Professional Documents

Culture Documents

Catalogo Torres PDF

Catalogo Torres PDF

Uploaded by

CrissHernándezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Catalogo Torres PDF

Catalogo Torres PDF

Uploaded by

CrissHernándezCopyright:

Available Formats

Engineering

Brochure

T-Model Cooling Towers

A Manufacturer for 42 Years

MEMBER

196 Lower Cherry Street

Macon, GA 31201

800-752-1905

478-755-1905

800-203-4925 FAX

478-755-8304 FAX

www.coolingtowersystems.com

info@coolingtowersystems.com

The Cooling Tower Systems Tower

Design Features:

The non-rusting FRP casing and basin, circular in

shape, eliminates special installation requirements. Water Distribution System:

Prevailing wind directions will not affect tower CTS models T-25 through T-260 use an ABS plastic

performance. sprinkler with stainless steel shaft. CTS models T-270

and above use an aluminum alloy sprinkler head. Both

Casing: types of sprinkler head require little or no head

Easy access through casing simplifies cleaning. pressure loss and minimum maintenance.

Individual fiberglass panels are stainless steel bolted

together for periodic wash down and general clean up. Inlet Louvers:

The CTS FRP cooling tower is designed for durability Non-rusting PVC plastic mesh provides easy access to

and long life even under the most severe environmental sump while preventing foreign objects from entering

weather conditions. water basin.

Fan Blades: Ladder:

Aerodynamically designed propeller type fan blades are Provided for maintenance and inspection accessibility

used to conserve power and assure quiet operations. to fan and sprinkler systems. (Models T-240 and

CTS models T-25 through T-230 feature a factory- above.)

balanced ABS plastic blade. CTS models T-240 and

above feature an all aluminum alloy adjustable fan. Fill Material:

Honeycomb heat-embossed PVC is formed to permit

Fan Drive: high heat transfer efficiency. The CTS fill is suitable for

CTS models T-25 through T-2200 have direct drive fan operation with inlet water temperatures of 125° F. For

motors. CTS models T-2225 and larger feature a higher temperatures, contact your representative for

unique belt drive, designed to reduce noise levels, with quote.

optional gear drives.

Engineered for Cost Efficiency & High Performance

The fan motor is weatherproofed and Housing panels and water basin are built

totally enclosed allowing for less noisy and of fiberglass-reinforced plastic ensuring

more efficient long-term performance. rust-free long-term performance even

under the most severe environmental

conditions.

The sprinkler pipes are sturdy PVC

material pierced with closely spaced holes

allowing thorough distribution of water in a

The efficiently designed PVC filler creates

rotating spray covering the entire surface

a surface area that allows for maximum

of the filler.

dispersion of water and creates a superior

cooling effect.

A large-capacity, durable water

basin constructed from rustproof

The round design permits fiberglass reinforced plastic

maximum air intake regardless guarantees low maintenance and

of wind direction. long-term operation.

A large diameter outlet pipe draws a

Efficient operation results from the smooth constant supply of cooled water

pumping of re-circulated water through the from the basin to serve the facility.

stand pipe and up into the sprinkler pipes.

www.coolingtowersystems.com -2- 42 Years of Manufacturing Experience

Dimensions and Pipe Connections

DIMENSIONS (IN.) PIPE CONNECTIONS (IN.) FAN FAN AIR NOMINAL

T MODEL MOTOR DIAMETER VOLUME

HEIGHT DIA. IN OUT O Dr FLOAT Q WATER FLOW (GPM)

(HP) (INCH) (CFM)

