Professional Documents

Culture Documents

1 PDF

Uploaded by

Sharath AlugandulaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 PDF

Uploaded by

Sharath AlugandulaCopyright:

Available Formats

Aim: To design a solid-liquid separator STP system for a high rise building.

Objectives:

Working on a solid-liquid separation system.

Comparison of solid-liquid separator with another STP system.

PCB norms of the domestic water.

Designing a solid-liquid separator system for high rise buildings.

Scope: Includes

1. Space occupancy of the systems.

2. Energy efficiency.

3. Effectiveness of the system.

4. Cost of system.

5. Operation & maintenance cost.

6. Life span.

7. Types of treatments.

8. Frequency of cleaning.

9. Difference between other STP and the solid-liquid separation system.

Limitations:

Analyse the existing working of the system and implementing to high rise building.

Methodology:

Introduction of the

solid-liquid separator

system.

Literature study of the

system

Desktop study on the

system

Case study

Comparative analysis

with other stp systems

Implementing solid

liquid separation system

to high rise building

Solid liquid separator

Introduction:

History of STP?

STP refers to sewage treatment plant.

This was the beginning of the biological aerobic and anaerobic treatments which are

fundamental to wastewater processes.

As pollution of water bodies became a concern, cities attempted to treat the sewage before

discharge.

At the end of the 19th century, since primary treatment still left odour problems, it was

discovered that bad odours could be prevented by introducing oxygen into the decomposing

sewage.

In the late 19th century some cities began to add chemical treatment

and sedimentation systems to their sewers. In the United States, the first sewage treatment

plant using chemical precipitation was built in Worcester, Massachusetts in 1890. Most cities in

the western world added more expensive systems for sewage treatment in the early 20th

century, after scientists at the University of Manchester discovered the sewage treatment

process of activated sludge in 1912. During the half-century around 1900, these public

health interventions succeeded in drastically reducing the incidence of water-borne diseases

among the urban population, and were an important cause in the increases of life

expectancy experienced at the time.

Sewage

Sewage is wastewater that is produced by a community of people. It consists mostly

of greywater (from sinks, bathtubs, showers, dishwashers, and clothes

washers), Blackwater (the water used to flush toilets, combined with the human waste that it

flushes away).

Sewage contains

• organic pollutants and nutrients (concentrations of ammonium,

nitrate, nitrogen, phosphorus)

• pathogens(bacteria, viruses, protozoa ,parasites)

• micro-pollutants(environmental persistent pharmaceutical pollutants)

Sewage treatment plant helps to utilize the water for further usage& conserve water.

Solid liquid separator

Importance of Having a STP System:

• Sewage treatment is the process of removing the contaminants from sewage to

produce liquid and solid (sludge) suitable for discharge to the environment or for

reuse. It is a form of waste management.

• Sewage treatment results in sewage sludge which requires sewage sludge

treatment before safe disposal or reuse.

• Under certain circumstances, the treated sewage sludge might be termed "bio

solids" and can be used as a fertilizer.

• All categories of sewage are likely to carry pathogenic organisms that can

transmit disease to humans and animals.

• Sewage also contains organic matter that can cause odor and attract flies.

• Sewage contains nutrients that may cause eutrophication of receiving water

bodies; and can lead to Eco toxicity.

• Sewage treatment plant preserve natural environment against pollution

• STP meet the standards for emission of pollutants set by the Government &

avoid heavy penalty

• Installation of sewage treatment plant reduces risk to public health and the

environment

Literature study:

• Solid-liquid separator is the eco-friendly system for those who want their own sludge

handling with easy and fast composting, with less space occupancy, less power

consumption.

• Which separates solids from flowing liquids - all without moving parts, only through

flushing speed of water & centrifugal force.

• In the case of a flushed toilet the solids are broken down to soil on a wormy composting

bed in the chamber below the solid-liquid separator, while the liquids are diverted to

treatment.

• After the point of generation of sewage the sewage flows through main stack, the main

stack is connected to solid-liquid separator which separated the solid-liquid through the

centrifugal force with the help of groves in the separator model.

Solid liquid separator

• This process completes with the help of flushing speed of the water and momentum

(gravity) of the sewage.

