Professional Documents

Culture Documents

Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)

Uploaded by

Muhammad MunadiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)

Uploaded by

Muhammad MunadiCopyright:

Available Formats

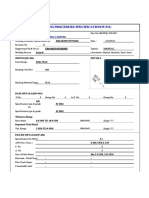

FORM QW-482 SUGGESTED FORMAT FOR WELDING PROCEDURE SPECIFICATIONS (WPS)

(See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)

Organization Name Politeknik Negeri Banjarmasin By Muhammad Munadi

Welding Procedure Specification No. Date Supporting PQR No.(s)

Revision No. Date

Welding Process(es) SMAW & GTAW Type(s) MANUAL

(Automatic, Manual, Machine, or Semi-Automatic)

JOINTS (QW-402) Details

Joint Design Double V

Root Spacing

Backing: Yes No

Backing Material (Type) N/A

(Refer to both backing and retainers)

Metal

Nonfusing Metal

Nonmetallic

Other

Sketches, Production Drawings, Weld Symbols, or Written Description

should show the general arrangement of the parts to be welded. Where

applicable, the details of weld groove may be specified.

Sketches may be attached to illustrate joint design, weld layers, and

bead sequence (e.g., for notch toughness procedures, for multiple

process procedures, etc.)]

*BASE METALS (QW-403)

P-No. 1

Group No. 1 to P-No. 1 Group No. 1

OR

Specification and type/grade or UNS Number ASTMA A 106 Grade B

to Specification and type/grade or UNS Number ASTMA A 106 Grade B

OR

Chem. Analysis and Mech. Prop.

to Chem. Analysis and Mech. Prop.

Thickness Range: 5 to 22 mm

Base Metal: Groove Fillet

Maximum Pass Thickness S 1/2 in. (13 mm) (Yes) (No)

Other

*FILLER METALS (QW-404) GTAW SMAW

Spec. No. (SFA) A5-1B A5-1

AWS No. (Class) ER709-2 E-7018

F-No. 6 4

A-No.

Size of Filler Metals

Filler Metal Product

Form Supplemental

Filler Metal Weld Metal

Deposited Thickness:

Groove

Fillet

Electrode-Flux (Class)

Flux Type

Flux Trade Name

Consumable Insert

Other

*Each base metal-filler metal combination should be recorded individually.

(07/13)

FORM QW-482 (Back)

WPS No. Rev.

POSITIONS (QW-405)

Position(s) of Groove ALL

Welding Progression: Up Hill Down

Position(s) of Fillet N/A

Other

PREHEAT (QW-406)

Preheat Temperature, Minimum min 10 deg C

Interpass Temperature, Maximim N/A

Preheat Maintenance N/A

Other

(Continuous or special heating, where applicable, should be

recorded)

ELECTRICAL CHARACTERISTICS (QW-409)

Filler Metal

Current

Weld Classifi- Type and Amps

Pass(es) Process cation Diameter Polarity (Range)

Amps and volts, or power or energy range, should be recorded for

Pulsing Current

Tungsten Electrode Size and Type

Mode of Metal Transfer for GMAW (FCAW)

Other

TECHNIQUE (QW-410)

String or Weave Bead

Orifice, Nozzle, or Gas Cup Size

Initial and Interpass Cleaning (Brushing, Grinding, etc.)

Method of Back Gouging

Oscillation

Contact Tube to Work Distance

Multiple or Single Pass (Per Side)

Multiple or Single Electrodes

Electrode Spacing

Peening

Other

(07/10)

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)mohammadNo ratings yet

- FORM QW-482 WELDING PROCEDURE SPECIFICATIONDocument2 pagesFORM QW-482 WELDING PROCEDURE SPECIFICATIONsbmmlaNo ratings yet

