Professional Documents

Culture Documents

CN30-8 (Classification Notes - Strength Analysis of Hull Structures in H PDF

CN30-8 (Classification Notes - Strength Analysis of Hull Structures in H PDF

Uploaded by

Michael CaoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CN30-8 (Classification Notes - Strength Analysis of Hull Structures in H PDF

CN30-8 (Classification Notes - Strength Analysis of Hull Structures in H PDF

Uploaded by

Michael CaoCopyright:

Available Formats

CLASSIFICATION NOTES

No. 30.8

STRENGTH ANALYSIS OF

HULL STRUCTURES IN

HIGH SPEED AND LIGHT CRAFT

AUGUST 1996

DET NORSKE VERITAS

Veritasveien 1, N-1322 Høvik, Norway Tel.: +47 67 57 99 00 Fax: +47 67 57 99 11

FOREWORD

DET NORSKE VERITAS (DNV) is an autonomous and independent Foundation with the object of safeguarding life,

property and the environment at sea and ashore.

DET NORSKE VERITAS AS (DNV AS), a fully owned subsidiary Society of the Foundation, undertakes classification and

certification and ensures the quality of ships, mobile offshore units, fixed offshore structures, facilities and systems, and

carries out research in connection with these functions. The Society operates a world-wide network of survey stations and is

authorised by more than 120 national administrations to carry out surveys and, in most cases, issue certificates on their behalf.

Classification Notes

Classification Notes are publications which give practical information on classification of ships and other objects. Examples of

design solutions, calculation methods, specifications of test procedures, as well as acceptable repair methods for some

components are given as interpretations of the more general rule requirements.

An updated list of Classification Notes is available on request. The list is also given in the latest edition of the Introduction-

booklets to the "Rules for Classification of Ships", the "Rules for Classification of Mobile Offshore Units" and the "Rules for

Classification of High Speed and Light Craft".

In "Rules for Classification of Fixed Offshore Installations", only those Classification Notes which are relevant for this type of

structure have been listed.

© Det Norske Veritas AS 1996

Data processed and typeset by Division Technology and Products, Det Norske Veritas AS

03/07/2003 10:43 AM - CN30-8.doc

Printed in Norway by Det Norske Veritas AS

9.96.2000

ERROR! AUTOTEXT ENTRY NOT DEFINED.

CONTENTS

1. GENERAL ...............................................................4 3.5 Reporting............................................................. 15

1.1 Introduction ...........................................................4 4. WATERJET DUCTS............................................ 16

1.2 Definitions .............................................................4 4.1 Introduction......................................................... 16

2. TRANSVERSE WEB FRAME ANALYSIS .........5 4.2 Load conditions................................................... 16

2.1 Introduction ...........................................................5 4.3 Modelling ............................................................ 18

2.2 Procedure ...............................................................5 4.4 Results and stress analysis .................................. 20

2.3 Load conditions .....................................................5 5. HIGH SPEED LIGHT CRAFT SUPPORTED BY

2.4 Beam element modelling .......................................8 FOILS................................................................................. 22

2.5 Finite element modelling .....................................10 5.1 Introduction......................................................... 22

2.6 Stress analysis......................................................10 5.2 Design loads on foil systems............................... 22

3. GLOBAL STRENGTH ANALYSIS....................12 5.3 Strength analyses................................................. 23

3.1 Introduction .........................................................12 5.4 Local analysis...................................................... 23

3.2 Design loads ........................................................12 5.5 Acceptance criteria.............................................. 23

3.3 Modelling.............................................................14 6. APPENDIX A TYPICAL STRUCTURAL

3.4 Design criteria......................................................15 DETAILS ........................................................................... 24

DET NORSKE VERITAS

4 Classification Notes- No. 30.8

August 1996

1. GENERAL 1.2.2 Notations

L = length of the craft in m defined as the length

1.1 Introduction between perpendiculars. Amidships is defined

These guidelines should be considered in connection with as the middle of L

DNV Rules for Classification of High Speed and Light Craft,

B = greatest moulded breadth in m

Pt.3 Ch.2 / Ch.3 Sec.9. The aim of these guidelines is to set a

standard for various types of direct strength calculations D = moulded depth in m

performed in addition to or as a substitute to the specific rule

requirements as given in the Rules for High Speed and Light T = fully loaded draught in m with craft floating

Craft. at rest in calm water

The application of direct stress analysis may be required as:

∆ = fully loaded displacement in tonnes in salt

a) Part of rule scantling determination. In such cases where water at draught T

simplified formulations are not able to take into account

Cb = block coefficient

special stress distributions, boundary conditions or

structural arrangements with sufficient accuracy, direct V = Maximum speed in knots

stress analysis has been required in the rules.

b) Alternative basis for the scantlings. In some cases direct Bwl = greatest moulded breath of the hull in m at the

stress calculations may give reduced scantlings, fully loaded water line, for multihull vessels

especially when optimisation routines are incorporated. Bwl is the net sum of the waterline breadths

1.1.1

g0 = standard acceleration of gravity = 9,81 m/s2

Due to complexity in design and extended need for direct

strength calculations, guidelines are given in excess of direct LCG = Longitudinal Centre of Gravity

rule requirements in some areas. Basis for class approval is

related to the general rule requirements applicable for the acg = vertical design acceleration at LCG (m/s2)

response to specific load conditions.

av = dynamic vertical design acceleration at

When direct calculations are intended as classification different positions along the length of the

documentation, the class should in general be approached craft (m/s2).

prior to submission of final documentation.

at = dynamic transverse acceleration (m/s2)

The aim of this Classification Note is to establish an

acceptable documentation standard with respect to direct ay, ary = as given in the Rules for Classification of

strength calculations as basis for a class approval of a HSLC Ships, Pt.3 Ch.1 Sec.4 B

design.

ρH = specified uniform cargo load (t/m2)

1.2 Definitions p = design pressure (kN/m2)

1.2.1 E = modulus of elasticity of the material, = 69 000

The following SI-units (International System of units) are N/mm2 for aluminium, = 206 000 N/mm2 for

used in this Note : steel

Mass tonne (t) Cw = wave coefficient

Length millimetre (mm) or meter (m), stated in Hs = significant wave height in m

each case

θ = rolling angle (deg).

Time seconds (s)

Force kilonewton (kN)

Acceleration meters per second square (m/s2).

DET NORSKE VERITAS

Classification Notes- No. 30.8 5

August 1996

When a 3-dimensional analysis is performed, the loads,

2. TRANSVERSE WEB FRAME ANALYSIS model and boundary conditions should correspond to the

approach outlined in this Classification Note.

2.1 Introduction

2.2.3

2.1.1

When pillars are fitted with regular intervals over the length

For girders which are part of a complex 2- or 3-dimensional of the cargo region, modelling of bottom and deck grillages

structural system, the Rules for Classification of High Speed may be necessary in addition to transverse web frame

and Light Craft require a complete structural analysis to be analysis. These additional calculations may involve an

carried out. The analysis is to show that the stresses are iteration process to obtain vertical force balance between the

acceptable for the structure in question when loaded in various grillage models. When this iteration process is

accordance with the described load conditions. necessary for simpler models, it is also valid to recommend a

bigger 3 dimensional model to include frames, decks and

Any recognised calculation method or computer program

pillars all together to make this iteration unnecessary.

may be applied, provided the effects of bending, shear, axial

and torsional deformations are considered when relevant. Bottom structures with longitudinal bottom girders and/or

large fuel or ballast tanks, should be analysed by a 3-

Strength analysis in accordance with the guidelines outlined

dimensional model. The model should preferably extend

in this Classification Note will normally be accepted as basis

from middle of one compartment to middle of next

for class approval.

compartment.

Guidance note:

When web frame strength analysis is submitted as documentation

for class approval of drawings, the following should be included:

− reference to drawings

− description of model including boundary conditions

− description of loads

− description of results

− conclusion.

See also 3.5.

End of Guidance note

2.1.2

Strength analysis as described is generally related to a web

frame structure of a High Speed and Light Craft, and unless

otherwise stated related to a 2-dimensional beam element

model.