• After the solid liquid separation the solid falls into the bio chamber below the model,

water is further sent for the treatment.

• In bio chamber the solid gets converted into manure by the process of

vermicomposting.

• There will be a filter mat placed inside the bio chamber for removal of excess water

from the solid waste, the removed excess water is transferred to the treatment process

along with the grey water line.

• The separated water is stored in a tank for further treatment, in that tank water settles

for some time, then transfers to UV and phosphorous trap to remove the viruses and

nutrients.

• Then the water is sent for tertiary treatment.

• Treated water is used for flushing, landscaping, groundwater recharge, hvac chiller

makeup tank.

Desktop study:

Location: CWBR (cape wine lands biosphere reserve) South Africa.

• The toilets is connected to solid liquid separator, which separates the solids and treats

liquids with UV light.

• Solid liquid separator systems are based on utilizing the moving energy of the flushing

Fluid, the centrifugal force and the gravity to separate particles from the liquid.

• The toilet is connected to solid liquid separator, the solid waste (feces and paper) from

water and urine.

• The solid waste is composted in a Bio Chamber

• The flushing water with urine is purified with UV to remove all bacteria

• The water further continues to aquaponics where the water is organically post treated,

and plants use the nutrients as fertilizers to grow food and feed local citizens.

• The water is then pumped up to a vertical garden to maximize food production. After

this the water flows back to the aquaponics. The system works as closed, constant flow

system.

Solid liquid separator

Bio chamber is the fixed plastic model in this case, which have 4 different chambers where its

used for settling of bio waste in it ,can be rotated to transfer to another chamber after filling of

one chamber.

Reaction happens in bio chamber is aerobic process, the bio waste is converted to manure

through vermicomposting.

Vermicomposting is a type of composting in which certain species of earthworms are used to

enhance the process of organic waste conversion and produce a better end-product. It is a

mesophilic process utilizing microorganisms and earthworms.

UV and phosphorous trap removes the virus content by passing UV rays in to the water, and

phosphorous trap removes the phosphorous content from the water.

The rich nutritious liquid is sent to natural treating process by aquaponics method where the

plants absorbed nutrients from the water which helps in production of food for plants.

Solid liquid separator

CASESTUDY STUDY (KONARK MULTI-SPECIALTY HOSPITAL)

• Konark Hospitals is a 100-bedded multi-specialty hospital in Jeedimetla, Hyderabad.

• The building has 19 toilets which are connected to one solid liquid separator unit

(placed in a newly constructed underground space) by diverting existing pipes.

• Solid liquid separator removes faecal solids from the wastewater flow and thereby

makes it straight forward and odor-free to treat the daily 13,000 liters (13lkd) of

wastewater from flushing, showers, hand wash and canteen.

• For tertiary treatment ozonator, activated media filter, carbon filter, micron cartridge

filter and bag filter are being used.

• All 19 toilets in the building are now connected to a single solid liquid separator unit

which separates faecal solids for natural decomposition in a 2400-liter bio-chamber.

• 2400 liter bio-chamber is constructed with missionary work.

• In order to reach PCB standards in domestic sewage water they have installed this solid

liquid separation STP system.

Solid liquid separator

• Under the bio-chamber, there is an 8700-liter settling tank, consisting of three

compartments separated by baffle walls. The settling tank is used to collect all grey

water as well as separated water from solid liquid separator.

• Ozonation takes place in the last compartment of the settling tank. After Ozonation, the

water is further polished with an AMF, ACF, MCF and bag filter.

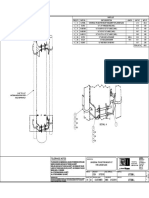

Underground setup:

Grey water pipe

1. solid-liquid separation

WC pipe (Black water)

2. 2400-liter bio-chamber for

faecal matter decomposition PARKING

3. 8700-liter tank for grey water AREA

and separated flushing water. Any Hospital KONARK

remaining suspended solids settle main

here. Ozonation also takes place entrance HOSPITALS

here 8700-liter UG

WC pipe

Settling tank

Aboveground: (Black water)

Aquatron &

4. Water from the 8700-liter tank 2400-liter bio-

is pumped up for polishing in AMF, chamber

ACF, MCF & bag filter. After Grey water pipe

WTP Shed

treatment, water is released into

the drain. PCB-standard treated

2 Top view of the site

water to municipal drain

5. The ozonator unit is placed in

the same aboveground shed.

