Professional Documents

Culture Documents

90cual Mig Wire

Uploaded by

Aris Wicaksono0 ratings0% found this document useful (0 votes)

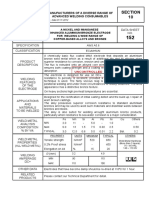

7 views1 pageThis document provides product information for Metrode's 90CuAl welding wire, including its specifications, composition, applications, welding parameters, packaging, storage requirements, microstructure, welding guidelines, and fume data. The wire is suitable for welding 5-11% aluminum bronzes and other copper alloys. It can also be used for overlaying steels and cast irons. Applications include corrosion resistant and spark resistant pumps, castings, and machinery parts for offshore, marine, and mining equipment.

Original Description:

Original Title

90CUAL-MIG-WIRE

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides product information for Metrode's 90CuAl welding wire, including its specifications, composition, applications, welding parameters, packaging, storage requirements, microstructure, welding guidelines, and fume data. The wire is suitable for welding 5-11% aluminum bronzes and other copper alloys. It can also be used for overlaying steels and cast irons. Applications include corrosion resistant and spark resistant pumps, castings, and machinery parts for offshore, marine, and mining equipment.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views1 page90cual Mig Wire

Uploaded by

Aris WicaksonoThis document provides product information for Metrode's 90CuAl welding wire, including its specifications, composition, applications, welding parameters, packaging, storage requirements, microstructure, welding guidelines, and fume data. The wire is suitable for welding 5-11% aluminum bronzes and other copper alloys. It can also be used for overlaying steels and cast irons. Applications include corrosion resistant and spark resistant pumps, castings, and machinery parts for offshore, marine, and mining equipment.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

METRODE PRODUCTS LTD

HANWORTH LANE, CHERTSEY

SURREY, KT16 9LL

Tel: +44(0)1932 566721

Fax: +44(0)1932 565168 Sales

+44(0)1932 569449 Technical DATA SHEET E-36

+44(0)1932 566199 Export

Email: info@metrode.com

Internet: http//www.metrode.com

90CuAl

Product description used on thicker sections, the lower preheat temperatures

being used for the high-zinc brasses.

9% Al bronze for welding similar 5-11% Al alloys.

Although this wire is suitable for many dissimilar

Specifications

combinations of copper and ferrous alloys, care is

AWS A5.7 ERCuAl-A2 necessary to minimise dilution by high chromium alloys

BS EN ISO 24373 S Cu 6180 / CuAl10Fe such as stainless steels. The limited tolerance to

BS 2901 pt 3 (C13) chromium pick-up may cause embrittlement and

DIN 1733 (SG-CuAl8, SG-CuAl10Fe) cracking especially if bend tests are applied. In this

situation low heat input buttering is beneficial.

ASME IX Qualification

QW432 F-No 36 Composition (wire wt %)

Cu Al Fe Zn Si Pb

Materials to be welded min -- 8.5 0.5 -- -- --

Aluminium bronze: UNS C61400, BS CA101-103, max bal 11.0 1.5 0.02 0.10 0.02

typ 90 9 1.0 <0.01 0.02 0.004

BS 1400 AB1 (cast), Alloy D.

Beryllium copper: Cu + 0.5-2%Be; closest strength. All-weld mechanical properties

Brass: Cu–Zn.

Typical as welded TIG

Aluminium brass: eg. Yorkalbro Cu-22%Zn-2%Al.

Tensile strength MPa 550-615

Manganese bronze: Cu + 20-45%Zn + 1-3%Mn.

0.2% Proof stress MPa 250-350

Silicon bronze: Cu + 1-3.5%Si, Elongation on 4d % 21

(also see data sheet E-31). Reduction of area % 25

Applications Typical parameters

For welding 5-11% Al bronzes plus other copper alloys TIG MIG

Shielding Ar Ar, He or Ar-He

as listed above. For brasses the weld colour is similar Current AC Pulsed

and the presence of aluminium in the filler helps to Diameter 2.4mm 1.2mm

suppress zinc volatilisation during welding. Parameters 250A, 15V 235A, 25V (mean)

It can also be used to overlay CMn steels and cast irons Packaging data

to give wear and corrosion resistant bearing surfaces, or

ø mm TIG MIG

to join these to most copper base alloys. 1.2 -- 15kg spool

Applications include corrosion resistant and spark 2.4 2.5kg tube --

resistant pumps, castings, machinery parts, heat

Storage

exchangers for offshore, marine and mining

equipment. Recommended ambient storage conditions: < 60% RH,

>18°C.