- Wps FormatDocument2 pagesWps FormatMeghan GhoneNo ratings yet

- WPS&PQR FormsDocument4 pagesWPS&PQR FormsArab WeldersNo ratings yet

- 3 BodyPart Edcb3a5f Eede 445f A423 Ea2f5809c15eDocument6 pages3 BodyPart Edcb3a5f Eede 445f A423 Ea2f5809c15emayank0738No ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- QW-482 SUGGESTED FORMAT FOR WELDING PROCEDURE SPECIFICATIONSDocument2 pagesQW-482 SUGGESTED FORMAT FOR WELDING PROCEDURE SPECIFICATIONSVaibhav GuptaNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- FORM QW-482 WELDING PROCEDURE SPECIFICATION FORMATDocument6 pagesFORM QW-482 WELDING PROCEDURE SPECIFICATION FORMATStan HonNo ratings yet

- Smaw Wps FinalDocument3 pagesSmaw Wps FinalsheikmoinNo ratings yet

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)MALABAR TIMESNo ratings yet

- Formas Soldadura ASME IX 2017Document7 pagesFormas Soldadura ASME IX 2017Ulises GómezNo ratings yet

- Ejemplo Prueba 991003Document2 pagesEjemplo Prueba 991003MARIO ALBANo ratings yet

- Form QW-482 Welding Procedure Specification FormatDocument4 pagesForm QW-482 Welding Procedure Specification FormatJesus Silva HenaoNo ratings yet

- WPS FormatDocument2 pagesWPS Formatakhilsyam21No ratings yet

- (Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Document6 pages(Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Saifulla CmpNo ratings yet

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- QW-482 (WPS) GTAW 4MM FilletDocument4 pagesQW-482 (WPS) GTAW 4MM FilletBalkishan DyavanapellyNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- Wps PQR FormDocument8 pagesWps PQR Formmayank0738No ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- WPS Vessel 1Document4 pagesWPS Vessel 1Naqqash SajidNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 pagesWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniNo ratings yet

- QW-482 Suggested Format For Welding ProcDocument2 pagesQW-482 Suggested Format For Welding Procsachin0% (1)

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)pradeep4545No ratings yet

- Qw-482 Suggested Format For Welding Procedure Specification (WPS)Document2 pagesQw-482 Suggested Format For Welding Procedure Specification (WPS)ING HARRINSON FERREBUSNo ratings yet

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument5 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCmkhalil1148No ratings yet

- WELDING PROCEDURE SPECIFICATION FOR FILLET WELDSDocument2 pagesWELDING PROCEDURE SPECIFICATION FOR FILLET WELDSAhmed saberNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- Tips Wps FormatDocument5 pagesTips Wps FormatWaqas WaqasNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (2)

- Welding Procedure Specification (W.P.S) : Alstom India LimitedDocument2 pagesWelding Procedure Specification (W.P.S) : Alstom India LimitedAhmed saberNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WELDING PROCEDURE SPECIFICATIONSDocument6 pagesWELDING PROCEDURE SPECIFICATIONSMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- WPSDocument3 pagesWPSSagar GourNo ratings yet

- METALS INSPECTION SERVICES WELDING PROCEDUREDocument6 pagesMETALS INSPECTION SERVICES WELDING PROCEDURELuis MuñozNo ratings yet

- AECOM ASME PQR for SA-516 Pipe WeldsDocument3 pagesAECOM ASME PQR for SA-516 Pipe Weldscorey jacobsNo ratings yet

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Welding Procedure SpecificationDocument12 pagesWelding Procedure Specificationsanjay sharmaNo ratings yet

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- Preliminary WPS for 12.7mm SMAW WeldingDocument3 pagesPreliminary WPS for 12.7mm SMAW WeldingAnonymous 4e7GNjzGW100% (1)

- WPS-46 - Gtaw & Smaw Tig + SmawDocument8 pagesWPS-46 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaNo ratings yet

- WPS-ASME SEC IX-for PSODocument3 pagesWPS-ASME SEC IX-for PSOSultan ZebNo ratings yet

- Welding Procedure Specification for Stainless SteelDocument5 pagesWelding Procedure Specification for Stainless SteelVarun Malhotra100% (5)

- Welding Procedure Specifications (WPS) : Universitas Negeri Yogyakarta Hanifan Nugroho - B2Document2 pagesWelding Procedure Specifications (WPS) : Universitas Negeri Yogyakarta Hanifan Nugroho - B2RahmadiNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- WPS SUMMARYDocument10 pagesWPS SUMMARYbhavin178No ratings yet

