnan VNo ratings yet

- Skim Penetration and Neutral Pricing StrategyDocument3 pagesSkim Penetration and Neutral Pricing StrategyYap Tat JunNo ratings yet

- CPAA EG Practice Exam 5Document23 pagesCPAA EG Practice Exam 5Ka Chun Ho0% (1)

- Blockchain in Supply Management PDFDocument13 pagesBlockchain in Supply Management PDFambujsa1027No ratings yet

- Customer Complaint Role PlayDocument1 pageCustomer Complaint Role PlayJewel AhmedNo ratings yet

- Bplan 23Document5 pagesBplan 23Julio Jerino Dela cruzNo ratings yet

- Supply Chain Management in Supershop StoreDocument22 pagesSupply Chain Management in Supershop StoreMd. Kamrul Islam Khan ShehabNo ratings yet