Changes to existing plumbing line which this mainly involved diversion of the existing WC

down takes to solid liquid separator, creating new grey water lines, connections from the

settling tank to the water treatment plant and pipework within the water treatment

plant.

There was an existing underground pipe with manholes leading out to the municipal

drain so instead of letting the down takes enter that, the pipes were cut and a new pipe

without manholes was drawn along the boundary.

Tertiary Water Treatment Plant and Ozonator

To complement the removal of faecal matter by solid liquid separator and provide a

sufficient treated water standard, a water treatment plant with an ozonator, bag filter,

AMF, ACF and MCF, 5mg ozonator was installed instead of uf (ultra filtration).

Solid liquid separator

COMPARISON OF SOLID LIQUID SEPARATION SYSTEM WITH MBBR.

Mbbr (Moving Bed Bio Film Reactor)

The treatment system consists of

1. primary treatment followed by,

2. Mbbr.

3. Tertiary treatment as filtration.

Components of treatment process are

Bar screen

Transfer pump/collection tank

Diffused aeration system

Diffuser & valves

Sludge pump

Filter feed pump

Pressure sand filter

Activated carbon filter

On line chlorination

Filter press

Uv filtration

Flow chart of mbbr

Inlet

Treated water is reused for flushing and chiller makeup tank recharge &landscaping.

Solid liquid separator

Solid liquid separator system:

The solid liquid separator Treatment system consists of

1. Solid liquid separation

2. Tertiary Treatment as Filtration

Components of treatment process are

Solid liquid separator.

Bio chamber.

Filter mat.

Settling tank.

UV filtration.

Activated media filter.

Activated carbon filter.

Pressure sand filter.

Solid liquid separator

CASE STUDY OF MBBR AT PVR IRRUM MANZIL

Capacity: 270kld

Flow mechanism:

Bar screen chamberequalization tank aeration tanktube settler tankclarifier

tankfilter feed pumppressurized sand filter activated carbon filterhypo

dosingtreated water tank.

Bar Screen Chamber:

Operation:

First stage of filtration where the large objects are separated from the

raw sewage.

Maintenance:

• Check and clean the bar screen at frequent intervals.

• Do not allow solids to overflow/escape from bar screen.

• Ensure no large gaps are formed due to corrosion of the screen. Bar screen Chamber

• Replace corroded/unserviceable bar screen immediately.

Equalization Tank:

Operation:

• In aeration tank they will add oxygen to the sewage.

Maintenance:

• Keep air mixing on all times Equalization Tank

• Ensure that the air mixing is uniform throughout the entire tank.

Tube Settler Tank:

Operation:

In tube settler tank they add cow dung and alum as a bioreactor to take Place

-Activated sludge process and after that the water is settled up to 2 to 3 hours.

Maintenance:

Tube Settler Tank

• Check and clean the bottom of the tank once a two years.

Solid liquid separator

Filter Feed Tank:

Operation:

It clarifies the sewage by removing the solid floating particles and removes the

Odour. Filter Feed Tank

Maintenance: Check and clean the tank periodically

Filter Feed Pump:

Consists of a filter which removes suspended particles above 30 microns size and

a centrifugal pump to transfer water with necessary operating pressure.

Filter Feed Pump

Pressure Sand Filter:

The Pressure Sand Filter consists of a multiple layer of sand with a variety in size

and specific gravity. These Filters are designed to remove turbidity and

suspended particles present in the feed water with minimum pressure drop.

Pressure Sand Filter

Activated carbon filter:

Consists of a carbon filter bed which are most effective at removing chlorine,

particles such as sediment, volatile organic compounds (VOCs), taste and odor

from water.

Activated Carbon Filter

Chemical dosing:

NAOCL is used to remove the iron salts.

The obtained clarified water is utilized for flushing in toilets.

Chemical Dosing

Solid liquid separator

Number of pumps used in mbbr system, and there capacities.

