Professional Documents

Culture Documents

4hp16 Cuerpo de Valvula PDF

4hp16 Cuerpo de Valvula PDF

Uploaded by

Daniel NavasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4hp16 Cuerpo de Valvula PDF

4hp16 Cuerpo de Valvula PDF

Uploaded by

Daniel NavasCopyright:

Available Formats

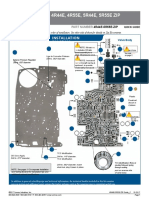

Technical Bulletin #1644

Transmission: ZF4HP16

Subject: Solenoid ID

Application: 04-07 Suzuki Forneza, 04-06 Suzuki Verona

Issue Date: October, 2014

ZF4HP16

Solenoid ID

Copyright © 2014 ATRA All Rights Reserved JW • Page 1 of 2

ZF4HP16 #1644

Solenoid ID

JW • Page 2 of 2 Copyright © 2014 ATRA All Rights Reserved

Technical Bulletin #1645

Transmission: A960E

Subject: Bench Notes and Rebuild Procedures

Application: Toyota

Issue Date: October, 2014

A960E TOYOTA A960-E

Bench Notes and Rebuild

This unit Procedures

components are as follow on the chart below

This unit’s components are as follow on the chart below.

C1 No 1 Clutch pack Amount of disc clutches 4

C2 No 2 Clutch pack Amount of disc clutches 5

C3 No 3 Clutch pack Amount of disc clutches 4

C4 No 4 Clutch pack Amount of disc clutches 4

B1 No 1 Clutch Brake Amount of disc clutches 3

B2 No 2 Clutch Brake Amount of disc clutches 4

B3 No 3 Clutch Brake Amount of disc clutches 3

B4 No 4 Clutch Brake Amount of disc clutches 5

F1 No 1 One Way Clutch Amount of Elements 21

F2 No 2 One Way Clutch Amount of Elements 22

F3 No 3 One Way Clutch Amount of Elements 22

F4 No 4 One Way Clutch Amount of Elements 25

The No of Sun Gear Teeth 33

FRONT

Inner 19

PLANETARY The No of Pinion Gear Teeth

GEARS Outer 18

The No of Ring Gear Teeth 75

The No of Sun Gear Teeth 26

CENTER

PLANETARY The No of Pinion Gear Teeth 20

GEARS

The No of Ring Gear Teeth 66

The No of Sun Gear Teeth 26

REAR

PLANETARY The No of Pinion Gear Teeth 20

GEARS

The No of Ring Gear Teeth 66

Copyright © 2014 ATRA All Rights Reserved RA • Page 1 of 6

A960E TOYOTA A960-E #1645

Bench Notes

Thisand Rebuild Procedures

unit components are as follow on the chart below

C1 No 1 Clutch pack Connects the input shaft and F4 intermidiate shaft

C2 No 2 Clutch pack Connects the input shaft and center planetary carrier

C3 No 3 Clutch pack Connects the input shaft and the sun gear

C4 No 4 Clutch pack Connects the input shaft and intermidiate shaft

B1 No 1 Clutch Brake Prevents front planets from turning clock or counterclock

B2 No 2 Clutch Brake Prevents front and center ring gear from turning either way *

B3 No 3 Clutch Brake Prevents outer race F2 from turning either way *

B4 No 4 Clutch Brake Prevents center planet carrier from turning either way *

F1 No 1 One Way Clutch Prevents front planet carrier from turning clockwise

When B3 operates the OWC prevents front sun gear from

F2 No 2 One Way Clutch turning counter clockwise

Prevents the center planetary carrier and rear ring gear from

F3 No 3 One Way Clutch turning counter clockwise

F4 Prevents the intermediate shaft from turning counter

No 4 One Way Clutch clockwise

These gears change the route through which driving force is transmitted

Planetary

in accordance with operation of each clutch and brake, in order to

Gears increase or reduce the output shaft speed.

Transmission type A960-E

Engine type 4GR-FSE

Gear Ratio 1st Gear 3.538

Gear Ratio 2nd Gear 2.060

Gear Ratio 3rd Gear 1.404

Gear Ratio 4th Gear 1.000

Gear Ratio 5th Gear 0.713

Gear Ratio 6th Gear 0.582

Gear Ratio Reverse 3.168

Fluid Capacity Genuine Toyota Fluid

Weight Reference Shows The figure of (164.7 lbs ) Fluid Fully Filled

Liters ( US qts / Import qts ) 7.2 (7.6, 6.3)