Microstructure

Fume data

In the as-welded condition consists of a duplex α + β

Fume composition, wt % typical (TIG fume negligible):

microstructure.

Fe Mn Cr Ni Mo Cu OES (mg/m3)

Welding guidelines 3 1 <0.1 <0.1 <0.1 80 0.3

For aluminium bronze alloys preheat is not required and Beryllium has a very low OEL (0.002mg/m3) so special

maximum interpass temperature should be 200°C. precautions may be required when welding beryllium

When welding brass a preheat of 100-300°C should be coppers.

Rev 05 10/09 DS: E-36 (pg 1 of 1)

You might also like

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Copperfil Cusi3: MIG-MAG Wires Nickel and Copper AlloysDocument1 pageCopperfil Cusi3: MIG-MAG Wires Nickel and Copper AlloyssatnamNo ratings yet

- Boehler CN 23 12 PW-FDDocument1 pageBoehler CN 23 12 PW-FDbrayanNo ratings yet

- Böhler Cat 409 Cb-Ig: Classifi CationsDocument1 pageBöhler Cat 409 Cb-Ig: Classifi CationsBranko FerenčakNo ratings yet

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeDocument7 pages22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeOnM deptNo ratings yet

- Er308l PDFDocument1 pageEr308l PDFnargissuhailNo ratings yet

- Consumables For E911 Crmo Steel: En/Din AstmDocument3 pagesConsumables For E911 Crmo Steel: En/Din Astmmohamed AdelNo ratings yet

- Met 05 Nonferrous WeldingDocument16 pagesMet 05 Nonferrous WeldingRaghu vamshiNo ratings yet

- GMM Mag.Document1 pageGMM Mag.Ehsan KhanNo ratings yet

- CHM 316LDocument1 pageCHM 316LImmalatulhusnaNo ratings yet

- B Bã-Hler Nibas 70 20-Fd Fcaw 02Document1 pageB Bã-Hler Nibas 70 20-Fd Fcaw 02kamals55No ratings yet

- Classifications: For Atmospheric Corrosion Resisting SteelDocument1 pageClassifications: For Atmospheric Corrosion Resisting Steelhuynh thanh truongNo ratings yet

- Nickel-Iron For Cast Iron: Data SheetDocument3 pagesNickel-Iron For Cast Iron: Data SheetSandro ChiliquingaNo ratings yet

- Railrod: Data SheetDocument1 pageRailrod: Data Sheetmohamed AdelNo ratings yet

- Böhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistanceDocument1 pageBöhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistancecocoNo ratings yet

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureDocument4 pagesA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16No ratings yet

- LM4 Aluminium Casting Alloy (Al - Si5Cu3) : Chemical CompositionDocument3 pagesLM4 Aluminium Casting Alloy (Al - Si5Cu3) : Chemical Compositiona.suleimanNo ratings yet

- Technical guide to ER316L stainless steel welding wireDocument1 pageTechnical guide to ER316L stainless steel welding wireslowmosquitoNo ratings yet

- Consumables To Match Cast & Wrought Alloy 800: Astm Bs en & DinDocument3 pagesConsumables To Match Cast & Wrought Alloy 800: Astm Bs en & Dinankitniranjan1390No ratings yet

- Doclib 4677 Autocraft 316lsi DatasheetDocument1 pageDoclib 4677 Autocraft 316lsi Datasheetamir moniriNo ratings yet

- 2219 Aluminium Alloy - WikipediaDocument2 pages2219 Aluminium Alloy - WikipediaVysakh VasudevanNo ratings yet

- Böhler Eas 2 PW-FDDocument1 pageBöhler Eas 2 PW-FDHAKANNo ratings yet

- 6030P Daiko CuMn13AlDocument1 page6030P Daiko CuMn13AlAris WicaksonoNo ratings yet

- Thermanit MTS 3 solid wire for joining and surfacing high temperature resistant steelsDocument1 pageThermanit MTS 3 solid wire for joining and surfacing high temperature resistant steelsbrunizzaNo ratings yet

- 11⁄4Cr-1⁄2Mo Steel Welding Electrodes Data SheetDocument7 pages11⁄4Cr-1⁄2Mo Steel Welding Electrodes Data Sheetanon_928750560No ratings yet