1. Air blowers (3) for aeration, each of 5hp.

2. Filter feed pump (2), each of 7.5hp.

3. Sludge recirculation pump (2), each of 5hp.

4. Filter feed press pump (2), each of 5hp.

5. Filter press pump(1), 5hp

Power consumptions of pumps

1hp =745 watts

Power consumption of air blowers = 5*3*745=11,175watts.

= 11.175 kW.

Power consumption of filter feed pump = 2*7.5*745=11,175watts.

= 11.175 kW.

Power consumption of sludge recirculation pump = 2*5*745=7450watts.

=7.45 kW.

Power consumption of filter feed press pump = 2*5*745=7450watts.

= 7.45 kW.

Power consumption of filter press pump = 1*5*745=3725watts.

=3.725 kW.

Mbbr system runs 6 hrs. a day on an average.

Total power utilization per hour = 11.175 + 11.175 +7.45 + 7.45 + 3.725 = 40.975kw/hr.

Total consumption per day = 40.975kw/hr. * 6 hrs.

= 245.85kw

1 unit = 1kw

Total no of units consumed by the system are 245.85 units, that is 246 units

Energy bill for STP is 246unit*10rs/unit= 2460 Rs /day charge.

Monthly = 2460*30 = 73,800rs.

Annual cost = 73800 * 12 = 8, 85,600rs.

Solid liquid separator

Average Characteristics of Raw Sewage effluent

Comparison of Characteristics of treated Sewage effluent

Sl. Parameter P CB Test method Mbbr Solid liquid

no system separator

Norms

01 Ph 5.5 - 9.0 IS:3025(PT-11) 6.85 7.5

02 Total Suspended Solids < 100 mg/l IS:3025(PT-17) 30 53

03 Oil & Grease < 10 mg/l IS:3025(PT-39) 1.2 9

04 Chemical Oxygen Demand < 250 mg/l IS:3025(PT-58) 36.4 28

05 Bio-Chemical Oxygen Demand < 30 mg/l IS:3025(PT-44) 9.6 6

Solid liquid separator

Types of treatment after solid liquid separation .

In solid liquid separation system primary treatment is done by solid liquid separator.

Secondary treatment is done in 2 ways.

1. Reed bed method.

2. Mechanical treatment.

Reed bed method

Red beds construction ponds are treatment ponds used for secondary & tertiary

treatment process.

Water contaminants are cleaned through the reed bed is cleaned by microorganisms

living on the root.

Reed beds are natural habitats found in floodplains, waterlogged depressions.

Reed beds are used to remove pollutants from grey water.

Reed beds can be constructed in a range of different shapes and scales designed to

complement the surrounding landscape.

Reed bed construction is done with course of gravel and sand with local available plants

tunga plants.

Reed bed Technology is a highly effective environmentally sustainable alternative to

high energy mechanical treatment systems, resulting in naturally lower operating costs

and a reduced carbon footprint:

Lowered operating costs by 80%.

Reducing carbon emissions by 90%.

Reduced noise and pollution.

Reduced maintenance.

Reduced energy consumption.

Solid liquid separator

Mechanical treatment

After primary treatment by the solid liquid separator

Secondary treatment is done with ozone generators, micron cartridge filters and bag

filters.

Tertiary treatment would be done with UV, and ACF (activated carbon filter), and sand

filter.

Cost comparison:

Cost comparison of Nicmar 30kld treatment system.

NICMAR in shameerpet had taken a quotation of solid liquid separator for their new

hostel building, of 30KLD requirement.

Solid liquid separator treatment system quotation which including secondary and

tertiary treatment was about 6 lakhs.

MBBR treatment system quotation was 9 lakhs. Where this is excluding tanks and civil

work. Which goes up to 14 lakhs including tanks & civil work.

Cost of konark hospital 13kld treatment plant.

Konark hospital in jeedimetla.

Which were taken from solid liquid separator which includes civil work and tertiary

treatment was 6 lakhs.

Where mbbr provided coated 10 lakhs for 13lkd treatment plant.