RA • Page 2 of 6 Copyright © 2014 ATRA All Rights Reserved

TOYOTA A960-E

#1645 A960E

This unit components are as follows on the chart below

Bench Notes and Rebuild Procedures

SOLENOID VALVES CLUTCHES BRAKES OWC

Shifter

Position

S1 S2 S3 S4 SR Sl1 Sl2 SLU C1 C2 C3 C4 B1 B2 B3 B4 F1 F2 F3 F4

P ON ON ON ON

R* ON ON ON ON

N ON ON ON ON

1st ON ON ON ON

2nd ON ON ON ON ON ON

D 3rd ON ON ON ON ON

S6 4th* ON ON ON ON

5th* ON ON ON ON

6th* ON ON ON ON ON

1st ON ON ON ON

2nd ON ON ON ON ON ON

S5 3rd ON ON ON ON ON

4th* ON ON ON ON

5th* ON ON ON

ON ON

1st ON ON

2nd ON ON ON ON ON ON

S4

3rd ON ON ON ON ON

4th* ON ON ON ON ON

1st ON ON ON ON

S3 2nd ON ON ON ON ON

3rd* ON ON ON

1st ON ON ON ON

S2

2nd ON ON ON ON ON

S1 1st* ON ON ON

OPERATIONAL OPERATES BUT NON EFFECTIVE

OPERATIONAL DURING ENG BRAKING * WITH ENG BRAKING

Copyright © 2014 ATRA All Rights Reserved RA • Page 3 of 6

A960E #1645

Bench Notes and TOYOTA

Rebuild Procedures

A960-E

This unit components are as follows on the chart below

FILL PLUG

OVERFLOW PLUG

50 60

40

70

30

80

20

90

10

5 100

0

RA • Page 4 of 6 Copyright © 2014 ATRA All Rights Reserved

#1645 A960E

Bench Notes and Rebuild Procedures

TOYOTA A960-E

This unit components are as follows on the chart below

FILLPLUG

OVERFLOW PLUG

CG#4

DLC3

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15 16

TC#13

Copyright © 2014 ATRA All Rights Reserved RA • Page 5 of 6

A960E #1645

Bench Notes and Rebuild Procedures

Checking the fluid level without the intelligent tester.

(1)-Connect terminals CG-4 and TC-13 on the DLC3 using SST.

(2)- Move the selector shift lever back and forth between N and D every 1.5 seconds for 6 seconds.

(3)-The D shift indicator on the combination meter comes on for 2 seconds. This indicates that the fluid

temperature check mode has been activated and started.

(4)- The shift indicator will come on again when the fluid temp reaches 46º C (115ºF ) and will blink

when exceeds 56º (133ºF ).

Always allow engine to come up to temperature of (115ºF).

Check Fluid Level

(a)- The fluid temperature must be between 39º (102ºF) and 49º (120ºF) to accurately check the fluid

level.

(b)- Remove the overflow plug with the engine running and check and see if fluid comes out the overflow

tube.

If fluid does not come out, proceed to step number (5).

If fluid comes out then wait till the fluid just trickles down then proceed to step number (5).

Refilling with fluid.

(5)- Install the over flow plug.

(6)- Stop the engine.

(7)- Remove the refill plug.

(8)- Add (0.42 us qts of fluid.

(9)- Allow the engine to idle and wait 10 seconds.

(10)- Go back to Checking the fluid level above.

After filling the transmission

(a)-Install the overflow plug with a new gasket and torque to 15 FT lbs.

(b)- Stop the engine.

(c)-Install the refill plug with a new O ring and torque to 29 FT lbs.

(d)- Install case cover.

NOTE:

Performed repair Fill Amount

Transmission oil pan and drain plug 1.0 liters (1.06 us qts)

Removal.

Transmission Valve body removal 2.2 liters (2.33 us qts)

Torque converter removal 3.7 liters (3.91 us qts)

Entire transmission assembly 7.2 liters (7.61 us qts)

RA • Page 4 of 6 Copyright © 2014 ATRA All Rights Reserved

Technical Bulletin #1646

Transmission: U660E, U660F, U760E & U760F

Subject: Lube Concerns, Bearing and Bushing Failures

or Transmission Overheats

Application: Toyota

Issue Date: October, 2014

U660E, U660F, U760E & U760F

Lube Concerns, Bearing and Bushing Failures, Overheating

While working on a U650E, U660F, U760E or a U760F transmission, you may encounter lube concerns,

bearing or bushing failures or transmission overheating concerns which may be caused by a worn sec-

ondary pressure regulator valve or bore. Replacing the secondary pressure regulator valve and sleeve

may be needed to repair this concern. Aftermarket parts are available to complete this repair.

