Professional Documents

Culture Documents

Medidor de Tension de Correas

Medidor de Tension de Correas

Uploaded by

ivan osorioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Medidor de Tension de Correas

Medidor de Tension de Correas

Uploaded by

ivan osorioCopyright:

Available Formats

INSTRUCTIONS

www.toolconnection.co.uk

info@toolconnection.co.uk of our catalogue.

Email please call or write for a copy

tools and equipment in our range,

01926 815888 If you would like details of other

3899

Fax

01926 815000

FOR CAM BELTS www.lasertools.co.uk Sales Direct

GAUGE ENGLAND

TENSIONING Southam Warwickshire CV47 0DR

UNIVERSAL Kineton Road Industrial Estate

The Tool Connection Ltd

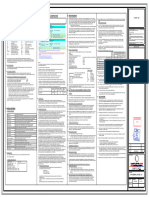

UNIVERSAL TENSIONING GAUGE FOR CAMBELTS Top

Large Scale

This tensioning gauge can be used to adjust the tension on the cam belts where the

UNIVERSAL

movement of the timing belt is measured by load (Nm). TENSIONING GAUGE

Suitable for use on Cam belts with various belt thickness

(For belts other than 5mm thickness see Cam Belt Size below) Optinum

FOR CAM BELTS

Tension

• Easy to use

• Clear incremental marking with knurled knob for precise

Bevelled

measurement Edge Bottom

• Dual scale allows reading from top or bottom of tool (Large and small numbers

Small Scale

for compatibility)

Precise

ALWAYS USE MANUFACTURERS’ RECOMMENDATIONS FOR CAM BELT TENSION AND Setting

POSITION OF MEASUREMENT. (E.g. between the timing gear and the water pump

pulley).

INSTRUCTIONS To adjust tension

To check tension 1. Using tensioning tool (as appropriate) apply sufficient force to the tensioning pulley until the sliding

1. Select correct position for tension measurement as recommended by the manufacturer’s scale indicates the correct value.

instructions. 2. Tighten the locking bolt on the tensioning pulley with the appropriate tool

(Measurements are visible from both sides of the tensioner). Cam Belt Size

2. Attach tensioner to Cam belt with Internal Slide visible from either side. (If using the reverse of the For belts thicker than 5mm – add the difference to the Tension Setting and Optimum Tension

tool make sure the smaller increments are used for precision setting)

For example

3. Check the manufacturers details for Cam belt tension including Cam Belt Deflection (mm) and Cam

If

Belt load (daN)

Cam Belt thickness is 6mm

4. Using the grid below find the appropriate tension setting (as shown)

and

5. Rotate the knurled knob until the beveled edge is on the required tension setting. Use the

Cam Belt Load 4.5daN

increments on the knob for precise setting.

Cam Belt Deflection 3.5mm

6. Read the actual tension from the internal slide and compare it with the Optimum Tension on the

Then

Grid. (If the internal slide is not visible it is likely it has been covered by the knurled knob and is Tension Setting = 16.0mm +1mm = 17.0mm

the Cam Belt is too tight – by slackening the tensioning pulley the internal slide should appear)

Optimum Tension = 13.0mm +1mm = 14.0mm

7. Adjust as necessary

LOAD ON THE CAM BELT (daN)

Shown by vehicle manufacturer

Cam Belt Deflection (mm) 0.0 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 7.9

Tension Setting 23.5

0.0

Optimum Tension 16.5

Tension Setting 19.9 19.5 19.0 18.6 18.1 17.7 17.2 16.8 16.4 16.0

0.5 Optimum Tension 16.0 16.0 16.0 16.0 16.0 16.0 16.0 16.0 16.0 16.0

Tension Setting 19.8 19.4 19.0 18.5 18.1 17.6 17.2 16.7 16.3 15.9 15.5

1.0 Optimum Tension 15.5 15.5 15.5 15.5 15.5 15.5 15.5 15.5 15.5 15.5 15.5

Values shown by vehicle manufacturer

Tension Setting 19.8 19.3 18.9 18.5 18.0 17.6 17.1 16.7 16.2 15.8 15.4 15.0

1.5 Optimum Tension 15.0 15.0 15.0 15.0 15.0 15.0 15.0 15.0 15.0 15.0 15.0 15.0

Tension Setting 19.7 19.3 18.8 18.4 18.0 17.5 17.1 16.6 16.2 15.7 15.3 14.9 14.5

2.0 Optimum Tension 14.5 14.5 14.5 14.5 14.5 14.5 14.5 14.5 14.5 14.5 14.5 14.5 14.5

Tension Setting 19.7 19.2 18.8 18.3 17.9 17.5 17.0 16.6 16.1 15.7 15.2 14.8 14.4 14.0

