Professional Documents

Culture Documents

Iso 11949 1995 PDF

Iso 11949 1995 PDF

Uploaded by

Tri-Sure More Than ClosuresOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Iso 11949 1995 PDF

Iso 11949 1995 PDF

Uploaded by

Tri-Sure More Than ClosuresCopyright:

Available Formats

INTERNATIONAL IS0

STANDARD 11949

First edition

1995-I 2-15

Cold-reduced electrolytic tinplate

Fer-blanc 6lectrolytique lamin a froid

This is a free 6 page sample. Access the full version online.

Reference number

IS0 11949:1995(E)

www.standards.com.au Copyright ISO www.isostandards.com.au

IS0 11949:1995(E)

Foreword

IS0 (the International Organization for Standardization) is a worldwide fed-

eration of national standards bodies (IS0 member bodies). The work of

preparing International Standards is normally carried out through IS0 tech-

nical committees. Each member body interested in a subject for which a

technical committee has been established has the right to be represented

on that committee. International organizations, governmental and non-

governmental, in liaison with ISO, also take part in the work. IS0 collabor-

ates closely with the International Electrotechnical Commission (IEC) on all

matters of electrotechnical Standardization.

Draft International Standards adopted by the technical committees are

circulated to the member bodies for voting. Publication as an International

Standard requires approvallby at least 75 % of the member bodies casting

a vote.

International Standard IS0 11949 was prepared by Technical Committee

ISO/TC 17, Steel, Subcommittee SC 9, Tinplate and b/a&p/ate.

It cancels and replaces IS0 111 l-1:1983, IS0 111 l-2:1983, IS0 4977-I:1984

and IS0 4977-2:1988.

Annexes A and B form an integral part of this International Standard. An-

nexes C, D and E are for information only.

This is a free 6 page sample. Access the full version online.

0 IS0 1995

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced

or utilized in any form or by any means, electronic or mechanical, including photocopying and

microfilm, without permission in writing from the publisher.

International Organization for Standardization

Case postale 56 l CH-1211 Geneve 20 l Switzerland

Printed in Switzerland

ii

www.standards.com.au Copyright ISO www.isostandards.com.au

INTERNATIONAL STANDARD o IS0 IS0 11949:1995(E)

Cold-reduced electrolytic tinplate

1 Scope 3.1 electrolytic tinplate: Low-carbon mild steel

sheet or coil coated on both surfaces with tin that is

This International Standard specifies requirements for applied in continuous electrolytic operation.

single and double cold-reduced low-carbon mild steel

electrolytic tinplate in the form of sheets or coils for 3.2 differentially coated electrolytic tinplate:

subsequent cutting into sheets. Cold-reduced electrolytic tinplate, one surface of

which carries a heavier tin coating than the other.

Single-reduced tinplate is specified in nominal thick-

nesses that are multiples of 0,005 mm, from 0,17 mm 3.3 single cold-reduced: Term used to describe

up to and including 0,49 mm. Double-reduced tinplate those products where the steel substrate has been

is specified in nominal thicknesses that are multiples reduced to the desired thickness in a cold-reduction

of 0,005 mm, from 0,14 mm up to and including mill and subsequently annealed and temper rolled.

0,29 mm.

3.4 double cold-reduced: Term used to describe

This International Standard applies to coils and sheets those products in which the steel base has had a sec-

cut from coils in nominal minimum widths of 500 mm. ond major reduction after annealing.

Annex E lists the relevant clauses for the selected 3.5 standard grade tinplate: Material in sheet form

product. which is the product of line inspection. It is suitable,

under normal conditions of storage, for established

lacquering and printing over the entire surface of the

sheet and does not contain any of the following:

2 Normative references

a) pinholes, i.e. any perforation through the whole

The following standards contain provisions which, thickness of the material;

through reference in this text, constitute provisions of

this International Standard. At the time of publication, b) thickness outside the tolerance range specified in

the editions indicated were valid. All standards are 10.3;

subject to revision, and parties to agreements based

This is a free 6 page sample. Access the full version online.

on this International Standard are encouraged to in- c) surface defects which render the material unsuit-

vestigate the possibility of applying the most recent able for the intended use;

editions of the standards indicated below. Members

of IEC and IS0 maintain registers of currently valid d) damage or shape-related defects which render the

International Standards. material unsuitable for the intended use.

