Professional Documents

Culture Documents

PQR (52a) Model

Uploaded by

SIDDHARTH BEHERAY0 ratings0% found this document useful (0 votes)

25 views1 pageOriginal Title

Pqr (52a) Model

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views1 pagePQR (52a) Model

Uploaded by

SIDDHARTH BEHERAYCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

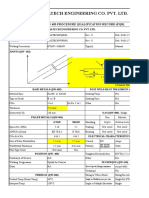

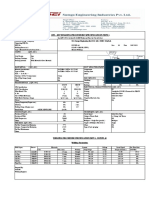

SHUSHMA ENGINEERS PVT. LTD.

QW - 483 PROCEDURE QUALIFICATION RECORDS ( PQR )

( SEE QW -200.2, SECTION IX, ASME Boiler And Pressure Vessel Code )

Page 01 Of 02

PQR No. PQR/15, Rev 0 Date 25.03.2015 Welding Process (es) GTAW

WPS No. WPS/15, Rev 0 Date 22.02.2015 Type (s) MANUAL

JOINTS ( QW - 402 )

75°

40NB Sch 160

1 to 2

Base Matals ( QW - 403 )

Material 1 Material 2

P. No. 1 P. No. 1

Group No. 1 Group No. 1

Specification / Grade SA 333 Gr 6 Specification / Grade SA 333 Gr 6

Thickness Range (mm)

Base Metal Thickness (mm) Groove 1.58 TO 17.42 Fillet ALL

Pipe Dia. Range Groove 1" to Unlimited Fillet ALL

Dep. Weld Thickness (mm) GTAW 17.42 MAX SMAW NA SAW NA FCAW NA

Other -

Filler Metals ( QW - 404 )

ROOT PASS FILL UP PASS (ES)

Spec. No. ( SFA ) 5.18 5.18

AWS No. ( Class ) ER - 70S ER - 70S

F. No. 6 6

A. No. 1 1

Size of Filler Metals (mm) Ø 2.4 Ø 2.4

Electrode - Flux ( class ) NA NA

Fulx Trade Name NA NA

Consumable Insert NA NA

Other NA NA

Position ( QW - 405 ) Preheat ( QW - 406 )

Position(s) of Groove 1G Thickness Range (mm) NA

Welding Progression NA Preheat Temp. (Min.)°C ROOM TEMP. 10°C MIN.

Position(s) of Fillet ALL Interpass Temp. ( Max.)°C 250

Other NA Preheat Maintenance NA

Post weld Heat Treatment ( QW - 407 ) Electrical Characteristics ( QW - 409 )

Loading/Unloading Temp. - NA Soaking Temp. - 600°C to 650°C Current (AC or DC) DC

Rate Of Heating - NA Rate of Cooling - 120°C/Hr Polarity (EN or EP) EN

Soaking Time - NA NA Amperes (Range) 152 - 162

Gas ( QW - 408 ) Voltage (Range) 15 - 18

Tungsten Type 2%Thoriated (Th2)

Gas (es) %Composition Flow Rate (LPM)

Tungsten Size Ø 3 mm

Shieding Gas ARGON Welding Grade (99.95%) 10

Mode Of Metal Transfer NA

Backing Gas NA NA NA

Wire Feed Speed Range NA

Trailing Gas NA NA NA

Other NA

Other NA

You might also like

- CALTECH ENGINEERING PQR PROCEDUREDocument8 pagesCALTECH ENGINEERING PQR PROCEDURESrikant GanjiNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- WPS GTAW Stainless SteelDocument7 pagesWPS GTAW Stainless SteelVarun MalhotraNo ratings yet

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- Welding Procedure Specification for Stainless SteelDocument5 pagesWelding Procedure Specification for Stainless SteelVarun Malhotra100% (5)

- WPS, PQR & WPQ - Duplex 2205Document20 pagesWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)attaullaNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- Preliminary WPS for 12.7mm SMAW WeldingDocument3 pagesPreliminary WPS for 12.7mm SMAW WeldingAnonymous 4e7GNjzGW100% (1)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- METALS INSPECTION SERVICES WELDING PROCEDUREDocument6 pagesMETALS INSPECTION SERVICES WELDING PROCEDURELuis MuñozNo ratings yet