2.5 Optimum Tension 14.0 14.0 14.0 14.0 14.0 14.0 14.0 14.0 14.0 14.0 14.0 14.0 14.0 14.0

Tension Setting 19.6 19.2 18.7 18.3 17.8 17.4 17.0 16.5 16.1 15.6 15.2 14.7 14.3 13.9 13.5

3.0 Optimum Tension 13.5 13.5 13.5 13.5 13.5 13.5 13.5 13.5 13.5 13.5 13.5 13.5 13.5 13.5 13.5

Tension Setting 19.1 18.7 18.2 17.8 17.3 16.9 16.5 16.0 15.6 15.1 14.7 14.2 13.8 13.4 13.0

3.5 Optimum Tension 13.0 13.0 13.0 13.0 13.0 13.0 13.0 13.0 13.0 13.0 13.0 13.0 13.0 13.0 13.0

Tension Setting 18.6 18.2 17.7 17.3 16.8 16.4 16.0 15.5 15.1 14.6 14.2 13.7 13.3 12.9 12.5

4.0 Optimum Tension 12.5 12.5 12.5 12.5 12.5 12.5 12.5 12.5 12.5 12.5 12.5 12.5 12.5 12.5 12.5

Tension Setting 18.1 17.7 17.2 16.8 16.3 15.9 15.5 15.0 14.6 14.1 13.7 13.2 12.8 12.4 12.0

4.5 Optimum Tension 12.0 12.0 12.0 12.0 12.0 12.0 12.0 12.0 12.0 12.0 12.0 12.0 12.0 12.0 12.0

Tension Setting 17.6 17.2 16.7 16.3 15.8 15.4 15.0 14.5 14.1 13.6 13.2 12.7 12.3 11.9 11.5

5.0 Optimum Tension 11.5 11.5 11.5 11.5 11.5 11.5 11.5 11.5 11.5 11.5 11.5 11.5 11.5 11.5 11.5

Tension Setting 17.1 16.7 16.2 15.8 15.3 14.9 14.5 14.0 13.6 13.1 12.7 12.2 11.8 11.4 11.0

5.5 Optimum Tension 11.0 11.0 11.0 11.0 11.0 11.0 11.0 11.0 11.0 11.0 11.0 11.0 11.0 11.0 11.0

Tension Setting 16.6 16.2 15.7 15.3 14.8 14.4 14.0 13.5 13.1 12.6 12.2 11.7 11.3 10.9 10.5

6.0 Optimum Tension 10.5 10.5 10.5 10.5 10.5 10.5 10.5 10.5 10.5 10.5 10.5 10.5 10.5 10.5 10.5

Tension Setting 16.1 15.7 15.2 14.8 14.3 13.9 13.5 13.0 12.6 12.1 11.7 11.2 10.8 10.4 10.0

6.5 Optimum Tension 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cameron Ring Joints DescriptionDocument8 pagesCameron Ring Joints DescriptionEDWIN M.PNo ratings yet

- Snap-Tite75 Series-Catalog 3800 - SectionBDocument3 pagesSnap-Tite75 Series-Catalog 3800 - SectionBfrancis_15inNo ratings yet

- Cushman - Cushman XP Sprayer - 7005734 - PartsDocument65 pagesCushman - Cushman XP Sprayer - 7005734 - Partsferminwinnie101No ratings yet

- Cam and Follower: Omar Ahmad Ali Ayman Mohammad Alkhwiter Eid Sunhat AlharbiDocument17 pagesCam and Follower: Omar Ahmad Ali Ayman Mohammad Alkhwiter Eid Sunhat AlharbiOmar AhmedNo ratings yet