IS0 1024:1989, Metallic materials - Hardness test -

Rockwell superficial test (scales ISN, 3ON, 45N, 15T, 3.6 second grade tinplate: Material which rep-

30T and 45T). resents the best sheets rejected from the standard

grade but may contain sheets exhibiting defects in

IS0 6892:1984, Metallic materials - Tensile testing. surface appearance and shape of limited extent. Suit-

ability for established lacquering and printing over the

entire surface of the sheet is not assured.

3 Definitions 3.7 batch annealed; box annealed (BA): Annealed

by the process in which the cold-reduced strip is an-

For the purposes of this International Standard, the nealed in tight coil form, within a protective atmos-

following definitions apply. phere, for a predetermined time-temperature cycle.

www.standards.com.au Copyright ISO www.isostandards.com.au

IS0 11949:1995(E) 0 IS0

3.8 continuously annealed (CA): Annealed by the 3.18 consignment: Quantity of material of the

process in which cold-reduced coils are unwound and same specification made available for dispatch at the

annealed in strip form within a protective atmosphere. same time.

3.9 finish: Surface appearance of tinplate, deter- 3.19 bulk package; bulk: Packaging unit comprising

mined by the surface characteristics of the steel base a base platform or pallet, the sheets and packaging

together with the conditioning of the tin coating which material. (See pallet.)

can be either flow-melted or unflow-melted.

3.20 pallet: Base platform on which a coil is placed

3.9.1 bright finish: Finish resulting from the use of

to facilitate ready transportation.

temper-mill work rolls that have been ground to a high

degree of polish together with a flow-melted or

unflow-melted tin coating. 3.21 stillage platform: Base platform on which

sheets are stacked to facilitate packing and ready

3.92 stone finish: Finish on flow-melted tinplate transportation.

characterized by a directional pattern, resulting from

the use of final-mill work rolls that have been ground 3.22 sample unit: 750 m of coil cut into sheets, for

to a lower degree of polish than those used for the the purposes of sampling.

smooth finish, together with a flow-melted tin coating.

3.23 line inspection: Final inspection of the finished

3.9.3 silver finish: Finish resulting from the use of product performed by instruments and/or visual

temper-mill work rolls that have been shot blasted, examination at normal production-line speeds.

together with a flow-melted tin coating.

3.24 anvil effect: Effect which a hard anvil can pro-

3.9.4 matt finish: Finish resulting from the use of

duce on the numerical hardness value obtained when

temper-mill work rolls that h,ave been shot blasted, a hardness test is performed on very thin sheet sup-

together with an unflow-melted tin coating. ported on such an anvil.

3.10 coil: Rolled flat strip product which is wound

into regularly superimposed laps so as to form a coil 4 Information to be supplied by the

with almost flat sides. purchaser

3.11 longitudinal bow; line bow: Residual curva- 4.1 General

ture in the strip remaining along the direction of roll-

ing. The following information shall be given in the enquiry

and order to assist the manufacturer in supplying the

3.12 transverse bow; cross bow: Mode of curva- correct material:

ture in the sheet such that the distance between its

edges parallel to the direction of rolling is less than a) the designation as given in clause 5 excluding the

the sheet width. annealing code, unless a specific type of annealing

is required;

3.13 centre buckle; full centre: Intermittent vertical

displacement or wave in the strip occurring other than

This is a free 6 page sample. Access the full version online.

b) the quantity, expressed on an area or mass basis;

at the edges.

c) for single-reduced tinplate, the finish required (see

3.14 edge wave: Intermittent vertical displacement 6.2.1);

occurring at the strip edge when the strip is laid on a

flat surface.

d) marking requirements for differentially coated

tinplate (see clause 12);

3.15 feather edge; transverse thickness profile:

Variation in thickness, characterized by a reduction in

thickness close to the edges, at right angles to the e) any further special requirements.

direction of rolling. NOTE 1 Appropriate classifications are suitable for shaping

operations such as stamping, drawing, folding, beading and

3.16 burr: Metal displaced beyond the plane of the bending, and assembly work such as joint forming, solder-

surface of the strip by shearing action. ing and welding. However, for tin coatings less than

2,8 g/m*, high-speed soft soldering cannot be guaranteed.