T-25 52 33 1/2 1 1/2 1 1/2 1 3/4 1/2 - 1/6 * 19 1/2 2118 15

T-28 56 33 1/2 1 1/2 1 1/2 1 3/4 1/2 - 1/6 * 19 1/2 2648 23

T-210 54 41 3/4 1 1/2 1 1/2 1 3/4 1/2 - 1/4 * 26 3/8 3531 30

T-215 59 46 2 2 1 1 1/2 - 1/4 * 26 3/8 4767 44

T-220 63 54 3/8 2 2 1 1 1/2 - 1/2 ** 30 1/4 6356 58

T-225 70 15/16 54 3/8 2 1/2 2 1/2 1 1 1/2 - 3/4 *** 30 1/4 7000 73

T-230 68 3/8 62 1/4 2 1/2 2 1/2 1 1 1/2 - 1 *** 30 1/4 8100 88

T-240 74 1/2 71 5/8 2 1/2 2 1/2 1 1 3/4 - 1 1/2*** 38 1/4 9800 118

T-250 74 1/2 78 3/4 3 3 1 1 3/4 - 1 1/2 *** 38 1/4 11500 148

T-260 74 11/16 78 3/4 3 3 1 1 3/4 - 1 1/2 *** 46 14700 177

T-270 79 3/8 85 5/8 4 4 1 1 3/4 - 1 1/2 *** 46 17500 207

T-280 79 3/8 85 5/8 4 4 1 1 3/4 - 2 *** 46 18900 237

T-2100 85 1/16 104 3/8 4 4 1 1 1 - 3 *** 57 7/8 24500 295

T-2125 87 120 1/8 6 6 2 1 1 - 3 *** 57 7/8 29060 369

T-2150 90 130 6 6 2 2 1 - 5 *** 68 7/8 33260 446

T-2175 97 7/8 130 5 5 2 2 1 - 5 *** 68 7/8 40250 518

T-2200 117 3/4 148 3/8 6 6 2 2 1 1/4 1 1/4 5 *** 68 7/8 43760 592

T-2225 125 5/8 148 3/8 6 6 2 2 1 1/4 1 1/4 7 1/2*** 93 61270 656

T-2250 125 5/8 148 3/8 8 8 2 2 1 1/4 1 1/4 7 1/2 *** 93 61270 737

T-2300 131 7/8 174 3/4 8 8 2 2 1 1/4 1 1/4 10 *** 93 77020 883

T-2350 133 1/2 188 5/8 8 8 2 2 1 1/4 1 1/4 10 *** 93 77020 1036

T-2400 153 1/8 203 7/8 8 8 4 2 2 2 15 *** 117 91030 1190

T-2500 154 11/16 219 5/8 10 10 4 2 2 2 15 *** 117 91030 1505

T-2600 171 5/8 259 7/8 10 10 4 2 2 2 20 *** 133 1/8 125000 1777

T-2700 181 5/16 259 7/8 10 10 4 2 2 2 20 *** 133 1/8 125000 2101

T-2800 194 11/16 299 1/4 12 12 4 3 2 2 30 *** 141 175000 2370

T-3000 202 1/2 299 1/4 12 12 4 3 2 2 30 *** 141 175000 3011

Electrical specifications: *110/220/1/60, 220/3/60, ** 110/220/1/60, 220/440/3/60, ***220/440/3/60

Tri-voltage fan motors (208-230-460-3-60) are available for ¾ h.p. and larger. Special order 50 cycle fan motors also available.

Nominal flow is defined as rate of water cooled from 95° to 85°, with 75° wet bulb temperature.

www.coolingtowersystems.com -3- 42 Years of Manufacturing Experience

WEIGHT (LBS.) DIMENSIONS (IN.) ANCHOR BOLT PUMP

QTY

T MODEL SIZE LENGTH HEAD

DRY OPERATING D1 W B A h h' C D2 (PCS.)

(INCH) (INCH) (FT.)