Solid liquid separator

Operational & maintenance cost

1. Solid liquid separator

2. Mbbr

Annual O & M costs for solid liquid separator-based STP at Konark Hospitals

Item Action Frequency Approx. cost/year

Underground room Cleaning and disinfection Annual

Aquatron Cleaning from inside and outside Annual

Bio-chamber Emptying compost Annual

Bio-filter mat Pressure wash Annual ₹ 12,000.00

Barrel & filter Pressure wash Monthly ₹ 6,000.00

Pump Repairs Occasionally dependent

AMF NA NA 0

ACF Media refill Annual ₹ 12,000.00

MCF Filter refill Monthly ₹ 5,040.00

Bag filter Filter refill Monthly ₹ 2,000.00

Ozonator electricity ₹ 6,000.00

Pump electricity ₹ 30,000.00

Total ₹ 73,040.00

Annual O & M costs for MBBR - based STP at IRRUM MANZIL

Item Action Frequency Approx. cost/year

Bar screen cleaning 12,000

Annual

collection tank cleaning 12,000

Annual

Diffused aeration system Pressure wash Monthly 6,000

Diffuser & valves Pressure wash Monthly 1,000

Sludge pump Pressure wash& repairs Monthly 1,500

Filter feed pump Pressure wash& repairs Monthly 2,000

Pressure sand filter Media refill Annual 25,000

Activated carbon filter Media refill Annual 12,000

On line chlorination Media refill dependent

dependent

Pump electricity 8,85,600

Total o&m cost of mbbr system=

12,000+12,000+72,000+12,000+18,000+24,000+25,000+12,000+8, 85,600=10, 72,600.

Power consumption:

Solid liquid separator

In solid liquid separation system.

There is no power consumption in primary treatment, every action is done with the

momentum of flushed water & centrifugal force.

Secondary treatment is done with ozone generators.

Ozonator power consumption: 0.2unit/hr.

Per day consumption: 1.4kw

200watts for hour consumption

Tertiary treatment would be done with UV, and ACF (activated carbon filter), and sand

filter.

System runs for 7hrs a day

UV unit power consumption: 30w/hr.

Per day consumption: 210watts = 0.21kw

Acf pump power consumption: 745kw/hr.

Per day consumption: 5.215kw

Total power consumption by the unit at the end of the day = 5.215+0.21+1.4=6.825kw

Monthly power consumption = 6.825*30= 204.75kw

Electric bill per month = 204.75*10= 2047.5rs.

Operation& maintenance of solid liquid separator

1. Depending upon the site utilization the internal walls of the separator has to be

cleaned.

2. Cleaning of bio chamber for every 2-3 years according to the requirement.

3. Bio chamber level has to be monitored (can be done manually or automation)

4. Acf cartridge refilling.

5. Bio mat needs to be pressure washed while cleaning of bio chamber.

Solid liquid separator

Design of a solid-liquid separator STP system.

Depends factors

Inlet Water Tank Capacity.

Filtration plant sizing.

No. of solid liquid separators.

Bio chamber.

Reuse purpose.

Inlet Water Tank Capacity.

Inlet water tank capacity defines the load of the system.

Filtration plant sizing

Filtration plant sizing depends upon the treatment capacity.(filtration hours)

Filtration hours being taken at an average of 10-12 hours per day. This ensures the system is not

overused. For example 40KLD, you take a 4000 LPH plant.

No of solid liquid separator

1 solid liquid separator connects for 25 -28 water closets.

No. of solid liquid separators depends upon

1. No of toilets.

2. Total horizontal distance from the last toilet in the pipeline.

Bio chamber

As a standard consideration

For residential = 1800 liters bio chamber for 50users.

For non-residential = 1800 liters bio chamber for 200users.

Sizing done according to the scaling factor of above references.

Solid liquid separator

Reuse purpose

Reuse purpose for the treated water determines the type of tertiary water treatment plant.

a. Reuse for gardening ACF and UV will suffice

b. Reuse for flushing AMF, ACF, UF

c. Reuse for chillers AMF, ACF, UF and RO if there is high TDS in the water

d. Groundwater recharge UV

e. Discharge after meeting PCB norms AMF, ACF, UF

Proposing a solid liquid separator STP system for Sandhya elite:

Sandhya elite is an 11 floors commercial building, with a built up area of 6, 50,000 sq.ft.

Located at nanakramguda.

