Professional Documents

Culture Documents

Asphalt Core Dams Veidekke PDF

Asphalt Core Dams Veidekke PDF

Uploaded by

aji0 ratings0% found this document useful (0 votes)

102 views6 pagesOriginal Title

Asphalt Core Dams Veidekke.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

102 views6 pagesAsphalt Core Dams Veidekke PDF

Asphalt Core Dams Veidekke PDF

Uploaded by

ajiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

ASPHALT CORE DAMS

An embankment dam with asphaltic concrete core

“is an appropriate dam type for the very highest future dams”

(COLD Bulletin 84 (1992)

Asphalt Core Dams

Advantages

Asphalt is 2 viscoelestic-plastic, flexible and ductile

material with a self-healing ability if there is tendency

to crack formation caused by differential displace-

ments or earthquake loads

Inside the dam body the asphalt core exists under

near ideal environmental conditions. It will remain

flexible and impervious over the dams lifetime

Placements of asphaltic cores are toa great

extent independent of the weather conditions. In

areas with much rain, the overall construction when

Choosing an asphalt core design, is simplified and

consifuction time shortened when compared with

the construction of clay cores. or asohalt- or concrete

face dams. In cold cimates the construction season

can be prolonged

Asphalt is completely non-harmful to fresh water and

irrigation water reservoirs.

Bitumen, the binder element in asphaltic concrete. is

‘8 natural product and contains no additives that can

pollute the environment or the water itset.

Adam with asphaltic core, permits impounding

during construction allowing potential seasonel water

to be collected prior to full competion of works.

Cofferdam design can often be simplified,

Asphalt cores in the interior of dams orovide the

highest protection against damage caused by acts of

‘war or sabotage

With asphaltic cores, the many scars from clay

borrow pits are eliminated.

Perlormance records from all existing ACED show no

leakage through the core, and provetly designed and

‘buill asphalt core dams are maintenance free

‘Asphalt core dams have proven to be a very competi-

tive alternative to other dam types.

1981-1987, Storvatn dam, Norway

Fairly standard mix-design criteria have been developed

{or the asphaltic concrete in asphaltic cores. The most

economical mix, which has the necessary workabil-

ty. complies with the Fuller's gradation curve for the

aggregates improved with a fine grade component

smaller than 0,063 mm {filler content. To eliminate

segregation and to improve workability, maximum

‘aagregate size should be less than 18 mm. Both gravel

and crushed rack may be used. Normal binder content

lies between 6,5 and 75 %

The properties af asphalt concrete can to a great

extent be tallored to satisfy specific cesign criteria

More and/or softer binder improves ductility and the

self healing properties of the core. This makes asphal-

tic cores especially suited for dams on compressible

foundations or in earthquake regions

Artule of thumb has previously called for a core

thickness at any level of 1% of the water head

With modern construction procedures and

quality control this seems unduly conservative

for high dams, For Storgiomvatn Dam on the

Svartisen Sceme in Northern Norway the

125 mhigh dam hed a core that gredually

tapered from 0.95 m 0.0.5 m

The machinery for placement of the asphalt

core in layers has been greatly improved over

the last 30 years. Mobility is better, the ex

tent of required hand placement is reduced,

and transportation and loading of the asohalt

are simplified, increasing the capacity, reduc-

ing heat lass and improving quality.

The adjacent transition zones are placed

simultaneously with the asphalt giving the

core immediate lateral suppor.

Three rollers, two on the tansition zones

working in parallel and one on the asphalt

core, normally carry out the compaction

The level of the screed is automatically controlled by a

rotating laser which ensures @ horizontal base for the

next layer,

The centerline is marked for each layer and fixed by

means af a thin metal string. A video camera mounted

in front of the machine and a monitor insice the cab

enable the operator to steer with precision following

the string

In front the machine is supplied with a gas fired

infrared heater witch dries and heats the previous

layer if required.

No tack coat is applied between the asphalt concrete

layers, as core sampling has proved that the joint is,

tight and hardly detectible.

