Professional Documents

Culture Documents

SWS Brochure

Uploaded by

Anonymous XzGgqTOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SWS Brochure

Uploaded by

Anonymous XzGgqTCopyright:

Available Formats

Jarry Sud

Water Technologies Kinmen - Taiwan

UNITS CAPACITY: 10-500 m /h 3

Ras Laffan-Qatar

UNITS CAPACITY: 50-2000 m /h 3

Azito - Cyprus La Spezia - Italy

UNITS CAPACITY: UP TO 1000 m3/h

SEA WATER DESALINATION Units DEAERATORS Thermal & Vacuum WATER & CONDENSATE Treatments

The Sea Water Desalination, by thermal evaporation MED (Multiple Effects Distillers) MVC (Mechanical Vapor(re) The Water Deaeration is necessary Spray & Trays SWS designs and supplies water treatment Industrial waste

process, is usually recommended whenever a heavy duty & ME/TVC (Vapour Thermo (re) Compression) for boilers and steam generators to eliminate Arrangement plants for the production of make-up water water treatment

desalination unit is requested for industrial use. the dissolved oxygen and preventing to boilers and of process water to refineries

The thermal evaporation units can be arranged according Compression) MVC process the boilers from corrosion. The usual required The feed water is sprayed above the trays. and petrochemical plants. The following - Deoiling (CPI separators)

to the following process families; duty is 5ppb as residual oxygen content. The inlet heating steam is conveyed from technologies are available and covering - Clari-Flocculation

Process: Similar to the MED / TVC process in terms of evaporator

the bottom by the walls of the same chamber, - Biological Treatment

each of these realizes a vacuum evaporation of the sea The sea water distillation is realized by heat transfer arrangement, the energy input is here from electric source The Thermal deaeration process involves the widest range of applications:

water, either by flash or by surface heat transfer, and no steam is required. A limited number of effects is the reaching of the saturation condition so that a countercurrent flow is established All SWS units are custom designed according

between condensing vapor and a thin liquid falling

and involves an energy input which is given applicable due to the low available pressure gain, usually of the water to reduce the partial pressure between the steam and the falling water. to the specific requirements of each project.

film evaporating. The process takes place through

by LP steam. The MVC process only doesn’t require a number of evaporation stages (effects) each of them arranged as single effect for small units or double effect for of the dissolved gases: under this condition While falling, the water is heated up to the Raw water treatment The expertise of SWS in the water technologies

larger units. working saturation condition and releases is then extended to every kind of treatments

for steam but electric power. working at a different pressure. Through this cascade the gas content in a saturated liquid is zero, - Clarification

Sea water excess is not required but only the make-up flow the gas content, so that at the last trays layer and uses, as SWS enjoys the most complete

of stages the vacuum rises up to the final condenser. the gases tendency is therefore leaving - Dechlorination

to the evaporator. no gas is present in water. scientific know-how in the field of the water

When Thermocompressor is applied, the liquid phase, crossing the liquid-vapor - Deferrization

MSF (Multi Stage Flash) the primary steam is supplied in pressure MVC special features interface and migrate to the vapor phase. The deaerated water falls down in the below

- Sand and multi-media filtration and its applications.

as motive fluid for the recompression of a portion - Activated carbon filters

MSF process: WELL TESTED PROCESS OPTIMIZATION PROGRAMS holding tank. Connections are also arranged

of vapor, by this increasing the mass performance Saturated conditions may be realized either - Reverse osmosis package units

The sea water evaporation is realized by flash - Coming from decades of field experience as steam pressure balance, since it is important

of the system. in pressure or under vacuum. On this basis - Demineralization units through ion

into multiple flash chambers each of them working - High thermal efficiency to have no pressure difference between the

Sea water is required in excess the deaerators can be divided into exchange resins

at a different pressure. Sea water is required in large - Optimization with the Thermocompressor tower and the tank.

as cooling medium, in order of the heat reject the following process families:

excess as cooling medium, in order to the heat performance The quality standards of SWS units are

for Heat Balance closure while only a portion

in compliance with the most severe requisitions

reject for Heat Balance closure, while only of the total sea water demand is used

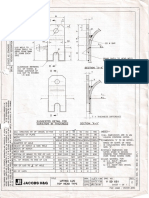

TUBE FIXING WITH RUBBER GROMMETS (PROPRIETARY

Thermal deaerators

of the Power Industry. Our expertize include

Desalinated

a portion of the total sea water demand is used as make-up to the process.