Welding, for coatings less than 1,4 g/m*, cannot be guaran-

3.17 rolling width: Width of the strip perpendicular teed. The end use should be borne in mind when the

to the direction of rolling. classification is selected.

www.standards.com.au Copyright ISO www.isostandards.com.au

0 IS0

4.2 Options 5 Designation

In the event that the purchaser does not indicate his 5.1 Single-reduced tinplate

wish to implement any of the options included in this

International Standard and does not specify his re- For the purposes of this International Standard, single-

quirements at the time of the enquiry and order, the reduced tinplate is designated in terms of a temper

product shall be supplied on the following basis: classification based on the Rockwell HR30Tm hard-

ness values given in table 2.

a) with cathodic surface passivation treatment using

a dichromate salt of an alkali metal (see 6.3); Single-reduced material covered by this International

Standard shall be designated by the following charac-

teristics in the given sequence:

b) where differential tin coatings are ordered, the

heavier coated surface shall be indicated by con-

a) a description of the material (either tinplate coil or

tinuous parallel lines spaced at 75 mm intervals

sheet);

(see clause 12);

b) the number of this International Standard;

c) for double-reduced tinplate, with a stone surface

finish (see 6.2.2); c) the temper designation in accordance with table 2;

d) for coils, the location of each joint shall be indi- d) the type of annealing used by the manufacturer

cated by a piece of non-rigid material and punched (see 9.1);

holes (see 11.3);

e) the type of finish (see 3.9);

e) for coils, they shall be dispatched with their cores

vertical and an internal diameter of 420 mm or f) the coating masses and their combinations, E (for

508 mm (see 16.1); equally coated) or D (for differentially coated),

together with numbers representing the nominal

coating mass on each surface (see clause 12);

f) for sheets, the direction of the runners of the

stillage platform is at the discretion of the pro-

ducer but shall be consistent within a consign- g) the dimensions, in millimetres:

ment (see 16.2);

- for coils, strip thickness x width;

g) for sheets, the rolling width shall be either of the - for sheets, thickness x width x length.

two specified dimensions (see note 2);

EXAMPLE

h) with a coating of DOS (see 6.3).

Single cold-reduced tinplate sheet, in accordance with

this International Standard, of steel grade TH61 +SE

(tinplated coating), continuously annealed (CA), stone

4.3 Additional information finish, equally coated with a coating mass of 2,8 g/m*,

with a thickness of 0,22 mm, a width of 800 mm and

This is a free 6 page sample. Access the full version online.

In addition to the information in 4.1 and 4.2, the pur- a length of 900 mm shall be designated:

chaser may wish to provide further information to the

supplier to ensure that the order requirements are Tinplate sheet IS0 11949 - TH6l+SE - CA - stone -

consistent with the end use of the product. E 2,8/2,8 - 0,22 x 800 x 900.

The purchaser shall inform the supplier of any modifi-

cations to his fabrication operations that will signifi- 5.2 Double-reduced tinplate

cantly affect the way in which the tinplate is used.

