Professional Documents

Culture Documents

Brass 58A (CuZn39Pb3) Machining Properties

Uploaded by

darshanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brass 58A (CuZn39Pb3) Machining Properties

Uploaded by

darshanCopyright:

Available Formats

BRASS 58A (CuZn39Pb3)

Pb alloyed free machining brass

Particularities The brass 58A (CuZn39Pb3) is the most used brass for machining on automatic

machines/lathes. It has an excellent machinability.

Furthermore, it can be easily warm formed.

Applications and uses Many different applications

Standards Material number CW614N (former DIN 2.0401)

EN CuZn39Pb3

ISO CuZn38Pb3

UNS / ASTM C38500

NF CuZn40Pb3

SNV CuZn39Pb3

UNI P-CuZn40Pb2

JIS C3603

Chemical composition Cu Pb Ni Fe Sn Al others Zn

(%wt) 57 2.5 max. max. max. max. max. balance

59 3.5 0.30 0.5 0.3 0.005 0.2

Dimensions and

tolerances

•Closer

Round bars and cold drawn:

tolerances on request.

1 – 22 mm ISO h8 (h9)

Executions and Standard delivery condition: thermally stress relieved

Delivery condition • Round bars and shaped bars:

bar ends:

in length of 3 m +50/0

pointed, chamfered

Straightness: 0.5 mm/m

Other executions on request

Availability Standard dimensions on stock, see: Sale program

Mechanical Standard delivery condition: thermally stress relieved

properties According to DIN 12164 Bars: condition: cold drawn (not stress relieved!)

Designation Rm (MPa) R0.2% (MPa) A (%) Hardness Hv/HB

Ø 2 – 6 mm: R550 550 (440) -- (150)

Ø 2 – 14 mm: R500 500 (390) 8 (150)

Ø 2 – 40 mm: R430 430 (250) 10 (120)

Cutting conditions Machining index: 100 (Europe: CuZn39Pb3 = 100; USA: CuZn36Pb3 = 100)

Machinability: very good

Modifications will not be adjusted automatically.

forms short acicular, needle like chips

• The brass 58A in the R550 (Rm = 550 MPa) hard condition can still be more easily

machined than in the semi-hard R400 (Rm = 400 MPa) condition.

• Cutting speed: Vc ≈ 60 - 120 m/min.

Last update 06/2017

The optimal cutting conditions depend on the machine tool, the cutting tools, the chip dimensions (cutting depth

and feed), the cutting speed, the lubricant-cooling fluid, the tolerances and surface roughness to be produced, and,

obviously, the experience of the machinist.

L. Klein AG • Längfeldweg 110 • CH-2504 Biel/Bienne

Telefon 0041 (0)32 341 73 73 • Telefax 0041 (0)32 341 97 20 • www.kleinmetals.swiss • info@kleinmetals.swiss 1/3

BRASS 58A (CuZn39Pb3)

Pb alloyed free machining brass

Microstructure The CuZn39Pb3 brass A58 is a two phases alloy Alpha-Beta in solid solutions. The

Alpha phase is cubic face centered, the Beta phase, richer in Zn, is cubic centered.

• The alloyed Pb addition is not soluble. Pb is present as fine particles uniformly

distributed, predominantly at the grain boundaries.

• The Pb addition permits a better control of the grain size during annealing.

• The volume Pb concentration is approximately 1.5%vol.

• Pb strongly favors the machinability by forming small acicular chips.

Forming Warm: 625 – 725°C, good formability

Cold: limited

• The cold reduction before annealing is limited to 20%.

Welding Gas, arc, WIG and MIG: difficult, not recommended

Resistance welding: average

• A not fully controlled welding operation can lead to Zn loss by dezincification of the

surface zone. The temperature of evaporation of Zn is 906°C only.

• The high Pb content of the Brass 58A renders its welding particularly challenging,

because the solidification shrinkage of the weld pools favors the formation of tensile

internal stresses in the assembled components.