2.2 Procedure

Figure 2-1 Frame or compartment for web frame

2.2.1 analysis

Calculations of the transverse web frame strength should

generally be performed for a typical frame in the midship

2.3 Load conditions

region for vessels less than 50 m. For larger vessels, and for 2.3.1

vessels with unusual arrangement, several sections along the

length of the vessel should be considered. Load Condition 1, sea pressure, maximum load on decks

(LC1)

2.2.2 This load condition is shown in Figure 2-2, and may be

When maximum response for a transverse web frame is to be decisive for side and deck structures.

established, a frame in the middle of a compartment is

normally analysed, see also Figure 2-1. The design pressures due to cargo loads (including structure)

are to be taken as :

Acceptable calculations may be performed by

p v = ρH ( g 0 + 0,5a v ) (kN/m2)

• 2-dimensional beam element framework analysis

• 3-dimensional framework or ρH = 0,35 t/m2 for accommodation decks, see also the Rules

• finite element calculations. Pt.3 Ch.1 Sec.2 C.

DET NORSKE VERITAS

6 Classification Notes- No. 30.8

August 1996

For wheel loaded decks, the actual wheel loads should be 2.3.2

applied. The worst combination of wheel loads on one frame Load Condition 2, symmetric bottom slamming (LC2)

should be analysed.

This load case is shown in Figure 2-3 and

In addition to a load case with point loads representing wheel

loads, an equivalent evenly distributed load should be Figure 2-4, and may be decisive for the bottom structure.

considered (minimum 4 kN/m2). The load case investigates the effect of symmetric impact

pressure on one frame, using the average impact pressure

Forces transferred to the analysed frame from surrounding values as given by the Rules.

structure should be applied as point loads (e.g. from

longitudinal girder when considering frame in way of The deck load distribution is the same as in LC1.

pillars).

The bottom slamming pressure is to be found from the Rules

Design sea pressures are to be taken in accordance with the Pt.3 Ch.1 Sec.2 C200-C300, and be taken as the greatest of

rules Pt.3 Ch.1 Sec.2 C500, and should be applied on all bottom slamming and pitching slamming. For frames

external surfaces. positioned where the forebody side and bow impact pressure

is largest, the loads must be applied up to main deck or

vertical part of craft side.

The design load area is normally taken as the frame spacing

times the length of the frame between the chine or upper turn

of bilge (m2) for bottom slamming.

For a 3-dimensional model, the bottom slamming pressure

should be applied for one frame, and sea pressure on the

bottom panels of the other frames.

Figure 2-2 Load condition 1 (definition of point loads Figure 2-3 Load condition 2. In midship region, bottom

from surrounding structure indicated schematic for one slamming pressure applied. In foreship area bow impact

pillar on one deck) pressure applied

DET NORSKE VERITAS

Classification Notes- No. 30.8 7

August 1996

0 .8 (m)

H L = 0 ,2 2 L ( k c − L)

1000

kc = 0,3 for catamaran, wave-piercer, SES, ACV, and

hydrofoil

kc = 0,5 for SWATH,

the tunnel top slamming pressure is to be replaced with sea

pressure.

In a 3-dimensional model, tunnel top slamming pressure only

needs to be applied to one frame (sea pressure on remaining

Figure 2-4 Definition of turn of bilge/chine for different frames).

hull shapes.

2.3.3

Load condition 3 and 4, asymmetric bottom slamming (LC3

and LC4)

This load case may be decisive for the bottom structure. The

load case investigates the effect of asymmetric impact

pressure on one frame, using the average impact pressure

values as given by the Rules. In the bottom area design loads

are applied on only one side at the time (inside slamming or

outside slamming).

The deck load distribution is the same as in LC1.

The bottom slamming pressure is to be taken from the Rules

Pt.3 Ch.1 Sec.2 C200-C300, and be taken as the greatest of

bottom slamming, pitching slamming and forebody and bow

impact pressure.

The design load area is taken as half of the area used in LC2.

In cases where a 3-dimensional analysis is performed, the

slamming pressure only needs to be applied to one frame

(sea pressure on other frames). Figure 2-5 Load condition 5

2.3.4 2.3.5

Load Condition 5, flat cross structure slamming (LC5) Load condition 6, transverse racking (LC6), monohull

vessels only.

This load case is shown in Fig.2.5, and may be decisive for

the cross structure of a multihull vessel. The load case This load case represents the vessel in heeled condition, and

investigates the effect of impact pressure on the wet deck, may be decisive for the lower side frames of a monohull. If a

using the average impact pressure values as given by the global racking calculation has been carried out, the

Rules. transverse and vertical displacements of decks and side

should be given as input, see also 3.3.10 regarding procedure

The deck load distribution is the same as in LC1, and the sea for global racking calculations.

pressure from water line to wet deck is taken from the Rules.

A simplified check may be performed as indicated below.

The tunnel top slamming pressure is to be taken from the

Rules Pt.3 Ch.1 Sec.2 C400. Design sea pressure is applied The deck vertical design load is taken as:

from centre line to design water line on the outside of the

p v = ρ H g 0 co s θ (kN/m2)

hull.

The design load area is taken as the frame spacing times the

distance between the hulls. The deck horizontal design load is taken as:

If the height from the water line to the wet deck is more than p h = 0 ,5 ρ H a t (kN/m2)

DET NORSKE VERITAS

8 Classification Notes- No. 30.8

August 1996

at = design transverse acceleration (m/s2), to be taken from • model transverse frame at pillars or between pillars

the rules Pt.3 Ch.1 Sec.2 B302 for multihull vessels in forced • model from side to side or half-model

roll, and from Rules for Classification of Ships for monohull • longitudinal position(s) of modelled frame(s).

vessels. See also 3.2.10.

2.4.2

θ = maximum roll inclination.

It is assumed that correlation between individual 2-

2.3.6 dimensional models is proven to be satisfactory (e.g. deck

and transverse frame models).

Load condition 7, asymmetric deck load (LC7)

The symbols used are described in Figure 2-8.

This load case is shown in Figure 2-6 and Figure 2-7, and is

only relevant for deck grillage including pillars.

2.4.3

Deck load as for LC1. Figure 2-9 and Figure 2-10 show typical models of

transverse frames for a monohull and a multihull. Racking is

not considered critical for a multihull vessel, and a half-

model with symmetry conditions at centre line is normally

modelled, while a full web frame is modelled for a

monohull.

2.4.4

Areas of the web frame with large curvature should be

modelled with increased number of elements.

Structural discontinuities, as end connections with brackets

or plate knuckles, should be modelled with rigid element

ends offering similar section properties. See also

Figure 2-11.

Additional nodes may have to be modelled at side and decks

in order to represent the loads properly.

Figure 2-6 Load condition 7, transversally asymmetric

deck load

Figure 2-7 Load condition 7, longitudinally asymmetric

deck load

Figure 2-8 Symbols

2.4 Beam element modelling

2.4.5

2.4.1

The efficiency of the girder flanges should be considered for

Separate considerations must be made case by case to decide girders with

the extent and position of the model. The following should

be considered when the extent of analysis is decided: • a large span

DET NORSKE VERITAS

Classification Notes- No. 30.8 9

August 1996

• curved plate or face flanges. l = distance between effective transverse bulkheads

(fixed box ends)

See also Fig.2.12.

n = number of loads along the box

As = actual shear area.

Note that the spring stiffness calculations are based on the

assumption that a frame in the middle of a compartment is

analysed. The formula is only applicable for l / D < 5, else

use 2.4.7.

In areas where the shell plating is not tangential to a typical

spring stiffness axis (program dependent), equivalent axial

bar elements should be used. The length of the “spring

element” may be found by :

EA

Figure 2-9 Transverse web frame model of monohull,

ls = (mm)

K

complete frame modelled between pillars.

A = cross-sectional area of “spring element”

ls = length of “spring element” (lengths exceeding

the length of the surrounding elements should be

avoided).

