Professional Documents

Culture Documents

Gas Absorption Study Apparatus Experimental Manual

Uploaded by

Shoaib PathanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gas Absorption Study Apparatus Experimental Manual

Uploaded by

Shoaib PathanCopyright:

Available Formats

1

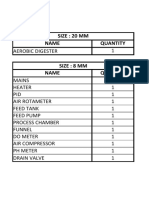

INDEX

SR NO SUBJECT PAGE NO

1. INTRODUCTION 2–4

2. DESCRIPTION OF INSTRUMENT 5

3. SAFETY 6

4. EXPERIMENTAL MANUAL 7–9

5. PRECAUTIONS 10

6. LINE DIAGRAM 11

GAS ABSORPTION STUDY APPARATUS EXPERIMENTAL MANUAL

2

INTRODUCTION:

The chemical industry affords numerous examples of processes in which a gas

is dissolved by a liquid and then undergoes a chemical reaction in the liquid phase.

For example, in the contact process for the manufacture of sulfuric acid the sulfur

trioxide formed by the catalytic oxidation of sulfur dioxide is absorbed in a mixture of

sulfuric acid and water with which it reacts chemically to produce more sulfuric acid.

Similarly, the nitrogen oxides formed by the catalytic oxidation of carbon dioxide are

absorbed in water and react to from nitric acid. In some cases, an unwanted impurity

in a gas is removed by scrubbing with a liquid capable of reacting with it, as in the

removal of sulfur dioxide from flue gas by absorption in an alkaline solution or a

suspension of slaked lime. The separation and recovery of one constituent of a gas

mixture may be affected by absorption in liquor with which it undergoes a reversible

chemical reaction. For example, carbon dioxide is removed from gases by absorption

in mono-or diethanolamine, with which it reacts to form carbonates, and

subsequently recovered by heating the solution. The regenerated amine is then

returned to the absorption plant. In this case the advantage over a process involving

physical solution, e.g. in water, is the much higher solubility of carbon dioxide in the

amine and the consequent reduction in the rate of circulation of liquid through the

absorber and regenerator.

The effect of a chemical reaction in the liquid phase is to increase the

solubility of the absorbed component and reduce its equilibrium partial pressure. If

the chemical reaction is irreversible, the equilibrium partial pressure is zero as long

as any free reactant remains in the liquid phase. Since the molecules of absorbed

component must diffuse into the liquid phase until they meet the reactant, and after

the reaction, the product must diffuse into the bulk of the liquid, the rate of

absorption must depend on the concentration and diffusivities of the reactant and

products, on the rate of chemical reaction and on the depth of the liquid film in

GAS ABSORPTION STUDY APPARATUS EXPERIMENTAL MANUAL

3

which the reaction occurs. The sequence of events for a fast-irreversible reaction is

illustrated by Figure 1.

Component A diffuses from the gas to the liquid surface (X), where its partial

pressure is pi and the equilibrium concentration in the liquid is ci. It then diffuses in

the liquid to a plane Y, where it meets reactant B which is diffusing in the opposite

direction from the bulk of the liquid, Z. Owing to the instantaneous reaction the

concentrations of A and B fall to zero, and the product AB is formed. This diffuses

back to the plane Z, representing the bulk of the liquid.

AB

B

A ci

pi

A B

X Y Z

Fig. 1 Concentration gradients in a liquid film when a component A dissolves at the

surface XX and reacts with component B in solution

The distance XY traversed by A is only a fraction of the total film thickness XZ

and the concentration gradient is greater than would be the case in physical

absorption. In consequence the mass transfer coefficient for absorption in the liquid

film is enhanced considerably when a rapid chemical reaction occurs. For example,

the absorption of sulfur dioxide by water is controlled by both the gas and liquid

films, but when it is absorbed by a dilute solution of caustic soda the liquid film

coefficient is increased to such an extent that the rate of absorption is controlled

almost entirely by the gas film.

GAS ABSORPTION STUDY APPARATUS EXPERIMENTAL MANUAL

4

INDUSTRIAL PROCESSES INVOLVING ABSORPTION WITH CHEMICAL REACTION:

The principal industrial processes involving absorption with chemical reaction

may be grouped under the following headings.

1. Absorption of carbon dioxide by caustic soda or potash solutions. Owing to

the expensive nature of the absorbent this is mainly used for removing the

last traces of carbon dioxide from a gas.