Copyright © 2014 ATRA All Rights Reserved PH • Page 1 of 1

Technical Bulletin #1647

Transmission: U151E

Subject: No 3rd Gear

Application: Sienna

Issue Date: October, 2014

U151E

No 3rd Gear

We have found that a no 3rd gear problem in a U151E transmission can be caused by the splines in the

forward planet being sheared off the pinion carrier.

Copyright © 2014 ATRA All Rights Reserved RA • Page 1 of 1

Technical Bulletin #1648

Transmission: 62TE

Subject: DTC P2764, TCC Stuck “ON”

Application: Chrysler

Issue Date: October, 2014

62TE

DTC P2764, TCC Stuck “ON”

This vehicle was towed in and the customer stated that he was on a long trip and when he got off

highway and stopped at gas station, his engine died. After getting gas he started the vehicle and every

time he put it in Drive the engine died but not in Reverse.

The EMCC VFS Solenoid is used to control the duty cycle of the Torque Converter Clutch (TCC). The

PCM monitors the voltage on the EMCC VFS Solenoid Control circuit. If the PCM detects a failure for 2

consecutive trips, a P2764 DTC is set.

Possible Causes

• (T84) EMCC VFS Control Circuit Open

• (T84) EMCC VFS Control Circuit Short to Voltage

• (T84) EMCC VFS Control Circuit Short to Ground

• (T84) EMCC VFS Control Circuit Short to Another Circuit

• EMCC VFS Control Solenoid Transmission Control Module

• Defective Solenoid

Replace the TCC solenoid

Part # 5169313AA

Copyright © 2014 ATRA All Rights Reserved MB • Page 1 of 1

Technical Bulletin #1649

Transmission: ZF6HP26/6R60

Subject: Delayed or Harsh Engagements

Application: BMW

Issue Date: October, 2014

ZF6HP26/6R60

Delayed or Harsh Engagements

While working on a ZF6HP26 or 6R60 transmission, you may encounter a delayed or harsh engage-

ment. This concern may be caused by a worn pressure regulator valve or bore. Replacing the pressure

regulator valve & reaming the bore may be needed to repair this concern. Aftermarket parts are avail-

able to complete this repair.

Copyright © 2014 ATRA All Rights Reserved PH • Page 1 of 1

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (347)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Aw 60-40le, 60-41SN (Af13)Document4 pagesAw 60-40le, 60-41SN (Af13)josue50% (2)

- Aw 60-40le, 60-41SN (Af13)Document4 pagesAw 60-40le, 60-41SN (Af13)josue50% (2)

- FORD 4R44E, 4R55E, 5R44E, 5R55E ZIP KIT: Installation DiagramDocument11 pagesFORD 4R44E, 4R55E, 5R44E, 5R55E ZIP KIT: Installation Diagramjosue100% (1)

- MX - Qro - Qro: Querétaro 76030 MexicoDocument4 pagesMX - Qro - Qro: Querétaro 76030 MexicojosueNo ratings yet

- Escape FallasDocument103 pagesEscape Fallasjosue100% (1)

- Toyota/Lexus A340, A340E/F/H: Click On Part Numbers For Product Details or VisitDocument1 pageToyota/Lexus A340, A340E/F/H: Click On Part Numbers For Product Details or VisitjosueNo ratings yet

- 09g Sensores de Velocidad Bora, Jetta de La Transmision Aut.: Venta: #1958854037 Cant: 1Document4 pages09g Sensores de Velocidad Bora, Jetta de La Transmision Aut.: Venta: #1958854037 Cant: 1josueNo ratings yet

- Troubleshooting The 604 (41TE) : CAUTION: BeforeDocument6 pagesTroubleshooting The 604 (41TE) : CAUTION: BeforejosueNo ratings yet

- LibroDocument2 pagesLibrojosueNo ratings yet

- DSG 6 SpeedDocument2 pagesDSG 6 Speedjosue100% (1)

- FWD 4 Speed: Output Shaft Side CoverDocument7 pagesFWD 4 Speed: Output Shaft Side CoverjosueNo ratings yet

- Mitsubishi Hyundai PDFDocument46 pagesMitsubishi Hyundai PDFjosueNo ratings yet

- 440-T4 / 4T60E / 4T65E: FWD 4 SpeedDocument8 pages440-T4 / 4T60E / 4T65E: FWD 4 SpeedjosueNo ratings yet

- 440-T4 / 4T60E / 4T65E: FWD 4 SpeedDocument8 pages440-T4 / 4T60E / 4T65E: FWD 4 SpeedjosueNo ratings yet