- CHG 55B2Document1 pageCHG 55B2Nhien ManNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- Böhler CM 5-IG solid wire for high-temperature steel weldingDocument1 pageBöhler CM 5-IG solid wire for high-temperature steel weldingPT. CATUR MATRA NusantaraNo ratings yet

- CHG 308LDocument1 pageCHG 308LImmalatulhusnaNo ratings yet

- Improving The Corrosion Resistance of Duplex Stainless Steel WeldsDocument29 pagesImproving The Corrosion Resistance of Duplex Stainless Steel WeldsRaghuram BathulaNo ratings yet

- WA Applications For HydropowerDocument6 pagesWA Applications For Hydropowersuharto ekoNo ratings yet

- P91 - Modified 9crmo: Alloy TypeDocument7 pagesP91 - Modified 9crmo: Alloy TypeHanLe DuyNo ratings yet

- Boehler CN 13 4-MC FDocument1 pageBoehler CN 13 4-MC FFilipe CordeiroNo ratings yet

- 409Document2 pages409satish04No ratings yet

- Piping FabricationDocument36 pagesPiping FabricationMouchartStéphanieNo ratings yet

- Metrode E2209 (B-60) ElectrodeDocument6 pagesMetrode E2209 (B-60) ElectrodeClaudia MmsNo ratings yet

- Avesta 310Document1 pageAvesta 310ulasNo ratings yet

- MIP Bohler Welding Austria 62Document1 pageMIP Bohler Welding Austria 62Pradeepta MohantyNo ratings yet

- Copper AlloysDocument4 pagesCopper AlloysMuhammed SulfeekNo ratings yet

- Er308 PDFDocument1 pageEr308 PDFKhedira Al JibrillNo ratings yet

- Welding of Copper and Its AlloysDocument30 pagesWelding of Copper and Its Alloysaj87_goswami100% (2)

- Carbofil Crmo9 (G Crmo9)Document1 pageCarbofil Crmo9 (G Crmo9)brunizzaNo ratings yet

- Data Sheet CuZn20Al2AsDocument1 pageData Sheet CuZn20Al2AsJean Carlos Reyna PascualNo ratings yet

- Ok Tigrod S2 Ok Tigrod S2 (SPL)Document1 pageOk Tigrod S2 Ok Tigrod S2 (SPL)Gokul RajanNo ratings yet

- 25 35 4CNbDocument1 page25 35 4CNbRomy MiftachNo ratings yet

- Boehler CN 13 4-MC - SWDocument1 pageBoehler CN 13 4-MC - SWSebastian AcostaNo ratings yet

- CF10MC (1.4571)Document3 pagesCF10MC (1.4571)Gilcimar Cavalcante GilcimarNo ratings yet

- CERTILAS EN Edition2023 320Document1 pageCERTILAS EN Edition2023 320Alireza KhodabandehNo ratings yet

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocument1 pageL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55No ratings yet

- Piping FabricationDocument36 pagesPiping Fabricationmurali100% (1)

- Avesta: Welding Wire TIGDocument1 pageAvesta: Welding Wire TIGErenBaşaraNo ratings yet

- B-41 Alloy20 Rev02Document2 pagesB-41 Alloy20 Rev02Stephen Rey CaldeaNo ratings yet

- CWC-BookletF1 15Document1 pageCWC-BookletF1 15satnamNo ratings yet

- Matching Alloy 625 Welding ConsumablesDocument5 pagesMatching Alloy 625 Welding Consumablesharan2000No ratings yet

- Cromarod Duplex B-1Document1 pageCromarod Duplex B-1Matija BušićNo ratings yet

- Summary Note For CSWIP 3.1Document9 pagesSummary Note For CSWIP 3.1Muhamad ShakyreenNo ratings yet

- Qingzhe Li, Ranfeng Qiu, Zhongbao Shen, Longlong Hou, Lihu CuiDocument5 pagesQingzhe Li, Ranfeng Qiu, Zhongbao Shen, Longlong Hou, Lihu CuiAris WicaksonoNo ratings yet

- 6030P Daiko CuMn13AlDocument1 page6030P Daiko CuMn13AlAris WicaksonoNo ratings yet

- Decorative High Gloss Enamel Paints - Specification: Draft ProposalDocument18 pagesDecorative High Gloss Enamel Paints - Specification: Draft ProposalAris WicaksonoNo ratings yet

- Material Safety Data Sheet: TM TMDocument6 pagesMaterial Safety Data Sheet: TM TMAris WicaksonoNo ratings yet