Brazing Average

Soldering Very well adapted to soldering

Gluing Well adapted to gluing

Heat treatments Soft anneal: 450 – 600 °C

Thermal stress relief: 250 – 350 °C

• A stress relieving anneal may reduce the strength of the heat-treated material.

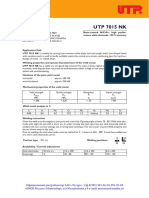

Diagram of the

mechanical properties

Modifications will not be adjusted automatically.

Last update 06/2017

L. Klein AG • Längfeldweg 110 • CH-2504 Biel/Bienne

Telefon 0041 (0)32 341 73 73 • Telefax 0041 (0)32 341 97 20 • www.kleinmetals.swiss • info@kleinmetals.swiss 2/3

BRASS 58A (CuZn39Pb3)

Pb alloyed free machining brass

Polishing Mechanical: very well adapted

Chemical: less adapted

Electrolytic: less to poorly adapted

Laser marking Fairly difficult

• The presence of Pb makes the laser marking more difficult, requiring additional

attention and precautions.

Electroplating Very well adapted

Corrosion resistance • The corrosion resistance of the Brass 58A (CuZn39Pb3) in water, saline and organ-

ic solutions is not as good as with the single phase, homogeneous Alpha brass. Its

Beta phase richer in Zn is more sensitive to corrosion.

• Under given circumstances, a “dezincification“ of the surface zone may take place

in soft water having a high Cl content and low carbonates content.

Stress Corrosion Cracking (SSC):

• Under the influence of internal, external or of both tensile stresses, the Brass 58A

(CuZn39Pb3) exposed to ammoniac, amines, or ammonium salts, can crack, or

even break catastrophically by SSC.

• The tensile stresses prevalent in operation, or build in during assembly of the parts,

may significantly increase the SSC risk.

• SSC can also be prevented, by submitting the finished machined parts, or assem-

blies, to a stress relieving treatment before their final use.

• The usage of thermally stress-relieved bars, as those supplied by L. Klein SA, con-

tribute to reduce – eliminate this risk.

Physical properties Properties Units Temperature (°C)

20 200 300 400

Density g cm-3 8.47

Young modulus of elasticity E GPa 97

Electrical resistance Ω mm2 m-1 0.066 0.083

Thermal coefficient of the K-1 1.7*10-2

electrical resistance

Specific thermal conductivity MS/m 15 12

Thermal expansion m m-1 K-1 20–100°C 20–200°C 20–300°C 20–800°C

10-6 19.3 21.0 21.4 24.7

Thermal conductivity W m-1 K-1 -200°C 20°C

50 123

Specific heat J kg-1 K-1 20°C 100 - 300°C

0.377 0.398

Modifications will not be adjusted automatically.

Magnetism diamagnetic: in the absence of free Fe only

Magnetic susceptibility cm3/g -0.173

1.39*10-4 with 0,15% free Fe present

Melting range 875-890°C

Last update 06/2017

Disclaimer: The information and data of this informative “Data sheet“ are indicative only. They are not use instruc-

tions. The users must define and endorse them in each case.

L. Klein AG • Längfeldweg 110 • CH-2504 Biel/Bienne

Telefon 0041 (0)32 341 73 73 • Telefax 0041 (0)32 341 97 20 • www.kleinmetals.swiss • info@kleinmetals.swiss 3/3

You might also like

- Chronifer M-4108Document3 pagesChronifer M-4108IltefatNo ratings yet

- BS1400 HTB1Document2 pagesBS1400 HTB1Atul KulkarniNo ratings yet

- Carbocast 1 - eDocument1 pageCarbocast 1 - eali torabiNo ratings yet

- Free Machining Brass - Alloy 385Document1 pageFree Machining Brass - Alloy 385Fred Duarte CaldeiraNo ratings yet

- CZ120 (CW612N) : Technical DatasheetDocument1 pageCZ120 (CW612N) : Technical DatasheetAmrut KanungoNo ratings yet

- Hilco Bronsil Aws A5.6 e Cusn-CDocument1 pageHilco Bronsil Aws A5.6 e Cusn-CVICENTE CABALLERONo ratings yet