For the purposes of this International Standard, the

NOTE 2 When ordering double cold-reduced tinplate, the mechanical properties in which double-reduced tin-

purpose of manufacture for which the material is intended plate complying with this International Standard is

should be stated. It should be noted that double cold- supplied are designated in terms of a system of

reduced tinplate is relatively less ductile than single cold- mechanical property classifications based on 0,2 %

reduced tinplate and has very distinct directional properties, proof stress given in table 3.

so for some uses, for example for built-up can bodies, the

direction of rolling should be stated. When double cold-

reduced tinplate is used for built-up can bodies, the direc- Double-reduced material covered by this International

tion of rolling should be around the circumference of the Standard shall be designated by the following charac-

can so as to minimize the hazard of flange cracking. teristics in the given sequence:

www.standards.com.au Copyright ISO www.isostandards.com.au

IS0 11949:1995(E) 0 IS0

a) a description of the material (either tinplate coil or finish required shall be specified at the time of order-

sheet); ing [see 4.1 c)].

b) the number of this International Standard; The appearance is governed by

c) the mechanical property designation (see table 3); a) the surface characteristics of the steel base which

principally result from controlled preparation of the

work rolls used during the final stages of temper

) the type of annealing used by the manufacturer

rolling;

(see 9.1);

b) the mass of the coating applied;

) the coating masses and their combinations, E (for

equally coated) or D (for differentially coated), c) whether the tin layer is flow-melted or unflow-

together with numbers representing the nominal melted.

coating mass on each surface (see clause 12);

the dimensions, in millimetres:

6.2.2 Double-reduced tinplate

- for coils, strip thickness x width;

Double cold-reduced tinplate is usually supplied with a

- for sheets, thickness x width x length. stone surface finish and a flow-brightened tin coating.

EXAMPLE

6.3 Passivation and oiling

Double cold-reduced tinplate coil, in accordance with

this International Standard, of steel grade T620+SE, The surface of electrolytic tinplate is normally sub-

continuously annealed (CA), differentially coated with jected to a passivation treatment and to oiling.

coating masses of 8,4 g/m* and 5,6 g/m*, with a Passivation, produced either by a chemical or an elec-

thickness of 0,18 mm and a width of 750 mm shall be trochemical treatment, gives a surface with an im-

designated: proved resistance to oxidation and improved suitability

for lacquering and printing. Unless otherwise agreed

Tinplate coil IS0 11949 - T620+SE - CA - D 8,4/5,6 - at the time of ordering [see 4.2a)], the usual passiva-

0,18 x 750. tion procedure is a cathodic treatment in a solution of

a dichromate salt of an alkali metal.

6 Manufacturing features Under normal conditions of transport and storage,

electrolytic tinplate shall be suitable for surface treat-

6.1 Manufacture ments such as established lacquering and printing

operations.

The purity of tin used to produce the coating shall be

not less than 99,85 % (m/m). Tinplate coils and sheets are supplied with an oil

coating. The oil shall be one that is recognized (i.e. by

the relevant national or international authority) as

The methods of manufacture of tinplate are the prov-

being suitable for food packaging. Unless otherwise

ince of the manufacturer and are not specified in this

This is a free 6 page sample. Access the full version online.

agreed at the time of ordering [see 4.2 h)], DOS

International Standard.

(dioctyl sebacate) shall be used.

The purchaser shall be informed if any alteration is

made to the method of manufacture that will affect

the properties of the tinplate. 6.4 Defects

NOTE 3 It is recommended that the manufacturer sup-

plies to the purchaser such details of the manufacturing 6.4.1 Coils

process as may assist the purchaser in his efficient use of

the tinplate. The producer is expected to employ his normal quality

control and line inspection procedures to ensure that

the tinplate manufactured is in accordance with the

6.2 Finish requirements of this International Standard.

6.2.1 Single-reduced tinplate However, the production of tinplate coils in continu-

ous-strip mill operations does not afford the oppor-

Single cold-reduced tinplate can be supplied with tunity for removal of all tinplate that does not comply

either a bright, silver, stone or matt finish, and the with the requirements of this International Standard.

www.standards.com.au Copyright ISO www.isostandards.com.au

ISO 11949:1995 Cold-reduced electrolytic tinplate

This is a free 6 page sample. Access the full version online.

The remainder of this document

is available for purchase online at

www.saiglobal.com/shop

SAI Global also carries a wide range of publications from a wide variety of Standards Publishers:

Click on the logos to search the database online.

