Professional Documents

Culture Documents

102-00094-I RIO ZUNI Operators Manual PDF

Uploaded by

Carlos MoralesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

102-00094-I RIO ZUNI Operators Manual PDF

Uploaded by

Carlos MoralesCopyright:

Available Formats

RIO Zuni™ Series On-Site

Generator 1.0 and 2.0

Installation, Operation, and Maintenance

Manual

1 December 2017

MIOX RIO Zuni™ Operators Manual P/N: 102-00094-I Page 1

MIOX RIO Zuni™ Operators Manual

MIOX maintains a constant product improvement program that may affect design and/or

specifications. The company reserves the right to make these changes without prior notice or

liability. Portions of the MIOX OSGs are covered by U.S. Patent

Customer Service

5601 Balloon Fiesta Parkway NE, Suite A

Albuquerque, NM 87113

Phone: 1.505.343.0093

Toll Free: 1.866.MIOX.HLP (1.866.646.9457)

FAX: 1.505.343.0093

MIOXservicedist@Matthey.com

www.MIOX.com

www.Matthey.com

International distributors and sales agents located worldwide

P/N: 102-00094-I Page 2

MIOX RIO Zuni™ Operators Manual

CONTENTS

CONTENTS .............................................................................................................. 3

List of Figures ......................................................................................................... 4

List of Tables .......................................................................................................... 4

INTRODUCTION AND OVERVIEW ............................................................................ 5

Regulatory Compliance ............................................................................................ 5

U. S. Environmental Protection Agency (US EPA) ..................................................... 5

List of Certifications .............................................................................................. 5

NSF International ................................................................................................. 5

State Approvals ................................................................................................... 5

System Description ................................................................................................. 6

System Specifications .............................................................................................. 7

System Illustrations and Component Descriptions ....................................................... 8

INSTALLATION AND STARTUP .............................................................................. 15

In the Box ......................................................................................................... 15

What you need ..................................................................................................... 15

Tools for install .................................................................................................. 16

Installation Location Requirements ....................................................................... 16

Connections ......................................................................................................... 16

Plumbing........................................................................................................... 16

Electrical ........................................................................................................... 17

Installing the RIO Zuni ........................................................................................... 19

Startup Tips ...................................................................................................... 21

OPERATION AND MAINTENANCE .......................................................................... 22

Normal Operation .................................................................................................. 22

Interface elements ............................................................................................. 22

Communications ................................................................................................ 23

Troubleshooting .................................................................................................... 24

Fault Conditions ................................................................................................. 24

Resolving Software Faults ................................................................................... 24

General Troubleshooting ..................................................................................... 25

Maintenance ......................................................................................................... 27

General Plumbing Checks .................................................................................... 27

P/N: 102-00094-I Page 3

MIOX RIO Zuni™ Operators Manual

Changing Peristaltic Pump Tubes .......................................................................... 27

Cell Replacement ............................................................................................... 28

APPENDICES ........................................................................................................ 32

Inline Pressure Reducer ......................................................................................... 33

Changing Pump Tubes ........................................................................................... 34

Water Quality Guidelines ........................................................................................ 40

Rio Zuni Spare Parts Identification/Ordering Guide .................................................... 41

List of Figures

Figure 1: RIO Zuni On-Site Generator (tabletop model) .................................................. 6

Figure 2: Generic diagram of a RIO Zuni OSG with necessary components ........................ 8

Figure 3: RIO Zuni 2.0 lb OSG with labeled system components. Cover not shown. .......... 11

Figure 4: RIO Zuni 2.0 lb OSG showing cells, thermowells, and I/O panels ...................... 12

Figure 5: RIO Zuni OSG I/O panels with labeled components ......................................... 13

Figure 6: One of two level switches before being installed in an oxidant tank ................... 14

Figure 7: Inline Pressure Reducer assembly ................................................................. 14

Figure 8: Image showing all connections for full operation of the RIO Zuni OSG. .............. 18

Figure 9: LED Indicator meanings .............................................................................. 22

Figure 10: RIO Zuni OSG with system cover and screw locations .................................... 30

Figure 11: Internal Top View of Zuni Showing Cell Hour Reset Button Location. ............... 31

List of Tables

Table 1: System Specifications .................................................................................... 7

Table 2: Fault conditions descriptions ......................................................................... 24

Table 3: General troubleshooting approaches .............................................................. 26

Table 4: Cell Replacement Tools Required ................................................................... 28

P/N: 102-00094-I Page 4

MIOX RIO Zuni™ Operators Manual

INTRODUCTION AND OVERVIEW

This manual is intended to provide basic installation, operation, and maintenance guidelines

for the operator of the RIO Zuni™ on-site generator (OSG). Variations between model types

may cause the images in this manual to not directly reflect the setup of every unit.

Properly operating and maintaining the system will increase cell life and overall system

performance. If you encounter problems or have questions not covered in this manual,

please contact MIOX Service at 1-888-646-9457.

Regulatory Compliance

U. S. Environmental Protection Agency (US EPA)

On-site generated oxidants are listed as a compliance technology for water disinfection. To

be listed as a compliance technology, the system must be cost effective and achieve

compliance with the regulated maximum contaminant levels (MCLs), and the operator must

be capable of reliably operating the technology. The on-site oxidant category was added to

this list in 1997 primarily based on independent research of MIOX technology.

List of Certifications

EPA Registration Number: 69723-NM-001

NSF International

MIOX maintains a policy of verification and compliance of MIOX technology for water

applications. The NSF Standard provides the criteria used to evaluate the public health

safety of materials, components, products, or systems that contact drinking water, drinking

water chemicals, or both. For details of specific NSF standards for specific MIOX equipment,

please consult with MIOX. NSF listings are also available through NSF International at (800)

NSF-Mark or their web site at www.nsf.org.

State Approvals

MIOX maintains a policy of obtaining state regulatory approval in all states where MIOX

equipment is installed and operated. MIOX has never been rejected for approval in any

state. For a complete list of states currently approving on-site oxidant technology, please

contact MIOX.

P/N: 102-00094-I Page 5

MIOX RIO Zuni™ Operators Manual

System Description

The MIOX RIO Zuni system is an on-site mixed oxidant generator that creates mixed

oxidant solution from water, salt, and electricity. The system can create either 1.0 lb. or 2.0

lbs. of Free Available Chlorine (FAC) per day, depending on the model ordered. When

producing oxidant the RIO Zuni system is automatically controlled by a pair of level switches

inside the oxidant storage tank.

Mixed oxidant solution is a powerful hypochlorite-based disinfectant with improved biological

kill efficacy that achieves more rapid and thorough inactivation of a wide range of microbial

contaminants.

Figure 1: RIO Zuni On-Site Generator (tabletop model)

P/N: 102-00094-I Page 6

MIOX RIO Zuni™ Operators Manual

System Specifications

RIO Zuni 1 RIO Zuni 2

1.0 lbs/day 2.0 lbs/day

Rated FAC Capacity

0.45 kg/day 0.9 kg/day

3.0 - 3.5 lb. salt/lb. FAC

Salt Conversion (SCE)*

3.0 - 3.5 kg salt/kg FAC

3.5 kW-hr/lb. FAC

Energy Conversion (ECE)*

7.7 kW-hr/kg FAC

FAC Concentration* 4,000 mg/L (+/- 1,000)

Salt Quality Requirement 99.5% NaCl or better^

Water Hardness 0-17 mg/L

Maximum Silica Limit 20 mg/L

1.3 gph 2.7 gph

Flow Rate#

4.9 lph 10.2 lph

Electrical Service Requirement+ 110 VAC to 240 VAC, 1 ph, 2A, 110 VAC to 240 VAC, 1 ph, 4A,

(OSG Only) 50/60 hertz 50/60 hertz

40°F to 110°F

Air Temperature Required

4°C to 43°C

Recommended Feed Water 55° to 80° F

Temperature* 12° to 27° C

Allowable Feed Water 40° to 95° F

Temperature* 4° to 35° C

1 - 75 psi

Feed Water Pressure@

6.8 – 517 kPa

Approximate OSG Dimensions 20.75 x 15.66 x 13.5 inches

(WxDxH) 52.71 x 39.78 x 34.29 cm

25 lbs

Approximate OSG Weight

11.5 kg

Self-Cleaning YES

+For continued protection against risk of fire, replace fuse only with a fuse of the same type and current rating

*Performance may vary depending on salt quality, water quality, and water temperature.