2.4.7

Transverse frames are often connected by longitudinal deck

girders, bottom girders and longitudinal bulkheads in the

cross structure of multihull vessels. In a 2-dimensional

model, this connection must be represented by springs. The

spring stiffness of slender elements may be calculated by the

following formula :

E

K= (N/mm)

( n + 1)l 3 2,6( n + 1)l

+

384 I 8 As

Figure 2-10 Transverse web frame model of catamaran, l = distance between effective transverse bulkheads

only half of the frame modelled at pillar row. Valid only (fixed box ends) or distance between pillars for

for symmetric load conditions deck beams supported by pillars

2.4.6 n = number of point loads along the box (e.g.

number of frames between pillars)

Vertical and horizontal springs corresponding to the stiffness

of the shell and decks are to be applied. As = actual shear area

The stiffness coefficient for the springs representing the shell I = actual moment of inertia.

and the decks may normally be calculated by the following

formula for l / D < 5:

E

K= (N/mm)

2,6( n + 1)l

8 As

DET NORSKE VERITAS

10 Classification Notes- No. 30.8

August 1996

2.5.2

The mesh fineness and element types used in finite element

models must be sufficient to allow the model to represent the

deformation pattern of the actual structure with respect to

matters such as:

• effective flange (shear lag)

• bending deformation of beam structures

• three dimensional response of curved regions.

2.5.3

In order to obtain sufficiently accurate results, the mesh

fineness should represent the true web frame structure. This

means modelling plating, webs and flanges as separate

elements. It is acceptable that only one frame is modelled

with a fine mesh (the highest loaded frame).

2.5.4

In order to properly consider shear and bending, 3 elements

should be used over the height of the web of the frame, and

with an element length to breadth ratio of 3.

Figure 2-11 Rigid element end

In areas with curved flanges, the element length should be

approximately equal the stiffener spacing.

2.5.5

In areas with discontinuities (ends of flanges, knuckles,

brackets), the model should represent the discontinuity with

increased mesh fineness An alternative solution is to perform

separate analysis by separate local models of such details.

2.5.6

Calculated stresses based on constant stress elements may

have to be considered with respect to the stress variation

within each element length.

2.5.7

Symmetry conditions are to be applied at each end of the

model. If the model only covers half of the breadth of the

vessel, symmetry conditions should also be applied at centre

line. Boundary conditions representing vertical support

should be added as vertical shear forces at the end nodes of

Figure 2-12 Effective flange consideration the model, in order to obtain a balanced model.

2.5 Finite element modelling 2.6 Stress analysis

2.5.1 2.6.1

A complex 3-dimensional finite element analysis may be For web frame analysis, the allowable stresses are normally

applied to analyse the structural strength of a transverse web taken as :

frame.

Normally the model should cover the length of one

compartment in the midship area from base line to upper

deck, and extend from centre of one compartment to centre

of next compartment.

DET NORSKE VERITAS

Classification Notes- No. 30.8 11

August 1996

Design loads Plating Stiffeners and 2.6.4

girders Peak stresses as obtained by fine meshed finite element

Dynamic loads (slamming) calculations may be allowed to exceed the values stated

− equivalent stress 220 f1 200 f1 above in local areas close to stress concentration points. The

allowable peak stress is subject to special consideration in

− bending stress 200 f1 180 f1

each case.

Static loading (sea pressure)

− equivalent stress 200 f1 180 f1

− bending stress 180 f1 160 f1 2.6.5

The results from the web frame analysis should be evaluated

Allowable shear stress: 90 f1. with respect to plate buckling of the girder plate flange.

The allowable stresses for dynamic loading are connected to

impact loads.

2.6.2

The allowable stresses given above assume that appropriate

considerations and conditions are taken with respect to the

model definition and result analysis. In particular the

following should be noted:

• areas representing girder flanges must be adjusted for

effective width in accordance with Pt.3 Ch.3 Sec.6 B200.

• structural details not modelled, as termination of flanges,

bracket connections, pillar landings etc., should be

separately evaluated based on forces taken from the

analysis, see also Figure 2-13.

Nominal stresses calculated by finite element calculations

are to be related to the allowable stresses given above to the

extent that such stresses do not refer to local stress

concentrations in the structure or to local modelling

deficiencies.

2.6.3 Figure 2-13 Local structural detail, effective web area

adjusted for cut-outs

Shear stresses in girder webs as obtained by beam- or finite

element calculation may only be related to the allowable

shear stresses outside of areas with openings not modelled.

Corrections for effective web area should be performed in

the case of cut-outs for stiffeners or similar not being

modelled, see also Figure 2-13.

DET NORSKE VERITAS

12 Classification Notes- No. 30.8

August 1996

3. GLOBAL STRENGTH ANALYSIS Load Description Application

Condition

3.1 Introduction LC 1 Still water Monohull/multihull

3.1.1 condition vessels

LC 2 Longitudinal ------- “ ------------

In accordance with the rules Pt.3 Ch.3 Sec.4 A103, a

hogging moment

complete 3-dimensional global analysis is to be performed

LC 3 Longitudinal --------“ ------------

for new designs of large and structurally complex craft. The

sagging moment

requirement for global strength analysis normally applies for

vessels more than 50 m in length. LC 4 Transverse split Multihull vessels

force

LC 5 Torsion moment / Monohull/multihull

3.1.2

pitch connecting vessels

The guidelines given in this Classification Note will provide moment

a framework for the evaluation of the hull structure based on LC 6 Combination Multihull vessels

a global strength analysis, where the analysis may be longitudinal

accepted as basis for approval. bending and

torsion

3.1.3 LC 7 Transverse racking Monohull vessels

Calculations required to be performed are to be carried out Table 3-1 Global load conditions

by computer programs recognised by DNV. Recognised

programs are considered programs used by shipyards where 3.2.4

reliable results have been experienced and accepted by

DNV. Load Condition 1, still water condition (LC1)

3.1.4 This load case is based on the difference between weight and

buoyancy in still water condition at design draught. A

General guidelines given by this Classification Note are only loading manual is to be prepared to document the various

applicable for High Speed Light Craft, and references are still water conditions. The load condition should be

given to the Rules for Classification of High Speed and Light accurately modelled to avoid trim of the model due to

Craft. different position of Longitudinal Centre of Gravity and

Longitudinal Centre of Buoyancy. The correct transverse and

3.2 Design loads longitudinal mass distribution should be used.

3.2.1 The load case is a supplement to LC2, LC3 and LC4.

The load calculations should be based on the Tentative Rules

for the Classification of High Speed and Light Craft 1996. 3.2.5

Design values should be agreed between designer and DNV Load Condition 2, longitudinal hogging moment (LC2)

prior to final analysis.

This load case is shown in Figure 3-1 and will be decisive

3.2.2 with regard to allowable longitudinal stresses and buckling

Alternative loads, i.e. from direct hydrodynamic capacity in the bottom area.

calculations, may be used for design calculations. Alternative

The longitudinal hogging moment may be derived from :

design load formulations must be agreed with DNV in each

case. Wave load analysis programs and their application will • rule crest landing formula, Pt.3 Ch.1 Sec.3 A200

only be accepted on a case to case basis. • rule hogging moment, Pt.3 Ch.1 Sec.3 A500

• direct calculations of hydrodynamic loads

3.2.3

Table 3-1 describes typical loading conditions and their Only the largest needs to be analysed.

applicability with respect to type of design. Each load case is

described below. An example of acceptable modelling of the load case is

shown in Figure 3-1. The mass distribution of the vessel is

Additional load conditions may be considered relevant. given (go+acg) vertical acceleration, and this load is balanced

with buoyancy line loads around LCG.

In order to verify that the loading is correct, regardless of

modelling for design global moment, it is necessary to

demonstrate that the following have been achieved :

DET NORSKE VERITAS

Classification Notes- No. 30.8 13

August 1996

• the required maximum bending moment SPLIT LOAD CONDITION

• maximum shear at approximately quarter length of vessel

M split

• the LCG is approximately in line with LCB y ⋅F y

1 3

• negligible reaction forces at supporting nodes. ⋅ ⋅ Fy 1 3

⋅ ⋅ Fy x

2 4 2 4

Correct transverse and longitudinal mass distribution is to be 1

used. ⋅ Fy

4

x+ y=h

Longitudinal and transverse mass Aft

distribution multiplied by (go + acg) 3

M split = Fy ⋅ y + M s ,keel

4

LCG

1

M s ,keel = Fy {( x + y ) − ~x}

4

Bouyancy applied at

Boundary conditions only bottom around LCG

to prevent rigid body movement x+ y =h

BASELINE

~

x

Figure 3-1 Load condition 2, only half of the vessel x~ = the “mean” offset line established by measuring the distance

between the keel and the baseline

shown

NOTE : - the sum of the horizontal forces is to act at 75% of the draught

- no mass is required to be modelled in this condition

3.2.6

Load Condition 3, global sagging moment (LC3)

Figure 3-2 Load condition 4, transverse split, split

This load case may be decisive with regard to allowable outwards shown

longitudinal stresses and buckling capacity in the upper

3.2.8

decks.

