Professional Documents

Culture Documents

Welding Procedure Specifications (WPS) : Universitas Negeri Yogyakarta Hanifan Nugroho - B2

Uploaded by

Rahmadi0 ratings0% found this document useful (0 votes)

21 views2 pages01

Original Title

Rahmadi WPS-ASME-2019 (1).xlsx

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document01

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views2 pagesWelding Procedure Specifications (WPS) : Universitas Negeri Yogyakarta Hanifan Nugroho - B2

Uploaded by

Rahmadi01

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 2

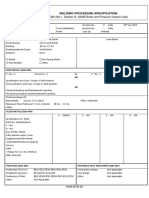

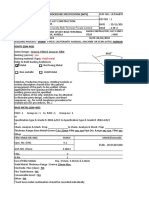

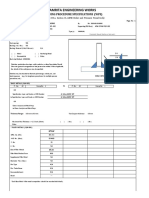

WELDING PROCEDURE SPECIFICATIONS (WPS)

Company : UNIVERSITAS NEGERI YOGYAKARTA Prepared by : Hanifan Nugroho - B2

Welding procedure Spec. No. : 1 Date : 01-09-2020 Rev No.: -

Supporting PQR No. : -

Welding Process : SMAW Type : Manual

Joint ( QW-402 ) Detail Joint

Joint Design : Single "V" groove

Root Spacing : 2.8

Backing : Yes No v

Backing Material : -

(Refer to both backing and retainers)

v Metal Non Fusing Metal

Non Metalic Other

Sketches, Production drawings, Weld symbols or written description

should show the general arragement of the part to be welded, where

applicable, the root spacing and the details of weld groove may be

specified.

( Sketches may be attached to ilustrate joint design, weld layer and

bead sequence, e.g. for notch toughness procedures, for multiple process

procedure, etc. )

Base Metal ( QW-403 )

P-No. : 32 Group No. : - to P-No. : 32 Group No. : -

OR

Specification type and grade, or UNS Number : C23000

to Specification type and grade , or UNS Number : C23000

OR

Chem. Analysis and Mech. Properties : -

to Chem. Analysis and Mech. Properties : -

Thickness Range :

Base Metal : Groove : 13 mm Fillet : -

Maximum Pass Thickness ≤ 1/2 in. (13 mm) (Yes) v (No)

Other :

Filler Metal ( QW-404 )

Spec. No. (SFA) 5.6

AWS No. ( Class ) EcuSI

F - No. 32

A - No. 1

Size of Filler Metals 2.6 mm, 3.2 mm

Filler Metal Product From -

Supplemental Filler Metal -

Weld Metal

Deposited Thickness:

Groove Max 50 mm

Fillet -

Electrode - Flux ( Class ) -

Flux Type -

Flux Trade Name -

Consumable Insert -

Other

*Each base metal-filler metal combination should be specified individually

WPS No. : 01/WPS-ASME/UNY/2020

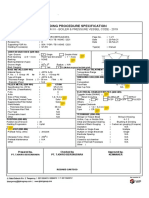

Position ( QW-405 ) Posweld Heat Treatment ( QW-407 )

Position (s) of Groove : 1G PLATE Temp Range : -

Welding Progression : Up - Down - Time Range : -

Position (s) of Fillet : - Other : -

Other : N/A

Preheat ( QW-406 ) Gas ( QW-408 )

Preheat Temp. (Min) : Min 10 deg C Percent Composition

Interpass Temp. (Max) : Max 250 deg C Gas (es) Mixture Flow Rate

Preheat Maintenance : - Shield : N/A N/A

Other : Trail : - - -

(Continous or special heating, where applicable, should be specified) Backing : - - -

Other : - - -

Electrical Characteristics ( QW-409 )

Filler Metal Current Wire Feed Energy or Travel

Weld Amps Volts

Process Classifi- Type and Speed Power Speed Other

Pass(es) Diameter (Range) (Range)

cation Polarity (Range) (Range) (Range)

1 SMAW 5.6 2.5 mm DCEP 50-70 - - 20-26 3-5 -

2 SMAW 5.6 3.0 mm DCEP 70-110 - - 20-27 5-6 -

3 SMAW 5.6 4.0 mm DCEP 100-150 - - 20-28 5-6 -

4 SMAW 5.6 5.0 mm DCEP 140-180

Pulsing Current : DC Heat Input (max.) :