^Refer to MIOX Salt Quality Guidelines for more details.

#Feed water flow rate is subject to +/- 15% variation.

@Feed water pressure for RO Kit and/or Integrated Brine Tank is 40-75 psi

Table 1 : System Specifications

P/N: 102-00094-I Page 7

MIOX RIO Zuni™ Operators Manual

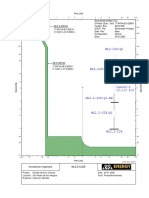

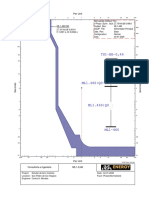

System Illustrations and Component Descriptions

RIO Zuni

Hydrogen Vent

Inline Pressure Reducer (must vent

(connect to water supply) outside)

Brine Tank

Oxidant

Level Switch

Assembly

Figure 2: Generic diagram of a RIO Zuni OSG with necessary components

RIO Zuni OSG

On-site mixed oxidant generator (OSG).

Water supply

Fresh water supply for the OSG. Runs through Inline Pressure Reducer assembly before

connecting to OSG.

Brine supply

Low-pressure supply of saturated brine to the OSG.

Oxidant Tank

Vented oxidant solution storage tank for OSG output.

P/N: 102-00094-I Page 8

MIOX RIO Zuni™ Operators Manual

Hydrogen Vents

Upward-sloping piping connected to outside environment for venting potentially dangerous

hydrogen gas (See Hydrogen Safety White Paper).

Level Switch Assembly

Assembly of two level switches and a level switch cable. The level switches control the OSG

when installed in the oxidant tank. The 15’ cable connects the level switches to the OSG.

See Figure 2 for details. Note: The level switches are orientation-sensitive and must be

installed with the arrow pointing upward in order to function properly.

System Cover

A rigid plastic housing that covers and protects the key components of the RIO Zuni.

LCD Display

Visual Display with a cycling menu of system status and operational parameters. See Figure

3 for details.

LED Indicator

A multi-color LED which displays system status. See Figure 3 for details.

Electrical Enclosure

An actively-cooled aluminum box housing the control board, power supplies and other

electronic components of the RIO Zuni System. See Figure 3 for details.

Brine Pump

An automated peristaltic pump which controls the system’s brine flowrate and acts as a

check valve to prevent brine supply dilution. Capable of withstanding up to 10 PSI of

pressure. See Figure 3 for details.

Water Pump

An automated peristaltic pump which controls the overall system flowrate and acts as a

check valve to prevent oxidant from flowing into the water supply. Capable of withstanding

up to 10 PSI of pressure. See Figure 3 for details.

MIOX Zuni Electrolytic Cell

A proprietary electrolytic cell manufactured by MIOX produces 1.0 lbs of FAC per day of

runtime. 1 lb. RIO Zuni OSGs use one cell while 2 lb. RIO Zuni OSGs use two cells. See

Figure 4 for details.

Thermowells

In-line temperature sensors used to evaluate operational efficiency of the system. See

Figure 4 for details.

Electrical Back Panel

All of the unit’s electrical connections, including the power switch, system fuse, IEC power

receptacle, and connectors for the Level Switch Assembly, a USB jump drive, and an

Ethernet cable. See Figure 5 for details.

P/N: 102-00094-I Page 9

MIOX RIO Zuni™ Operators Manual

Plumbing I/O Panel

3 barb fittings for connecting the water supply, brine supply and oxidant outlet. See Figure

5 for details.

Hydrogen Vent Kit

Kit of parts consisting of an oxidant tank inlet, drop tube assembly, warning labels and a

vent strainer. Refer to the Oxidant Tank Manual for details.

Inline Pressure Reducer Kit

Three (3) piece assembly to reduce line pressure to an appropriate pressure for the OSG.

Kit has a female ¾” NPT inlet connection. See Figure 7 and Appendices for details.

Integrated Brine Tank (Optional)

Optional integrated tank with automatic brine generation system designed explicitly for the

RIO Zuni. See Integrated Brine Tank Manual for installation and operation.

NOTE: For items not listed above see the appendices and

Documentation Kit. Additional items may include, but are not limited

to the oxidant tank, hydrogen vent, oxidant pump, water heater and

water chiller. Contact MIOX for additional details on available options.

P/N: 102-00094-I Page 10

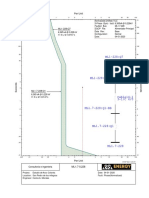

MIOX RIO Zuni™ Operators Manual

Electrical

Enclosure

Brine Pump

Water

Pump

Check

Valve

LCD Display LED

Indicator

Figure 3: RIO Zuni 2.0 lb. OSG with labeled system components.

(System cover not shown)

P/N: 102-00094-I Page 11

MIOX RIO Zuni™ Operators Manual

2 MIOX RIO Zuni

Electrolytic Cells

Electrical Back

Panel

Thermowells

Plumbing I/O (T-shaped elements in

plumbing line)

Figure 4: RIO Zuni 2.0 lb. OSG showing cells, thermowells, and I/O panels

P/N: 102-00094-I Page 12

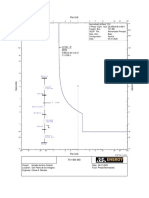

MIOX RIO Zuni™ Operators Manual

USB Port

for data Ethernet Port

logging

Power ON/OFF

Entry Switch

Module

Fuse

Holder

Water Oxidant

Inlet Outlet

Level Switch

Brine Inlet Assembly

Figure 5: RIO Zuni OSG I/O panels with labeled components

P/N: 102-00094-I Page 13

MIOX RIO Zuni™ Operators Manual

Figure 6: One of two level switches before being installed in an oxidant tank

Figure 7: Inline Pressure Reducer assembly

P/N: 102-00094-I Page 14

MIOX RIO Zuni™ Operators Manual

INSTALLATION AND STARTUP

The RIO Zuni OSG has been factory tested and must be properly installed per the

instructions in this manual.

Safety SAFETY PRECAUTIONS AND WARNINGS

Ensure that the facility and the installation are in conformance with all codes

and standards.

Please refer to the MIOX Hydrogen Safety White Paper or your local authority

having jurisdiction for more information.

A liquid barrier system is mandatory. Ensure that all hydrogen vent lines

slope towards the oxidant tank.

Ensure that no valves, drop legs, or P-traps are in the hydrogen vent lines.

Do NOT cross connect vent lines.

Ensure that brine and oxidant tanks are labeled properly.

Disconnect power before working on the system. Do not reconnect the power

to the rear panel until installation is complete.

All MIOX systems require a good earth ground. A neutral is not a substitute

for a proper earth ground. Electrical wiring to all MIOX systems should be

performed by a certified electrician.

In the Box

1) RIO Zuni OSG

2) RIO Zuni Quickstart Guide

3) RIO Zuni Installation, Operation, and Maintenance Manual

4) Documentation Kit

5) Power Cord

6) Standard Parts Kit

a. Level Switch Assembly (comes pre-installed if an Oxidant Storage Tank was

ordered from MIOX)

b. Tubing and hose clamps

7) Integrated Brine Tank (if ordered)

8) Oxidant Storage Tank (if ordered)

9) Inline Pressure Reducer Kit

10) Hydrogen Vent Kit (comes partially pre-installed if an Oxidant Storage Tank was

ordered from MIOX)

What you need

To install the MIOX RIO Zuni, you need:

P/N: 102-00094-I Page 15

MIOX RIO Zuni™ Operators Manual

1) MIOX RIO Zuni OSG

2) 5 foot by 5 foot indoor environment

3) 110-240 VAC 10A circuit with standard grounded wall plug

4) Saturated Brine Supply (see MIOX Salt Quality Guidelines for salt

specifications)

5) Fresh Water Supply (see Appendices for Water Quality Guidelines)

6) Oxidant Storage Tank with Hydrogen Venting (see Hydrogen Safety White

Paper for details)

7) Tubing and hose clamps (provided with OSG)

8) Level Switch Assembly (provided with OSG)

9) Power Cord (provided with OSG)

Tools for install

The MIOX RIO Zuni can be installed without any tools, although MIOX recommends using a

pair of pliers to tighten the hose clamps on the plumbing I/O panel.