20-25cM

Asphalt core impermeability

The single most important property of a core or facing is its imoetmeabil-

ty. Impermeability is achieved in asphalt core dems by strict quality control

and quality assurance of air void content in the asphalt mx - a messure-

ment quickly and easily performed

The relationship between permeability end void content in compacted

asohalt cores is well documented in numerous research projects and

studies. Technical specifications generally stipulate a void content of

< 3% in Marshall samples, at which point asphalt is effectively rendered

impervious.

2008, construction of Nemiscu-1 Dam, first Asphalt Core Rockfill Dam in

North-America

Impermeabilty of asphalt concrete as a

unetion of av wig content

af : i

11s common practice during the design

‘phase to use (naval tess f0 investigate

the stress-strn-sirength properties of ihe

compacted asphalt core mx, The mix may

Ihave t0 be changed if the tax! results re

‘not savstactory

Asphalt Concrete Core for Embankment Dams

(acc)

For more than 50 years, asphalt concrete has been used as an impermeable

central (core) wall in embankment dams with a perfect no-leakage record.

The very first asphaltic core dam was built in Germany in 1962. As of today,

worldwide, more than 130 asphalt core embankment dams have been built.

The interest in asphalt core technology has been bolstered by comprehensive

technological research and the development of modern machinery. During the

last 5 years, nine such dams have been built in North and South America.

Veidekke, with 30 years of experience, is internationally recognized as the

world’s leading Asphalt Core Dam contractor and is well renowned for

its excellent cooperation with clients, consultants and local contractors.

NTT aoe) ol Roe ode ae eo eo) ola eee a

studies, initial testing, mix designs, supervision, on-site training, and

eas a Cee

Veidekke

om: Ber Lrg

Re ene EU ea Rem OLR

Tel: +47 21 05 50 50 © Fax: +47 21055051

Peg OC eae Ley

A NU eC Ue ee au RC RC Lad

Ree Sie

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Area Kegiatan IPDMIPDocument1 pageArea Kegiatan IPDMIPajiNo ratings yet

- 2.3 - Analisa EskalasiDocument8 pages2.3 - Analisa EskalasiajiNo ratings yet

- KAK DD Rehab Tambak - SerangDocument22 pagesKAK DD Rehab Tambak - SerangajiNo ratings yet

- 2.2 - Index Kontrak MYCDocument6 pages2.2 - Index Kontrak MYCajiNo ratings yet

- Cover Katalog Sungai JangkokDocument2 pagesCover Katalog Sungai JangkokajiNo ratings yet

- SOP Waduk Cascade CitarumDocument11 pagesSOP Waduk Cascade CitarumajiNo ratings yet

- DD Rehab TambakDocument11 pagesDD Rehab TambakajiNo ratings yet

- What Is The Implementation Completion and Results Report?Document58 pagesWhat Is The Implementation Completion and Results Report?ajiNo ratings yet

- Peta Pola Kab. BandungDocument1 pagePeta Pola Kab. BandungajiNo ratings yet

- Dokumen Permiritaan Memasukkan Penawaran: Dam Operational Improvement An13 Safety Project (Doisp)Document9 pagesDokumen Permiritaan Memasukkan Penawaran: Dam Operational Improvement An13 Safety Project (Doisp)ajiNo ratings yet

- OP BendunganDocument38 pagesOP BendunganajiNo ratings yet

- Guidelines ICRDocument62 pagesGuidelines ICRajiNo ratings yet

- TOR Supervisi Remedial - SetupatokDocument38 pagesTOR Supervisi Remedial - SetupatokajiNo ratings yet

- ASEIDocument1 pageASEIajiNo ratings yet

- Ahli Dokumen LelangDocument6 pagesAhli Dokumen LelangajiNo ratings yet

- Petunjuk Ops - RTRW Kab BandungDocument66 pagesPetunjuk Ops - RTRW Kab BandungajiNo ratings yet

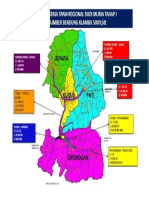

- SPAM Dadi MuriaDocument1 pageSPAM Dadi MuriaajiNo ratings yet

- E-Procurement Practices in IndonesiaDocument10 pagesE-Procurement Practices in IndonesiaajiNo ratings yet