- Brass Material Property Data Sheet for Custom FastenersDocument2 pagesBrass Material Property Data Sheet for Custom FastenersMuzammil Ali KhanNo ratings yet

- Lasting Connections with Seamless Cored WireDocument2 pagesLasting Connections with Seamless Cored WireDavid RodriguesNo ratings yet

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Document1 pageTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNo ratings yet

- 51 CR V4Document4 pages51 CR V4armin_kunosic9871No ratings yet

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Document3 pagesAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338minhyen88No ratings yet

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Document3 pagesAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Karan NanwaniNo ratings yet

- CZ108 (CW508L) : Technical DatasheetDocument1 pageCZ108 (CW508L) : Technical DatasheetGeorge MadisonNo ratings yet

- Bronze c54400 SpecificationsDocument3 pagesBronze c54400 SpecificationsRam Parimalam100% (1)

- Böhler HL 51 T-MC: Seamless Cored WireDocument2 pagesBöhler HL 51 T-MC: Seamless Cored WireFer VFNo ratings yet

- Flux Cored Arc Welding for Low Carbon 18%Cr-12%Ni-2%Mo Stainless SteelDocument1 pageFlux Cored Arc Welding for Low Carbon 18%Cr-12%Ni-2%Mo Stainless Steelmohamed AdelNo ratings yet

- UTP 6222 MoDocument1 pageUTP 6222 ModantegimenezNo ratings yet

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- Albromet-W 240: Data Sheet High-Conductivity CopperDocument1 pageAlbromet-W 240: Data Sheet High-Conductivity CopperPaolo MilaniNo ratings yet

- Böhler Cat 409 Cb-Ig: Classifi CationsDocument1 pageBöhler Cat 409 Cb-Ig: Classifi CationsBranko FerenčakNo ratings yet

- 90cual Mig WireDocument1 page90cual Mig WireAris WicaksonoNo ratings yet

- B Bã-Hler Nibas 70 20-Fd Fcaw 02Document1 pageB Bã-Hler Nibas 70 20-Fd Fcaw 02kamals55No ratings yet

- Boehler CN 23 12 PW-FDDocument1 pageBoehler CN 23 12 PW-FDbrayanNo ratings yet

- Fluxofil M42: Cored Wires High-Strength SteelsDocument1 pageFluxofil M42: Cored Wires High-Strength SteelsCristian BoselliNo ratings yet

- Diamondspark Ni1 RC: Seamless Cored WireDocument2 pagesDiamondspark Ni1 RC: Seamless Cored Wiresanul mulyNo ratings yet

- Bohler Fox S EV 50-1Document1 pageBohler Fox S EV 50-1kamals55No ratings yet

- Your reliable partner for railway welding solutionsDocument8 pagesYour reliable partner for railway welding solutionskamals55No ratings yet

- Cromarod Duplex B-1Document1 pageCromarod Duplex B-1Matija BušićNo ratings yet

- Boehler CM2-UPDocument1 pageBoehler CM2-UPdiahNo ratings yet

- Sandvik SAF 2304: Duplex Stainless SteelDocument8 pagesSandvik SAF 2304: Duplex Stainless SteelmattiaNo ratings yet

- Cored Wires for High Toughness Welding of C-Mn and Low-Alloy SteelsDocument1 pageCored Wires for High Toughness Welding of C-Mn and Low-Alloy SteelsCristian BoselliNo ratings yet

- Böhler Ti 2 Ni T-FD: Seamless Cored WireDocument2 pagesBöhler Ti 2 Ni T-FD: Seamless Cored WireThanh TamNo ratings yet

- Cu Zn 15 alloy properties and applicationsDocument2 pagesCu Zn 15 alloy properties and applicationsPetrus UngureanuNo ratings yet

- BronzeLG2LeadedGunmetalBronze PDFDocument2 pagesBronzeLG2LeadedGunmetalBronze PDFAnthonyNo ratings yet

- Alloy 6082 - Rev2012Document2 pagesAlloy 6082 - Rev2012Ysraels Santisteban DurandNo ratings yet