T-25 86 251 21 5/8 18 3/4 8 6 1/2 4 3/4 3 5.0

T-28 93 262 21 5/8 18 3/4 8 6 1/2 4 3/4 3 5.0

T-210 123 443 29 1/2 25 5/8 8 6 1/2 4 3/4 3 5.0

T-215 139 536 34 5/8 30 8 6 1/2 4 3/4 3 5.3

T-220 190 719 44 38 1/4 8 6 1/2 4 3/4 3 5.6

T-225 227 887 44 38 1/4 8 6 1/2 4 3/4 3 5.6

T-230 253 1074 52 1/2 37 8 6 1/2 4 3/4 4 6.0

T-240 369 1133 57 7/8 40 7/8 10 8 1/2 4 3/4 4 6.6

T-250 435 1313 66 1/8 46 3/4 10 8 1/2 4 3/4 4 6.6

T-260 504 1472 66 1/8 46 3/4 10 8 1/2 4 3/4 4 6.6

T-270 610 1555 69 3/8 34 1/2 10 8 9 1/2 10 1/2 4 3/4 5 6.6

T-280 642 1588 69 3/8 34 1/2 10 8 9 1/2 10 1/2 4 3/4 5 6.6

T-2100 887 2361 92 1/2 46 1/4 12 12 14 12 5/8 8 5 8.2

T-2125 1025 2983 103 1/8 51 1/2 12 12 14 12 5/8 8 5 10.0

T-2150 1375 5731 112 1/2 56 1/4 12 12 13 1/2 16 5/8 8 5 10.0

T-2175 1569 5887 112 1/2 56 1/4 12 12 13 1/2 16 5/8 8 5 11.0

T-2200 1914 7612 132 93 3/8 12 5 1/8 12 16 23 5/8 8 8 11.0

T-2225 2112 7744 132 93 3/8 12 5 1/8 12 16 23 5/8 8 8 11.0

T-2250 2266 7854 132 93 3/8 12 5 1/8 12 16 23 5/8 8 8 12.0

T-2300 2823 9995 156 1/8 110 3/8 12 5 1/2 12 16 23 5/8 8 8 12.0

T-2350 2996 10164 169 1/8 119 5/8 12 5 1/2 12 16 23 5/8 8 8 13.2

T-2400 4776 14984 200 3/4 100 3/8 20 5 1/2 12 16 31 1/2 114 1/4 3/4 8 12 13.2

T-2500 5342 15550 216 1/2 108 1/4 20 5 1/2 12 16 31 1/2 122 3/4 8 12 13.2

T-2600 7401 23637 255 1/8 97 5/8 20 5 1/2 12 16 31 1/2 141 3/4 3/4 8 16 16.4

T-2700 7848 24127 255 1/8 97 5/8 20 5 1/2 12 16 31 1/2 141 3/4 3/4 8 16 18.2

T-2800 9636 26356 295 1/4 113 20 5 1/2 12 16 31 1/2 163 1/2 3/4 8 16 20.0

T-3000 10199 27359 295 1/4 113 20 5 1/2 12 16 31 1/2 163 1/2 3/4 8 16 20.0

Specifications subject to change without notice.

www.coolingtowersystems.com -4- 42 Years of Manufacturing Experience

Sound Pressure Levels and Tower Capacities

SOUND PRESSURE LEVELS OF COOLING TOWER SYSTEMS TOWERS

LEVEL OF MEASUREMENT: db

NOTE: THE ACCURACY OF MEASURING

VALUE IS ±3 DECIBELS

REMARKS:

1. POINT 1 IS 45° EXTENSION OF FAN DISCHARGE.

2. DISTANCE "S":

(1) T MODELS 2125 & LOWER - 4'11"