You might also like

- 1 E-1742Document15 pages1 E-1742punitg_2No ratings yet

- Service Manual: (Snowmobile)Document196 pagesService Manual: (Snowmobile)serg perNo ratings yet

- Astm17 0303Document5 pagesAstm17 0303Edgardo Emilio CantillanoNo ratings yet

- Astm B393-09Document6 pagesAstm B393-09Srinivasan KrishnamoorthyNo ratings yet

- PRCI - ACMitigationDocument158 pagesPRCI - ACMitigationwasre100% (2)

- AISE No. 7 Specifications For Ladle HooksDocument7 pagesAISE No. 7 Specifications For Ladle HookscadyfemNo ratings yet

- MSS SP 25 Marking System For Valves PDFDocument29 pagesMSS SP 25 Marking System For Valves PDFMariano Emir Garcia OdriozolaNo ratings yet

- Iso 642-1999Document24 pagesIso 642-1999jerfmos100% (3)

- EGWDocument2 pagesEGWpratishgnairNo ratings yet

- Se 1316Document46 pagesSe 1316leonciomavarezNo ratings yet

- Asme Sec Ii C Sfa-5.11Document32 pagesAsme Sec Ii C Sfa-5.11AliNo ratings yet

- ACCA F1 CBE Black Mock - WWW - ACUTEACCA.TKDocument28 pagesACCA F1 CBE Black Mock - WWW - ACUTEACCA.TKPakistan Dramas80% (5)

- Accelerated Corrosion Testing For Product Qualification: November 2007Document11 pagesAccelerated Corrosion Testing For Product Qualification: November 2007Hendri WaeNo ratings yet

- A508Document8 pagesA508doshi78No ratings yet

- Business Strategy For Cloud IBMDocument16 pagesBusiness Strategy For Cloud IBMMichael PangNo ratings yet

- SEC Form F-100Document2 pagesSEC Form F-100Jheng Nuqui50% (2)

- CS-2 CS-3Document24 pagesCS-2 CS-3Anonymous V9cxdfNo ratings yet

- SSPC Visual 2Document5 pagesSSPC Visual 2Chris Mendoza100% (1)

- ASTM E1003 13 Hydrostatic Leak Testing 1 PDFDocument3 pagesASTM E1003 13 Hydrostatic Leak Testing 1 PDFAndrea Fabiana BlaschiNo ratings yet

- A271 96Document3 pagesA271 96nishanthNo ratings yet

- 18 Astm A403 A403m-2018Document10 pages18 Astm A403 A403m-2018FYNo ratings yet

- Certification Document - Da200 Contour ProbeDocument1 pageCertification Document - Da200 Contour ProbeTonyRiverosBecerraNo ratings yet

- Pages Welding High Strength Bolts: Anchor Bolt and Construction Fastener ManufacturerDocument4 pagesPages Welding High Strength Bolts: Anchor Bolt and Construction Fastener ManufacturermauricioveracorreaNo ratings yet

- Compressible-Washer-Type Direct Tension Indicators For Use With Structural FastenersDocument5 pagesCompressible-Washer-Type Direct Tension Indicators For Use With Structural FastenersDarwin DarmawanNo ratings yet

- ASTM B 337 Seamless & Welded Titanium & Titanium Alloy Pipe - 1995Document4 pagesASTM B 337 Seamless & Welded Titanium & Titanium Alloy Pipe - 1995ecsuperalNo ratings yet

- En 10025-2Document4 pagesEn 10025-2Sebastián Araya MoraNo ratings yet

- Astm A6 2004 PDFDocument64 pagesAstm A6 2004 PDFSofiaJabadanEspulgarNo ratings yet

- ASTZM E1476-97 Metals Sorting Guide PDFDocument12 pagesASTZM E1476-97 Metals Sorting Guide PDFKewell LimNo ratings yet

- ASTM E340-95 Standard Method of Macroetch Metal AlloyDocument11 pagesASTM E340-95 Standard Method of Macroetch Metal Alloynearmiss82100% (1)