- Diamondspark Ni1 MC: Seamless Cored WireDocument2 pagesDiamondspark Ni1 MC: Seamless Cored WireDavid RodriguesNo ratings yet

- Copper Cu-Dhp / Sf-Cu: Page 1/2Document2 pagesCopper Cu-Dhp / Sf-Cu: Page 1/2gemilanglpNo ratings yet

- Fluxofil 41 (T 55 6 1nimo B M, C 3 h5)Document1 pageFluxofil 41 (T 55 6 1nimo B M, C 3 h5)brunizzaNo ratings yet

- Section 2 - Nikko Welding ConsumablesDocument9 pagesSection 2 - Nikko Welding Consumablesangga franugrahaNo ratings yet

- CW617N - Stång - Eng - Utg 3Document4 pagesCW617N - Stång - Eng - Utg 3Jarco PetrinNo ratings yet

- Electrode Booklet F Web 22Document1 pageElectrode Booklet F Web 22satnamNo ratings yet

- C83600 Continuous Cast Red Brass Product DetailsDocument2 pagesC83600 Continuous Cast Red Brass Product DetailsLin DouaiNo ratings yet

- 570 950mpa High Tensile Strength SteelDocument32 pages570 950mpa High Tensile Strength SteelAde Aidil SyuhadaNo ratings yet

- BW FOX+NiCuCr EN 2019 GL 233 PreviewDocument2 pagesBW FOX+NiCuCr EN 2019 GL 233 PreviewRaviTeja BhamidiNo ratings yet

- Material Data Sheet for 52CrMoV4 Spring SteelDocument3 pagesMaterial Data Sheet for 52CrMoV4 Spring SteelMartin HristovNo ratings yet

- Material Data Sheet for 52CrMoV4 Spring SteelDocument3 pagesMaterial Data Sheet for 52CrMoV4 Spring SteelMartin HristovNo ratings yet

- Diamondspark 52 MC: Seamless Metal-Cored WireDocument2 pagesDiamondspark 52 MC: Seamless Metal-Cored WireDavid RodriguesNo ratings yet

- AISI 1012 Steel, Cold Drawn Bar, 19-32 MM (0.75-1.25 In) Round or ThicknessDocument2 pagesAISI 1012 Steel, Cold Drawn Bar, 19-32 MM (0.75-1.25 In) Round or ThicknessdavmedclNo ratings yet

- Lasting Connections with Seamless Cored WireDocument2 pagesLasting Connections with Seamless Cored WireEduardo FarfanNo ratings yet

- Supabase X Plus 2Document1 pageSupabase X Plus 2Michael FortunaNo ratings yet

- Aluminium-Alloy-6082-T6 or T651Document2 pagesAluminium-Alloy-6082-T6 or T651Marcelo Noé CorsiNo ratings yet

- CWC-BookletF1 15Document1 pageCWC-BookletF1 15satnamNo ratings yet

- Weldable Fine Grain Structural Steels For Pressure Vessels P355NH PDFDocument2 pagesWeldable Fine Grain Structural Steels For Pressure Vessels P355NH PDFRABEEA ALFLAHINo ratings yet

- Steel SpecificationsDocument4 pagesSteel Specificationsgaurav tiwariNo ratings yet

- Low alloy steel electrode for high strength weldingDocument1 pageLow alloy steel electrode for high strength weldingsatnamNo ratings yet

- Utp 7015 NKDocument1 pageUtp 7015 NKsergey.pu4kaNo ratings yet

- Böhler Ti 60 T-FD: Seamless Cored WireDocument2 pagesBöhler Ti 60 T-FD: Seamless Cored WireMilos StoisavljevicNo ratings yet

- Non-Ferrous Alloys: Dr. Indika de Silva Senior Lecturer Dept. of Materials Science & Engineering University of MoratuwaDocument68 pagesNon-Ferrous Alloys: Dr. Indika de Silva Senior Lecturer Dept. of Materials Science & Engineering University of MoratuwaChandima K Priyamal100% (1)

- Ficha Técnica CarborodDocument1 pageFicha Técnica CarborodAndres NuñezNo ratings yet