- 14 Cast Heat Resistant Alloy HH Type I and Type II ASTM A 447 and ASTM A 297Document5 pages14 Cast Heat Resistant Alloy HH Type I and Type II ASTM A 447 and ASTM A 297Aris WicaksonoNo ratings yet

- Heat-Resistant Alloy Castings Guide to Properties and DesignationsDocument1 pageHeat-Resistant Alloy Castings Guide to Properties and DesignationsAris WicaksonoNo ratings yet

- Knapp Steven 2014 ThesisDocument129 pagesKnapp Steven 2014 ThesisAris WicaksonoNo ratings yet

- Effect of Welding Sequence and The Transverse GeomDocument18 pagesEffect of Welding Sequence and The Transverse GeomAris WicaksonoNo ratings yet

- Advanced welding electrode for aluminium bronzesDocument1 pageAdvanced welding electrode for aluminium bronzesAris WicaksonoNo ratings yet

- GL Iii-1-1 e PDFDocument278 pagesGL Iii-1-1 e PDFalwyNo ratings yet

- E8E8M-15a Standard Test Methods For Tension Testing of Metallic MaterialsDocument29 pagesE8E8M-15a Standard Test Methods For Tension Testing of Metallic MaterialsmahdiNo ratings yet

- Technical Update Heat Input and Interpass Temperature During Welding PDFDocument6 pagesTechnical Update Heat Input and Interpass Temperature During Welding PDFVishal Sparkle QE3No ratings yet

- Install Insulation ProcedureDocument3 pagesInstall Insulation ProcedureabimanyubawonoNo ratings yet

- Maxsurf Example.1 - Three Ways To Model A Chine HullDocument10 pagesMaxsurf Example.1 - Three Ways To Model A Chine HullHasib Ul Haque Amit100% (1)

- LRQFNST DecryptDocument3 pagesLRQFNST DecryptSon Hong QuiNo ratings yet

- LRQFNST DecryptDocument3 pagesLRQFNST DecryptSon Hong QuiNo ratings yet

- GL Iii-1-1 e PDFDocument278 pagesGL Iii-1-1 e PDFalwyNo ratings yet

- Tank Vessel HandbookDocument76 pagesTank Vessel HandbooklsgmzNo ratings yet

- 2005 Utkast NorsokDocument30 pages2005 Utkast NorsokFarzad RezaeiNo ratings yet

- Revofil R308Lt: Stainless Filler MetalDocument1 pageRevofil R308Lt: Stainless Filler MetalAris WicaksonoNo ratings yet

- SR Terpasang PPU 8 SeptDocument2 pagesSR Terpasang PPU 8 SeptAris WicaksonoNo ratings yet

- Shop Fabrication of Structural SteelDocument12 pagesShop Fabrication of Structural SteelAris WicaksonoNo ratings yet

- Manual Recipientes Sometidos Presion PDFDocument29 pagesManual Recipientes Sometidos Presion PDFckkashyap0007No ratings yet

- p1 PP 234 Ic Dat 14 - Lfo Day Tank - Instrument Datasheet - pbc902 l006 LSLL r2Document5 pagesp1 PP 234 Ic Dat 14 - Lfo Day Tank - Instrument Datasheet - pbc902 l006 LSLL r2Aris Wicaksono100% (1)

- Price List Wintech AccesoriesDocument9 pagesPrice List Wintech AccesoriesAris WicaksonoNo ratings yet

- Technical Update Heat Input and Interpass Temperature During Welding PDFDocument6 pagesTechnical Update Heat Input and Interpass Temperature During Welding PDFVishal Sparkle QE3No ratings yet

- The Basics of API 650 Standard for Storage TanksDocument52 pagesThe Basics of API 650 Standard for Storage Tanksferdad79% (19)

- Asme PQRDocument4 pagesAsme PQRHong Dae Yoon100% (2)

- QC AbrasiveBlast 10-19-11Document62 pagesQC AbrasiveBlast 10-19-11Sherif AbdelhameedNo ratings yet

- DRW Questions 2Document16 pagesDRW Questions 2Natasha Elena TarunadjajaNo ratings yet

- Azbil - SS2 DEO412 0010 02Document12 pagesAzbil - SS2 DEO412 0010 02Magoroku D. YudhoNo ratings yet

- Standards in Nursing Education ProgrammeDocument13 pagesStandards in Nursing Education ProgrammeSupriya chhetryNo ratings yet

- Bhushan Steel LTD (BHUS IN) - Balance SheetDocument4 pagesBhushan Steel LTD (BHUS IN) - Balance SheetVamsi GunturuNo ratings yet