(2) T MODELS 2150 & ABOVE - FAN DIAMETER

TOWER MODEL T-25 T-28 T-210 T-215 T-220 T-225 T-230

MEASURING PT. 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3

SCALE A 62 59 48 63 58 47.5 64 59 48.5 69 66 53 69 66 53 70 67 57 73 67 59

TOWER MODEL T-240 T-250 T-260 T-270 T-280 T-2100 T-2125

MEASURING PT. 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3

SCALE A 77 70 59 77 70 59 79 73 64 81 75 66 82 76 67 79 71 60 84 74 64

TOWER MODEL T-2150 T-2175 T-2200 T-2225 T-2250 T-2300 T-2350

MEASURING PT. 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3

SCALE A 77 71 62 80 75 65 79 73 63 76 71 62 76 71 62 77 72 63 77 72 63

TOWER MODEL T-2400 T-2500 T-2600 T-2700 T-2800 T-3000

MEASURING PT. 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3

SCALE A 79.5 74.5 65.5 79.5 74.5 65.5 77.5 72.5 63.5 77.5 72.5 63.5 78.5 74 65 80 75 66

TOWER CAPACITIES

HOT WATER 90 ° F 90 ° F 95 ° F 92 ° F 95 ° F 97 ° F 95 ° F 95 ° F 96 ° F 98 ° F 90 ° F 94 ° F

COLD WATER 80 ° F 80 ° F 85 ° F 82° F 85 ° F 87 ° F 85 ° F 85 ° F 86 ° F 88 ° F 83 ° F 85 ° F T MODEL

WET BULB 65 ° F 70 ° F 70 ° F 72 ° F 75 ° F 75 ° F 77 ° F 78 ° F 80 ° F 82 ° F 75 ° F 75 ° F

17 12 20 13 15 18 12 11 10 11 15 16 T-25

27 20 32 21 23 29 20 18 16 17 25 26 T-28

34 25 39 27 30 35 25 23 20 23 31 32 T-210

51 37 60 40 44 54 37 33 31 33 46 48 T-215

68 49 80 53 58 72 49 45 41 44 62 64 T-220

85 62 97 66 73 90 62 56 52 56 77 79 T-225

101 75 119 80 88 108 75 68 63 68 93 96 T-230

134 100 156 106 118 142 101 92 85 91 124 128 T-240

168 127 195 134 148 178 127 116 108 115 155 159 T-250

201 150 224 160 177 211 151 138 128 137 185 191 T-260

236 176 262 188 207 251 176 160 150 160 218 224 T-270

268 203 308 215 237 253 203 185 173 184 248 256 T-280

335 250 382 266 295 356 252 230 213 228 309 319 T-2100

GPM 420 316 480 235 369 446 316 289 270 289 388 400 T-2125

504 383 574 405 446 534 383 353 328 350 466 479 T-2150

588 441 676 471 518 611 444 407 377 404 541 558 T-2175

669 509 774 542 592 712 512 469 440 469 621 640 T-2200

757 559 885 595 656 803 559 503 468 503 696 717 T-2225

838 625 970 666 737 889 630 574 533 569 772 798 T-2250

1011 775 1175 800 883 1075 755 685 634 678 934 960 T-2300

1176 889 1340 946 1036 1240 895 818 767 818 1087 1119 T-2350

1349 1023 1540 1084 1190 1420 1023 930 871 932 1240 1278 T-2400

1657 1301 1885 1377 1505 1763 1324 1226 1157 1233 1551 1604 T-2500

2006 1526 2322 1625 1777 2137 1537 1406 1319 1406 1864 1919 T-2600

2317 1819 2640 1928 2101 2469 1841 1700 1641 1711 2177 2242 T-2700

2675 2035 3096 2166 2370 2849 2050 1875 1759 1875 2486 2559 T-2800

3303 2616 3760 2762 3011 3300 2660 2484 2353 2499 3098 3201 T-3000

NOTE: TONS OF REFIRGERATION AT 250 BTU/MIN WITH 3GPM/TON.

www.coolingtowersystems.com -5- 42 Years of Manufacturing Experience

You might also like

- Alcpt 1 - 35Document220 pagesAlcpt 1 - 35الحربي الحربي93% (14)

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- GS3BA Series High Efficiency Air Conditioner: Technical SpecificationsDocument4 pagesGS3BA Series High Efficiency Air Conditioner: Technical Specificationstrien15No ratings yet

