Professional Documents

Culture Documents

Uploaded by

VishalVaishOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uploaded by

VishalVaishCopyright:

Available Formats

NPTEL Syllabus

Welding Engineering - Video

course

COURSE OUTLINE

Welding is one most the most commonly used fabrication

techniques. For successful application of welding to produced

NPTEL

sound weld joints, it is utmost important to understand the http://nptel.ac.in

science and technology behind the welding. This course is

aimed at familiarizing the students with the fundamentals of arc

welding processes, weld joint design, metallurgical aspects in

welding of steel, and assessing the quality and suitability of

Mechanical

weld joints. Topics related with weldablity of metals (steel, cast

iron and aluminium alloys of commercial importance) shall

Engineering

also be covered to equip the students technological input for

handling the problems in welding of selected metals and alloys.

Contents: Fundamentals of arc welding processes, physics of Pre-requisites:

arc, arc forces, arc blow, selection of power sources for

different arc welding processes, principles of weld joint design,

Understanding of basic

welding symbols, metallurgical aspects in welding of steel, heat concept of welding.

flow in welding and its effect on the performance of weld

joints, residual stress and distortion in weld joints and UG course on Basic

assessing the quality and suitability of weld joints, destructive Manufacturing

and non-destructive testing method. Processes.

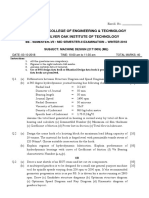

COURSE DETAIL Additional Reading:

AWS welding

Sl. Topic Hours handbooks

No

Coordinators:

1. Introduction: 2 Dr. D. K. Dwivedi

Department of Mechanical

Evolution of welding; classification of and Industrial EngineeringIIT

welding processes; heat sources and Roorkee

shielding methods.

2. Physics of Welding Arc 4

Welding arc; voltage distribution along the

arc; thermionic and non-thermionic

cathodes; theories of cathode and anode

mechanism; arc characteristics and its

relationship with power source; arc

efficiency; heat generation; effect of type of

shielding gas on arc; isotherms of arcs.

3. Welding Power Sources 2

Conventional welding power sources;

constructional features; static and dynamic

characteristics; duty cycle; influence of

inductance on arc and power source

characteristics; internal and external

regulation; specific power source

requirements; special welding power

sources.

4. Arc Welding Processes 8

Consumable electrode welding processes.

Manual metal arc (MMA) welding; Gas

metal arc welding; pulsed MIG welding;

Submerged arc welding, Significance of

flux-metal combination; Electroslag

welding: heat generation; principle; Gas

tungsten arc welding; selection of polarity,

Plasma arc welding; transferred and

nontransferred plasma arc welding;

selection of gases; welding parameters;

keyhole technique.

5. Heat flow in welding 5

Effect of welding parameter on heat

distribution; calculation of peak

temperatures; thermal cycles; cooling rate

and solidification; Residual stresses and

their distribution in welds; influence of

residual stresses in static and dynamic

loading, distortion

6. Design of weld joints 6

Introduction to design; engineering

properties of steels; Type of welds and

weld joints; description of welds:

terminology, definitions and weld symbols;

edge preparation; sizing of welds in

structure; Design for Static loading, Weld

Calculations in lap, butt and fillet welds;

design for fatigue loading, Introduction to

Fatigue; nature of the fatigue process;

fatigue strength; factors affecting fatigue

life; improvement methods for fatigue

strength; reliability analysis and safety

factors applied to fatigue design.

7. Testing and inspection of weld joints 6

Chemical tests; Metallographic tests;

Hardness tests; Mechanical test for groove

and fillet welds-full section, reduced section

and all-weld- metal tensile tests, root, face

and side bend tests, fillet weld break tests,

creep & fatigue testing. Non-Destructive

Testing of Weldments; Visual inspection;

Dye-penetrant inspection; Magnetic

particle inspection; Ultrasonic inspection-

principle of ultrasonic testing, Radiographic

inspection –principle of radiography, X-ray

tubes, gamma-ray sources, defect

discernibility; Eddy current inspection; Leak

tests: N.D.T. Standard procedure for

specification and qualification of welding

procedure; WPS and PQR, WPQ

8. Weldability of metals 7

Solidification of weld metal; heat affected

zone (HAZ), factors affecting properties of

HAZ; gas-metal, slag-metal and solid state

reactions in welding and their influence on

soundness of weld joint; lamellar tearing

and hydrogen damage; weldability;

definition, factor affecting the weldability of

steel Carbon equivalent. weldablity of

steel, cast iron and aluminium alloys of

commercial importance, failure analysis of

welded joints.