Design for Reuse for flushing AMF, ACF, and UF.

Solid liquid separator

Reuse for chillers AMF, ACF, UF and RO if there is high TDS in the water.

Sandhya elite is g+10 floor building with 3basement levels.

Sandhya elite has a load around 4790 users (occupancy).

Where we calculate standardly as 1800 liters bio chamber for 200 users for non-

residential purpose.

Therefore we require around 43,110 liter capacity bio chamber on peak demand, so by

considering some extra load also lets choose 50k liters.

It is a typical floor structure building with 2 washrooms for ladies and gents situated side

by side on backside facing of the building.

Gents toilet has 13 water closets, 11 washbasins, 10 urinals, 1 ph toilet (1water closet, 1

wash basin).

Ladies toilet has 13 water closets, 16 washbasins, and 1 ph toilet (1water closet, 1 wash

basin).

Each solid liquid separator connected to 28wc’s, where total requirement of solid liquid

separators are 12.

Depending upon the location of toilets zoned into 2 parts, left zone (gents) and right

zone (ladies).

Each zone consists of 6 solid liquid separators. Where each solid liquid separator is

connected to 2 floors and placed in basement levels 1, 2.

Treatment plant can be installed in b3 level.

Where the size of the stp is 50kld.

Each solid liquid separator size is 600*600*600 (l*b*h).

Where in left zone we have 6 sls (solid liquid separator).

Left zone (gents) Solid liquid No.of wc’s users

separators(sls) connected

Ground & 1st SLS-1 28 610

2nd & 3rd SLS-2 28 610

4th & 5th SLS-3 28 610

6th & 7th SLS-4 28 610

8th & 9th SLS-5 28 610

10th SLS-6 14 305

Solid liquid separator

Right zone (ladies) Solid liquid No.of wc’s users

separators(sls) connected

Ground & 1st SLS-7 28 261

2nd & 3rd SLS-8 28 261

4th & 5th SLS-9 28 261

6th & 7th SLS-10 28 261

8th & 9th SLS-11 28 261

10th SLS-12 14 130

Total 12 SLS for 11 floors with 2 zones and a load of 50kld and 4790 users.

SLS: solid liquid separator.

Treatment plant mode

Design for Reuse for flushing AMF, ACF, and UF.

Reuse for chillers AMF, ACF, UF and RO if there is high TDS in the water.

Where system is designed as connective mode of both process

Tertiary treatment plant size of 10k lph plant where it takes 5 hrs. Of run time for

treatment in a day.

Solid liquid separator

Solid liquid separator

Solid liquid separator

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- SE05457A - Henderson Inlet KGI Tower Verizon - NSD - PCD - 04.02.24Document24 pagesSE05457A - Henderson Inlet KGI Tower Verizon - NSD - PCD - 04.02.24Sharath AlugandulaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- UTSM-L (Assembly)Document1 pageUTSM-L (Assembly)Sharath AlugandulaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Go AwayDocument3 pagesGo AwaySharath AlugandulaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- COUNTRY CLUB ROAD - 100 S - Rev1 - 04.01.2024Document19 pagesCOUNTRY CLUB ROAD - 100 S - Rev1 - 04.01.2024Sharath AlugandulaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- CS12548921 VF86559 5 Tefna Ga Reva AzeemDocument17 pagesCS12548921 VF86559 5 Tefna Ga Reva AzeemSharath AlugandulaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- CS12548921 - VF86559 - 5 - Tefna - Ga - Reva - Azeem QCDocument17 pagesCS12548921 - VF86559 - 5 - Tefna - Ga - Reva - Azeem QCSharath AlugandulaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Geography Module 4 Map Reading Student VersionDocument6 pagesGeography Module 4 Map Reading Student VersionJustin KoNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 5 Ways To Reduce COD in WastewaterDocument2 pages5 Ways To Reduce COD in WastewaterSo MriNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- KWI DAF Minicell BrochureDocument4 pagesKWI DAF Minicell Brochurei.tultaevNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Irjet V6i2264Document4 pagesIrjet V6i2264Broken AngelNo ratings yet