Refer to the Integrated Brine Tank Manual for tools needed to install the Integrated

Brine Tank.

Refer to the Oxidant Tank Manual for tools needed to install the Level Switch Assembly.

Installation Location Requirements

The RIO Zuni OSG must be installed indoors on a flat level surface approximately 5 feet long

by 5 feet wide (1.52m by 1.52m). The ambient air temperature at the installation location

must be between 40°F (5°C) and 110°F (43°C). Additional space may be required for the

water, brine, and oxidant tanks. MIOX recommends placing the OSG and tank near an

available drain for ease of draining the tank or in case of minor overflows. Additionally,

MIOX recommends placing the RIO Zuni near an external wall for ease of hydrogen venting

as described in the Hydrogen Safety White Paper.

NOTE: Failure of the system that can be traced to improper

temperature conditions is not covered under the MIOX warranty.

Connections

Plumbing

The RIO Zuni has three barbed plumbing connections on the plumbing I/O panel: water

inlet, brine in, and oxidant out. The ¼” barbed water inlet must be connected to the

appropriate location on the included Inline Pressure Reducer Kit. The ¼” barbed brine inlet

must be connected to an unpressurized saturated brine supply.

If using the integrated brine tank with the RIO Zuni OSG, the water and brine inlets

will connect to the labeled water and brine outlets on the integrated brine/water

tank. Please refer to the Integrated Brine Tank Manual for more details.

P/N: 102-00094-I Page 16

MIOX RIO Zuni™ Operators Manual

The 3/8” barbed oxidant outlet must be connected to an oxidant tank and a hydrogen vent

line. All barb fittings must be secured with the included hose clamps.

Safety Only supply the RIO Zuni OSG brine (fully-saturated salt water) and fresh

water. Feeding other solutions instead of brine and water can cause severe

damage to the equipment or operator. Follow MIOX Salt Guidelines for salt

quality used in operating on-site generation equipment.

For direct injection applications, the RIO Zuni OSG can inject into a maximum

of 10PSI.

Electrical

The RIO Zuni requires only power and level switch connections for normal operation. The

included 10 foot power cord connects the system to 110-120 VAC and should be connected

to the standard IEC receptacle on the electrical back panel. For a 220-240 VAC connection,

replace the supplied power cord with a 10A rated 220VAC IEC Cable (220VAC cable not

provided by MIOX).

All RIO Zuni OSG systems ship with a pre-installed 2A or 4A fuse, depending on model. A

spare fuse is also included with the unit.

NOTE: Failure of the system that can be traced to a poor power source

is not covered under the MIOX warranty.

The level switches should be installed in the oxidant tank as described in the GA drawing

or Oxidant Tank Manual. The level switch cable is keyed so there is only one orientation

that matches the connectors on the back panel. Without level switches plugged in, the OSG

will never operate and instead will remain in ‘Standby’ mode.

Safety All MIOX systems require a good earth ground. A neutral is not a substitute for

an earth ground. Electrical wiring to all MIOX units should be wired on a

separate circuit from other power devices, like pumps, etc. MIOX cannot be

held responsible for systems wired improperly that do not meet UL or National

Electrical Code (NEC) requirements. If the system is improperly grounded, the

MIOX warranty is void. If a local code requires a GFI (Ground Fault

Interrupter) circuit breaker, it is the responsibility of the customer to install

the GFI to meet local code requirements.

P/N: 102-00094-I Page 17

MIOX RIO Zuni™ Operators Manual

Figure 8: RIO Zuni Connections.

P/N: 102-00094-I Page 18

MIOX RIO Zuni™ Operators Manual

Installing the RIO Zuni

1) Unpack The Boxes

Unpack the RIO Zuni OSG and all included components.

2) Position the OSG

Tabletop configuration: Place the RIO Zuni OSG on a flat, level surface.

Integrated Brine Tank configuration: Place the RIO Zuni OSG on the integrated

brine tank by following instructions in the Integrated Brine Tank Manual.

3) Install Inline Pressure Reducer

Following the instructions in the Appendices for installing the Inline Pressure

Reducer, connect the water source to the water inlet of the OSG through the Inline

Pressure Reducer.

4) Connect Water Source

Tabletop configuration:

Connect water source to brine source.

Integrated Brine Tank configuration:

Connect pressurized water source to the brine tank using the 1/4” diameter LDPE

tubing. Secure with hose clamps. Leave valves closed.

5) Connect Water & Brine Inputs to OSG

Use the smaller diameter clear vinyl tubing to connect the water and brine feeds to

the OSG. Secure with hose clamps. Leave valves closed.

6) Load Salt

Load the brine tank with salt. If Integrated Brine Tank was ordered from MIOX,

follow instructions in the Integrated Brine Tank Manual.

NOTE: Only use salt that meets or exceeds the salt quality

specifications in the MIOX Salt Guidelines.

7) Connect Oxidant Tank

Connect the oxidant outlet to the oxidant tank using the larger diameter clear vinyl

tubing and hose clamps. If Oxidant Storage Tank was ordered, follow installations

instructions in the Oxidant Tank Manual.

8) Install Level Switch

Plug the level switch assembly cable into the electrical I/O panel of the OSG. Follow

installations instructions in the Oxidant Tank Manual for the Level Switch

Assembly.

P/N: 102-00094-I Page 19

MIOX RIO Zuni™ Operators Manual

NOTE: Oxidant tank level switches must be installed correctly for the

system to operate.

9) Hydrogen Venting

Install hydrogen venting in the oxidant tank. Hydrogen must be vented outdoors.

Follow the Hydrogen Vent Kit instructions in the Oxidant Tank Manual and MIOX

Hydrogen Safety White Paper.

10) Attached Power Cord

Attach power cord to IEC on the back panel of OSG. Connect to 220-240 VAC. For a

220-240 VAC connection, replace the supplied power cord with a 10A rated 220VAC

IEC Cable (220VAC cable not provided by MIOX).

11) Open Valves on OSG

Open the water and brine feed valves on the OSG.

12) Open Water Source Valve

Open the facility water source valve.

13) Brine Saturation

Wait 30 minutes to 1 hour to allow brine to fully saturate before turning system on.

14) Turn System On

Turn on the unit by switching the power switch on the back panel. The RIO Zuni will

enter into a priming cycle. RIO Zuni will automatically start producing oxidant after

the system has completed the priming cycle.

NOTE: Visually verify that water and brine are being delivered to the

plumbing I/O panel on the back of the OSG.

If water and/or brine are not visibly entering the OSG at the end of the priming

cycle, restart the priming cycle by turning the unit off, waiting 5 seconds, then

turning the unit on again. Wait for the priming cycle to end and then repeat this

process until both water and brine are successfully delivered to the plumbing I/O

panel. Refer to the troubleshooting guide located within this manual if system does

not start after priming cycle.

P/N: 102-00094-I Page 20

MIOX RIO Zuni™ Operators Manual

Startup Tips

Things to check if any issues arise during the initial system startup:

Brine saturation level

Unsaturated brine may cause the system to fault on initial startup. Adding more salt to the

brine tank and waiting about 30 minutes before restarting the system should resolve this

problem.

Plumbing length

In some installations, the system must go through multiple priming cycles before liquid

reaches the unit. MIOX recommends minimizing the length of hose in between the water

and brine supplies and the OSG.

NOTE: Assure there are no kinks or pinches in the tubing.

Plumbing connections

The pumps in the RIO Zuni are self-priming, but they rely on sealed tube and hose

connections. If any of the connections are leaking, the system will not perform properly.

Level Switch Assembly Installation

Check that the level switches are installed appropriately. Follow the instructions in the

Oxidant Tank Manual to troubleshoot the level switches and the level switch cable.