Load Condition 5, torsion moment / pitch connecting

Modelling of this load case may in principle be as for LC2. moment (LC5)

3.2.7 This load case is shown in Figure 3-3, and may be decisive

for the cross structure. As indicated in Figure 3-3, the torsion

Load Condition 4, transverse split force (LC4) and pitch connecting moments are combined in the same

load condition. The load condition may be modelled without

This load case is shown in Figure 3-2 (split force acting

a mass distribution.

outwards) and is decisive for the structure between the hulls,

the side and bulkheads for a multihull vessel. The load case A full structural model should be applied.

represents horizontal wave loads acting on the hulls.

The horizontal transverse split force Fy is found from the 3.2.9

Rules, Pt.3 Ch.1 Sec.3 B202. According to the rules, the split Load Condition 6, combination of longitudinal bending and

moment caused by the split force should be combined with torsion (LC6)

the still water transverse bending moment. A combination of

the transverse moments may be obtained by combining LC1 This load case is a combination of LC2 and LC5 or LC3 and

with this load condition. It is advised that both positive and LC5. Only the maximum longitudinal bending moment

negative split forces are combined with LC1 and analysed as needs to be combined with LC5. The following

two load conditions. combinations should be analysed:

a) 80 % longitudinal bending and 60 % LC5.

b) 80 % LC5 and 60% longitudinal bending.

DET NORSKE VERITAS

14 Classification Notes- No. 30.8

August 1996

ph

qs

qb

Figure 3-3 Possible modelling of Load condition 5,

alternative ways may be used Figure 3-4 Load condition 7

3.2.10 3.3 Modelling

Load Condition 7, transverse racking, dynamic loads only 3.3.1

(LC7)

The global finite element model should in general cover the

This load case is shown if Figure 3-4, and may be decisive complete ship. In particular it is necessary that the model

for the lower side frames and transverse bulkheads for a covers the geometrical hull shape, transverse bulkheads,

monohull vessel. decks, and any torsional box structures.

A combination of vertical and transverse deck loads should 3.3.2

be applied for the upper decks in accordance with:

Size, type and number of elements should be selected to

monohull vessel: ensure that the effects of bending, shear and torsion of the

hull beam are fully accounted for.

at = g0sinθ + ary m/s2

Typical maximum element size may be influenced by

θ, ary, see Rules for Classification of Ships, Pt.3 Ch.1 Sec.4 element type. If four noded elements are used, a typical

B. element size is maximum three elements per frame spacing

in the longitudinal direction and 3 elements for each tier.

− multihull vessels:

2 Normally a length to breadth ratio of 3 is acceptable as

2π element size (normally not less than 1 m in breadth).

at = θ r rr + g0 sin θ m/s 2

TR An example of a global Finite Element Model is shown in

Figure 3-5.

TR, θr, rr, see rules for HSLC, Pt.3 Ch.1 Sec.2 B.

3.3.3

Dynamic horizontal deck loads are taken as

A basic description of the model is to be provided indicating

ph = 0,5ρHat (kN/m2) the extent of the actual structure to be modelled, and stating

that the model will represent the structural drawings

where ρH is 0,35 t/m2 for passenger deck. adequately and which simplifications have been utilised.

Drawings are to be referenced and, if possible, the modelled

The transverse deck racking loads should be balanced by a areas indicated on these drawings. Input units should be

horizontal line load (qs in Figure 3-4) at the design water line listed.

of the vessel. The resulting moment should be balanced by a

counteracting vertical force couple (qb in Figure 3-4). All

load components should be balanced in order to ensure that

an equilibrium load condition is achieved, with minimised

support node reaction forces.

Figure 3-5 Example of a Finite Element Model

DET NORSKE VERITAS

Classification Notes- No. 30.8 15

August 1996

3.3.4 • buckling capacity of various panels, stiffeners and girder

Simplified modelling compared to the real structure is systems, Pt.3 Ch.3 Sec.10 for aluminium and Pt.3 Ch.2

acceptable, but must be clearly identified. A list of Sec.10 for steel craft.

assumptions and simplifications to be specified may include

items such as: 3.4.3

In areas with peak stresses exceeding the allowable rule

• representation of stiffeners as lumped to the nearest mesh values, such as at cut-outs or other structural discontinuities,

line and inertia correcting techniques the extent of the peak stresses and consequence of yield

• element connections should be documented.

• curved plates modelled as straight

• representation and modelling of cut-outs

• transverse frame lumping techniques

3.5 Reporting

• slight arrangement changes due to nodal locations 3.5.1

• masses lumped as discrete points

In order to accept the global FEM analysis as basis for

• list of internal structure not included. approval, the analysis and the results must be reported to the

class.

3.3.5

The correct choice of boundary conditions is essential in 3.5.2

achieving reasonable results from an FEM analysis. The The following items should as a minimum be covered in the

chosen boundary conditions should reflect symmetry (if so report from the FEM analysis:

desired) and prevent numerical errors from occurring.

Attention should always be paid to the stresses and a) Basis for the work that is performed. This should include:

deflections resulting from the modelled boundary conditions.

− description of analysis

Generally the boundary conditions are checked by verifying − reference to program(s) used

that they are in balance without reaction forces, and that only − reference to drawings of the analysed structure

rigid body movements are prevented. − reference to quality plan used during the work with the

analysis.

3.3.6

A verification of the model should be available for result b) Description of model, including:

evaluations. Plots of the model showing boundary

− model extent and reference drawings

conditions, shell thicknesses, co-ordinate axis orientation − element description (type, coarseness of model)

should be given. − deviations between model and drawings

− boundary conditions

− input/output units

3.4 Design criteria

− global/local co-ordinate system.

3.4.1

c) Description of loads and load conditions.

Allowable global stresses are in general to be taken as given

in Pt.3 Ch.3 Sec.4. Where shear-lag effects dominate, stress d) Results from analysis. Based on the purpose of the

distribution and peak stresses should be carefully considered. analysis, relevant results to present may be:

Special attention should be given to structural discontinuities

or areas where the stress flow is not properly taken into − stress distribution for all load cases 1)

account due to a coarse element mesh or simplifications

during modelling. − stress components for documentation of local strength

(shear, bending, buckling)

3.4.2 − principal stresses for fatigue analysis (separately agreed)

− pillar forces

The results from the analysis should be evaluated with

respect to: − deflections (transverse racking, distortion of openings).

1) If contour plots are used instead of numerical plots, this will

• comparison of main results with simplified calculations require:

• reaction versus applied loads narrow bandwidth

• allowable global stresses according to Pt.3 Ch.3 Sec.4 for colour plots.

aluminium and Pt.3 Ch.2 Sec.4 for steel craft

• combination of global and local stresses according to Pt.3 e) Conclusion from the analysis:

Ch.3 Sec.9 for aluminium and Pt.3 Ch.2 Sec.9 for steel

craft − summary of the results from the analysis

− summary of modifications found necessary.

DET NORSKE VERITAS

16 Classification Notes- No. 30.8

August 1996

4. WATERJET DUCTS

4.1 Introduction

4.1.1

The reaction forces from the waterjet nozzles need to be

transmitted into the hull structure in a manner for which

adequate strength and fatigue life of critical details can be

ensured through careful design.

4.1.2

For steerable jet units the reaction forces will typically arise

from acceleration (thrust) and manoeuvring actions.

For booster nozzles with no steering function reaction forces

arise from acceleration (thrust) forces only. Figure 4-2 Typical duct / jet nozzle configuration critical

areas

Additional to this vibration forces from impeller

pulses/cavitation, turbulent waterflow in duct and around 4.1.5

stator vanes, and various other possible sources (shaft

misalignment, shaft/impeller imbalance etc.) will be present. The duct and the structural details of the duct must be

considered to be experiencing high and low cycle loads and

Figure 4-1 shows a typical steering gear for a waterjet unit, will therefore have to be considered for fatigue strength. For

which through manoeuvring actions will transmit reaction this reason it is recommended to design with few welded

forces through the bolted connection at the transom to the details and attachments on the duct itself, and that due

duct and hull structure. attention is paid to the detail design and execution of welds

(e.g. grinding of welds).