2. Absorption of carbon dioxide by sodium or potassium carbonate solutions.

The solution may be regenerated by heating to decompose the bicarbonate.

3. Absorption of carbon dioxide by mono-or diethanolamine solutions, followed

by desorption and regeneration at a higher temperature.

4. Absorption of carbon dioxide by carbon dioxide Cal solutions to produce

ammonium carbonate. This reaction is used in the Solvay process for

manufacture of sodium carbonate.

5. Absorption of hydrogen sulfide by sodium hydroxide or carbonate solutions.

6. Absorption of hydrogen sulfide by ethanolamine solutions, followed by

desorption and regeneration.

7. Absorption of sulfur dioxide by water and alkaline solutions.

8. Absorption of sulfur trioxide by sulfuric acid.

9. Absorption of chlorine.

10. Absorption of nitrogen oxides and manufacture of nitric acid.

11. Absorption of hydrogen fluoride.

GAS ABSORPTION STUDY APPARATUS EXPERIMENTAL MANUAL

5

DESCRIPTION OF EQUIPMENT

The equipment consists of approx. 55 mm inner diameter & 750 mm long

borosilicate glass column filled with Rasching ring (12 mm). Pressure tapings are

provided at the base and top of the column to determine pressure drop across the

column with Mercury manometer. The liquid outlet streams and feed solution are

also equipped with sampling points. Water/ Aq. NaOH soln./ Dil. KOH soln. is taken

from a Closed Air Operated Feed tank and feed enters the column via a calibrated

flow meter.

CO2 Gas is taken from a pressure cylinder through a calibrated flow meter, and

mixed with air supply and monitored from an air compressor in a predetermined (but

variable) mixture ratio. A suitable mixing length and mixer are included to mix Air

and CO2 thoroughly. The mixture is fed to the base of the tower. The exhaust gas

leaves at the top of the tower and is intended to be exhausted to atmosphere

outside the laboratory building.

• 55 mm dia. 750 mm long borosilicate column with bed of Rasching ring (12

mm)

• Air compressor (1.0 HP) and Rotameter.

• CO2 cylinder (6.8 kg) with pressure regulator and Rotameter

• Water/ dilute NaOH Solvent circulation system with Feed tank (20 Liters

approx. SS 304) and Rotameter.

• Liquid and Air Distributor.

• Suitable manometric measurement arrangement with pressure taps at the

bottom and top.

GAS ABSORPTION STUDY APPARATUS EXPERIMENTAL MANUAL

6

SAFETY

• Carbon Dioxide is both toxic and combustible. If a major carbon dioxide leak

develops, evacuate the laboratory immediately, without attempting to shut

off the cylinder valve. Open the main cylinder valve only about one-half turn,

to prevent discharge at high rates.

• Wear safety glasses at all times. Be sure the lab ventilation system is operating

before using carbon dioxide. Be sure the carbon dioxide cylinder valve is

closed before ending the experiment. Know the safety shower and eye wash

station locations.

• Wear jeans or slacks, a long-sleeved shirt, and sturdy shoes that give good

traction on possibly wet floors.

• Guard against electrical hazards by making sure that all equipment is well

grounded using three-wire plugs and other means.

• Handle with great care any solvents or other potentially volatile, flammable,

toxic, or otherwise dangerous chemicals. In this experiment air, water, carbon

dioxide, and a solution of Potassium/ Sodium chloride are used. Potassium/

Sodium chloride is toxic if ingested in large amounts. Carbon dioxide is toxic in

higher concentrations.

• Guard against falls, burns, cuts, and other physical hazards. Use heavy gloves

to open or close hot steam or condensate valves.

• THINK FIRST OF SAFETY IN ANY ACTION YOU TAKE. If not certain, ask the TA or

a faculty member before you act.

GAS ABSORPTION STUDY APPARATUS EXPERIMENTAL MANUAL

7

GAS ABSORPTION STUDY APPARATUS EXPERIMENTAL MANUAL

AIM:

➢ To study the flooding conditions and the absorption of CO2 from Air using a

NaOH/ water solution in a packed column.

➢ To gain experience with the packed bed gas absorption column and its

analysis system.

PREPARATION OF SOLUTIONS:

FEED SOLUTION

Prepare the dilute NaOH solution in the tank. Add 60 gm of NaOH pellets in to

15 liters water to make 0.1 N solution of the NaOH. Stir the solution well to dissolve.

Do not let the pellets clump in the bottom.