Tungsten Electrode Size and Type : -

Mode of Metal Transfer for GMAW (FCAW) : -

Electrode Wire Feed Speed Range : -

Other : -

Technique ( QW-410 )

String or Weaving : Stringer and Weave Bead

Orifice or Gas Size : -

Initial and Interpass Cleaning : Grinding

Methode of Back Gouge : -

Oscillation : -

Contact Tube to Work Distance : -

Multiple or Single Pass ( per side ) : Multiple

Multiple or Single Electrode : Multiple

Electode Spacing : -

Peening : -

Other : -

Approved by, Reviewed & witnessed by, Prepared by,

( ) ( ) (Rahmadi Nurapela)

You might also like

- Ejemplo Prueba 991003Document2 pagesEjemplo Prueba 991003MARIO ALBANo ratings yet

- QW-482 Suggested Format For Welding ProcDocument2 pagesQW-482 Suggested Format For Welding Procsachin0% (1)

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Ex Wps Train 01Document2 pagesEx Wps Train 01aidil30No ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad MunadiNo ratings yet

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocument3 pagesWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- SILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Document2 pagesSILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Abdulmecit YetisNo ratings yet

- Wps For Ss 304Document3 pagesWps For Ss 304Sajit PillaiNo ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- QW - 482 Welding Procedure Specification (WPS)Document5 pagesQW - 482 Welding Procedure Specification (WPS)Arijit GhoshNo ratings yet

- WPS & PQR of Ravindra KumarDocument4 pagesWPS & PQR of Ravindra Kumartripatipankaj023No ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Metals Inspection Services, Inc.: QW - 482 Suggested Format For Welding Procedure Specification (WPS)Document6 pagesMetals Inspection Services, Inc.: QW - 482 Suggested Format For Welding Procedure Specification (WPS)Luis MuñozNo ratings yet

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (5)

- Welding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Document3 pagesWelding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Budi Setia RahmanNo ratings yet

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- WPS FormatDocument3 pagesWPS Formatvivek bhangaleNo ratings yet

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- QW - 482 Welding Procedure Specifications (WPS) : BASE METAL (S) (QW-403) : JOINTS (QW-402) : or ToDocument2 pagesQW - 482 Welding Procedure Specifications (WPS) : BASE METAL (S) (QW-403) : JOINTS (QW-402) : or ToattaullaNo ratings yet

- Qw-482 Welding Procedure SpecificationDocument2 pagesQw-482 Welding Procedure SpecificationAmanSharmaNo ratings yet

- Aic Asf PQR 133Document3 pagesAic Asf PQR 133AHMED MEDANYNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Wps Format Asme Sec - IxDocument2 pagesWps Format Asme Sec - IxDeepu ChandranNo ratings yet

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit GhoshNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)mohammadNo ratings yet

- Mechanical Engineering M.Abdul GhoziDocument4 pagesMechanical Engineering M.Abdul GhoziRizaldy PhoenksNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- (P1) NSC-1020-TR-0102-1.1-WPS-06Document6 pages(P1) NSC-1020-TR-0102-1.1-WPS-06BIIS QAQC Babu SivaNo ratings yet

- PQR A106 HAL-1Document1 pagePQR A106 HAL-1Budi Setia RahmanNo ratings yet

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- WPS 360-1 Rev0 PDFDocument14 pagesWPS 360-1 Rev0 PDFAhmed GomaaNo ratings yet

- Sample Editable WPSDocument2 pagesSample Editable WPSsbmmlaNo ratings yet

- Wps Blank Form 2sheetDocument4 pagesWps Blank Form 2sheetdidi sudiNo ratings yet

- Wps FormatDocument2 pagesWps FormatMeghan GhoneNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Wps For Akbtpl E-6013 - ModifiedDocument13 pagesWps For Akbtpl E-6013 - ModifiedvinayNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- WPS, PQR, WPQ PoojaDocument10 pagesWPS, PQR, WPQ PoojaRajmahesh Dakhore100% (1)

- (Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Document6 pages(Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Saifulla CmpNo ratings yet

- WPS&PQR FormsDocument4 pagesWPS&PQR FormsArab WeldersNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- QW-482 (WPS) GTAW 4MM FilletDocument4 pagesQW-482 (WPS) GTAW 4MM FilletBalkishan DyavanapellyNo ratings yet