References:

1. The Metallurgy of Welding, 6th Edition , Lancaster, William

Andrew Publishing, NY.

2. Principles of Welding (Processes, Physics, Chemistry and

Metallurgy), Robert and Messler, Wiley Interscience

Publishers.

3. Welding Hand Book Vol. 5; 7th edition, AWS, 1984.

4. Welding METALLURGY, S Kou, John Wiley, USA, 2003.

A joint venture by IISc and IITs, funded by MHRD, Govt of India http://nptel.ac.in

You might also like

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Nptel: Welding Engineering - Video CourseDocument2 pagesNptel: Welding Engineering - Video CourseAshok KumarNo ratings yet

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- Chapter Wise Mapping With Course Outcomes: Date: / / Page: 1 of 3 Department:Mechanical EngineeringDocument4 pagesChapter Wise Mapping With Course Outcomes: Date: / / Page: 1 of 3 Department:Mechanical EngineeringMitul patelNo ratings yet

- 20MD017Document2 pages20MD017benyfirstNo ratings yet

- Brittle Fracture in Steel StructuresFrom EverandBrittle Fracture in Steel StructuresG.M. BoydNo ratings yet

- Advance WeldingDocument217 pagesAdvance Weldingnarayan mishra100% (1)

- Welding & Joining - 04th AugustDocument7 pagesWelding & Joining - 04th AugustSURAJ SINGH VAISHNo ratings yet

- Advanced Welding Technology SyllabusDocument1 pageAdvanced Welding Technology Syllabusfaiz ahmadNo ratings yet

- 46595-261231-302061 A Welding TechnologyDocument2 pages46595-261231-302061 A Welding TechnologyVijay Kumar DodaiNo ratings yet

- Advance Welding PDFDocument2 pagesAdvance Welding PDFRajeevNo ratings yet

- Elective 7Document1 pageElective 7Other StuffNo ratings yet

- Unit No. Topics Teaching HoursDocument1 pageUnit No. Topics Teaching HourspmagrawalNo ratings yet

- AnggeDocument28 pagesAnggeGizelle DueñasNo ratings yet

- 2019 A Review On Resistance Spot Welding of Steel MaterialDocument13 pages2019 A Review On Resistance Spot Welding of Steel Materialguravshubham7777No ratings yet

- BMP - Other Welding ProcessesDocument76 pagesBMP - Other Welding Processessujay nayakNo ratings yet

- BTEC Assignment BriefDocument3 pagesBTEC Assignment Briefmahmoud ahmedNo ratings yet

- Welding Lectures 1-4Document68 pagesWelding Lectures 1-4ganeshNo ratings yet

- Experimental Analysis of Sissimilar Metal Weld Joint Ferritic To Austenitic Stainless TeelDocument10 pagesExperimental Analysis of Sissimilar Metal Weld Joint Ferritic To Austenitic Stainless TeelIvan PicchiNo ratings yet

- English For Welding 2Document3 pagesEnglish For Welding 2MOSES7 WISENo ratings yet

- Grabulov - Current Approach To WeldabilityDocument8 pagesGrabulov - Current Approach To WeldabilityVuhic VuhicNo ratings yet

- Evaluation of Welds - Macro-Examination - Hardness PDFDocument37 pagesEvaluation of Welds - Macro-Examination - Hardness PDFdavideNo ratings yet

- RM01 SawDocument15 pagesRM01 SawAnonymous cgcKzFtXNo ratings yet

- M. Tech WLF SyllabusDocument22 pagesM. Tech WLF SyllabusAkhil AroraNo ratings yet

- Review WeldingDocument15 pagesReview WeldingHasnain TariqNo ratings yet

- 112103263Document689 pages112103263Aakash TiwariNo ratings yet

- Dissimilar Steel WeldingDocument9 pagesDissimilar Steel Weldingbh hbNo ratings yet

- 01 - Welding Lectures 1-6Document113 pages01 - Welding Lectures 1-6Govind GuptaNo ratings yet

- Assignment 1 - Brief - Unit 13 - LA 062016 No ComDocument4 pagesAssignment 1 - Brief - Unit 13 - LA 062016 No ComIsaiahNo ratings yet

- Friction Stir WeldingDocument30 pagesFriction Stir WeldingDilip Patel100% (1)

- Welding Lectures 1-4Document88 pagesWelding Lectures 1-4Thriloknath PallaNo ratings yet