- ASME Boiler Pressure Vessel Welding Procedure SpecificationDocument2 pagesASME Boiler Pressure Vessel Welding Procedure SpecificationBalasahebNo ratings yet

- Mechanical Engineering M.Abdul GhoziDocument4 pagesMechanical Engineering M.Abdul GhoziRizaldy PhoenksNo ratings yet

- AECOM ASME PQR for SA-516 Pipe WeldsDocument3 pagesAECOM ASME PQR for SA-516 Pipe Weldscorey jacobsNo ratings yet

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Document2 pagesWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Ejemplo Prueba 991003Document2 pagesEjemplo Prueba 991003MARIO ALBANo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (2)

- PQR 11 Noram GTDocument6 pagesPQR 11 Noram GTross anthonyNo ratings yet

- WPS Vessel 1Document4 pagesWPS Vessel 1Naqqash SajidNo ratings yet

- PQR Procedure Qualification RecordsDocument6 pagesPQR Procedure Qualification RecordsDaniel CamposNo ratings yet

- Tecnicas Reunidas S.A: Welding Procedure Specification (WPS)Document2 pagesTecnicas Reunidas S.A: Welding Procedure Specification (WPS)BIIS QAQC Babu SivaNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument5 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCmkhalil1148No ratings yet

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Document2 pagesWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- Tips Wps FormatDocument5 pagesTips Wps FormatWaqas WaqasNo ratings yet

- WPS 6G CS Pipe CorrectDocument4 pagesWPS 6G CS Pipe CorrectAla ReguiiNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- Wps PQR Welder Qualification Certification ConsultancyDocument2 pagesWps PQR Welder Qualification Certification ConsultancyEmam SayedNo ratings yet

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviNo ratings yet

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- PQR 9 DuplexDocument6 pagesPQR 9 Duplexross anthonyNo ratings yet

- Form : EIPL/WT/F-01,Rev.01 Welding Procedure SpecificationDocument2 pagesForm : EIPL/WT/F-01,Rev.01 Welding Procedure SpecificationSampath KumarNo ratings yet

- WPS-ASME-007-1 Rev0Document1 pageWPS-ASME-007-1 Rev0Ahmed LepdaNo ratings yet

- Wps 18Document2 pagesWps 18Avishek GuptaNo ratings yet

- WPS 360-1 Rev0 PDFDocument14 pagesWPS 360-1 Rev0 PDFAhmed GomaaNo ratings yet

- Final WPS - ItdcDocument2 pagesFinal WPS - ItdcsarancivilrajNo ratings yet

- Smaw Wps FinalDocument3 pagesSmaw Wps FinalsheikmoinNo ratings yet

- Form WPS for MIG Welding ProcedureDocument10 pagesForm WPS for MIG Welding ProcedurePrakash PatelNo ratings yet

- LOGOS ENGINEERING WELDING PROCEDURE SPECIFICATIONDocument5 pagesLOGOS ENGINEERING WELDING PROCEDURE SPECIFICATIONKAMALNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- WPS for Gas Field Development WeldingDocument2 pagesWPS for Gas Field Development WeldingAhmed LepdaNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviNo ratings yet

- WPS For Carbon Steel THK 7.11 GTAWDocument1 pageWPS For Carbon Steel THK 7.11 GTAWAli Moosavi100% (1)

- WPS-46 - Gtaw & Smaw Tig + SmawDocument8 pagesWPS-46 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- Joint Detail (Qw-402)Document2 pagesJoint Detail (Qw-402)Nitesh Patel100% (3)

- PT - SAE WPS PQR - MIGAS (PGDP) - Unlocked-2Document16 pagesPT - SAE WPS PQR - MIGAS (PGDP) - Unlocked-2Batara SinagaNo ratings yet

- Welding Procedure Specification: PQR 2" Dia-5.54mm THKDocument2 pagesWelding Procedure Specification: PQR 2" Dia-5.54mm THKNil BorichaNo ratings yet

- (Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Document6 pages(Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Saifulla CmpNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Sax AltoDocument2 pagesSax AltoJohnny GervasioNo ratings yet

- Measure Science AccuratelyDocument41 pagesMeasure Science AccuratelyAnthony QuanNo ratings yet