- DPM PIFA StandardDocument4 pagesDPM PIFA StandardAnonymous 3VAQ9SNxl7No ratings yet

- Top 100 Concrete Technology Interview Questions and AnswersDocument49 pagesTop 100 Concrete Technology Interview Questions and Answers210140106013.zaheeransariNo ratings yet

- SM NTPELDocument68 pagesSM NTPELvempadareddyNo ratings yet

- Uhde Brochures PDF en 18Document32 pagesUhde Brochures PDF en 18geocottonNo ratings yet

- Volume III of VDocument412 pagesVolume III of VrkvaitlaNo ratings yet

- Cat 7395Document2 pagesCat 7395Erick Yamir Abril ValdiviaNo ratings yet

- Fire Hydrants PDFDocument22 pagesFire Hydrants PDFangel onofre castelanNo ratings yet

- Aesculap Ba720rDocument118 pagesAesculap Ba720rmlopezNo ratings yet

- HAZOP Unit DescriptionDocument3 pagesHAZOP Unit Descriptionsj_scribdNo ratings yet

- Rinnai Service ManualDocument112 pagesRinnai Service Manualrlynch33100% (1)

- Tyre Cord SRKDocument33 pagesTyre Cord SRKMehmood Ahmed100% (1)

- GS-TS02 Tyre Slip Monitoring System-Operation ManualDocument8 pagesGS-TS02 Tyre Slip Monitoring System-Operation Manualvsrikala68No ratings yet

- Seat Tracks and Anchor Plates CatalogDocument7 pagesSeat Tracks and Anchor Plates CatalogSergey FedorinovNo ratings yet

- TUTORIAL3 Series-Paralel-Branched Pipe SystemDocument5 pagesTUTORIAL3 Series-Paralel-Branched Pipe SystemNurul QurratuNo ratings yet

- PDF Translator 1600853339225 PDFDocument193 pagesPDF Translator 1600853339225 PDFNaveed ShoukatNo ratings yet

- LP I-Joists 20-32 PDFDocument16 pagesLP I-Joists 20-32 PDFJoseNo ratings yet

- prEN 13474 3 2008Document33 pagesprEN 13474 3 2008Marco FoglieriNo ratings yet

- Quality Evaporator Coils GuideDocument10 pagesQuality Evaporator Coils GuideYaretiNo ratings yet

- Single Stage Rotary: World Class Efficiency ReliabilityDocument5 pagesSingle Stage Rotary: World Class Efficiency ReliabilitySethuraman Kumarappan (KPCL)No ratings yet

- Stainless Steel Technical HandbookDocument27 pagesStainless Steel Technical Handbookravikumarang100% (1)

- General Specifications: Model FU20 Widebody Type pH/ORP SensorDocument21 pagesGeneral Specifications: Model FU20 Widebody Type pH/ORP SensoringNo ratings yet

- AF335Document44 pagesAF335yasinNo ratings yet

- R 102 Manual PDFDocument141 pagesR 102 Manual PDFEvi SceradorNo ratings yet

- Faculty Workshop Machinery Safety GuideDocument16 pagesFaculty Workshop Machinery Safety GuidebhaskarjalanNo ratings yet

- New Assembly Instruction of SMG 1Document49 pagesNew Assembly Instruction of SMG 1akhilesh120No ratings yet

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Document3 pagesDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Deblina MukherjeeNo ratings yet

- Catalogue enDocument38 pagesCatalogue enAndré Luiz Tombini100% (1)

- Prep Application & Troubleshooting Guide: Commercial and Industrial Flooring SystemsDocument7 pagesPrep Application & Troubleshooting Guide: Commercial and Industrial Flooring Systemsben100% (1)

- Backfill NotesDocument1 pageBackfill NotesOscar Alberto Jáuregui AquinoNo ratings yet

- ACE ACADEMY ESE - 2020 (Prelims) - Offline Test Series 01 SolutionDocument13 pagesACE ACADEMY ESE - 2020 (Prelims) - Offline Test Series 01 SolutionAbhilasha CIVILNo ratings yet