- 09g Arnes de La Transmision Automatica: Venta: #1996794097 Cant: 1Document4 pages09g Arnes de La Transmision Automatica: Venta: #1996794097 Cant: 1josueNo ratings yet

- 6-Speed Dual Clutch Transmission 02e Eng PDFDocument157 pages6-Speed Dual Clutch Transmission 02e Eng PDFjosueNo ratings yet

- Automatic Transaxle Overhaul : Group 23CDocument86 pagesAutomatic Transaxle Overhaul : Group 23CjosueNo ratings yet

- Nakhodka, Russia: Position UN Locode IncludingDocument11 pagesNakhodka, Russia: Position UN Locode IncludingHarman SandhuNo ratings yet

- 777F MG SistemasDocument118 pages777F MG SistemasDavid Mercado100% (1)

- EnDocument8 pagesEnStoyan KostovNo ratings yet

- Lesson 17Document14 pagesLesson 17Kha LaiNo ratings yet

- Rental Agreement # 245795: USAVE Truck & Van RentalsDocument2 pagesRental Agreement # 245795: USAVE Truck & Van RentalsSafenaz BolesNo ratings yet

- Orfano - History of Camera Movement PDFDocument2 pagesOrfano - History of Camera Movement PDFAudrey HernandezNo ratings yet

- Railway Board Has Referred Three AllowancesDocument73 pagesRailway Board Has Referred Three AllowancesTvs ReddyNo ratings yet

- BQDocument26 pagesBQNyomar ThanNo ratings yet

- 3dxplus 4WDDocument1 page3dxplus 4WDEsyamAzmanNo ratings yet

- Steamboats - Hudson River - From 1786Document214 pagesSteamboats - Hudson River - From 1786Clyde Steamers100% (1)

- Integrated Urban Mass Transit System For Sustainable DevelopmentDocument96 pagesIntegrated Urban Mass Transit System For Sustainable Developmentgosetsuke100% (1)

- Industry Structure and Competitiveness of The Philippine Inter-Island ShippingDocument38 pagesIndustry Structure and Competitiveness of The Philippine Inter-Island ShippingJeremy YapNo ratings yet

- 4045 6068productsheet11Document1 page4045 6068productsheet11EngAbdelrahman KhamesNo ratings yet

- Chat GPTDocument17 pagesChat GPTfarunahi123No ratings yet

- Achievement Chart UpdatedDocument1 pageAchievement Chart UpdatedrubenNo ratings yet

- Tempus Trans Broshure 2018Document1 pageTempus Trans Broshure 2018GrazvydasNo ratings yet

- Oil Free CompressorsDocument1 pageOil Free Compressorspkhanifmu1No ratings yet

- BS A1 Oct (Daniel)Document11 pagesBS A1 Oct (Daniel)Duy HưngNo ratings yet

- Design of Flexible PavementsDocument165 pagesDesign of Flexible Pavementskyugu67% (3)

- Direct Current TransmissionDocument264 pagesDirect Current TransmissionAkshay SinghNo ratings yet

- Advanced Insulationfor Subsea ApplicationDocument2 pagesAdvanced Insulationfor Subsea ApplicationAforbajeNo ratings yet

- CSIR NET Life Sciences June 2011 Question Paper Key PDFDocument47 pagesCSIR NET Life Sciences June 2011 Question Paper Key PDFAmrita NepaliaNo ratings yet

- Área de Inglés Pre-Grado: Elva Taica Burga Hamburg Port Janet Gutierrez RiveraDocument23 pagesÁrea de Inglés Pre-Grado: Elva Taica Burga Hamburg Port Janet Gutierrez Riveraelva taica burgaNo ratings yet

- Quiz Cell MembraneDocument4 pagesQuiz Cell MembraneDeepan Chakkaravarthi100% (1)

- Astra Opc GBDocument3 pagesAstra Opc GBmnbvqwertNo ratings yet

- Internship Report On Wheat Processing at Naga LTD.: Logesh.DDocument16 pagesInternship Report On Wheat Processing at Naga LTD.: Logesh.Dlogesh dhanapalNo ratings yet

- VP Director Distribution Operations in Dallas FT Worth TX Resume Reginald DavisDocument3 pagesVP Director Distribution Operations in Dallas FT Worth TX Resume Reginald DavisReginaldDavisNo ratings yet

- 6E 2134 1015 Hrs Zone 2 17F: Boarding Pass (Web Check In)Document2 pages6E 2134 1015 Hrs Zone 2 17F: Boarding Pass (Web Check In)alondraortega07No ratings yet

- Impact Bed Techdata RsaDocument2 pagesImpact Bed Techdata RsaEnter ExitNo ratings yet