- Communicate With S7-1200 Via EhernetDocument6 pagesCommunicate With S7-1200 Via EhernetRegisNo ratings yet

- BUSINESS TALE - A Story of Ethics, Choices, Success - and A Very Large Rabbit - Theme of Ethics Code or Code of Business Con - EditedDocument16 pagesBUSINESS TALE - A Story of Ethics, Choices, Success - and A Very Large Rabbit - Theme of Ethics Code or Code of Business Con - EditedBRIAN WAMBUINo ratings yet

- IWR 0174 Ed12 - Jabra Headsets Amplifiers - OmniPCXplatforms - SoftphonesDocument83 pagesIWR 0174 Ed12 - Jabra Headsets Amplifiers - OmniPCXplatforms - SoftphonesAsnake TegenawNo ratings yet

- Analyzing Air Asia in Business Competition Era: AirasiaDocument14 pagesAnalyzing Air Asia in Business Competition Era: Airasiashwaytank10No ratings yet

- CIMA Introduction To NLPDocument4 pagesCIMA Introduction To NLPsambrefoNo ratings yet

- Cameron VBR-II (Variable Bore Ram) PackerDocument2 pagesCameron VBR-II (Variable Bore Ram) Packerjuan olarteNo ratings yet

- Analysis Report PDFDocument4 pagesAnalysis Report PDFJever BorjaNo ratings yet

- The Influence of Culture Subculture On Consumer BehaviorDocument55 pagesThe Influence of Culture Subculture On Consumer Behaviorvijendra chanda100% (12)

- Water Quality For Irrigation Free PPT - Google SearchDocument3 pagesWater Quality For Irrigation Free PPT - Google SearchJames NeoNo ratings yet

- Cis Bin Haider GRP LTD - HSBC BankDocument5 pagesCis Bin Haider GRP LTD - HSBC BankEllerNo ratings yet

- Index NumbersDocument23 pagesIndex NumbersemmaNo ratings yet

- Lucsuhin National High School Daily Lesson Plan on Accounting ConceptsDocument6 pagesLucsuhin National High School Daily Lesson Plan on Accounting ConceptsALMA ACUNANo ratings yet

- 06 Plastic Model KitsDocument1 page06 Plastic Model KitsLeonidas MianoNo ratings yet

- Standards PoolsDocument26 pagesStandards PoolsKimMyPatZaNo ratings yet

- Telecommunications: Office of The Communications Authority (OFCA)Document2 pagesTelecommunications: Office of The Communications Authority (OFCA)ChiWoTangNo ratings yet

- Day 1 What Is Phased Array How Phased Array Works? Beam Forming Beam Focusing Beam Streeing Sectorial Scan and Linear ScanDocument64 pagesDay 1 What Is Phased Array How Phased Array Works? Beam Forming Beam Focusing Beam Streeing Sectorial Scan and Linear ScanvibinkumarsNo ratings yet

- Internship ReportDocument171 pagesInternship ReportShahrukh MunirNo ratings yet

- The Effect of Multicollinearity in Nonlinear Regression ModelsDocument4 pagesThe Effect of Multicollinearity in Nonlinear Regression ModelsKeshav PoolaNo ratings yet

- Career Profile: Nidhi PathakDocument4 pagesCareer Profile: Nidhi PathaknidhipathakNo ratings yet

- A Teacher Education ModelDocument128 pagesA Teacher Education ModelMelinda LabianoNo ratings yet

- Dialogic DSI Signaling Servers: SIU Mode User ManualDocument304 pagesDialogic DSI Signaling Servers: SIU Mode User ManualAdiansyah Rama67% (3)

- Indexed Addressing & Flow Rate AveragingDocument5 pagesIndexed Addressing & Flow Rate AveragingMestrecal MeloNo ratings yet

- Connection StringsDocument18 pagesConnection Stringsapi-3808731100% (4)

- Segilola Gold ProjectDocument11 pagesSegilola Gold ProjectaishaNo ratings yet

- Epc50-50e Om 2-20Document46 pagesEpc50-50e Om 2-20Sidhi SadanNo ratings yet

- Rsa Netwitness Endpoint: Detect Unknown Threats. Reduce Dwell Time. Accelerate ResponseDocument8 pagesRsa Netwitness Endpoint: Detect Unknown Threats. Reduce Dwell Time. Accelerate ResponseRaghavNo ratings yet