- Truwater - TCM SeriesDocument12 pagesTruwater - TCM SeriesnkhhhNo ratings yet

- Csa 10 To 20Document6 pagesCsa 10 To 20peterpunk75No ratings yet

- Yu-Gi-Oh Card CodesDocument18 pagesYu-Gi-Oh Card CodesBenjamin CoxNo ratings yet

- Catalogo - Torres - PDF Versión 1 PDFDocument5 pagesCatalogo - Torres - PDF Versión 1 PDFRafael QuirogaNo ratings yet

- Condensadora Westinghouse 5TR Mod DS3BA - DS5BADocument4 pagesCondensadora Westinghouse 5TR Mod DS3BA - DS5BAOscar Sanchez Velasquez0% (1)

- CGAT Catalog0303Document2 pagesCGAT Catalog0303Chinith HengNo ratings yet

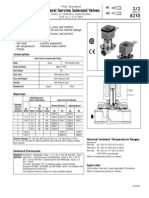

- Valvulas ASCO PDFDocument4 pagesValvulas ASCO PDFelkin880604No ratings yet

- Tee Type StrainersDocument3 pagesTee Type StrainersSrinu AmulojuNo ratings yet

- Someflu FP ECO-N ENDocument2 pagesSomeflu FP ECO-N ENAnonymous r3MoX2ZMTNo ratings yet

- 09 Se CatalogDocument80 pages09 Se CatalogOtto AcnNo ratings yet

- T Ces Series PDFDocument12 pagesT Ces Series PDFDaniel InostrozaNo ratings yet

- Peerless Blowers Direct Drive Blowers Forward CurveDocument6 pagesPeerless Blowers Direct Drive Blowers Forward CurveLuis Alonso Zavala GuerraNo ratings yet

- TXSSeries PDFDocument16 pagesTXSSeries PDFRCYABONo ratings yet

- Ventilator - Mixvent-Td (En)Document23 pagesVentilator - Mixvent-Td (En)Muhidin KozicaNo ratings yet

- SST Series Engineering Manual 413a-Sem 0Document52 pagesSST Series Engineering Manual 413a-Sem 0Gerber GarciaNo ratings yet

- Series 919 Specification SheetDocument4 pagesSeries 919 Specification SheetWattsNo ratings yet

- Comparision Sheet-Ccoling TowersDocument16 pagesComparision Sheet-Ccoling TowersKenny RuizNo ratings yet

- MotivairDocument8 pagesMotivaircortezt0% (1)

- Catalogo ChillerDocument8 pagesCatalogo ChillerJoan Sebastian DazaNo ratings yet

- Air Cooled Screw Chiller R134aDocument12 pagesAir Cooled Screw Chiller R134aamitbslpawar0% (1)

- Section E: EnclosuresindexDocument32 pagesSection E: EnclosuresindexNMETETRNo ratings yet

- FlierDocument2 pagesFlierSatish ChakravarthyNo ratings yet

- Cooling Tower CatalogDocument16 pagesCooling Tower CatalogKannan VellasamyNo ratings yet

- SELENOIDE-Valv Solen 8210Document6 pagesSELENOIDE-Valv Solen 8210MARACO46No ratings yet

- Amcot Cooling Towers-1 PDFDocument3 pagesAmcot Cooling Towers-1 PDFJR VargasNo ratings yet

- Catalogohce090 150Document18 pagesCatalogohce090 150Xol DiaMa GarciaNo ratings yet

- Chiller Koolman CgakDocument8 pagesChiller Koolman Cgakfabieduarte440No ratings yet

- Asco Series 210 General Service CatalogDocument6 pagesAsco Series 210 General Service CatalogEric ToroNo ratings yet

- Trane CommercialDocument2 pagesTrane CommercialilieoniciucNo ratings yet

- CLCP Euro - Commercial May 09: Quick Selection ProcedureDocument2 pagesCLCP Euro - Commercial May 09: Quick Selection ProcedurehfrankieNo ratings yet