TECHNOLOGY)

Operating at the saturated conditions either

condensate, make-up demineralized water

water treatments

as make-up water to the evaporator. atmospheric or under pressure with steam inlet.

MED and ME/TVC special features: - Employment of low grade material tubes and sea water to be deaerated in a large range - Chemical conditioning through

MSF special features: WELL TESTED PROCESS OPTIMIZATION PROGRAMS - Absence of galvanic corrosion of production rates from 10t/h up over 1000t/h. chemicals dosing units

Flash deaerators

WELL TESTED PROCESS OPTIMIZATION PROGRAMS - Coming from decades of field experience Operating under vacuum without steam inlet. - Demineralization by ion exchange

- Coming from decades of experience - High thermal efficiency TUBES STIFFENING WITH PLASTIC DISTANCERS The efficiency of the process arrangement, - Resin mixed bed filters

The kinetic process is then an important factor Trieste - Italy

- High thermal efficiency - Optimization with the Thermocompressor performance - Ease in tubes dismantling the excellent design of the spraying valves - Remineralization units by either salts

since the resident time must be set adequate

- Optimization of the brine recirculation - Complete absence of direct contact between and trays, the ability in localizing large portions dosing and mineral bed drums

to let the time to gases for disengaging (potabilization)

TUBE FIXING WITH RUBBER GROMMETS different metals of the construction works worldwide enhance

from the liquid phase.

EXCELLENT DEAERATION OF SEA WATER MAKE UP WATER (PROPRIETARY TECHNOLOGY) SWS’s flexibility and competitiveness.

- No need for oxygen scavengers - Employment of low grade material tubes SED® SYSTEM (SWS patent)

- Prevention of corrosion - Absence of galvanic corrosion - Desalinated water TDS < 0,5 ppm Condensate

water treatment

SED® SYSTEM

WELL PROVEN PROPRIETARY DESIGN TUBES STIFFENING WITH PLASTIC DISTANCERS - Fine physical filtration through self

OF BRINE TRENCHES (PRE-FLASH) - Ease in tubes dismantling The produced vapor is driven through a double layer cleaning cartridges filters Chivasso - Italy

- Wide range of modulation of the brine recirculation - Complete absence of direct contact between demisters battery, a thin spray film of water is placed - Deoiling on either activated carbons and

- Enhanced operation flexibility (lower TDR) different metals in between. The achieved consequence is a vapor coalescing resin filters

SED® SYSTEM (SWS patent) washing so that droplets escaping are free from salts - Polishing by ion exchange resins

- Desalinated water TDS < 0,5 ppm SED® SYSTEM (SWS patent) more than in conventional demister banks, resulting through systems with either internal

- Desalinated water TDS < 0,5 ppm in a distilled water purity up to 0,5 ppm. Spray Valves and external regeneration process

GROMMETS - Electrodeionization package units

The seal tube-to-shell side is well ensured at the low - Chemical conditioning units by

operating pressure difference. This method allows chemicals injection

for complete disconnection between different metals (for Boiler Feed Water)

and granting for absence of galvanic effects

and the relevant corrosion phenomena, by this

sacrificial anodes are no more necessary

compared with conventional technology.

It also enables ease in assembly and dismantling

of the tube bundle in connection to the SWS

typical evaporator arrangement.

MED process MSF process Grommets detail Piombino-Italy Cutro- Italy

Who we are...

Company

SWS was estabilished in 1996 with the scope to design and supply,

on its proprietary know-how, package units for the primary water

treatment and the production of pure water for industrial use in power

generation, oil & gas and petrochemical industry.

SWS is the operational division of Sofinter S.p.a. dedicated to water

treatment technologies.