- Smaw Wps FinalDocument3 pagesSmaw Wps FinalsheikmoinNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Getting You To Test Day: An 8-Week Prep Plan For The TOEFL TestDocument2 pagesGetting You To Test Day: An 8-Week Prep Plan For The TOEFL Testsmith90No ratings yet

- Giamarie Marbella - SP Essay Rough DraftDocument11 pagesGiamarie Marbella - SP Essay Rough Draftapi-667933283No ratings yet

- Ug Vol1Document433 pagesUg Vol1Justin JohnsonNo ratings yet

- List of ItemsDocument5 pagesList of ItemsMoiNo ratings yet

- L-04 Analysis and Design of Two-Way Slab With Beams (Coloured)Document63 pagesL-04 Analysis and Design of Two-Way Slab With Beams (Coloured)Hidayat Ullah100% (3)

- Nursery Car Seat Supplement 2023Document40 pagesNursery Car Seat Supplement 2023doniNo ratings yet

- Original Instructions Alkuperäiset Ohjeet Αρχικýj Οδηγßεj: Rev. 4 5/31/11 BrwDocument32 pagesOriginal Instructions Alkuperäiset Ohjeet Αρχικýj Οδηγßεj: Rev. 4 5/31/11 BrwnikosvitalNo ratings yet

- Reaction PaperDocument2 pagesReaction PaperMisna Blasco Zurbano50% (2)

- Practical FileDocument108 pagesPractical FileRakesh KumarNo ratings yet

- Airsprings - TroubleshootingDocument4 pagesAirsprings - TroubleshootingCihan CantaşNo ratings yet

- 2013 - To and Fro. Modernism and Vernacular ArchitectureDocument246 pages2013 - To and Fro. Modernism and Vernacular ArchitecturesusanaNo ratings yet

- Ruskin As A Social Reformer - Docx ADocument2 pagesRuskin As A Social Reformer - Docx AAtif Hayat50% (2)

- Pure Theory of Law Hans Kelson-Ltp..Document45 pagesPure Theory of Law Hans Kelson-Ltp..ShabnamNo ratings yet

- Understanding The Self Lecture Lesson 1 Revised PDFDocument41 pagesUnderstanding The Self Lecture Lesson 1 Revised PDFKylie CuadraNo ratings yet

- UFO and PentagonDocument69 pagesUFO and PentagonNur Agustinus100% (3)

- Banksy Responses Done With A Partner 655512Document122 pagesBanksy Responses Done With A Partner 655512api-569248887No ratings yet

- 12auxiliary ViewsDocument22 pages12auxiliary Viewsmanishjangid9869No ratings yet

- Soft-Starter: Programming ManualDocument162 pagesSoft-Starter: Programming ManualThaylo PiresNo ratings yet

- Mining EsriDocument30 pagesMining EsriCipta Nur Asa100% (1)

- Las-Shs Gen - Chem Melc 1 q2 Week-1Document11 pagesLas-Shs Gen - Chem Melc 1 q2 Week-1Carl Baytola RatesNo ratings yet

- BA427 Chapter 7Document11 pagesBA427 Chapter 7Maloloy-on, JeromeNo ratings yet

- Welding SymbolDocument8 pagesWelding SymbolMuhammad Cahya Adi PNo ratings yet

- Legend 1028KDocument2 pagesLegend 1028KAndres Fdo Mora DNo ratings yet

- Planmeca Promax 3D Max CBVT Product PresentationDocument36 pagesPlanmeca Promax 3D Max CBVT Product PresentationAD TwentyOne DentalNo ratings yet

- FAUDI Aviation Diesel - Company Profile-ENDocument6 pagesFAUDI Aviation Diesel - Company Profile-ENAttila HontváriNo ratings yet

- Cold-Formed Steel Portal Frame Moment-Resisting Joints Behaviour Capacity and DesignDocument13 pagesCold-Formed Steel Portal Frame Moment-Resisting Joints Behaviour Capacity and DesignAhmed MoniemNo ratings yet

- Unit 2-Translation Practice MarkDocument3 pagesUnit 2-Translation Practice MarkHương ThảoNo ratings yet

- 335 Model DDX-LP Dry Pipe Valve SystemDocument8 pages335 Model DDX-LP Dry Pipe Valve SystemM Kumar MarimuthuNo ratings yet

- Example of Annual Audit Planning Work ProgramDocument2 pagesExample of Annual Audit Planning Work Programrindwa100% (1)