4.2 Load conditions

4.2.1

The critical details of the duct and connections to the hull

structure should be dimensioned for the following static load

conditions (LC) generally specified by the manufacturer of

the waterjet:

Load Condition Description

LC 1 Crash stop

LC 2 Maximum loads from reversing

LC 3 Maximum loads from steering

LC 4 Waterjet unit weight accelerated as

cantilever in pitching

In addition, high cycle loads from impeller pulses should be

Figure 4-1 Typical waterjet steering gear

considered, if available from the manufacturer.

4.1.3 Guidance note :

The steering nozzle reaction forces should normally be High cycle loads and loadpaths are generally not specified by

transmitted into the hull structure in one of the following manufacturer and will vary with size and make, so a recommended

manners: way to take account for these loads in duct design is, for each

critical detail, to design to the best possible fatigue class (see part

− through the duct and into transverse frames, bulkheads four for typical details and fatigue classes). Also very important is

and bottom plating shaft alignment at installation, balancing of shaft and impeller and

− through additional stiffening structure at transom. condition of bearings during service.

4.1.4 End of Guidance note

For a jet unit assembly with the duct constructed from

welded aluminium, where forces are transferred through the

duct, some typical critical details which require attention

during design are illustrated in Figure 4-2.

DET NORSKE VERITAS

Classification Notes- No. 30.8 17

August 1996

Figure 4-3 shows typical application of forces to the duct as 4.2.2

they may be split into horizontal and vertical forces and For fatigue life calculations, the long term load distributions

moments. in Table 4-1 should normally be considered:

Long term load distribution Description

Load distribution 1, Reversing loads (LD1) The accumulated sum of stresses will have the profile as shown.

Maximum value, σ max, is taken from analysis of LC2.

Assumption: maximum reversing load 20 times per day.

Total number of cycles in 20 years is

Nreversing= 1,46 x 105

Load distribution 2, Steering loads (LD2) The steering load varies with the angle ranging from corrective

steering 5° (flat water) and full steering 30° (heavy seas).

It may be assumed that steering at any angle varies from port to

starboard at any one cycle, so that stress range at a detail is

double that calculated from the static equivalent at any angle ,

Maximum values may be taken from the analysis of LC3 (for

fatigue assessment of flanges stress range can be considered as

the range from bending stresses and axial stresses when in tension

to only axial stresses in compression).

Assumption : Assuming steering cycle of 20 seconds 12

hours per day for all sea-states.

The total number of steering cycles;

Nsteering= 1,57 x 107

corresponding to 5° steering (1/6 σmax).

Assuming full steering 40 hours per year for 20 years;

Nfull steering= 1,44 x 105

corresponding to 30° steering (σmax).

DET NORSKE VERITAS

18 Classification Notes- No. 30.8

August 1996

Load distribution 3, pitching load (LD3) The vertical accelerations at the stern will cause cyclic cantilever

bending loads from the waterjet.

The maximum value may be found from the analysis of LC4.

The accumulated sum of stresses will have the profile as shown.

Assumption : Assuming 12 hour operation per day.

Assuming linear variation of pitching loads between 0

and maximum and a total number of cycles;

Npitching= 2 x 107

Table 4-1 Long-term load distribution

v

Such model should extend from the transom flange and at

least to the first vertical support, though preferably to the

second (web frame or bulkhead).

Depending on the details involved (flange connections,

discontinuities), the boundary conditions and load

x

applications should be chosen according to the general

principles described below.

Steering Reversing / Crash-stop

4.3.3

The loads on an axi-symmetric model may be applied as a

unit linear load around the circumference. Results may be

Figure 4-3 Manoeuvring force components scaled to the correct values for forces and moments.

4.2.3 Alternatively, if the modelling application used allows, the

acting axial load and moment may be applied separately.

Limited data is available for the above load cycles and their That is, the moment may be applied as an asymmetric unit

distribution, but should generally be used for design fatigue load with a sinusoidal distribution around the circumference.

calculations. The resulting stresses may then be combined to give unit

load stress at any point of interest.

The curves for steering and cantilever action is linked to a

standard sea load distribution curve.

The steering curve does not take into account the long term

distribution for angle of encounter of seas, nor seakeeping

characteristics of particular ship types.

4.3 Modelling

4.3.1

Due to the complex structure, Finite Element Method

analysis should normally be used for the assessment of the Linear unit load Sinusiodal unit load distribution

transom region.

4.3.2 Figure 4-4 Axi-symmetric model, load application

For waterjet ducts with flange connections and/or

discontinuities along the length, an axi-symmetric model

may be used to study and record the stresses in way of

critical details.

DET NORSKE VERITAS

Classification Notes- No. 30.8 19

August 1996

4.3.4 This approach will give somewhat high stresses in way of

Boundary conditions should be carefully selected. The duct, the transom flange thickness transition, but the maximum

when continuous, should be held against axial and radial stress will move from the inside of the duct to the outside of

displacement at the forward end. If there are any transverse the duct and the difference in magnitude may not be very

web frames with connections to the duct along the modelled large. The condition giving the largest stress should be used

section, these should be taken into account by restricting this as design criteria.

particular point against displacement in the direction

The significance of these simplified boundary conditions

transverse to the duct, see Figure 4-5.

may be considered negligible on the details further along the

duct.

4.3.5

For alternative flange connections, it is in general 4.3.6

recommended to design for a condition where the bolt

For a more detailed study of ‘‘standard’’ flange connections

pretension of the bolts is lost. This gives a model boundary

for dimensioning flange connections, bolt pretension, gaskets

condition where the flange is partly restricted to rotate. The

and washers with respective geometry and material quality,

stiffness of the rotational spring will depend on the size of

and local geometry such as fillet radii of transition between

facing jet bowl flange and size and material of bolts.

duct and flange etc., may be included in the model.

This condition should be used as minimum fatigue design

Bolt pretension may be modelled using temperature loads or

criteria.

forced displacement. To study the non linear effects of

As the modelling of a partly stiff flange is uncertain, one gasket and washer compression more advanced methods

may alternatively consider the two conditions where the need to be applied.

flange is free to rotate (see Figure 4-6) and completely

restricted against rotation (see Figure 4-7). 4.3.7

Non-continuous ducts with flange connections along the duct

may be simplified by fixing nodes from the line of the flange

bolts to the outside edge of the flange against axial and radial

displacement, see Figure 4-8.

Ft

Fc

Figure 4-5 Aft part of duct, actual boundary conditions (Ft and Fc are tensile and compressive load respectively).

Ft

Fc

Figure 4-6 Aft part of duct, simplified boundary conditions (Ft and Fc is tensile and compressive load respectively, for

top and bottom)

DET NORSKE VERITAS

20 Classification Notes- No. 30.8

August 1996

Ft

Fc

Figure 4-7 Aft part of duct, simplified boundary conditions (Ft and Fc is tensile and compressive load respectively, for

top and bottom)

Ft

Fc

Figure 4-8 Non-continuous duct, boundary conditions joining flange (Ft and Fc are tensile and compressive loads

respectively)

η = Σ n i / Ni

4.4 Results and stress analysis

4.4.1 Where;

Stresses should be taken from the model as principal stresses η = fatigue damage ratio

along the local element axis.

ni = number of cycles at stress range ∆σi

For static analysis (LC1 to LC4), the allowable stresses are:

Ni = number of cycles to failure at stress range ∆σi.

Load condition Combined axial-and Shear

bending In general the damage ratio at one point is the sum of the

damage ratio from each of the load effects.

LC 1 180 f1 100 f1

LC2, LC3, LC4 160 f1 90 f1 ηtotal = ηrev + ηsteer + ηpitch

For fatigue assessment the stress range at the detail, from

For water jets the steering loads will not act in the same

maximum tension to maximum compression should be used.

point as the others, therefore

4.4.2 ηsteer = 0 when considering the top and bottom parts of

The analysis results should be used to establish areas of high the duct.

and low loading.

The sum of the damage ratio from each of the load effects or

Welded joints in the duct should typically be placed as far in the case of steering the sum for steering alone should be

away from stress ‘hot spots’ as possible. Results from an axi- kept less than one.

symmetric FEA, where linear stresses can be read at the

actual position of the weld, should be used to position and i.e Σ η < 1

design the welded connection with respect to fatigue.