PROCEDURE:

• Feed the supply tank with the prepared 0.1 N NaOH/ Water solution about 15

liters.

• Check the concentration of the feed solution by titration against 0.1 N HCl.

• Connect the Air Compressor to the single-phase power supply.

• Initially start the air compressor and collect sufficient air in the pressure tank

so as the pressure is about 3-4 kg/ cm2.

• Open the valve of the pressure tank and allow the air to pass through the

column.

• Set the air flow at the desired value and then open the valve of the CO2

cylinder and adjust the flow rate to predetermined value. The inlet

concentration of CO2 in Air should not be more than 10%. (For example, if rate

of Air is 30 LPH insert CO2 at 3 LPH.

GAS ABSORPTION STUDY APPARATUS EXPERIMENTAL MANUAL

8

• Now start the feed (NaOH soln.) by allowing air in to feed tank and using

rotameter set the desired value of flow rate.

• After sometime take the sample at various points and analyze them.

• Initially start the liquid flow at sufficiently high rate (VL = 0.03 m/s) to ensure

that all the packing is wetted.

• The flow rates of gas and liquid are adjusted at predetermined values with the

help of rotameters.

• The CO2 flow rate should be such that the %CO2 in the mixed gas is about 8-

10%. The gas velocity has no effect on the interfacial area in a packed column.

Hence a value of VG between 0.1 - 0.2 m/s may be chosen for all the

experiments and keeping it constant.

• The linear superficial liquid velocity V is the most important variable. The

range for V should be fixed between 0.001 - 0.007 m/s.

• The system is allowed to reach steady state after fixing the liquid level in the

bottom section at a marked height.

• Inlet and outlet liquid samples are withdrawn for analysis.

COLLECTING THE SAMPLE:

• Collect the Samples by means of opening the sample tap.

• Note the temperature at the time of collection.

OBSERVATIONS:

System : (CO2 + Air) - Aq. NaOH Solution

Packing Used : Rasching ring of size 12 mm

Column Dia. : 55 mm (ID)

Pressure : 101.325 k N/m2

Packed Height : 600 mm

VG : m / sec

GAS ABSORPTION STUDY APPARATUS EXPERIMENTAL MANUAL

9

TITRATION:

• Pour 50 ml of 0.1 N HCL solution in burette.

• Take 10 ml sample of NaOH in to flask.

• Add 3 drops of Phenolphthalein in to flask.

• Stir flask firmly and start to pour 0.1 N HCl solution from the burette.

• Stop when pink color indicates in to flask.

• Note down the burette reading.

FEED ANALYSIS

Burette = 0.1 N HCL solution (N2)

Pipette = 10 ml feed solution (V1)

Indicator – Phenolphthalein

OBSERVATION TABLE:

NORMALITY OF NAOH BURETTE NORMALITY OF

BURETTE READING

SR. NO. (BEFORE EXPERIMENT) READING OF NAOH (AFTER

OF HCL (ML) (V2)

(N1) HCL (ML) (V2) EXPERIMENT) (N1)

1.

2.

3.

CALCULATIONS:

1. Normality of NaOH Before Experiment

N1V1 = N2*V2

= N2*V2 / V1

N1 = _____ N

2. Normality of NaOH After Experiment

N1V1 = N2*V2

= N2*V2 / V1

N1 = _____ N

RESULT:

GAS ABSORPTION STUDY APPARATUS EXPERIMENTAL MANUAL

10

PRECAUTIONS:

• CO2 IS HAZARDOUS GAS SO, HANDLE WITH CARE EVERYTIME.

• Sufficient Ventilation system is required to perform this experiment.

• Wear Mask, Goggles, Gloves etc. during experiment.

• Every time open CO2 cylinder slightly to avoid any accident.

• Maintain CO2 flow very slow (About 8-10 % in CO2+Air Mixer) with the

help of rotameter.

• Every time store sufficient air in to Air Compressor prior to experiment.

• Every time after experiment close CO2 cylinder tightly by spanner

provided.

• Drain out any remaining feed after completion of experiment by opening

drain valve provided below the feed Tank.

• Pour clean water in to feed tank twice or thrice to remove any traces of

NaOH present in the feed tank.

• Then fill clean water in to feed tank and run clean water into system

after completion of experiment to remove any traces of NaOH.