- Gravity - Flow Water Systems Chapter 1: Introduction: 1.1 DefinitionDocument5 pagesGravity - Flow Water Systems Chapter 1: Introduction: 1.1 Definitionraju acharyaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- SC Project 'Water Audit at Home'Document10 pagesSC Project 'Water Audit at Home'cassandra gohNo ratings yet

- DeKalb County Land Disturbance Permit Review For Cop CityDocument5 pagesDeKalb County Land Disturbance Permit Review For Cop CityJonathan Raymond100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Environmental Impact AssessmentDocument17 pagesEnvironmental Impact AssessmentRonn ArtajoNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Yeshwantrao Chavan College of Engineering: (Accredited 'A' Grade by NAAC With A Score of 3.25)Document47 pagesYeshwantrao Chavan College of Engineering: (Accredited 'A' Grade by NAAC With A Score of 3.25)Utkarsh GohatreNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Hydrological CycleDocument3 pagesHydrological CycleAshis MingalaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- GE Water & Process Technologies. Protecting Public Health With ZeeWeed MembranesDocument77 pagesGE Water & Process Technologies. Protecting Public Health With ZeeWeed MembranesTiagoNo ratings yet

- 02 Aust CE 333 Lecture2 Pit Latrine Options, DesignDocument35 pages02 Aust CE 333 Lecture2 Pit Latrine Options, DesignTanjim IrtizaNo ratings yet

- EBT 2309 - Lesson 03 - Dam DesignDocument18 pagesEBT 2309 - Lesson 03 - Dam DesignNelson CheruiyotNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- De Thi Thu Tieng Anh Vao 10 Quan Ha Dong Ha NoiDocument4 pagesDe Thi Thu Tieng Anh Vao 10 Quan Ha Dong Ha NoiThu LêNo ratings yet

- ECOSTP Flyer Ver 2 PDFDocument2 pagesECOSTP Flyer Ver 2 PDFAzfer KhanNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hydrological Analysis of Kavre Valley Water Supply ProjectDocument4 pagesHydrological Analysis of Kavre Valley Water Supply ProjectSitu SainjuNo ratings yet

- National Plumbing Code of Trinidad and TobagoDocument51 pagesNational Plumbing Code of Trinidad and Tobagosam smithNo ratings yet

- Design and Construction of and Automatic Small Scale Water Treatment MachineDocument34 pagesDesign and Construction of and Automatic Small Scale Water Treatment MachineIsla Nkya Jr.No ratings yet

- Unit7-3-WWT-Biological Treatment PDFDocument85 pagesUnit7-3-WWT-Biological Treatment PDFnickNo ratings yet

- Logsheet Kualitas Air PT. KBNDocument1 pageLogsheet Kualitas Air PT. KBNslamet supriyadiNo ratings yet

- Mirza Mohib 14-CLE-39 Enviormental Engineering-I Submitted ToDocument6 pagesMirza Mohib 14-CLE-39 Enviormental Engineering-I Submitted ToWali BakhtNo ratings yet

- 3006 14611 1 PBDocument6 pages3006 14611 1 PBWidiyantoNo ratings yet

- GRR Tuban TLDocument41 pagesGRR Tuban TLmoch.ardhan.khamdan-2019No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- WWTF Improvements Project Design Report Technical Memorandum - INFLUENT PUMP STATIONDocument60 pagesWWTF Improvements Project Design Report Technical Memorandum - INFLUENT PUMP STATIONveliger100No ratings yet

- 2 Evaluation of Porous Pavements in Urban Regions Using Construction and Demolition WasteDocument23 pages2 Evaluation of Porous Pavements in Urban Regions Using Construction and Demolition Wastemansuralishaik.1234567890No ratings yet

- Otonabee Conservation 2023 Watershed Report CardDocument11 pagesOtonabee Conservation 2023 Watershed Report CardPeterborough ExaminerNo ratings yet

- Bakolori DamDocument4 pagesBakolori DamJonathan HigginsNo ratings yet

- Economy of Kanpur: Master PlanDocument1 pageEconomy of Kanpur: Master PlanPooja Aradhana PradhanNo ratings yet

- Dinamik KTADocument6 pagesDinamik KTAFerdina RahmaNo ratings yet

- Thesis Water QualityDocument7 pagesThesis Water Qualitydwr11wf4100% (2)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)