- BMP - Metal WorkingDocument17 pagesBMP - Metal Workingmantra2010No ratings yet

- BMP PDFDocument17 pagesBMP PDFmantra2010No ratings yet

- Production Engineering: Teaching ScheduleDocument2 pagesProduction Engineering: Teaching ScheduleSantosh SangleNo ratings yet

- Welding Research PaperDocument7 pagesWelding Research Paperkifmgbikf100% (1)

- Eperimental Investigation of Effects of Welding Current and Elektrode AngleDocument3 pagesEperimental Investigation of Effects of Welding Current and Elektrode AngleMuizz AbdullahNo ratings yet

- Block Syllabus As On 06 Jan 24Document3 pagesBlock Syllabus As On 06 Jan 24ASHVIN YADAVNo ratings yet

- Effectof Welding Processeson Microstructure MechanicalDocument12 pagesEffectof Welding Processeson Microstructure MechanicalDr. Rachid djoudjouNo ratings yet

- Assignment 1 Brief Unit 13 LA 062016 No ComDocument4 pagesAssignment 1 Brief Unit 13 LA 062016 No ComMomo AbdulrasaqNo ratings yet

- Solid State Welding and Application in Aeronautical IndustryDocument8 pagesSolid State Welding and Application in Aeronautical Industrymaster002 XDNo ratings yet

- Unit 2 - Manufacturing Process - WWW - Rgpvnotes.inDocument11 pagesUnit 2 - Manufacturing Process - WWW - Rgpvnotes.inIPL 2020 LIVE100% (1)

- Brief Introduction To Welding Technology: (Advanced Welding Technology (PE-ME 702H) Continuous Assessment 2 (CA 2)Document17 pagesBrief Introduction To Welding Technology: (Advanced Welding Technology (PE-ME 702H) Continuous Assessment 2 (CA 2)Prabhat RoutNo ratings yet

- Charotar Institute of Technology-Changa: Metal Forming and Fabrication Technique (M-505)Document17 pagesCharotar Institute of Technology-Changa: Metal Forming and Fabrication Technique (M-505)patangegs653No ratings yet

- BMP - Electric Arc WeldingDocument91 pagesBMP - Electric Arc Weldingsujay nayakNo ratings yet

- Microstructural Parameter Controlling Weld Metal Cold CrackingDocument4 pagesMicrostructural Parameter Controlling Weld Metal Cold CrackingSadhasivam VeluNo ratings yet

- Btech Syllabus 4th Semester PDFDocument11 pagesBtech Syllabus 4th Semester PDFAmAn DeEpNo ratings yet

- WT SyllabusDocument1 pageWT SyllabuschandrasekarcncetNo ratings yet

- J Matpr 2017 07 083Document8 pagesJ Matpr 2017 07 083anandhunehNo ratings yet

- Experimental & Quantitative Techniques: MSU - 40 Hrs L&T - 0 HRDocument12 pagesExperimental & Quantitative Techniques: MSU - 40 Hrs L&T - 0 HRJay BalarNo ratings yet

- Arc WeldingDocument14 pagesArc WeldingAnkitPandeyNo ratings yet

- متطلبات تخصص الصيانة الكهروميكانيكة العامةDocument68 pagesمتطلبات تخصص الصيانة الكهروميكانيكة العامةibraheemNo ratings yet

- Effect of Multi-Pass SMAW Welding On The Surface HDocument7 pagesEffect of Multi-Pass SMAW Welding On The Surface HYousab CreatorNo ratings yet

- Syllabus WELDING TECHNOLOGY R2017Document2 pagesSyllabus WELDING TECHNOLOGY R2017CHANDRAPRAKASHNo ratings yet

- Theory of Arc Welding pt1Document115 pagesTheory of Arc Welding pt1Koushik SarkarNo ratings yet

- Shielded Metal Arc WeldingDocument45 pagesShielded Metal Arc WeldingBharichalo007No ratings yet

- Optimization of Submerge Arc Welding Parameter For Joining Dissimilar Material Using Taguchi MethodDocument17 pagesOptimization of Submerge Arc Welding Parameter For Joining Dissimilar Material Using Taguchi MethodidgadibNo ratings yet

- Fracture ToughnessDocument46 pagesFracture Toughnessbabak_rajiNo ratings yet

- Online 20 Lessons of Two Hour Each - Transition Arrangement CandidatesDocument1 pageOnline 20 Lessons of Two Hour Each - Transition Arrangement CandidatesDhanush NairNo ratings yet