- CI Close-Coupled End Suction Pumps: Water Circulation Pumps & CirculatorsDocument12 pagesCI Close-Coupled End Suction Pumps: Water Circulation Pumps & CirculatorsAndre Gazali MalikNo ratings yet

- RXVRXHDCYPDocument31 pagesRXVRXHDCYPFARIDNo ratings yet

- General Service Solenoid Valves: NC NODocument6 pagesGeneral Service Solenoid Valves: NC NOAngel Azathoth GoetzNo ratings yet

- Bryant 561CDocument28 pagesBryant 561Cspencer_lawrence_2No ratings yet

- Gardner Denver Industrial Blowers TF 140L K202Document8 pagesGardner Denver Industrial Blowers TF 140L K202Aleksandar JočićNo ratings yet

- Axial Flow FanDocument8 pagesAxial Flow FanNagam AbhishekNo ratings yet

- Toyo Butterfly Valve PDFDocument20 pagesToyo Butterfly Valve PDFJimmy Adi100% (2)

- Catálogo M-DA InglêsDocument20 pagesCatálogo M-DA Inglêsjf2003No ratings yet

- 06 SCT Extended PDFDocument40 pages06 SCT Extended PDFSlobodan Antic100% (2)

- TM Uat 1114 BDocument92 pagesTM Uat 1114 BDennis Lai Zhan WenNo ratings yet

- KSB ETA CD Low Pressure PDFDocument4 pagesKSB ETA CD Low Pressure PDFjosebaldes100% (1)

- Valvula SolenoideDocument6 pagesValvula SolenoideArnezNo ratings yet

- Ariel JGK and JGT CompressorsDocument5 pagesAriel JGK and JGT CompressorsPablo GutierrezNo ratings yet

- Product Data: 38CKE 50Hz Air Conditioner With R - 410a Refrigerant Single and Three Phase 1 - 1/2 To 5 TonsDocument26 pagesProduct Data: 38CKE 50Hz Air Conditioner With R - 410a Refrigerant Single and Three Phase 1 - 1/2 To 5 Tonsalmig200No ratings yet

- Keystone 990 (Pentair Retail)Document4 pagesKeystone 990 (Pentair Retail)Etienne SavatNo ratings yet

- Dryplus 3Document10 pagesDryplus 3sallehasanNo ratings yet

- York Furnace ManualDocument8 pagesYork Furnace ManualToky100No ratings yet

- Series TDV Specification SheetDocument2 pagesSeries TDV Specification SheetWattsNo ratings yet

- Series 909RPDA Specification SheetDocument4 pagesSeries 909RPDA Specification SheetWattsNo ratings yet

- ATC BrochureDocument24 pagesATC BrochureCésar HermosoNo ratings yet

- Large Cap Fan Coils PD2010Document6 pagesLarge Cap Fan Coils PD2010Mohd AdieNo ratings yet

- Split Type Airconditioner CS-C9DKD CU-C9DKD Service ManualDocument85 pagesSplit Type Airconditioner CS-C9DKD CU-C9DKD Service Manualchrspta67% (3)

- Feed Water Heater - Isolation System: Features & BenefitsDocument9 pagesFeed Water Heater - Isolation System: Features & BenefitsAkash PatilNo ratings yet

- Severe Service - Stainless Steel Air Separators Spa 2-Ss To Spa 24-SsDocument1 pageSevere Service - Stainless Steel Air Separators Spa 2-Ss To Spa 24-SsMaria Das Dores RodriguesNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Wind Turbines in Cold Climates: Icing Impacts and Mitigation SystemsFrom EverandWind Turbines in Cold Climates: Icing Impacts and Mitigation SystemsNo ratings yet