P/N: 102-00094-I Page 21

MIOX RIO Zuni™ Operators Manual

OPERATION AND MAINTENANCE

Normal Operation

In normal operation, the RIO Zuni automatically enters ‘Run’ and ‘Standby’ modes based on

the oxidant level in the oxidant tank. The RIO Zuni will also automatically enter a ‘Cleaning’

mode on the first startup after a predefined number of operating cell hours.

Safety The mixed oxidant solution generated by the OSG should be used as quickly as

possible to take advantage of the improved disinfection efficacy. If the mixed

oxidant solution is stored for more than 30 minutes before use, store it in a

vented and covered container made of HDPE. Properly stored mixed oxidant

solution will retain its disinfection efficacy for up to 5 days.

Interface elements

LED

System in Standby

System in Normal Operation

System in Startup or Shutdown

System faulted and needs reset

System faulted and will automatically restart

System operating atypically – check brine and

salt supply

Figure 9: LED Indicator meanings

The colored LED on the front of the OSG indicates the operational mode of the unit. Solid or

flashing green indicates that the system is normal operation conditions and is producing

oxidant. Solid or flashing yellow indicates a fault condition. Flashing blue indicates that

there may be a problem with the brine supply. The system will also flash blue to indicate the

system is about to run out of salt. Refer below for a more detailed breakdown of the various

operating modes and the behaviors associated with them.

Standby

The system is “turned off” and not generating nor attempting to generate oxidant

P/N: 102-00094-I Page 22

MIOX RIO Zuni™ Operators Manual

Normal Operation

The system is within the normal operating window for oxidant generation and is

running correctly

Startup/Shutdown

During the startup and shutdown modes of operation, the system flushes the lines

and cell with water to remove any excess salt that may crystalize and clog the plumbing

while the system is not in use. After the system enters this mode, it will automatically enter

Normal Operation or Standby after the flush is performed depending on whether or not it

was startup or shutdown.

NOTE: Excessive startups/shutdowns will dilute the oxidant in the storage tank due to the

excess water being added to the tank.

System Fault

The system has encountered an abnormality in the operating parameters and is

either attempting to resolve it automatically (flashing) or needs manual resetting and

inspection (solid). Refer to the Fault Conditions sub-section of the Troubleshooting guide

included in this manual for more information of fault conditions and actions to remove them.

Brine Supply Issues

If the system has an abnormally high brine pump duty, the LED will flash blue. High

brine duty can be caused by a number of things all relating to the amount of salt entering

the cell. Check brine lines for leaks/clogs, brine salt concentration levels, and pump hoses to

ensure that they are all in working order. If the problem persists, contact your customer

support provider for additional troubleshooting assistance.

LCD Display

The display constantly updates with the current operating conditions of the system.

Information including system hours, cell hours, operational mode, cell current, inlet

temperature and outlet temperature cycles continuously through the display when in ‘Run’

mode.

Level Switch Assembly

The level switches in the oxidant tank act as the ‘Run/Stop’ switch for the unit. When both

level switches are low, the OSG enters ‘Run’ mode and makes oxidant until both level

switches are high. Once both level switches have been triggered high, the unit enters

‘Standby’ until both level switches are again in the low position.

If desired, the unit may be put into constant run mode by connecting together the two

halves of the level switch cable on the back I/O panel. This will bypass the level switches

and prevent the unit from ever going into standby.

Communications

P/N: 102-00094-I Page 23

MIOX RIO Zuni™ Operators Manual

USB

A USB memory stick can be plugged into the USB port on the back panel at any time to log

the system’s status and operational parameters. The log is stored in a dated text file on the

memory stick and any readily available memory stick should be able to log months of

operation without any issues. The headers for the log are not included but are available

through your sales representative or service provider. MIOX recommends always restarting

the unit after plugging in a USB memory stick.

NOTE: MIOX recommends using a new, dedicated USB memory stick

for any data logging to prevent any unexpected file interactions with

the RIO Zuni OSG.

Ethernet

To remotely monitor the system over Ethernet, an Ethernet cable must be connected from

the back of the unit to an existing Ethernet network that supports DHCP. The system will

periodically display its assigned IP address after the priming cycle completes. System data

may be viewed remotely through any modern web browser; enter the IP address

periodically displayed by the system into your web browser’s address bar. The webpage is

served with data in the form of an .xml file, while it is possible to parse this data with some

modern SCADA systems this feature is not supported.

Troubleshooting

Fault Conditions

The RIO Zuni is preprogrammed with a number of fault conditions which trigger whenever

the system is running atypically. The faults are classified as either hard or soft faults. Hard

faults automatically shut the system down and require a power cycle to reset the system.

Soft faults try to resolve themselves and automatically restart the system a number of

times before requiring a power cycle reset.

Fault # of

Fault Type Restarts Cause

Oxidant Tank Level Hard 0 Level Switches are in an invalid position (Low level

Error switch is low while high level switch is high)

Very High Current Hard 0 Cell current has surpassed 125% of target current

Very High Oxidant Temp Hard 0 Oxidant temp measured above 145°F (62°C)

Soft 3 Measured temperature rise across cell has surpassed

Delta Temp

50°F (27°C)

Low Feed Water Temp Soft 1 Inlet water temp measured below 33°F (1°C)

High Brine Pump Duty Soft 3 Brine pump usage over 250% of normal

Table 2: Fault conditions descriptions

Resolving Software Faults

The only way to clear a fault from the system is to reset it by cycling power as described in

step 14) of the installation instructions. This resetting will rerun the priming cycle and flush

the cell before restarting. Please note that restarting the system does not necessarily mean

the problem will go away, only that the unit will try to resume normal operation. If the unit

still cannot resume normal behavior, the system will continue to fault after the

P/N: 102-00094-I Page 24

MIOX RIO Zuni™ Operators Manual

restart/priming cycle. Refer to Table 3 and the rest of the General Troubleshooting section

for assistance in resolving faults. If the cause of the fault cannot be resolved, contact your

service provider for more advanced troubleshooting.

General Troubleshooting

Every RIO Zuni is fully tested before leaving the factory, but sometimes things do go wrong.

The table below lists common potential problems, their possible causes, and how to resolve

them.

Problem Probable Cause(s) Remedial Action

System primes but never 1. Failure in the level switch 1. Confirm level switches are

starts. assembly. installed and oriented

2. Too much conductivity in properly and all electrical

cell. connections are solidly

connected.

2. Close the brine feed. Toggle

3X for 30 seconds each, let

third restart complete and

open brine feed.

No display visible when switch 1. Correct power not getting to 1. Confirm power is available

turned on. system. from the wall, power cord is

2. Power Supply Failure properly connected to unit,

and fuse is not blown.

2. Contact Customer Support

for guidance on

troubleshooting and/or

getting the power supply

replaced.

MIOX system chlorine 1. High flow through cell. 1. Measure flow.

production lower than normal, 2. Cell exit ports blocked. 2. Clear blockage. If blockage

or chlorine residual in water 3. Injection system cannot be removed, replace

system below normal. malfunction. cell.

4. Cell life depleted. 3. Check cell amperage, flow,

5. Break in water distribution chlorine production, and salt

lines. consumption. Replace cell if

6. Mixed oxidants stored too necessary.

long before use. 4. Check for leaks and repair.

7. System Running outside of 5. Call sales agent or MIOX

specifications. Customer Support.

6. Verify measurements with

demand free water.

7. Confirm all parameters are

within system specifications

outlined in Table 1. If the

problem persists, contact

your service provider.

System faults immediately on 1. Brine is not fully saturated. 1. Add more salt and wait 30-

startup. 2. Water or Brine feed not 60 minutes to allow brine to

getting to system fully saturate. Then restart

the system.

2. Confirm brine and water

feeds are connected and all

valves in between supplies

and inlets are open. Check

for and remove salt crystals

P/N: 102-00094-I Page 25

MIOX RIO Zuni™ Operators Manual

that have formed blockages

in the brine lines.

System faults immediately on 1. Water or brine feed not 1. Confirm brine and water

startup. getting to system. feeds are connected and all

valves in between supplies

and inlets are open.