Guidance note :

- The fatigue check for welded aluminium details should be

4.4.3 based on the ECCS "EUROPEAN RECOMMENDATIONS FOR

ALUMINIUM ALLOY STRUCTURES FATIGUE DESIGN"

The fatigue assessment may be based on the Miner-Palmgren

method for accumulated fatigue damage. - Reference stress for fatigue check is the principal stresses in the

main load carrying member.

DET NORSKE VERITAS

Classification Notes- No. 30.8 21

August 1996

- Stress concentrations due to the weld detail itself is included in

the curve.

- For practical purpose, using FEM analysis, the surface stress on

the main member in the principal directions should be used.

- Additional stress concentrations from geometrical effects may

be included by the use of stress concentration factors K. Such

effects may be cut-outs (not covered by an axe-symmetric FEM

model), geometrical transitions or fillet radii.

- For thicknesses of more than 25 mm a correction factor is to be

used on the fatigue strength.

- The reference curves in the ECCS guideline refer to dry Figure 4-10 Critical areas steering with two adjacent jets

environment.

- Parts subjected to corrosion need to be specially evaluated (i.e

parts not coated and exposed to sea-water).

End of Guidance note

4.4.4

When forces are transferred through the duct into the hull

structure, the relative deflection between the duct and the

hull structure may be most prominent at the connection to

the transom. It is therefore necessary to allow this relative

movement (mainly axial) between the transom flange

connection and the vessel’s bottom and sides without

stresses in critical weld connections exceeding those given

by the respective loadcases against yield and fatigue.

A typical critical point in way of connection between

transom and bottom plating is shown in Figure 4-9.

Figure 4-9 Typical critical detail due to duct deflection in

reversing/crash-stop

4.4.5

In situations where two steerable jets are located next to each

other, the total relative displacement should be taken into

account when estimating the stresses. Sufficient distance

between such jets should be ensured to allow sufficient

flexibility in the transom plating usually having a thickness

dimensioned to take the vertical shear forces.

The critical welds in this area should be considered with

respect to fatigue when exposed to the distribution of

steering actions over the lifetime of the vessel.

Below is shown typical critical areas in way of transom for

steering manoeuvres with two adjacent jets.

DET NORSKE VERITAS

22 Classification Notes- No. 30.8

August 1996

5. HIGH SPEED LIGHT CRAFT 5.2.2

SUPPORTED BY FOILS The hydrodynamic loading is generally to be based on

5.1 Introduction extreme loads which may be considerably higher than

“design loads” as expected during normal service. Normally

5.1.1 the extreme loads are to be based on theoretical maximum

As a part of the approval procedure, an extended safety values when cavitation or ventilation starts to occur. It is

evaluation compared to the conventional high speed light considered important that the angular movement of any

craft concept is required. In addition to the general safety rudder function of the foil system is limited at high speeds.

aspects as covered by the rules, the following aspects are to

be especially taken into consideration when the extent of 5.2.3

required documentation is considered :

The loads on the foil system should as a minimum include

• consequence analysis to be documented for accidental the following:

events such as deflection/loss of foil/flaps, loss of “active

ride control” (hull appendages and part of Failure Mode • maximum positive lift

and Effect Analysis (FMEA) for vessel or also subject to • maximum negative lift

structural evaluation) • maximum side force

• type of foils - if horizontal and completely submerged • maximum asymmetric loading (side wave, “broaching”,

foils, the need for active stability control by flaps etc. is extreme rudder functions)

vital, hence the foil system is to be considered as an • drag forces

essential system and treated accordingly • obstruction loading

• extent of lift - if hull completely out of water, the more • secondary loading due to propulsion system (propeller

severe consequences of accidental loss of lift forces, induced forces, internal pressure in water inlets).

hence foil/strut connections to be considered both with

respect to strength and performance of main function as

per rules Pt.1 Ch.1.

5.1.2

It is considered important that well defined full scale test

series of the vessel is to conclude the concept evaluation,

verifying theoretical simulations, model testing and any

important basic assumptions made during the earlier

evaluation.

Controlled prototype testing will provide a better reference

for final definition of operational restrictions related to

navigation in different sea states and manoeuvring

characteristics at high speeds.

5.2 Design loads on foil systems

5.2.1

The builder should provide complete documentation of

design loads for the foil system. Due to the fact that the

profile shape and system configuration of the foil system

affect the level of design loads, no empirical or simplified

expressions should be used for design load calculations, and

Figure 5-1 Schematic example of loads on T-foil

final load cases to be established case by case. The following

parameters affecting the design loads should be considered: 5.2.4

• profile shape and lift coefficient Fatigue loading has to be established based on service

• speed/sea-state combinations and expected lift at various notation and varying parameters, such as :

wave heights, corresponding speed loss at large wave • sea condition

heights

• headings

• physical limitation of profile lift due to ventilation or

• vessel speed and frequency of encounter.

cavitation

• local distribution of loads on foil member (chordwise, 5.2.5

spanwise)

Global load cases for global analysis of hull strength will be

• ratio between maximum values and “in service” values

considered individually based on size of vessel, level of

• long term distribution of loads.

design vertical acceleration and concept evaluation.

DET NORSKE VERITAS

Classification Notes- No. 30.8 23

August 1996

As a minimum the following should be documented from the A separate analysis should be performed as a verification of

yard : local strength in way of hull support for the foil system.

Forces acting on the hull, derived from the foil system

• still water global bending moments

analysis, should be considered with regard to structural

• longitudinal and transverse bending moments in foil-born

strength of the supporting structure. Acceptance criteria are

condition, subject to design vertical acceleration at

to be as given in the rules Pt.3 Ch.2 or Pt.3 Ch.3.

longitudinal centre of gravity.

5.4.3

5.3 Strength analyses Bolted connections between foil system components

5.3.1 Bolted connections should be considered separately. Forces

The builder should submit complete documentation for acting on the bolted connections are to be taken from the

calculations of forces, stresses and deflections for the foil analysis of the foil system. In the analysis of bolted

system. The quality and extent of the calculations may connections, the following items should be taken into

influence the settings of operational limitations for the consideration:

vessel. − geometry of the bolted connection

(symmetry/asymmetry, stiffness of flanges, local stress

5.3.2 concentration)

Local strength analyses of each foil system, as well as − pretension of bolts (stress in bolts, surface pressure

strength calculations of hull structure in way of support for below nuts/bolthead)

foil system are required. − stiffness of bolts versus stiffness of bolted material (note

that gaskets or similar will reduce the stiffness of the

5.3.3 bolted material, and hence increase the loading of the

Based on the structure in question, simplified analysis (such bolts)

as beam element analysis) may not be sufficient for a proper − distribution of forces through the bolted connection.

evaluation of the stress distribution. Finite element analysis

of the complete foil structure or parts of the structure may be 5.4.4

required. Highly stressed areas in foil structure

5.3.4 Highly stressed areas should be specially considered with

Stress analysis respect to local stress concentration and evaluation of stress

concentration factors for fatigue assessment.

The results from the strength analyses should identify:

5.4.5

• deflections

• distribution of shear forces and bending moment, and Vibration and/or buckling analysis

reaction forces at all boundary nodes for the analysis

Vibration analysis should in general be performed. The

• stress distribution and identification of areas with

safety of local as well as global buckling of the foil system

maximum values of stresses

should be documented.

• direction and size of principle stresses for areas later

subject to fatigue assessment

• all forces acting on bolted connections. 5.5 Acceptance criteria

5.4 Local analysis 5.5.1

For the evaluation of the strength analysis, the following

5.4.1 allowable stresses are applicable:

In addition to the general strength assessment of the foil

structure, local analysis may be required. Typical areas combination bending/axial stresses : σ = 160 f1

where this may be required are: shear stresses : τ = 90 f1

− connection between foil system and hull structure f1 as given in Pt.3 Ch.2 or Pt.3 Ch.3.

− bolted connections between foil system components

Guidance note :

− highly stressed areas in foil structure

Based on material yield stress (taken as minimum upper yield

− vibration and/or buckling analysis. stress in N/mm2, not to be taken greater than 70% of the ultimate

tensile strength), the allowable stresses should nowhere exceed

5.4.2 values giving a factor of safety against yield of 1,5. For shafts or

axles the corresponding factor of safety should not exceed 1,8.

