Professional Documents

Culture Documents

Tabla STEALTH 14

Uploaded by

luz_cuellar_15Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tabla STEALTH 14

Uploaded by

luz_cuellar_15Copyright:

Available Formats

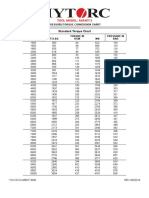

HYTORC

TOOL MODEL:HY-STEALTH 14 with HEX LINK

PRESSURE/TORQUE CONVERSION CHART

Standard Torque Chart

PRESSURE IN TORQUE IN PRESSURE IN

PSI FT. LBS. KGM NM BAR

1500 2105 291 2854 104

1600 2247 311 3047 110

1800 2532 350 3433 124

2000 2817 390 3819 138

2200 3102 429 4205 152

2400 3386 468 4590 165

2600 3671 508 4976 179

2800 3955 547 5362 193

3000 4240 586 5748 207

3200 4525 626 6134 220

3400 4810 665 6520 234

3600 5094 705 6906 248

3800 5379 744 7292 262

4000 5664 783 7678 276

4200 5948 823 8063 290

4400 6232 862 8449 303

4600 6517 901 8834 317

4800 6801 941 9219 331

5000 7085 980 9604 345

5200 7372 1020 9993 358

5400 7659 1059 10382 372

5600 7945 1099 10771 386

5800 8232 1139 11160 400

6000 8519 1178 11548 414

6200 8805 1218 11936 427

6400 9091 1257 12324 441

6600 9377 1297 12711 455

6800 9663 1336 13099 468

7000 9949 1376 13487 482

7200 10237 1416 13878 496

7400 10525 1456 14268 510

7600 10814 1496 14659 524

7800 11102 1535 15050 538

8000 11390 1575 15440 552

8200 11676 1615 15828 565

8400 11962 1654 16216 579

8600 12248 1694 16603 593

8800 12534 1733 16991 607

9000 12820 1773 17379 620

9200 13107 1813 17768 634

9400 13394 1852 18157 648

9600 13681 1892 18546 662

9800 13968 1932 18935 676

10000 14255 1971 19324 690

* ISO DOCUMENT 9000 REV. 03/03

IMPORTANT SAFETY INSTRUCTIONS

WARNING: Your HYTORC TORQUE MACHINE is a power tool, and as with any power tool, certain safety precautions should be

observed to avoid accidents or personal injury. The following tips will assist you.

• READ ALL INSTUCTIONS.

• KEEP WORK AREA CLEAN AND WELL LIT.

• CONSIDER WORK AREA ENVIRONMENT. Electrical Pumps should never be used in an atmosphere which can be

considered potentially volatile. If there is any doubt, use an air pump. Also Note: metal to metal contact can cause sparks, precautions

should be taken.

• AVOID PREMATURE TOOL STARTING. The Pump Remote Control is for the TOOL OPERATOR only.

• STAY CLEAR DURING OPERATION. In most cases, the tool will allow “hands free” operation. If the tool must be held or steadied

during operation, use alternative means of securing the tool to the application

• GUARD AGAINS ELECTRIC SHOCK. Ensure the pump is properly grounded and the proper voltage is being used.

• STORE IDLE TOOLS. When not in use, tool sand accessories should be properly stored to avoid deterioration

• USE RIGHT TOOL. Don’t force small tools or attachments to do the job of a larger tool. Don’t use a tool for purposes not intended.

• PROPER SAFETY ATTIRE. When handling/operating hydraulic equipment use work gloves, hard hats, safety shoes and other

applicable clothing.

• USE SAFETY GLASSES.

• MOVING EQUIPMENT. Do not use hydraulic hoses, uni-swivels, pump power or remote cords as means of moving the equipment.

• MAINTAIN TOOLS WITH CARE. For top performance, inspect tools, powerpack and accessories for visual damage frequently and

always prior to use. Always follow instruction for proper tool and pump maintenance. Refer to the Operations Maintenance Section for

further clarification

• STAY ALERT. Watch what you are doing. Use Common sense. Do not use power equipment under the influence of any mood altering

substances.

• PRIOR TO OPERATION

Ensure that all hydraulic connections are securely connected and there is no leakage

Verify that the Hydraulic hoses are not kinked or otherwise damaged.

Ensure the square drive and its retainer are fully and securely engaged.

Be certain that all connectors, elbows, fitting and swivels are not bent, loose or damaged.

• PRIOR TO USE.

Check sockets for size, quality and flaws. (Do not use if questionable)

Cycle tool to ensure proper function.

Locate a solid, secure reaction point.