Display Reads: VERY HIGH 1. Loss of water supply. 1. Check water feed line to RIO

CURRENT (Cell #1 or Cell 2. Blockage of cell exit ports. Zuni™ System.

#2) 3. Too much conductivity in 2. Turn system off, remove cell

cell. exit port disconnects, and

remove any obstructions

within ports.

4. Close the brine feed. Toggle

3X for 30 seconds each, let

third restart complete and

open brine feed.

Display Reads: VERY HIGH 1. Loss of water supply. 1. Check water feed line to RIO

CELL OX TEMP (Cell #1 or Cell 2. Blockage of cell exit ports. Zuni™ System.

#2) 3. Temperature sensor failure 2. Turn system off, remove cell

exit port disconnects, and

remove any obstructions

within ports.

Display Reads: LOW FEED 1. Feed water temperature too 1. Increase feed water

WATER TEMP X˚F low. temperature to above 50˚F

2. Temperature sensor failure (10˚C) prior to restarting

system.

2. Temporarily swap the

thermowell assemblies or

otherwise verify correct

temperature is being

displayed on the Rio Zuni,

Display Reads: HIGH BRINE 1. Low brine concentration. 1. Check the salt, water and

PUMP DUTY 2. Brine pump air locked. brine level in the brine tank.

3. Brine pump locked due to Add salt to the brine tank to

debris. salt fill level.

4. Brine line ruptured or 2. Verify brine inlet valve is

clogged. open. Remove the tube on

5. Controller board failure or the inlet to the brine pump

brine pump worn out. and purge the air from the

6. Cell life depleted brine line.

3. Remove debris from brine

pump.

4. Replace peristaltic pump

brine line with provided

tubing.

5. Verify pump turns by

removing the cover and

manually rotating the roller.

6. Replace brine pump.

Display Reads: DELTA TEMP 1. Blockage of fl ow through 1. Turn system off, remove cell

CELL cell (#1 or #2). exit port disconnects and

2. Temperature sensor failure. remove any obstructions

within the ports.

2. Replace temperature sensor.

3. Verify temperature (inlet

oxidant temp).

Table 3 : General troubleshooting approaches

P/N: 102-00094-I Page 26

MIOX RIO Zuni™ Operators Manual

NOTE: Following any troubleshooting, reset the system by cycling power. If

the suggested remedial action does not resolve the problem and the system

continues to not function properly, contact your service provider for further

assistance.

Maintenance

The MIOX RIO Zuni is designed for minimal maintenance. As long as the water and brine

supplies are within the specifications, there should be almost no maintenance required to

keep the unit running.

Salt Loading

Salt load will be required to maintain saturated brine levels. The conversion efficiency for

the RIO Zuni is 3.0 – 3.5 lb./kg salt per lb./kg FAC. This means 300 lbs of salt will provides

enough brine for up to 100 lbs mixed oxidant production. This equates to 12 to 16 weeks of

continuous operations of a RIO Zuni 1 lb. system or 6 to 8 weeks of continuous operation of

a RIO Zuni 2 lb. system.

General Plumbing Checks

The RIO Zuni comes preassembled with secured plumbing connections which should never

require replacement; however, if any of the internal plumbing connections are broken, the

connections should be resealed with zip ties or hose clamps.

Changing Peristaltic Pump Tubes

Other maintenance which might be necessary is changing the peristaltic pump tubes for the

water and brine pumps. The pump tubes should be changed if overall system flowrate falls

below 50% of the specified flow or if liquid is seen running out of the system housing.

To change the peristaltic pump heads, remove the system cover and find the two peristaltic

pumps. The system cover is held to the base with four screws on the bottom corners of the

cover (See Figure 10). Once the cover is removed and the pumps are accessible, change the

tubes by following the instructions included in the Appendices of this manual, Changing

Pump Tubes.

Safety Caution should be taken to prevent accidental exposure of brine and oxidant to

skin or eyes when servicing the unit. If this occurs, rinse affected areas with

water and apply first aid as needed.

Safety Always disconnect power from unit before removing cover.

P/N: 102-00094-I Page 27

MIOX RIO Zuni™ Operators Manual

Cell Replacement

In the event that your RIO Zuni needs to have an electrolytic cell replaced, use the following

procedure to replace the cell and reset the cell hour counter to zero.

Tool Purpose Step(s) Used

1/8” Allen Wrench Zuni Cover Removal 3, 10

3/8” Crescent Wrench Cell Mounting Bolt Removal 4, 7

7/64” Allen Wrench Cell Lead Removal 5, 7, 8

5/16” Crescent Wrench Cell Lead Removal 5, 7, 8

Pliers (Optional) Hose Clamp Removal 6, 7

1/4" Wrench (Crescent or Electrical Cover Removal 9, 10

Socket)

Table 4: Cell Replacement Tools Required

1) Disconnect Power

Disconnect power to the unit completely by first turning the power switch to the ‘off’

position and then unplugging the power cord.

2) Disconnect Plumbing

Close the valves that connect to the water and brine inlets, as well as the oxidant

outlet to the OSG. After the unit is isolated from all plumbing lines, remove the three

external plumbing connections from the back of the unit by sliding the vinyl tubing

off of the hose fittings.

Note: The OSG will still contain a small amount of liquid within the internal

plumbing as well as the cell(s). This will begin to drain out of the unit once

the lines are disconnected. Use a bucket placed underneath the hose fittings

to catch this drainage.

3) Remove the Outer Cover From the OSG

Remove the plastic cover from the OSG by removing the 4 screws located near the

base of the cover in the corners and lifting the cover upwards as shown in Figure 10

to gain access to the cell(s).

4) Unmount the Cell

Remove the old cell from its mounting location by removing the four 10-32 hex nuts

holding the cell(s) to the unit at all four corners (shown in Figure 4) and sliding the

mounting hardware and cell off of the threaded studs sequentially.

Note: On 2lb units where the inner-most cell must be replaced it is necessary to

remove the outer cell from the mounting bracket to remove the inner cell.

5) Disconnect Cell Leads

Disconnect the red (+) and black (-) wires from the cell by removing the 6-32 socket

head screws (1 each, 2 total) that attach the wires to the cell using an Allen wrench.

It may be necessary to hold onto the 6-32 hex nut on the other side of the

connection with a wrench in order to back the screw out.

6) Disconnect Cell Plumbing

P/N: 102-00094-I Page 28

MIOX RIO Zuni™ Operators Manual

Remove the inlet (bottom) and outlet (top) plumbing connections from the cell by

sliding the tubing off of the hose fittings on the cell.

Note: liquid may still be present within the cell and plumbing lines, watch

out for leaks and use a cup or similar container to help catch excess liquid.

7) Install the New Cell

Install the new replacement cell by following steps 4 through 6 in reverse order.

Though the unit should be completely disconnected from power at this point, it is

good practice to ensure that the outside of the cell and surrounding area are

completely dry before connecting the cell leads as excess oxidant can corrode the

electrical hardware and/or cause a short once power is restored to the unit.

8) Restore OSG to Operating Condition

Once the new cell is installed and mounted to the unit, ensure the entire area is dry

to avoid damaging electrical components. After drying the area, double check ALL

electrical and cell connections contained within the OSG enclosure to ensure that

nothing came loose during the replacement process. Re-install the plumbing and

electrical connections by performing steps 1 and 2 in reverse order. Once the unit is

back to its normal operating configuration (but with the plastic cover still removed),

turn on the unit and monitor it closely throughout the priming process to ensure

there are no leaks.

9) Reset the Cell Hours

Once the unit has completed the priming process, remove the top cover of the

electrical enclosure by removing the four 8-18 hex head self-drill screws located at

the four corners as shown in Figure3 to gain access to the controls board. With the

unit still powered on, locate and press the small orange button closest to the USB

port for more than 5 seconds to reset the cell hours counter to zero (Figure 11).

Verify this is complete by watching the display, when the ‘Cell Hours’ screen appears,

the counter should be reset.

NOTE: The reset will not work if the system is still in priming mode, make sure to

wait until the unit is in either ‘Run’ or ‘Standby’ modes before performing this step.

Be careful of exposed electrical components that may present a shock hazard.