- Api 578 Positive Material Identification Pmi PDFDocument24 pagesApi 578 Positive Material Identification Pmi PDFSANKARAN.KNo ratings yet

- Astm A270 PDFDocument1 pageAstm A270 PDFgaminNo ratings yet

- Astm B337 PDFDocument1 pageAstm B337 PDFgaminNo ratings yet

- Sfa-5 31Document10 pagesSfa-5 31Sarvesh MishraNo ratings yet

- Specification For Coating SteelDocument28 pagesSpecification For Coating SteelSaud PathiranaNo ratings yet

- A5 10-A5 10M-1999 - R2007PVDocument7 pagesA5 10-A5 10M-1999 - R2007PVfeni4kaNo ratings yet

- API STD 1104 Sept. 2013 Errata1 April 2014 PDFDocument2 pagesAPI STD 1104 Sept. 2013 Errata1 April 2014 PDFIngenius TeamNo ratings yet

- En 13920-2015Document8 pagesEn 13920-2015mihaiNo ratings yet

- Astm A 961-2002Document7 pagesAstm A 961-2002David Cruz PalaciosNo ratings yet

- Astm A 516 Gr.60n Plate SpecificationDocument3 pagesAstm A 516 Gr.60n Plate Specificationharishbabuek100% (1)

- A5 30-A5 30M-2007PVDocument6 pagesA5 30-A5 30M-2007PVJawad MunirNo ratings yet

- Aws-5 18Document42 pagesAws-5 18Nick McalpinNo ratings yet

- Method Statement For In-Situ Metallography Test: DCSM Project 2019Document5 pagesMethod Statement For In-Situ Metallography Test: DCSM Project 2019Thinh NguyenNo ratings yet

- Astm E446 - 10Document4 pagesAstm E446 - 10laythNo ratings yet

- ASTM E1916 - 97 Identificación Positiva Materiales PDFDocument3 pagesASTM E1916 - 97 Identificación Positiva Materiales PDFCristian OtivoNo ratings yet

- Sa 435 (Ed 2013)Document4 pagesSa 435 (Ed 2013)Mohd Idris MohiuddinNo ratings yet

- JIS Z 2320-1-2007 Non-Destructive Testing - Magnetic Particle Testing - Part 1 General Principles-6 PDFDocument31 pagesJIS Z 2320-1-2007 Non-Destructive Testing - Magnetic Particle Testing - Part 1 General Principles-6 PDFNguyễn Hữu BằngNo ratings yet

- Bs 5996Document13 pagesBs 5996Sintha AidroosNo ratings yet

- Qualified Products List OF Products Qualified Under Sae Aerospace Material Specification SAE AMS 2644Document33 pagesQualified Products List OF Products Qualified Under Sae Aerospace Material Specification SAE AMS 2644Sen SeyNo ratings yet

- Echograph 1095 PDFDocument6 pagesEchograph 1095 PDFBlack NevadaNo ratings yet

- Accreditation Criteria For Inspection Programs For Manufacturers of Metal Building Systems AC472Document29 pagesAccreditation Criteria For Inspection Programs For Manufacturers of Metal Building Systems AC472이혁재No ratings yet

- Development of UNS S 32760Document8 pagesDevelopment of UNS S 32760TasmanijskaNemaNo ratings yet

- Norma ASTM A380.27738-1Document12 pagesNorma ASTM A380.27738-1windeletaNo ratings yet

- Asme Section II A Sa-358 Sa-358mDocument10 pagesAsme Section II A Sa-358 Sa-358mAnonymous GhPzn1xNo ratings yet

- A319Document2 pagesA319malika_000% (1)

- Api 1104Document3 pagesApi 1104Tahar DabbarNo ratings yet

- Jis G3101 1995Document14 pagesJis G3101 1995TUAN NGUYEN VANNo ratings yet

- Astm-E1209 - 99Document6 pagesAstm-E1209 - 99DESTINY SIMONNo ratings yet

- Nace Withdrawn Standards PDFDocument2 pagesNace Withdrawn Standards PDFyusbelis0% (1)