Be sure the reaction arm retaining clamp is fully engaged.

Be sure the hydraulic hoses are free of the reaction point.

Pressurize the system momentarily; if the tool tends to “ride up” or to “creep”, stop and re-adjust the reaction arm to a more solid and

secure position.

NOTE: Remain clear of the reaction arm during operation and never put body parts between reaction arm and reaction surfaces.

• ALWAYS USE QUALITY ACCESSORIES. Always use top quality impact sockets in good condition which are the correct size and

fully engage the nut. Hidden flaws, however, remain a possibility which could cause breakage, so stay clear of sockets during operation

• DO NOR USE other equipment to enhance performance (Hammer on Socket/Tool)

NOTE: Hytorc Pumps are designed to operate Hytorc Tools only. Damage may occur to the pump or the product that is being operated

due to misuse.

SAVE THESE INSTRUCTIONS FOR FUTURE USE!

You might also like

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- Technical Tables for Schools and Colleges: The Commonwealth and International Library Mathematics DivisionFrom EverandTechnical Tables for Schools and Colleges: The Commonwealth and International Library Mathematics DivisionNo ratings yet

- XLCT 14Document2 pagesXLCT 14carlosNo ratings yet

- mxt10 PDFDocument2 pagesmxt10 PDFTaufikNo ratings yet

- AVANTI 3 Torque Conversion ChartDocument2 pagesAVANTI 3 Torque Conversion ChartJovani SecrettiNo ratings yet

- Tool Model: Hy-5Xlt: Standard Torque ChartDocument2 pagesTool Model: Hy-5Xlt: Standard Torque ChartFabioNo ratings yet

- Tool Model: HY-3MXT: Pressure/Torque Conversion ChartDocument2 pagesTool Model: HY-3MXT: Pressure/Torque Conversion ChartBhavin GamiNo ratings yet

- Captura de Pantalla 2022-03-30 A La(s) 20.30.14Document2 pagesCaptura de Pantalla 2022-03-30 A La(s) 20.30.14Manuel CaipoNo ratings yet

- STEALTH 2 Torque Conversion ChartDocument2 pagesSTEALTH 2 Torque Conversion Chartluisantoniojimenezperez31No ratings yet

- Hytorc Avanti 3 Torque ChartDocument2 pagesHytorc Avanti 3 Torque ChartDarwin Tovar ZuriqueNo ratings yet

- MXT 1 Pressure/Torque Conversion Chart & Safety InstructionsDocument2 pagesMXT 1 Pressure/Torque Conversion Chart & Safety InstructionsWahyu WidiyantoNo ratings yet

- ICE 1 Torque Conversion ChartDocument2 pagesICE 1 Torque Conversion ChartDeivid BezerraNo ratings yet

- RT10 Torque ChartDocument2 pagesRT10 Torque ChartRoy Ramos100% (1)

- Satuan GDocument1 pageSatuan GWoro IndrianiNo ratings yet

- Stealth Torque Pressure ChartDocument3 pagesStealth Torque Pressure Chartnarft narftNo ratings yet

- XLCTTorqueDocument4 pagesXLCTTorqueSebastin DrignyNo ratings yet

- HTL DS Series Torque Pressure ChartDocument1 pageHTL DS Series Torque Pressure ChartElmo JuiceNo ratings yet

- EDGE 6 - Torque - Conversion - ChartDocument1 pageEDGE 6 - Torque - Conversion - ChartindunilNo ratings yet

- TableBookErrata PDFDocument4 pagesTableBookErrata PDFLutfi LailaNo ratings yet

- TableBookErrata PDFDocument4 pagesTableBookErrata PDFIbnuyusoff77No ratings yet

- Hazen-Williams Formula PDFDocument4 pagesHazen-Williams Formula PDFyehuoy100% (1)

- Hazen William Formula PDFDocument4 pagesHazen William Formula PDFMac ShaikNo ratings yet

- Pressure Vs Torque Conversion Chart: Titan T Series ToolsDocument1 pagePressure Vs Torque Conversion Chart: Titan T Series ToolsHanselPerezAguirreNo ratings yet

- TR0040dh4 Centrifuge SpeedDocument1 pageTR0040dh4 Centrifuge SpeedrofiqsnNo ratings yet

- 3MXT Torque ConversionDocument2 pages3MXT Torque ConversionRodrigo SanzNo ratings yet

- RTX04_torque_chartDocument1 pageRTX04_torque_chartYang Kyo OhNo ratings yet

- Sitio WebDocument15 pagesSitio WebRoberto RodriguezNo ratings yet

- Pressure Versus Torque - S-Series Torque WrenchesDocument5 pagesPressure Versus Torque - S-Series Torque WrenchesManga MinNo ratings yet