10) Replace Covers & Resume Normal Operation

Re-install the cover for the electrical enclosure using the hex screws. Replace the

plastic outer cover by performing step 3 in reverse. Monitor the unit closely for the

first hour after replacement to ensure that there are no leaks.

P/N: 102-00094-I Page 29

MIOX RIO Zuni™ Operators Manual

Figure 10: RIO Zuni OSG with system cover and screw locations

P/N: 102-00094-I Page 30

MIOX RIO Zuni™ Operators Manual

Brine (Small)

Pump

Cell Hour Reset

↓ Fron t of Un it ↓

Figure 11: Internal Top View of Zuni Showing Cell Hour Reset Button Location.

P/N: 102-00094-I Page 31

MIOX RIO Zuni™ Operators Manual

APPENDICES

a. Inline Pressure Reducer

b. Changing Pump Tubes

c. Water Quality Guidelines

d. Spare Parts Identification/Ordering Guide

P/N: 102-00094-I Page 32

MIOX RIO Zuni™ Operators Manual

Inline Pressure Reducer

For all installations a pre-assembled Inline Pressure Reducer Kit is provided.

The Inline Pressure Reducer Kit includes the following:

1) Pressure Reducing Valve (PRV), ¾” NPT that regulates outlet pressure to 4-psi

2) Coupling ¾” PVC, adapts PRV to provided barb fitting

3) Adapter, ¾”MT x ¼” Barb, HDPE, provides connection to ¼” hose and PRV/Coupling

The kit should be provided pre-assembled. If assembly is required, wrap both ¾” NPT

threads on PRV and Adapter with Teflon Tape. The tape should be wrapped 3 times (3X)

around the threads. Screw one end of the Coupling into the PRV and then screw the

adapter into the other end of the Coupling. Connections should be hand tight with an

additional ½ turn utilizing a wrench or channel lock pliers. Connect one end of the ¼” hose

to the ¼” barb on the Adapter and the other end to the ¼” barb water inlet fitting on the

RIO Zuni. Use hose clamp or cable ties to ensure barb connections will not leak. The

pressurized feed water should be connected to the unused end of the PRV, this connection

size is also ¾” NPT. Proper fittings should be utilized that can handle appropriate feed

water pressure.

NOTE: Check all fittings for leaks prior to operating the RIO Zuni.

P/N: 102-00094-I Page 33

MIOX RIO Zuni™ Operators Manual

Changing Pump Tubes

The following pages show how to change the pump tubes on the RIO Zuni peristaltic pumps.

They are excerpts from the Welco Instruction Manuals.

P/N: 102-00094-I Page 34

MIOX RIO Zuni™ Operators Manual

P/N: 102-00094-I Page 35

MIOX RIO Zuni™ Operators Manual

P/N: 102-00094-I Page 36

MIOX RIO Zuni™ Operators Manual

P/N: 102-00094-I Page 37

MIOX RIO Zuni™ Operators Manual

P/N: 102-00094-I Page 38

MIOX RIO Zuni™ Operators Manual

P/N: 102-00094-I Page 39

MIOX RIO Zuni™ Operators Manual

Water Quality Guidelines

Knowing what to look for when sizing a system will help remove hidden surprises after

installation. Most of the items on the following list will be below the limits but should be

checked nonetheless. Concentrations or measurements in brine feed water and/or treated

water that are less than the stated limits are not anticipated to have the stated effect.

These factors can affect the oxidant demand of each individual water system, the oxidant

production of the MIOX system, or the life of the cell itself. It is important to use “worst

case” measures since water quality can vary from season to season.

WHAT IS IMPACTED

MEASURE LIMIT Oxidant Chlorine

Cell Life

Demand Production

grains/gal <1 grain

Total Hardness ** • •

(or mg/L) (<17 mg/L)

<1 mg/L

Iron (Fe) **† mg/L • •

**

<50 µg/L

Manganese (Mn) µg/L • • •

**

Fluoride (Fl) mg/L <1 mg/L •

Silica (SiO2) mg/L <20 mg/L • •

Bromide mg/L <50 mg/L •

Cyanide mg/L <1 mg/L •

Lead (Pb) mg/L <2 mg/L •

Dissolved Sulfides (as

mg/L *** •

H2S)

Ammonia Nitrogen (NH3-

mg/L *** •

N)

Organic Nitrogen (Org-N) mg/L *** •

Total Organic Carbon

mg/L *** •

(TOC)

pH - 5-9 • •

Water Temperature 55-80 °F

°F (or °C) • •

Range ^ (12-27°C)

**Caution: water softeners will remove these components up to a limit. See references to maximum

ferrous iron and manganese in water softener documentation. Total hardness affects cell life only in

that higher hardness requires acid washing to remove carbonate deposits from the cell. Use of water

softened to < 1 grain hardness should not require acid washing of the cell.

*** Oxidant demand is affected by any level of H2S, ammonia or organic nitrogen, or TOC.

† Iron may deposit Fe(OH)3 on the anode, causing an electrical “blind”, which would increase the

brine proportion pump signal voltage (brine proportion pump speed) needed for the system to reach

the operating window. Chlorine production would remain the same, but salt conversion efficiency will

decrease. The same effect is true of silica on the cathode.

^ The system will operate with water temperatures outside this range; however, there will be a

performance change. Follow the system specifications for absolute limits.

P/N: 102-00094-I Page 40

MIOX RIO Zuni™ Operators Manual

Rio Zuni Spare Parts Identification/Ordering Guide

Below is a list of common parts on the Rio Zuni along with their MIOX part number to aid in

any troubleshooting event where identifying or replacing a part may be necessary.

Additionally, these parts can be ordered and kept on hand as a spare in case a replacement

is needed in a more time sensitive manner. Contact your MIOX Customer Support provider

for additional information on ordering these or any other parts for the Rio Zuni.

Rio Zuni Spare Parts

CELL, RIO ZUNI

201-01251-07

PUMP,WPX1,1/8”,STEP,PHARMED

301-00374

P/N: 102-00094-I Page 41

MIOX RIO Zuni™ Operators Manual

PUMP,WP11,3/16",STEP,PHARMED

301-00375

TUBE, 1/8"-135, WT6, PHARMED

301-00376

TUBE, 3/16"-2, WT6, PHARMED

301-00377

P/N: 102-00094-I Page 42

MIOX RIO Zuni™ Operators Manual

TUBING, 1/4" x 3/8"

300-00349

ADAPTER,1/4x1/4x1/4 BARB, HDPE

300-02757

ADAPTER,3/8x3/8BARBx1/4,HDPE

300-02759

BULKHEAD, 1/4" NUTS, STR, NYLO

300-02640

P/N: 102-00094-I Page 43

MIOX RIO Zuni™ Operators Manual

TUBING 3/8 OD PE

700-00447

TUBING 3/8 ID x 5/8 OD VINYL

700-00447

CLAMP HOSE SNAP 3/8 OD ACETAL

700-01193

CLAMP HOSE SNAP 5/8 OD ACETAL

700-00449

P/N: 102-00094-I Page 44

MIOX RIO Zuni™ Operators Manual

FUSE, 5x20mm, 4A/250V (2PPD SYSTEM)

400-02548

FUSE, 5x20mm, 2A/250V (1PPD SYSTEM)

400-01199

ASSY, CELL LEAD #1

400-02557-D

ASSY, CELL LEAD #2

400-02558-D

ASSY, TEMP SENSOR. 1/4"DIA

400-02551-B

P/N: 102-00094-I Page 45

MIOX RIO Zuni™ Operators Manual

CONTROL BOARD ASSY

400-02083-04

POWER SUPPLY, 240W, 15V, 16A

400-02078

P/N: 102-00094-I Page 46

You might also like

- Practical Process Control for Engineers and TechniciansFrom EverandPractical Process Control for Engineers and TechniciansRating: 5 out of 5 stars5/5 (3)

- 102-00094-I RIO ZUNI Operators ManualDocument46 pages102-00094-I RIO ZUNI Operators ManualCarlos MoralesNo ratings yet