GAS ABSORPTION STUDY APPARATUS EXPERIMENTAL MANUAL

11

GAS ABSORPTION STUDY APPARATUS EXPERIMENTAL MANUAL

You might also like

- Apparatus For Measurement of Thermal Conductivity of Good and Bad Conductors Manual FDocument13 pagesApparatus For Measurement of Thermal Conductivity of Good and Bad Conductors Manual FShoaib PathanNo ratings yet

- Ball Mill Experimental Manual GuideDocument11 pagesBall Mill Experimental Manual GuideShoaib Pathan100% (3)

- Apparatus For Friction Losses in Pipe Fittings ManualDocument17 pagesApparatus For Friction Losses in Pipe Fittings ManualShoaib PathanNo ratings yet

- Absorption and Stripping Equipment Manual FDocument19 pagesAbsorption and Stripping Equipment Manual FShoaib PathanNo ratings yet

- Cre Lab EquipmentDocument1 pageCre Lab EquipmentShoaib PathanNo ratings yet

- Basket CentrifugeDocument1 pageBasket CentrifugeShoaib PathanNo ratings yet

- Aerobic Digester Experimental ManualDocument25 pagesAerobic Digester Experimental ManualShoaib PathanNo ratings yet

- Aerobic Digester Experimental ManualDocument25 pagesAerobic Digester Experimental ManualShoaib PathanNo ratings yet

- Sedimentation Equipment TEX 45 Technical SpecDocument1 pageSedimentation Equipment TEX 45 Technical SpecShoaib PathanNo ratings yet

- Aerobic Digester GraphsDocument4 pagesAerobic Digester GraphsShoaib PathanNo ratings yet

- Gas Absorption Study ApparatusDocument1 pageGas Absorption Study ApparatusShoaib PathanNo ratings yet

- Industrial Gas Absorption with Chemical ReactionDocument17 pagesIndustrial Gas Absorption with Chemical ReactionShoaib PathanNo ratings yet

- Cocurrent and Counter Current Liquid-Liquid ExtractorDocument2 pagesCocurrent and Counter Current Liquid-Liquid ExtractorShoaib PathanNo ratings yet

- Forced Draft Tray DryerDocument1 pageForced Draft Tray DryerShoaib PathanNo ratings yet

- Leaching Apparatus: Technical Specifications: The Equipment Consists Mainly of The Following: 1) Percolation LeacherDocument1 pageLeaching Apparatus: Technical Specifications: The Equipment Consists Mainly of The Following: 1) Percolation LeacherShoaib PathanNo ratings yet

- Vibrating Screen: Technical SpecificationDocument1 pageVibrating Screen: Technical SpecificationShoaib PathanNo ratings yet

- Cyclone Separator and Water Scrubber: Technical SpecificationsDocument1 pageCyclone Separator and Water Scrubber: Technical SpecificationsShoaib PathanNo ratings yet

- Industrial Gas Absorption with Chemical ReactionDocument17 pagesIndustrial Gas Absorption with Chemical ReactionShoaib PathanNo ratings yet

- Sedimentation Unit Experimental ManualDocument17 pagesSedimentation Unit Experimental ManualShoaib PathanNo ratings yet

- Foam and PropertiesDocument40 pagesFoam and PropertiesShoaib PathanNo ratings yet

- Leaching Apparatus Experimental ManualDocument12 pagesLeaching Apparatus Experimental ManualShoaib PathanNo ratings yet

- Construction, Working and Maintenance of Electric Vibrators and Vibrating ScreensDocument70 pagesConstruction, Working and Maintenance of Electric Vibrators and Vibrating ScreensmareesanNo ratings yet

- Vibrating Screen Experimental ManualDocument16 pagesVibrating Screen Experimental ManualShoaib Pathan50% (2)

- Wetted Wall Column: Technical SpecificationsDocument1 pageWetted Wall Column: Technical SpecificationsShoaib PathanNo ratings yet

- Cyclone Seperator Experimental ManualDocument12 pagesCyclone Seperator Experimental ManualShoaib PathanNo ratings yet

- Leaf Filter Experimental ManualDocument12 pagesLeaf Filter Experimental ManualShoaib Pathan67% (3)

- Sedimentation Unit Experimental ManualDocument17 pagesSedimentation Unit Experimental ManualShoaib PathanNo ratings yet

- Industrial Gas Absorption with Chemical ReactionDocument17 pagesIndustrial Gas Absorption with Chemical ReactionShoaib PathanNo ratings yet