Connection between foil system and hull structure The allowable stresses are based on the requirement to the

assessment of fatigue strength of the structure. Where a proper

fatigue analysis is not performed, the allowable stresses may be

reduced.

DET NORSKE VERITAS

24 Classification Notes- No. 30.8

August 1996

End of Guidance note Fatigue calculations of critical details should normally be

performed. 20 years lifetime should normally be

5.5.2

documented.

6. APPENDIX A

TYPICAL STRUCTURAL DETAILS

The appendix shows some selected typical structural details

where a good design is found important for life time of

detail. Alternative solutions may be proposed, and the detail

solutions shown in the appendix are to be considered as

guidelines.

DET NORSKE VERITAS

Classification Notes- No. 30.8 25

August 1996

DET NORSKE VERITAS

You might also like

- Strength Analysis of Hull Structures in TankersDocument40 pagesStrength Analysis of Hull Structures in TankersMahdiNo ratings yet

- Chinese Cooking For BeginnersDocument92 pagesChinese Cooking For Beginnersclemesha96% (23)

- DNV-RP-C205-what Is New Analysis of Wave-In-Deck LoadsDocument44 pagesDNV-RP-C205-what Is New Analysis of Wave-In-Deck LoadsLiang SunNo ratings yet

- Garme2012 - Resistance and PoweringDocument63 pagesGarme2012 - Resistance and PoweringSrikanth ShivramNo ratings yet

- Improving Fluency in Young Readers - Fluency InstructionDocument4 pagesImproving Fluency in Young Readers - Fluency InstructionPearl MayMayNo ratings yet

- RP C103 PDFDocument30 pagesRP C103 PDFBassem BalghouthiNo ratings yet

- Comparison of Juice Extractors: Enzymes: Michael Donaldson, PH.DDocument0 pagesComparison of Juice Extractors: Enzymes: Michael Donaldson, PH.DRobert RomanNo ratings yet

- Technical Paper - Modelling Suction Pile Lowering Through The SplashzoneDocument9 pagesTechnical Paper - Modelling Suction Pile Lowering Through The Splashzonecxb07164No ratings yet

- Metabolic AftershockDocument36 pagesMetabolic AftershockVicWoods0% (1)

- Mooring Design & Mooring Analysis IndiaDocument17 pagesMooring Design & Mooring Analysis IndiaMermaid coNo ratings yet

- Math4 q1 Mod6 EstimatingProducts v2Document16 pagesMath4 q1 Mod6 EstimatingProducts v2Jobelle CanlasNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Aqwa Programs Tutorial-2Document17 pagesAqwa Programs Tutorial-2Syed Hasan100% (1)

- 3 - DNV Rules For Marine OperationsDocument50 pages3 - DNV Rules For Marine OperationsTord Martinsen100% (2)

- SamplingDocument2 pagesSamplingMerleAngeliM.SantosNo ratings yet

- CBSE Class 6 Maths Question Paper SA 2 2013Document2 pagesCBSE Class 6 Maths Question Paper SA 2 2013SujeshNo ratings yet

- Is 4651 3 2020Document26 pagesIs 4651 3 2020JAYARAJU MAILAPALLI100% (2)

- Structural Design of Offshore Ships: DNV-OS-C102Document9 pagesStructural Design of Offshore Ships: DNV-OS-C102MinhddNo ratings yet

- A Criteria On For Assessing Wind Induced Cross Flow Vortex Vibonsion Wind Sensitive Structuresoth379Document62 pagesA Criteria On For Assessing Wind Induced Cross Flow Vortex Vibonsion Wind Sensitive Structuresoth379Kirti BairathiNo ratings yet

- Piperack ModularisationDocument4 pagesPiperack ModularisationSubhojit AdhikaryNo ratings yet

- 3 - DNV Rules For Marine OperationsDocument48 pages3 - DNV Rules For Marine OperationsgalvigarciaNo ratings yet

- DNV Marine Operations Rules For Subsea LiftsDocument47 pagesDNV Marine Operations Rules For Subsea LiftsAnonymous ugCWo0Acz3100% (1)

- Response Based Weather-Routing and Operation Planning of Heavy Transport VesselsDocument9 pagesResponse Based Weather-Routing and Operation Planning of Heavy Transport VesselsKuya Fabio VidalNo ratings yet

- 3 DNV Marine Operations RulesDocument48 pages3 DNV Marine Operations RulesSi Rerumpai LautNo ratings yet

- 85M 2S折臂吊机操作手册Document317 pages85M 2S折臂吊机操作手册joseflores888No ratings yet

- DNV - OS-E301 (Mooring 2004)Document73 pagesDNV - OS-E301 (Mooring 2004)drailota100% (2)

- Fatigue Assessment of Ship StructuresDocument25 pagesFatigue Assessment of Ship StructuresAlex TheodoulNo ratings yet

- DNV CN - 31-3Document40 pagesDNV CN - 31-3EmdadNo ratings yet

- CFDLV15 N6 P54 64Document11 pagesCFDLV15 N6 P54 64mabm89No ratings yet

- 1 5018530 PDFDocument11 pages1 5018530 PDFJohn WoodNo ratings yet

- TN167 - A New Approach To Asphalt Pavement DesignDocument43 pagesTN167 - A New Approach To Asphalt Pavement DesignMacNo ratings yet

- CFD Investigation Into The Wave Added Resistance of Two ShipsDocument20 pagesCFD Investigation Into The Wave Added Resistance of Two ShipsSahil JawaNo ratings yet

- Determining The Drag Force With CFD Method ANSYS Workbench 11.00Document13 pagesDetermining The Drag Force With CFD Method ANSYS Workbench 11.00Dang Tien PhucNo ratings yet

- An Integrated Tool For Concept and FinalDocument15 pagesAn Integrated Tool For Concept and FinaljasserjederNo ratings yet

- Fishing Vessel Hull Design and Towing Resistance Calculation by The CFD MethodsDocument4 pagesFishing Vessel Hull Design and Towing Resistance Calculation by The CFD MethodsshahjadaNo ratings yet

- ITTC - Recommended Procedures and Guidelines: Practical Guidelines For Ship CFD ApplicationsDocument18 pagesITTC - Recommended Procedures and Guidelines: Practical Guidelines For Ship CFD ApplicationsHamed HmNo ratings yet

- RINA - Developments in Heavy Transport Design CalculationsDocument12 pagesRINA - Developments in Heavy Transport Design CalculationsdsrfgNo ratings yet

- HT Puah Headrace Tunnels DBM and Hydraulic Design-R0Document41 pagesHT Puah Headrace Tunnels DBM and Hydraulic Design-R0fuad aliNo ratings yet

- Sahyd c23 EngDocument7 pagesSahyd c23 EngDragos NackaNo ratings yet

- Extreme Loading EvaluationDocument39 pagesExtreme Loading EvaluationMuhd RadzifNo ratings yet

- Pier Coping Falsework Design - HframeDocument8 pagesPier Coping Falsework Design - Hframebart porquiado100% (1)

- Alternatif ShipDesign-MassDocument28 pagesAlternatif ShipDesign-MassgemlilifyiNo ratings yet

- 54 The Principles of Naval Architecture SeriesDocument21 pages54 The Principles of Naval Architecture SeriesJuan SilvaNo ratings yet

- This Chapter Be Added In: Near FutureDocument10 pagesThis Chapter Be Added In: Near FuturejcasafrancaNo ratings yet

- Structural Modeling and Analysis - 38Document1 pageStructural Modeling and Analysis - 38dunglxNo ratings yet

- Chapter 3Document7 pagesChapter 3saubhagya majhiNo ratings yet

- Computational Fluid Dynamics Vol - III - HoffmannDocument188 pagesComputational Fluid Dynamics Vol - III - HoffmannNasim BoshraNo ratings yet

- Guidelines For Direct Calculation Assessment of Hull Structure Including Springing and Whipping 2018Document28 pagesGuidelines For Direct Calculation Assessment of Hull Structure Including Springing and Whipping 2018ZulfikarAdytiaVernandaNo ratings yet