- Physio Control Lifepak 20 Defibrillator ManualDocument227 pagesPhysio Control Lifepak 20 Defibrillator ManualOmar RicoNo ratings yet

- Enabling the Business of Agriculture 2016: Comparing Regulatory Good PracticesFrom EverandEnabling the Business of Agriculture 2016: Comparing Regulatory Good PracticesNo ratings yet

- Lifepak 20e: Operating InstructionsDocument218 pagesLifepak 20e: Operating InstructionsJorge ArturoNo ratings yet

- C262, C265 Service ManualDocument459 pagesC262, C265 Service ManualRobert Kliewer100% (2)

- Manual Service G160 Gestetner 7526dnDocument605 pagesManual Service G160 Gestetner 7526dnmrzorbatronNo ratings yet

- PJWXC1110 ServicioDocument78 pagesPJWXC1110 ServicioJuan Carlos De Leon CoradoNo ratings yet

- Ricoh c440 Manual de ServicioDocument790 pagesRicoh c440 Manual de ServiciogeniuxNo ratings yet

- (M018, M019) SP C231SF, Aficio SP C232SF Parts & Service ManualDocument292 pages(M018, M019) SP C231SF, Aficio SP C232SF Parts & Service Manualbramirez8098100% (3)

- Apx 8500 Mobile Radio: Basic Service ManualDocument204 pagesApx 8500 Mobile Radio: Basic Service ManualА ENo ratings yet

- AF2022 - AF2027 MS - v01Document849 pagesAF2022 - AF2027 MS - v01Oscar OmañaNo ratings yet

- Datalogic DS1500 Reference ManualDocument64 pagesDatalogic DS1500 Reference ManualAntonio L. MartinezNo ratings yet

- Userguide Motorola Mototrbo dr3000 PDFDocument61 pagesUserguide Motorola Mototrbo dr3000 PDFdot16eNo ratings yet

- SCITON - JOULE Operator ManualDocument280 pagesSCITON - JOULE Operator ManualKrzysztof Zajkowski100% (1)

- mp2500 Service Manual PDFDocument806 pagesmp2500 Service Manual PDFwilliam lozadaNo ratings yet

- Subsea Production Guide Aug18Document111 pagesSubsea Production Guide Aug18Jay JayNo ratings yet

- 11.5.10 Flow ManufacturingDocument362 pages11.5.10 Flow ManufacturingvinodkundyannaNo ratings yet

- RM650 RM650 RM650 RM650Document170 pagesRM650 RM650 RM650 RM650kamala 123No ratings yet

- Iso 7500 1Document24 pagesIso 7500 1Saul QuezadaNo ratings yet

- EVOIPneo Active For Mitel MiVoice 5000 SP UsDocument123 pagesEVOIPneo Active For Mitel MiVoice 5000 SP UsDedis CorpNo ratings yet

- Regen ManualDocument52 pagesRegen ManualBrian KippeNo ratings yet

- Ricoh - d062 - d063 - d065 - MP 8001Document1,347 pagesRicoh - d062 - d063 - d065 - MP 8001Valfredo SOUSANo ratings yet

- B245, B276, B277 Service ManualDocument318 pagesB245, B276, B277 Service Manualslam_virgilio100% (1)

- E-Com Droc User ManualDocument91 pagesE-Com Droc User ManualPatou PatriceNo ratings yet

- PJ3351Document182 pagesPJ3351ereyNo ratings yet

- MS MP1500 Inglês PDFDocument744 pagesMS MP1500 Inglês PDFhoanam2009No ratings yet

- 2105 Service Manual RicohDocument1,245 pages2105 Service Manual RicohHarsa RaduNo ratings yet

- UG0817 User Guide Programming and Functional Failure GuidelinesDocument21 pagesUG0817 User Guide Programming and Functional Failure Guidelinesgsavithri_4017No ratings yet

- D093/D094 Service ManualDocument779 pagesD093/D094 Service ManualMr DungNo ratings yet

- MOTOTRBO™ Repeater: Basic Service ManualDocument61 pagesMOTOTRBO™ Repeater: Basic Service Manualdot16eNo ratings yet

- EL406 Operator S Manual 7181000 Rev BDocument264 pagesEL406 Operator S Manual 7181000 Rev BАлексей ЖижченкоNo ratings yet

- MACH - EQUIP - Auto 8 10Document205 pagesMACH - EQUIP - Auto 8 10Cor GavNo ratings yet

- Roc306/Roc312 Remote Operations Controller: Instruction ManualDocument160 pagesRoc306/Roc312 Remote Operations Controller: Instruction ManualtenithomasNo ratings yet

- Oxy IQ ManualDocument91 pagesOxy IQ ManualBibhu Ranjan MohantyNo ratings yet

- B003/B004/B006/B007 Service Manual: Ricoh Group CompaniesDocument974 pagesB003/B004/B006/B007 Service Manual: Ricoh Group CompaniesJose Cristobal MartinezNo ratings yet

- MEF 55 - LSO Reference Architecture and FrameworkDocument57 pagesMEF 55 - LSO Reference Architecture and FrameworkbalaiitmNo ratings yet

- Manual Micros m3700Document44 pagesManual Micros m3700Rafael CanulNo ratings yet

- B205/B209/D007/D008 Service Manual: Cópia Não ControladaDocument881 pagesB205/B209/D007/D008 Service Manual: Cópia Não ControladaRenê GuerraNo ratings yet

- Synchronous Motor SpecificationDocument51 pagesSynchronous Motor SpecificationHossam RedaNo ratings yet

- OIF Micro ITLA 01.1Document19 pagesOIF Micro ITLA 01.1jaschaNo ratings yet

- SP 377 Manual Deserv I CosDocument184 pagesSP 377 Manual Deserv I CosDawood AhmedNo ratings yet

- AriesoGEO 5.1.2 Release GuideDocument57 pagesAriesoGEO 5.1.2 Release GuideKirti GuptaNo ratings yet

- Datalogic OPOS Service Objects: User ManualDocument60 pagesDatalogic OPOS Service Objects: User Manualguillermo garicaNo ratings yet

- 00 7341026 Rev E - PrefaceDocument9 pages00 7341026 Rev E - PrefacePhong LeNo ratings yet

- B010 Service Manual: Ricoh Group CompaniesDocument323 pagesB010 Service Manual: Ricoh Group CompaniesThanhvinh NguyenNo ratings yet

- Aficio 470W SM PDFDocument349 pagesAficio 470W SM PDFphotocopythanhbinhNo ratings yet

- Vol 3Document986 pagesVol 3Geronimo JaimeNo ratings yet

- Waters Driver Pack 2017 Release 2 Release Notes 716005259raDocument32 pagesWaters Driver Pack 2017 Release 2 Release Notes 716005259racarlos julio german ariasNo ratings yet

- My Lab X5Document116 pagesMy Lab X5Filipe Rafael100% (1)

- Tesco Maintenance Guide PDFDocument136 pagesTesco Maintenance Guide PDFdraghiceanu50% (2)

- FabriPulseBV IOMDocument23 pagesFabriPulseBV IOMFranco Angelo RegenciaNo ratings yet

- Production Riser Life Extension: Guidance Notes OnDocument24 pagesProduction Riser Life Extension: Guidance Notes OnGopalakrishnanNo ratings yet

- SM rfg045948 PDFDocument1,991 pagesSM rfg045948 PDFCopyzoom PlusNo ratings yet

- Gemini VII 2390 Operator Manual V3.03Document426 pagesGemini VII 2390 Operator Manual V3.03PablosNo ratings yet

- 1DMotorolaSE 955guideDocument268 pages1DMotorolaSE 955guidefahlbergNo ratings yet

- UltraFast IGBT with Soft Recovery Diode Optimized for Motor ControlDocument10 pagesUltraFast IGBT with Soft Recovery Diode Optimized for Motor ControlFerney Martinez RomeroNo ratings yet

- Electrical Protection Application Get 8402Document15 pagesElectrical Protection Application Get 8402javedsmg1No ratings yet

- ML2 2-0,228 PDFDocument1 pageML2 2-0,228 PDFCarlos MoralesNo ratings yet

- InRush Grupo 4 PantanilloDocument1 pageInRush Grupo 4 PantanilloCarlos MoralesNo ratings yet