- Tesco Saves Millions With Supply Chain AnalyticsDocument3 pagesTesco Saves Millions With Supply Chain AnalyticsWessim BmwNo ratings yet

- Reflection EssayDocument2 pagesReflection Essayapi-240936133No ratings yet

- Humiseal 1A33 Conformal Coating English TdsDocument2 pagesHumiseal 1A33 Conformal Coating English TdsLee HitchensNo ratings yet

- Different Residential Design in Different Region of NepalDocument10 pagesDifferent Residential Design in Different Region of Nepalsujan shrestha100% (1)

- Application of Infrared Thermography Technique in Uilding Finish EvaluationDocument9 pagesApplication of Infrared Thermography Technique in Uilding Finish EvaluationNicolas De NadaiNo ratings yet

- Nevada Sagebrush Archives 02/03/09Document28 pagesNevada Sagebrush Archives 02/03/09The Nevada SagebrushNo ratings yet

- Beaufort Wind Scale, Weather, Ice, Tides y Ship Motions EquipmentDocument5 pagesBeaufort Wind Scale, Weather, Ice, Tides y Ship Motions EquipmentAndres Garcia VisbalNo ratings yet

- 2015, HOLMES WhatIsNationalSecurityDocument10 pages2015, HOLMES WhatIsNationalSecurityRodrigo LentzNo ratings yet

- Spatial Prediction in HydrologyDocument21 pagesSpatial Prediction in HydrologyOfee ZaRaagoozaaNo ratings yet

- YARI SDG&E TestimonyDocument38 pagesYARI SDG&E Testimonyonell.soto653No ratings yet

- Bladedesign CalcDocument55 pagesBladedesign CalcMeiring PretoriusNo ratings yet

- Engaged Learning Project Itec 7400Document4 pagesEngaged Learning Project Itec 7400api-259247005No ratings yet

- JROSDocument8 pagesJROSRio ApertaNo ratings yet

- SRCC GBO 2010 Exam PaperDocument21 pagesSRCC GBO 2010 Exam PaperMBAGLUE82% (11)

- Perter GrimesDocument2 pagesPerter GrimesjotopoNo ratings yet

- Clean Burning Biomass Cookstoves 2016Document179 pagesClean Burning Biomass Cookstoves 2016PetrovecNo ratings yet

- Earth and Life Science: Quarter 1 - Module 8Document12 pagesEarth and Life Science: Quarter 1 - Module 8Sweet MintNo ratings yet

- DLP 7 - Grade 7 - ASORDocument6 pagesDLP 7 - Grade 7 - ASORayanasor6100% (1)

- Have Had To Go To Parts of The Town Which Were Not: Word FormDocument6 pagesHave Had To Go To Parts of The Town Which Were Not: Word Formthuymilk100% (1)

- Access Design StandardsDocument90 pagesAccess Design Standardsgustavo sevillaNo ratings yet

- Catalogue Conditioner AirDocument85 pagesCatalogue Conditioner AirjotalopecincoNo ratings yet

- Where Hudson's Voyage EndedDocument40 pagesWhere Hudson's Voyage Endedhanderklander99No ratings yet

- Poultry Housing Revised-2 PDFDocument31 pagesPoultry Housing Revised-2 PDFAli BairleNo ratings yet

- Adendum 1Document10 pagesAdendum 1Chidinma Glory EjikeNo ratings yet

- Opportunities For Opportunities For: Work, WorkDocument5 pagesOpportunities For Opportunities For: Work, WorkMaarten JacobsNo ratings yet

- Brother Sewing Machine InstructionsDocument56 pagesBrother Sewing Machine InstructionsDwaine Webb100% (1)

- All Cheats Including Pok EmeraldDocument68 pagesAll Cheats Including Pok EmeraldWiznu MurtiNo ratings yet

- List of Magickas (Spellbook Spells) - Magicka TipsDocument11 pagesList of Magickas (Spellbook Spells) - Magicka TipsSkullfernoNo ratings yet