- Ansi B36.19Document13 pagesAnsi B36.19BimaNo ratings yet

- D EquipmentDocument44 pagesD Equipmentosvald97No ratings yet

- Universal Uberoid WM8650 v10.1Document4 pagesUniversal Uberoid WM8650 v10.1noniggin nignogNo ratings yet

- GEOMETRY CH 5 Law of SinesDocument2 pagesGEOMETRY CH 5 Law of SinesJackson LudtkeNo ratings yet

- Fluid Mechanics EXERCHAP05Document4 pagesFluid Mechanics EXERCHAP05scribdgggNo ratings yet

- Week 2 - L2 - Review of Laplace TransformDocument39 pagesWeek 2 - L2 - Review of Laplace TransformOlerile AnaniaNo ratings yet

- CH-2 Relational ModelDocument51 pagesCH-2 Relational ModelhkNo ratings yet

- DRIVINGDocument4 pagesDRIVINGMarcelino ZarateNo ratings yet

- Basic CommandsDocument13 pagesBasic Commandsramana6nNo ratings yet

- ALC887Document82 pagesALC887EmmanuelchatoNo ratings yet

- MySQL Installation SOP Ver1.0Document14 pagesMySQL Installation SOP Ver1.0pavanlondonNo ratings yet

- HW 01Document2 pagesHW 01Hëņřý ØjđNo ratings yet

- Accounting exam covers receivables, payablesDocument3 pagesAccounting exam covers receivables, payableseXpadaNo ratings yet

- The Diesel Cycle Verified For Methanol OperationDocument12 pagesThe Diesel Cycle Verified For Methanol OperationVăn Tuấn NguyễnNo ratings yet

- Data Structures and Algorithms IntroductionDocument22 pagesData Structures and Algorithms IntroductionTadele Molla ታደለ ሞላNo ratings yet

- Maths Practice Test with Multiple Choice QuestionsDocument8 pagesMaths Practice Test with Multiple Choice QuestionsBernard ChanNo ratings yet

- 14EIT72 Instrumentation System Design UNIT-V - P&I Diagrams and Instrument InstallationDocument38 pages14EIT72 Instrumentation System Design UNIT-V - P&I Diagrams and Instrument Installationksjanarthanan_sriNo ratings yet

- ICEA-AEIC Diameter ComparisonDocument3 pagesICEA-AEIC Diameter ComparisonsupernaenergyNo ratings yet

- KCA-201 Online PUE Theory of Automata & Formal Languages MCA 2nd SemDocument13 pagesKCA-201 Online PUE Theory of Automata & Formal Languages MCA 2nd SemakttripathiNo ratings yet

- Certified Associate in Python Programming: Python Institute PCAP-31-03 Dumps Available Here atDocument6 pagesCertified Associate in Python Programming: Python Institute PCAP-31-03 Dumps Available Here athk python123No ratings yet

- Lathe Machine OperationDocument68 pagesLathe Machine OperationKarthick N100% (8)

- XFOILDocument2 pagesXFOILbwwatsonNo ratings yet

- Bank Statement QueryDocument13 pagesBank Statement QuerySiddiq MohammedNo ratings yet

- Average IfDocument22 pagesAverage IfXenia MorenoNo ratings yet

- Alan Turing PresentationDocument42 pagesAlan Turing PresentationPaul Mu100% (1)

- Acid Base and Redox Titration CalculationsDocument33 pagesAcid Base and Redox Titration CalculationsoscarbecNo ratings yet

- MagnusDocument26 pagesMagnussvsreeramaNo ratings yet

- Comparison of methods for determining the plateau modulus and entanglement molecular weightDocument19 pagesComparison of methods for determining the plateau modulus and entanglement molecular weightfaezehNo ratings yet

- 3rd Quarter Mathematics Home Take Final Exam For Grade 10Document4 pages3rd Quarter Mathematics Home Take Final Exam For Grade 10John DejuNo ratings yet