- Force Draft Tray Dryer Experimental ManualDocument21 pagesForce Draft Tray Dryer Experimental ManualShoaib Pathan100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Candidates applied for Medical Officer post on contract basisDocument11 pagesCandidates applied for Medical Officer post on contract basiszephyrNo ratings yet

- Micro Bio Disease ListDocument168 pagesMicro Bio Disease Listspiff spacemanNo ratings yet

- Symbol High Low R5 R4 R3 R2: DailyDocument8 pagesSymbol High Low R5 R4 R3 R2: Daily257597 rmp.mech.16No ratings yet

- TestDocument4 pagesTestCristina BariNo ratings yet

- Dowell's Price List 18.3.2022Document26 pagesDowell's Price List 18.3.2022Sunil WadekarNo ratings yet

- Appendix VIII - Civil and Structural Scope of WorkDocument140 pagesAppendix VIII - Civil and Structural Scope of WorkjaganrajNo ratings yet

- Administrative Case ResolutionDocument2 pagesAdministrative Case ResolutionEunice Osam RamirezNo ratings yet

- Will The Real SMART Goals Please Stand Up?: Robert S. Rubin Saint Louis UniversityDocument2 pagesWill The Real SMART Goals Please Stand Up?: Robert S. Rubin Saint Louis UniversityKyoko TakayanagiNo ratings yet

- Shrimp ReceipeDocument2 pagesShrimp Receipedonna blazoNo ratings yet

- Major Emergencies in Power PlantDocument29 pagesMajor Emergencies in Power Plantsourav mahapatraNo ratings yet

- Polythionic Acid Stress Corrosion CrackingDocument2 pagesPolythionic Acid Stress Corrosion CrackingVajid MadathilNo ratings yet

- The Role of Technology in AgricultureDocument35 pagesThe Role of Technology in AgricultureDivyesh ThumarNo ratings yet

- Menu Baru Kopi GandapoeraDocument7 pagesMenu Baru Kopi GandapoeraAlwan AhpNo ratings yet

- General Biology 1 - Power Point Presentation (Group 8)Document14 pagesGeneral Biology 1 - Power Point Presentation (Group 8)Archan Dom ReyesNo ratings yet

- Synovial Joints StructureDocument20 pagesSynovial Joints StructureJayricDepalobosNo ratings yet

- Smartphone Addiction Among Utmspace Student (Final)Document20 pagesSmartphone Addiction Among Utmspace Student (Final)kyo_kusanagi_jb100% (1)

- IRIS 2017 DOG Treatment Recommendations 09may18Document15 pagesIRIS 2017 DOG Treatment Recommendations 09may18crilala23No ratings yet

- Rational Choice TheoryDocument6 pagesRational Choice TheoryMaria Theresa HerbolingoNo ratings yet

- STM - Merck Case AnswersDocument2 pagesSTM - Merck Case AnswersreetayanNo ratings yet

- GMP TD Ar FPL 11033Document1 pageGMP TD Ar FPL 11033Sammy NguyenNo ratings yet

- ODN102001 ATN Products Hardware Introduction ISSUE 1.00Document43 pagesODN102001 ATN Products Hardware Introduction ISSUE 1.00Jonathan Eduardo Tapias BeltranNo ratings yet

- Blue Bloods 1Document166 pagesBlue Bloods 1anastomaNo ratings yet

- F.E. Campbell - Sweet Slavery - HIT 139Document115 pagesF.E. Campbell - Sweet Slavery - HIT 139HokusLocus67% (3)

- Apcosil 605Document1 pageApcosil 605rihtak123No ratings yet

- Fosfomycin: Review and Use Criteria BackgroundDocument12 pagesFosfomycin: Review and Use Criteria BackgroundAbu Azzam Al-Hadi100% (1)

- Master Key Bonus - The Healing CodeDocument8 pagesMaster Key Bonus - The Healing CodeChanterelle Vasto100% (12)

- World Bank ReportDocument14 pagesWorld Bank Reportaditya_erankiNo ratings yet

- California ProfileDocument3 pagesCalifornia ProfileLigaya BacuelNo ratings yet

- Let's Check: To Eliminate Unrealized Gain On Sale of LandDocument4 pagesLet's Check: To Eliminate Unrealized Gain On Sale of Landalmira garciaNo ratings yet

- Trilon C Types TI enDocument11 pagesTrilon C Types TI enjuanfelipehincapieNo ratings yet