- Iso 10630 1994Document9 pagesIso 10630 1994gabriela1963No ratings yet

- Tower AccessoriesDocument2 pagesTower AccessoriesmulualemNo ratings yet

- Continuously Pre-Pained Galvanized Steel Sheets and Coils (First Revision of IS 14246) ICS 77.140.50Document8 pagesContinuously Pre-Pained Galvanized Steel Sheets and Coils (First Revision of IS 14246) ICS 77.140.50Trdipraj VaghelaNo ratings yet

- FRS Electrical Panel Spec EOIDocument20 pagesFRS Electrical Panel Spec EOITravis WoodNo ratings yet

- P208R2 NyomatékokDocument1 pageP208R2 NyomatékokkiaoNo ratings yet

- Chapter 48 P.L. 1999Document4 pagesChapter 48 P.L. 1999RCNo ratings yet

- 2250at 1 HelicopterDocument10 pages2250at 1 Helicopterahmed fouadNo ratings yet

- Clo 1 PPT - GlobalizationDocument16 pagesClo 1 PPT - GlobalizationMila NacpilNo ratings yet

- Encal 3000 Quad Gas Chromatograph Hardware ManualDocument52 pagesEncal 3000 Quad Gas Chromatograph Hardware ManualMohamed El MaadawyNo ratings yet

- File - 20221010 - 105336 - Test 1Document8 pagesFile - 20221010 - 105336 - Test 1Trinh Nông Ngọc LongNo ratings yet

- Cpi Catalog Section 2Document65 pagesCpi Catalog Section 2Seth PortmanNo ratings yet

- Aspirin PDFDocument3 pagesAspirin PDFRayan FuadNo ratings yet

- Astar TutorialDocument5 pagesAstar Tutorialayesha_khan963No ratings yet

- Finance Case Study SolutionDocument4 pagesFinance Case Study SolutionOmar MosalamNo ratings yet

- Campground Concession Business PlanDocument19 pagesCampground Concession Business PlanSirine HedhliNo ratings yet

- Amines All DPPDocument7 pagesAmines All DPPmurugan NishanthNo ratings yet

- Hempalin Enamel 52140: Product CharacteristicsDocument4 pagesHempalin Enamel 52140: Product CharacteristicsM BayuNo ratings yet

- Ebook Ebook PDF Principles of Healthcare Leadership by Bernard J Healey PDFDocument41 pagesEbook Ebook PDF Principles of Healthcare Leadership by Bernard J Healey PDFdonita.nichols650100% (37)

- M CommerceDocument31 pagesM CommerceMustaqeem SheikhNo ratings yet

- Literature Review On Digital ThermometerDocument4 pagesLiterature Review On Digital Thermometerafdtovmhb100% (1)

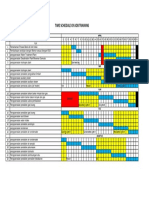

- Time Schedule On Job Training: Elemen Kompetensi AprilDocument1 pageTime Schedule On Job Training: Elemen Kompetensi AprilEastor Rainhard Dogma TambunanNo ratings yet

- CU360 Sales-Guide FinalDocument4 pagesCU360 Sales-Guide FinalDanny Montero FloresNo ratings yet

- Catalog and Data SheetDocument2 pagesCatalog and Data SheetKRISH kmsNo ratings yet

- PCTOCDocument105 pagesPCTOCmvnivanNo ratings yet

- Introduction To Computer SoftwareDocument8 pagesIntroduction To Computer SoftwareJericho ArmamentoNo ratings yet

- Health 10 Module 1Document15 pagesHealth 10 Module 1Kate BatacNo ratings yet

- LumberLok Fixing ManualDocument124 pagesLumberLok Fixing Manualjcvalencia100% (1)

- Production Function With Two Variable Inputs - Iso - QuantDocument13 pagesProduction Function With Two Variable Inputs - Iso - QuantabhilashNo ratings yet

- Tuten 5e PPT02Document20 pagesTuten 5e PPT02deiaaldeen30No ratings yet