- Metals 12 01157Document17 pagesMetals 12 01157N Sudheer RêddyNo ratings yet

- ScienceLesson1 PDFDocument54 pagesScienceLesson1 PDFMichelle Gonzales Caliuag100% (1)

- User Manual 2015 PDFDocument44 pagesUser Manual 2015 PDFbilly_gfroererNo ratings yet

- F18 Thermal NoiseDocument6 pagesF18 Thermal NoiseJonahNo ratings yet

- Tectonics Zagros DehbozorgiDocument13 pagesTectonics Zagros DehbozorgiMukteshwar MishraNo ratings yet

- Reinforced Concrete StructuresDocument5 pagesReinforced Concrete StructuresopulitheNo ratings yet

- PHD Research Proposal - S D BubaDocument9 pagesPHD Research Proposal - S D BubasanibubaNo ratings yet

- Sample Problems ExergyDocument5 pagesSample Problems ExergySamer Al-MimarNo ratings yet

- Silver Oak College of Engineering & Technology Aditya Silver Oak Institute of TechnologyDocument2 pagesSilver Oak College of Engineering & Technology Aditya Silver Oak Institute of TechnologyShree PrajapatiNo ratings yet

- Goode Homolosine Projection Map BenefitsDocument3 pagesGoode Homolosine Projection Map BenefitsFabienneNo ratings yet

- 3500-45 Position Monitor Datasheet - 141537Document21 pages3500-45 Position Monitor Datasheet - 141537Mahesh Kumbhar100% (1)

- Tutorial 3-Rigid Jointed Frame AnalysisDocument23 pagesTutorial 3-Rigid Jointed Frame AnalysissagarNo ratings yet

- Cramer JohnDocument59 pagesCramer JohnClifford StoneNo ratings yet

- 03 VESPR and PolarityDocument5 pages03 VESPR and PolarityNursalfarinah BasirNo ratings yet

- Secrets of The Sun - Your Spiritual Revolution - Dec 2007 IssueDocument40 pagesSecrets of The Sun - Your Spiritual Revolution - Dec 2007 IssueAmitt Parikh83% (12)

- Nzs 4219 2009Document114 pagesNzs 4219 2009fausto giovannardiNo ratings yet

- A Ash To L RFD Bridge DesignDocument88 pagesA Ash To L RFD Bridge DesignOnurUmanNo ratings yet

- Reinforced Concrete DesignDocument19 pagesReinforced Concrete Designcielo_cetd367050% (4)

- THERMODYNAMICS-3 Kca NotesDocument23 pagesTHERMODYNAMICS-3 Kca NotesAbraham ChackoNo ratings yet

- Iso 29201 2012 en PDFDocument11 pagesIso 29201 2012 en PDFMaría Claudia Ossa MondragonNo ratings yet

- HomotopyDocument13 pagesHomotopyfalcon_vamNo ratings yet

- Design Calculation-CYL VERTICAL 1.0mDIA X 1.10m ST HT TankDocument17 pagesDesign Calculation-CYL VERTICAL 1.0mDIA X 1.10m ST HT TankEleazar Mendoza50% (2)

- Function: X Is Chosen at Random From The First 1000 Natural Numbers. If (.) Denotes TheDocument4 pagesFunction: X Is Chosen at Random From The First 1000 Natural Numbers. If (.) Denotes TheShrey PandeyNo ratings yet

- My Seminar Report On ThermographyDocument20 pagesMy Seminar Report On ThermographyAnup Khandelwal50% (2)

- Asymptote Guide To CryopreservationDocument42 pagesAsymptote Guide To CryopreservationIulia ChiriacNo ratings yet

- Mathematical Modelling and FunctionsDocument6 pagesMathematical Modelling and FunctionsDr Srinivasan Nenmeli -K100% (1)

- Orbeco-Hellige ET 740, ET 750 Floc Tester ManualDocument32 pagesOrbeco-Hellige ET 740, ET 750 Floc Tester ManualtinuvalsapaulNo ratings yet

- Computational Astronomy and The Earliest VisibilitDocument21 pagesComputational Astronomy and The Earliest VisibilitAHLUSSUNNAH WAL JAMAA"AH [ASHA:'IRAH & MATURIDIYAH]No ratings yet

- Ma 1252Document25 pagesMa 1252Nagalingaraja RnrNo ratings yet

- 1Document21 pages1rcpretoriusNo ratings yet

- Steam Turbine Rotor CrackDocument11 pagesSteam Turbine Rotor Crackpoloko7100% (1)