Skills and capabilities

The in-house product development is extensive and the engineering

capabilities cover all of the disciplines for process calculation, basic

design, mechanical, electrical and instrumentation detail design.

Continuous attention to the products update and continuous r&d

programs devoted to the constant improvement of the technology

complete the profile of SWS.

The professional and flexible company structure of SWS is particularly

suitable to meet the customers different needs by provision of the proper

custom designed solution.

The project management is oriented to the customer satisfaction while

keeping the job schedule under control.

Certifications

One of SWS major target is the achievement of excellent results.

SWS operates in strict compliance with its quality system which is certified

ISO 9001 : 2000. Moreover, SWS is committed to pursue

an effective policy for the environment protection; the relevant

procedures are taking care of the ambient impacts while keeping under

control the quality of the equipment design and fabrication phases.

Worldwide reference

The membership to Sofinter is conferring to SWS the most effective

worldwide service capability for a timely and appropriate after-sale

assistance.

Plants are arranged as package units delivered on ExWorks,

FOB, CIF, DDU, FOT basis according to customer needs.

Saline Water Specialists

SEA WATER DESALINATION UNITS

THERMAL & VACUUM DEAERATORS

WATER & CONDENSATE TREATMENTS

Largo Buffoni, 3 21013 Gallarate (VA) Italy

Tel. +39 0331 738204 - Fax +39 0331 738229

swsinfo@swsonweb.com - www.swsonweb.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Vol. 2 Table of Contacts HPP&G Vol 2 0806 Rev0913Document7 pagesVol. 2 Table of Contacts HPP&G Vol 2 0806 Rev0913amandalodgeNo ratings yet

- MBBR PDFDocument40 pagesMBBR PDFAquasoul Co100% (4)

- Boiler Design Fundamentals and Procedure GuideDocument5 pagesBoiler Design Fundamentals and Procedure GuideAnonymous XzGgqTNo ratings yet

- Maximizing weld strength and vessel integrityDocument1 pageMaximizing weld strength and vessel integrityAnonymous XzGgqTNo ratings yet

- Bomb Defusal ManualDocument23 pagesBomb Defusal ManualcontactzumorioNo ratings yet

- Sorf Flange Detail S.No NB Class Size in Inch Fastners Size Bolt Length IN MMDocument17 pagesSorf Flange Detail S.No NB Class Size in Inch Fastners Size Bolt Length IN MMAnonymous XzGgqTNo ratings yet

- Is 800: 1984Document144 pagesIs 800: 1984Guru Prasad92% (12)

- Time Vs Vacuum: S.No Time (Min) Time Difference Vacuum Pressure (Mbar)Document3 pagesTime Vs Vacuum: S.No Time (Min) Time Difference Vacuum Pressure (Mbar)Anonymous XzGgqTNo ratings yet

- End Plate Vs Dished HeadDocument2 pagesEnd Plate Vs Dished HeadAnonymous XzGgqTNo ratings yet

- Is 800: 1984Document144 pagesIs 800: 1984Guru Prasad92% (12)

- CodeDocument7 pagesCodeAnonymous XzGgqTNo ratings yet

- Heat TreatmentDocument5 pagesHeat TreatmentAnonymous XzGgqTNo ratings yet

- Welding Metallurgy for InspectorsDocument27 pagesWelding Metallurgy for InspectorsAnonymous XzGgqTNo ratings yet

- Pipe ScheduleDocument1 pagePipe ScheduleAnonymous XzGgqTNo ratings yet

- Bomb Defusal ManualDocument23 pagesBomb Defusal ManualcontactzumorioNo ratings yet

- Development of Cone: Mean Dia Larger Diameter D: Smaller Diameter D: Thickness of The Plate Length of The Cone LDocument2 pagesDevelopment of Cone: Mean Dia Larger Diameter D: Smaller Diameter D: Thickness of The Plate Length of The Cone LAnonymous XzGgqTNo ratings yet

- House Drain and Sewer RequirementsDocument4 pagesHouse Drain and Sewer RequirementsCristian OmacNo ratings yet