- San Lam Stratus FundsDocument2 pagesSan Lam Stratus FundsTiso Blackstar GroupNo ratings yet

- Sajid Bhuiya CVDocument3 pagesSajid Bhuiya CVapi-612088476No ratings yet

- Capacity Based On Shear Parameters As Per IS 6403: C C C C W Q Q Q Q F y y y yDocument5 pagesCapacity Based On Shear Parameters As Per IS 6403: C C C C W Q Q Q Q F y y y yKishore KumarNo ratings yet

- V200 User ManualDocument171 pagesV200 User ManualuriahskyNo ratings yet

- v16 n3Document219 pagesv16 n3Mark ReinhardtNo ratings yet

- HackSpace - June 2021Document116 pagesHackSpace - June 2021Somnath100% (1)

- READING U8Document4 pagesREADING U8Như TrầnNo ratings yet

- MJP Rate Schedule for Water Supply Pipeline ProjectDocument6 pagesMJP Rate Schedule for Water Supply Pipeline ProjectJalal TamboliNo ratings yet

- Micro800 4-Channel and 8-Channel Analog Voltage/Current Input and Output ModulesDocument12 pagesMicro800 4-Channel and 8-Channel Analog Voltage/Current Input and Output ModulesSyarifudin WahidNo ratings yet

- CV Jubilee Bubala Environmental SpecialistDocument4 pagesCV Jubilee Bubala Environmental SpecialistNomayi100% (2)

- Neil Strauss - The Annihilation Method - Style's Archives - Volume 1 - The Origin of Style - How To Transform From Chump To Champ in No TimeDocument132 pagesNeil Strauss - The Annihilation Method - Style's Archives - Volume 1 - The Origin of Style - How To Transform From Chump To Champ in No TimeDaniel Nii Armah Tetteh100% (2)

- Vernacular Terms in Philippine ConstructionDocument3 pagesVernacular Terms in Philippine ConstructionFelix Albit Ogabang IiiNo ratings yet

- Age Hardening Gold Alloys For JewelryDocument4 pagesAge Hardening Gold Alloys For JewelryReinol Eko SianturiNo ratings yet

- Quickguide Students For CopyrightsDocument2 pagesQuickguide Students For Copyrightslordvorldomort100% (1)

- WEEK 7 ICPS - and - ICSSDocument31 pagesWEEK 7 ICPS - and - ICSScikguhafidzuddinNo ratings yet

- VariablesDocument11 pagesVariablesKzy ayanNo ratings yet

- Falling Weight Deflectometer (FWD) Projects in IndiaDocument13 pagesFalling Weight Deflectometer (FWD) Projects in IndiaKaran Dave100% (1)

- Food, Family, and FriendshipsDocument256 pagesFood, Family, and FriendshipsBianca PradoNo ratings yet

- Qualitative Research On Vocabulary and Spelling Skills of A Student Chapters I IIIDocument23 pagesQualitative Research On Vocabulary and Spelling Skills of A Student Chapters I IIIarniza blazoNo ratings yet

- Hatsun Supplier Registration RequestDocument4 pagesHatsun Supplier Registration Requestsan dipNo ratings yet

- HistoryDocument20 pagesHistoryAlexandru RomînuNo ratings yet

- LinAlg CompleteDocument331 pagesLinAlg Completes0uizNo ratings yet

- Pub1308 WebDocument193 pagesPub1308 WebyucemanNo ratings yet

- SRT95 Off-Highway Truck Rear Axle Assembly: Structure and Installation Part 2 Parts Presentation Part 3 MaintenanceDocument29 pagesSRT95 Off-Highway Truck Rear Axle Assembly: Structure and Installation Part 2 Parts Presentation Part 3 MaintenanceoktopusNo ratings yet

- Project Management OfficeDocument42 pagesProject Management OfficeqazqazNo ratings yet

- Design Report For Proposed 3storied ResidentialbuildingDocument35 pagesDesign Report For Proposed 3storied ResidentialbuildingMohamed RinosNo ratings yet

- Leadership's Ramdom MCQsDocument48 pagesLeadership's Ramdom MCQsAhmed NoumanNo ratings yet