- 3 Piece Burr Puzzle Build and SolveDocument14 pages3 Piece Burr Puzzle Build and Solvepedro.guzmanNo ratings yet

- The Viscosity and Density of Sulphuric Acid and OleumDocument4 pagesThe Viscosity and Density of Sulphuric Acid and OleumSyaifullah Sa'abaNo ratings yet

- STR Final 02112319473547375Document20 pagesSTR Final 02112319473547375Muhammad AfrasiyabNo ratings yet

- AT03121 - Last Chance Filter ClogDocument4 pagesAT03121 - Last Chance Filter ClogJheison ValenciaNo ratings yet

- Ground MILLHOGDocument22 pagesGround MILLHOGrnachooosNo ratings yet

- Anchoring and Dock AccessoriesDocument40 pagesAnchoring and Dock AccessorieswguenonNo ratings yet

- CHANCE TDM Edition 3 PDFDocument410 pagesCHANCE TDM Edition 3 PDFPaul BardoffNo ratings yet

- Nara Bassinet Maintenance ManualDocument46 pagesNara Bassinet Maintenance ManualAnonymous KiraNo ratings yet

- CR (N) 2&4 D&RDocument14 pagesCR (N) 2&4 D&RRudo RockNo ratings yet

- Sc41-45ta-Ca GB04 6053 - 174Document646 pagesSc41-45ta-Ca GB04 6053 - 174Phan Văn100% (1)

- FORM P-2 MANUFACTURERS DATA REPORT FOR ALL TYPES OF BOILERS EXCEPT WATERTUBE AND ELECTRIC Edit2017Document3 pagesFORM P-2 MANUFACTURERS DATA REPORT FOR ALL TYPES OF BOILERS EXCEPT WATERTUBE AND ELECTRIC Edit2017msb_75No ratings yet

- Cutting DepartmentDocument8 pagesCutting Departmentjohnchristy2002100% (1)

- Guide of Anchoring A Ship PDFDocument19 pagesGuide of Anchoring A Ship PDFRashidul HasanNo ratings yet

- 1st R.A DPDC NDDocument27 pages1st R.A DPDC NDAbigail SpencerNo ratings yet

- Puff Panel Plan NewDocument1 pagePuff Panel Plan NewahahNo ratings yet

- Manual For First Year's Swing GateDocument8 pagesManual For First Year's Swing GateNoah AlbrechtNo ratings yet

- Tfu 28.00.00.011 7 PDFDocument2 pagesTfu 28.00.00.011 7 PDFPHI nguyễnNo ratings yet

- 4-12 Uht-20 SN801+Document75 pages4-12 Uht-20 SN801+Alexander DonatoNo ratings yet

- Shear Wall MOSDocument8 pagesShear Wall MOSAsdia Aseffah FathiyaNo ratings yet

- Hira Gi SheetDocument1 pageHira Gi SheetChandresh SinghNo ratings yet

- PRAMAC - Service and Parts Online CenterDocument20 pagesPRAMAC - Service and Parts Online CenterChasiwat aksornpreechanonNo ratings yet

- Automatic Condensate Drains Eco Drain Series: For Compressor Capacities Up To 1,700 M /minDocument7 pagesAutomatic Condensate Drains Eco Drain Series: For Compressor Capacities Up To 1,700 M /minCatalin Frincu100% (1)

- SF YLMC1 2DP CAD MULT Instld Yield-Link-Installation-1-Detail-SheetDocument1 pageSF YLMC1 2DP CAD MULT Instld Yield-Link-Installation-1-Detail-Sheetdiegopizarro23No ratings yet

- BISSELL User Guide PowerLifter Pet Bagged 2019 Vacuum PDFDocument24 pagesBISSELL User Guide PowerLifter Pet Bagged 2019 Vacuum PDFJeff DonnellyNo ratings yet

- Data Sheet BRCMDocument20 pagesData Sheet BRCMDiego MartinezNo ratings yet

- Choke Manifold JHCDocument31 pagesChoke Manifold JHCahouaNo ratings yet