- InRush Grupo 3 PantanilloDocument1 pageInRush Grupo 3 PantanilloCarlos MoralesNo ratings yet

- ML1-228:Q7 ML1-228:Q7: Per UnitDocument1 pageML1-228:Q7 ML1-228:Q7: Per UnitCarlos MoralesNo ratings yet

- TX1 BB 460 PDFDocument1 pageTX1 BB 460 PDFCarlos MoralesNo ratings yet

- TX1 BB 460Document1 pageTX1 BB 460Carlos MoralesNo ratings yet

- Tbu Ca PDFDocument7 pagesTbu Ca PDFCarlos MoralesNo ratings yet

- ML1-228:Q3 ML1-228:Q3: Per UnitDocument1 pageML1-228:Q3 ML1-228:Q3: Per UnitCarlos MoralesNo ratings yet

- Tbu Ca PDFDocument7 pagesTbu Ca PDFCarlos MoralesNo ratings yet

- Fault analysis report for substation ML1.1-460Document1 pageFault analysis report for substation ML1.1-460Carlos MoralesNo ratings yet

- TX1-BB-0,46 TX1-BB-0,46: Per UnitDocument1 pageTX1-BB-0,46 TX1-BB-0,46: Per UnitCarlos MoralesNo ratings yet

- ML1-460:Q9 ML1-460:Q9: Per UnitDocument1 pageML1-460:Q9 ML1-460:Q9: Per UnitCarlos MoralesNo ratings yet

- ML1 1-0,46pdf PDFDocument1 pageML1 1-0,46pdf PDFCarlos MoralesNo ratings yet

- 369 Ge Rele PDFDocument294 pages369 Ge Rele PDFepala01No ratings yet

- BZM1 2 3-XA.-XU. Installation ManualDocument2 pagesBZM1 2 3-XA.-XU. Installation ManualCarlos MoralesNo ratings yet

- Connecting the Sepam Base UnitDocument11 pagesConnecting the Sepam Base UnitMoinullah Khan AteeqNo ratings yet

- F8L10D LoRa Module User Manual V1.2.0Document33 pagesF8L10D LoRa Module User Manual V1.2.0Xiamen Four-Faith Industrial Router supplierNo ratings yet

- DKCDocument407 pagesDKCCarlos MoralesNo ratings yet

- Primary-Side Transformer ProtectionDocument11 pagesPrimary-Side Transformer ProtectionganeshkumarkotaNo ratings yet

- Nema 1Document8 pagesNema 1Liliana LeiroNo ratings yet

- 1788HP-En2PA-R User Manual v1.00.02 Link Device PADocument30 pages1788HP-En2PA-R User Manual v1.00.02 Link Device PACarlos MoralesNo ratings yet

- 2017 Series: Features ApplicationsDocument4 pages2017 Series: Features ApplicationsCarlos MoralesNo ratings yet

- 1788-PP004A-EN-P - Web Link Device FF PDFDocument2 pages1788-PP004A-EN-P - Web Link Device FF PDFCarlos MoralesNo ratings yet

- Varistor Catalog PDFDocument254 pagesVaristor Catalog PDFsantosh_babar_26100% (1)

- 1788-PP004A-EN-P - Web Link Device FF PDFDocument2 pages1788-PP004A-EN-P - Web Link Device FF PDFCarlos MoralesNo ratings yet

- 1788HP-En2PA-R User Manual v1.00.02 Link Device PADocument30 pages1788HP-En2PA-R User Manual v1.00.02 Link Device PACarlos MoralesNo ratings yet

- Specification for Child MUAC Tape Quality ChecksDocument4 pagesSpecification for Child MUAC Tape Quality ChecksM HussainNo ratings yet

- Piston Water MeterDocument2 pagesPiston Water MeterMark PamularNo ratings yet

- Eells Chap 5 6Document24 pagesEells Chap 5 6Joaquín OlivaresNo ratings yet

- Letter From Springfield Mayor Sarno To License Commission Re: Late Night Hours.Document12 pagesLetter From Springfield Mayor Sarno To License Commission Re: Late Night Hours.Patrick JohnsonNo ratings yet

- Pds - Sunshades Instrument CoverDocument2 pagesPds - Sunshades Instrument CoverAntonio LantiguaNo ratings yet

- Self Esteem and The Real Body ImageDocument12 pagesSelf Esteem and The Real Body ImageChy Alcarde50% (2)

- SG Salary Guide 2021-22Document66 pagesSG Salary Guide 2021-22Gilbert ChiaNo ratings yet

- MWRC Policies & Procedures Manual 2020Document10 pagesMWRC Policies & Procedures Manual 2020Emma RyersonNo ratings yet

- SpamDocument2 pagesSpamAshutosh SinghNo ratings yet

- Buller, Paul F. - Schuler, Randall S - Managing Organizations and People - Cases in Management, Organizational Behavior and Human Resource Management-Thomson - South-Western (2006)Document530 pagesBuller, Paul F. - Schuler, Randall S - Managing Organizations and People - Cases in Management, Organizational Behavior and Human Resource Management-Thomson - South-Western (2006)ezekiel capuzNo ratings yet

- English Form 2 Mod23042022001Document10 pagesEnglish Form 2 Mod23042022001Qiash JontezNo ratings yet

- ProVent - MANN + HUMMEL ProVent - Oil Separator For Open and Closed Crankcase Ventilation SystemsDocument29 pagesProVent - MANN + HUMMEL ProVent - Oil Separator For Open and Closed Crankcase Ventilation SystemsJosephNo ratings yet

- Renub Research: Singapore Medical Tourist Arrivals, Medical Tourism Market & Forecast To 2015Document13 pagesRenub Research: Singapore Medical Tourist Arrivals, Medical Tourism Market & Forecast To 2015api-114525849No ratings yet

- Bacnet® Fixed Function Thermostat: For Fan Coil/Heat Pump/Conventional SystemsDocument8 pagesBacnet® Fixed Function Thermostat: For Fan Coil/Heat Pump/Conventional Systemsamjadjaved033148100% (1)

- Practical-2 Simulation of ReactorsDocument2 pagesPractical-2 Simulation of ReactorsniralNo ratings yet

- MaryamDocument1 pageMaryamHAIZA FATHIMANo ratings yet

- VAC Form 2 CityMunicipal Consolidated FormDocument1 pageVAC Form 2 CityMunicipal Consolidated Formalex almarioNo ratings yet

- Sectors of The Indian EconomyDocument5 pagesSectors of The Indian EconomyhavejsnjNo ratings yet

- Sheath CurrentsDocument5 pagesSheath Currentsscribdkkk100% (1)

- Bi Metallic Corrosion PDFDocument34 pagesBi Metallic Corrosion PDFDerek OngNo ratings yet

- 7Document40 pages7Felipe RichardiosNo ratings yet

- Artificial Intelligence in Rheumatology: Applications and ChallengesDocument39 pagesArtificial Intelligence in Rheumatology: Applications and ChallengesMaryame BoutkhilNo ratings yet

- Application Format For Child CustodyDocument2 pagesApplication Format For Child CustodyDHUP CHAND JAISWAL100% (3)

- Space suit essentialsDocument6 pagesSpace suit essentialsAdam PaiggeNo ratings yet

- Thermal Destruction of Microorganisms in 38 CharactersDocument6 pagesThermal Destruction of Microorganisms in 38 CharactersRobin TanNo ratings yet

- Corporate Governance at HavellsDocument16 pagesCorporate Governance at HavellsVishal Pundir100% (1)

- Fault Tracing: FMI 3: Checking The Sensor CircuitDocument1 pageFault Tracing: FMI 3: Checking The Sensor Circuituser1No ratings yet

- Etymology: StructureDocument2 pagesEtymology: StructureNaga VNo ratings yet

- 08 Ergonomics - 01Document35 pages08 Ergonomics - 01Cholan PillaiNo ratings yet

- Survitec Mooring Ropes BrochureDocument20 pagesSurvitec Mooring Ropes Brochurearifsarwo_wNo ratings yet