- Surface Water Treatment PlantDocument4 pagesSurface Water Treatment Plantmisama910No ratings yet

- Water Treatment Plant WTP Process Sequence of Water Treatment PlantDocument4 pagesWater Treatment Plant WTP Process Sequence of Water Treatment Plantzynab123No ratings yet

- Brian Boswell, P.E. UIUC Operations ManagerDocument8 pagesBrian Boswell, P.E. UIUC Operations ManagerbooboosdadNo ratings yet

- Unit7-3-WWT-Biological Treatment PDFDocument85 pagesUnit7-3-WWT-Biological Treatment PDFnickNo ratings yet

- PID NGOMA+Layout Option 1 & 2-WTP - PRINCIPAL OPTION 2Document1 pagePID NGOMA+Layout Option 1 & 2-WTP - PRINCIPAL OPTION 2manzi gratienNo ratings yet

- HTES Company ProfileDocument9 pagesHTES Company ProfileNISHANTH GANESHNo ratings yet

- Circular Clarifier Design & Rebuild ServicesDocument5 pagesCircular Clarifier Design & Rebuild ServicesLien NguyenNo ratings yet

- Sewage Treatment PlantDocument22 pagesSewage Treatment PlantJordan Allen BarriosNo ratings yet

- Bilfinger Water Technologies - Global Unit Water Treatment - EDocument40 pagesBilfinger Water Technologies - Global Unit Water Treatment - EmohamedNo ratings yet

- The Expertise Behind The Worlds WWW Solutions - Xylem (ITT)Document36 pagesThe Expertise Behind The Worlds WWW Solutions - Xylem (ITT)sandip333No ratings yet

- Introduction to Sedimentation in Water and Wastewater TreatmentDocument4 pagesIntroduction to Sedimentation in Water and Wastewater TreatmentMassofia MANo ratings yet

- Approval document titleDocument1 pageApproval document titleKhalid OnlyNo ratings yet

- Literature Review On Wastewater TreatmentDocument8 pagesLiterature Review On Wastewater Treatmentfvg93a8v100% (1)

- Gap II Funding - Project Listing - Final - April 18 2018Document4 pagesGap II Funding - Project Listing - Final - April 18 2018The Republican/MassLive.comNo ratings yet

- Zeosorb Brochure PDFDocument4 pagesZeosorb Brochure PDFcfaguaNo ratings yet

- Data Sheet: Clarifier AP: Description Lamella SeparatorDocument2 pagesData Sheet: Clarifier AP: Description Lamella SeparatorTuesou MachereNo ratings yet

- PF - Passavant Revolving Chain Screen Kur-CDocument2 pagesPF - Passavant Revolving Chain Screen Kur-Cmohamed100% (1)

- SCIRT 6 Month Work ScheduleDocument8 pagesSCIRT 6 Month Work ScheduleDiacNo ratings yet

- Daftar PustakaDocument3 pagesDaftar PustakaDanies Forensky IrawanNo ratings yet

- Textile Environmental PresentationDocument52 pagesTextile Environmental PresentationNayeem RahmanNo ratings yet

- BRF PresentationDocument22 pagesBRF Presentationárokszállási norbertNo ratings yet

- WPL Lamella Separator Technical DatasheetDocument1 pageWPL Lamella Separator Technical Datasheettallef001No ratings yet

- SIWW2024 Water Convention Call For PapersDocument15 pagesSIWW2024 Water Convention Call For PapersAssistant General Manager R&DNo ratings yet

- Civil - 2018 - Research TopicsDocument17 pagesCivil - 2018 - Research TopicsElizabeth SantiagoNo ratings yet

- ISF019 AWRC D7 Yatala 4-2 123 3Document12 pagesISF019 AWRC D7 Yatala 4-2 123 3Josephine NguNo ratings yet

- Lecture Notes - Sedimentation TankDocument45 pagesLecture Notes - Sedimentation TankJomer Levi PortuguezNo ratings yet

- Industrial Water Treatment-Ufc 3 240 13fnDocument262 pagesIndustrial Water Treatment-Ufc 3 240 13fnh5n1watcherNo ratings yet