- Thesis PPRabe FINALDocument110 pagesThesis PPRabe FINALMuhammad Rafiq RavinNo ratings yet

- CatamaranS89 CompressedDocument28 pagesCatamaranS89 CompressedAndrea GaonaNo ratings yet

- Bachelor's Research DissertationDocument18 pagesBachelor's Research Dissertationhasna.boneNo ratings yet

- CFDLV14 N5 P98 105Document8 pagesCFDLV14 N5 P98 105mabm89No ratings yet

- Experimental and CFD Resistance Calculation of A Small Fast CatamaranDocument7 pagesExperimental and CFD Resistance Calculation of A Small Fast CatamaranChandra SibaraniNo ratings yet

- RINA 2008 - Marine Heavy Transport Lift Paper AmarconDocument9 pagesRINA 2008 - Marine Heavy Transport Lift Paper AmarconAna TNo ratings yet

- Comentários MODU ABSDocument5 pagesComentários MODU ABSLucas TarcioNo ratings yet

- Mean Load EffectsDocument12 pagesMean Load EffectsPier FrancescoNo ratings yet

- Fluid Mechanics Submarine Design: Australian Maritime CollegeDocument44 pagesFluid Mechanics Submarine Design: Australian Maritime CollegeEng-Mohammad Nabel Alqam100% (1)

- CFD Simulation of A Planing Hull: International Journal For Traffic and Transport Engineering (IJTTE) September 2019Document7 pagesCFD Simulation of A Planing Hull: International Journal For Traffic and Transport Engineering (IJTTE) September 2019shahjadaNo ratings yet

- Motion Analysis Offer Superb Support On BoardDocument25 pagesMotion Analysis Offer Superb Support On BoardJorge Del RioNo ratings yet

- 2 AtiDocument8 pages2 AtiSachin SithikNo ratings yet

- DNV CN41-5Document9 pagesDNV CN41-5Constantinos IvNo ratings yet

- Wave and Tidal EnergyFrom EverandWave and Tidal EnergyDeborah GreavesNo ratings yet

- Toaùn 4 Chuoãi Vaø Phöông Trình Vi PhaânDocument10 pagesToaùn 4 Chuoãi Vaø Phöông Trình Vi PhaânCông TuấnNo ratings yet

- TOAÙN 1 HK1 0708: - Baøi 2: Haøm Soá (SV)Document22 pagesTOAÙN 1 HK1 0708: - Baøi 2: Haøm Soá (SV)Công TuấnNo ratings yet

- Bang Cuu ChuongDocument18 pagesBang Cuu ChuongCông TuấnNo ratings yet

- Heat Transfer Applications: SimscaleDocument24 pagesHeat Transfer Applications: SimscaleCông TuấnNo ratings yet

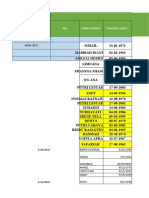

- Current Date: 8/7/2018 9:39:07 PM Units System: KN - MDocument1 pageCurrent Date: 8/7/2018 9:39:07 PM Units System: KN - MCông TuấnNo ratings yet

- Condition Summary: 5Hsruw7LphɝDocument81 pagesCondition Summary: 5Hsruw7LphɝCông TuấnNo ratings yet

- Your Name FGHDocument1 pageYour Name FGHCông TuấnNo ratings yet

- Interface Between Gusset - Bottom Left BraceDocument3 pagesInterface Between Gusset - Bottom Left BraceCông TuấnNo ratings yet

- Steel Connections: Demands Description Pu Load TypeDocument2 pagesSteel Connections: Demands Description Pu Load TypeCông TuấnNo ratings yet

- Present Continuous: I Am +V - Ing He, She, It Is +V - Ing We, They, You Are +V - IngDocument2 pagesPresent Continuous: I Am +V - Ing He, She, It Is +V - Ing We, They, You Are +V - IngCông TuấnNo ratings yet

- U OED - Offshore Engineering Department U AA - Advanced Analysis Department U SED - Ship Engineering Department U Materials & Welding Department U Naval Engineering DepartmentDocument1 pageU OED - Offshore Engineering Department U AA - Advanced Analysis Department U SED - Ship Engineering Department U Materials & Welding Department U Naval Engineering DepartmentCông TuấnNo ratings yet

- I. Even-Zohar, G. Toury: Introduction To Translation Theory and Intercultural RelationsDocument8 pagesI. Even-Zohar, G. Toury: Introduction To Translation Theory and Intercultural RelationssonjolinaNo ratings yet

- OceanofPDF - Com Learning To Love Myself - Alex AubreyDocument143 pagesOceanofPDF - Com Learning To Love Myself - Alex AubreyJeshvanthNo ratings yet

- Hasbro ANNUAL REPORT & ACCOUNTS 2019Document192 pagesHasbro ANNUAL REPORT & ACCOUNTS 2019Kumar PranayNo ratings yet

- 1.2 Bo Cuc 1 Bai EssayDocument2 pages1.2 Bo Cuc 1 Bai Essay32 - 10A2 - Phương ThúyNo ratings yet

- 4.0 Manual Kelman TransfixDocument31 pages4.0 Manual Kelman Transfixcorreo_hechizo100% (2)

- About Sheepdog Church Security Equipment?Document2 pagesAbout Sheepdog Church Security Equipment?hmareidNo ratings yet

- Socio-Demographic Characteristics of Male Contraceptive Use in IndonesiaDocument6 pagesSocio-Demographic Characteristics of Male Contraceptive Use in IndonesiaBella ValensiaNo ratings yet

- PTM Mei 2022Document38 pagesPTM Mei 2022lisaNo ratings yet

- Lamas-Lopez Et Al. - Assessment of Integration Method for Displacement Determination Using Field Accelerometer and Geophone Data利用现场测试的加Document14 pagesLamas-Lopez Et Al. - Assessment of Integration Method for Displacement Determination Using Field Accelerometer and Geophone Data利用现场测试的加Paulo PereiraNo ratings yet

- Kinematic Structure of Machine ToolsDocument23 pagesKinematic Structure of Machine ToolswagoheNo ratings yet

- EXTREME PLUS QT SDS English Spot RemoverDocument5 pagesEXTREME PLUS QT SDS English Spot RemoverDonna PhillipsNo ratings yet

- Q2 2nd SUMMATIVE TEST IN SCIENCEDocument3 pagesQ2 2nd SUMMATIVE TEST IN SCIENCEAssyla Segarra OfallaNo ratings yet

- Bell's Palsy - Symptoms and Causes - Mayo ClinicDocument6 pagesBell's Palsy - Symptoms and Causes - Mayo ClinicRoxan PacsayNo ratings yet

- RCoE - Training Book - Id-63-87Document25 pagesRCoE - Training Book - Id-63-87PILAR TIARA LELEPADANGNo ratings yet

- EDEM 506 Activity No. 1 - Compare and Contrast MatrixDocument5 pagesEDEM 506 Activity No. 1 - Compare and Contrast MatrixD-Lyca Fea SalasainNo ratings yet

- Arc Chute Filter TechnologyDocument2 pagesArc Chute Filter TechnologyantigeniusNo ratings yet

- Ili RiverDocument4 pagesIli RiverRathiJyothiNo ratings yet

- Holden Trailblazer 284082Document9 pagesHolden Trailblazer 284082Luke AustinNo ratings yet

- PDS-Mosalinker PC30 (V1.0) enDocument2 pagesPDS-Mosalinker PC30 (V1.0) enLIM YE HENGNo ratings yet

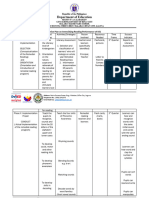

- Kinder Catch Up Friday Action PlanDocument4 pagesKinder Catch Up Friday Action PlanAriane PimentelNo ratings yet

- ANSYS Ncode DesignLife v13Document20 pagesANSYS Ncode DesignLife v13j_c_garcia_dNo ratings yet

- Synonyms: XylitolDocument4 pagesSynonyms: Xylitolyuni fadilahNo ratings yet

- Eternalsun Spire - Whitepaper - Improving Uncertainty of Temperature Coefficients - v11 Hot Graphs TS SRDocument36 pagesEternalsun Spire - Whitepaper - Improving Uncertainty of Temperature Coefficients - v11 Hot Graphs TS SRShubham KumarNo ratings yet