- Datasheet LR 13000Document13 pagesDatasheet LR 13000RasoolKhadibi100% (1)

- 1 May 2019 Avocab New LP New March W.E.F - May 1stDocument1 page1 May 2019 Avocab New LP New March W.E.F - May 1stKaushal JhaNo ratings yet

- DD-140 Parts ManualDocument162 pagesDD-140 Parts ManualClaudinei Marcos SilvaNo ratings yet

- DIN 2215 V Belt SpecificationDocument1 pageDIN 2215 V Belt SpecificationumeshNo ratings yet

- Br. Naziv Prostorije Gubici (W) Tip Radijatora Dužina (CM) Izaberi Tip 0 Temp (°C) Površina (m2) Po Radijatoru Protok Grijanje (KG/H)Document5 pagesBr. Naziv Prostorije Gubici (W) Tip Radijatora Dužina (CM) Izaberi Tip 0 Temp (°C) Površina (m2) Po Radijatoru Protok Grijanje (KG/H)Damir ĆavarNo ratings yet

- HighTensileFastners PDFDocument24 pagesHighTensileFastners PDFMallika SahniNo ratings yet

- catchment area to runoff yield 2 ١Document1 pagecatchment area to runoff yield 2 ١Ahmed NabilNo ratings yet

- Kode HS Deskripsi HS January Nil/Val (US $) January BRT/WGT (KG)Document7 pagesKode HS Deskripsi HS January Nil/Val (US $) January BRT/WGT (KG)eniNo ratings yet

- Laboratory Exercise No. 5 Rheological PropertiesDocument16 pagesLaboratory Exercise No. 5 Rheological PropertiesANIME CHANNo ratings yet

- Alliance 533 Implement TireDocument2 pagesAlliance 533 Implement TireJosé Rojas AlvaradoNo ratings yet

- Atlas Copco TFX08 Torque ChartDocument1 pageAtlas Copco TFX08 Torque Chartgauthamac07No ratings yet

- Marine Chain DataDocument7 pagesMarine Chain DataIrwan SyahNo ratings yet

- Draft Calibration Chart of SKO Tank # T-104 IPF LAP 19-01-2019Document1 pageDraft Calibration Chart of SKO Tank # T-104 IPF LAP 19-01-2019Muhammad Usman MirzaNo ratings yet

- Hytorc Pressure/Torque Conversion Chart For MXT Hydraulic Torque Wrenches Hytorc Pressure/Torque Conversion Chart For MXT Hydraulic Torque WrenchesDocument2 pagesHytorc Pressure/Torque Conversion Chart For MXT Hydraulic Torque Wrenches Hytorc Pressure/Torque Conversion Chart For MXT Hydraulic Torque WrenchesMarcello LaraNo ratings yet

- Pet Cons 821ker Dcu Nus ADocument4 pagesPet Cons 821ker Dcu Nus AShrekNo ratings yet

- Partial Horizontal Tank Volumes: ParametersDocument4 pagesPartial Horizontal Tank Volumes: ParametersSagar DhuriNo ratings yet

- GC-3000 Torque ChartDocument1 pageGC-3000 Torque Chartgerryocnahron86No ratings yet

- DDDDDDDDDDDDDDDDocument2 pagesDDDDDDDDDDDDDDDfredjbps@gmail.comNo ratings yet

- Datasheet PTC 140 DsDocument10 pagesDatasheet PTC 140 Dsasdasd asdasdNo ratings yet

- 6 - Cost Estimate SimulationDocument9 pages6 - Cost Estimate SimulationVENSAR CONSTRUCTIONNo ratings yet

- Posedroniche MatrixDocument572 pagesPosedroniche MatrixAnonymous vDi0LMxNo ratings yet

- CRS Manual - PPPU PumpDocument27 pagesCRS Manual - PPPU PumpRishabh VermaNo ratings yet

- 1-Rev Pay Scale - Army (New-2022)Document3 pages1-Rev Pay Scale - Army (New-2022)Syed Asif BadshahNo ratings yet

- Load Inertia TablesDocument7 pagesLoad Inertia TablesgabrielaNo ratings yet

- Collaboration ChartDocument1 pageCollaboration Chartlubnayaqoob0808No ratings yet

- Phone:-Director Office FAX WWW - Kerala.gov - in 0471-2305230 0471-2305193 0471-2301740Document2 pagesPhone:-Director Office FAX WWW - Kerala.gov - in 0471-2305230 0471-2305193 0471-2301740Rajesh RamachandranNo ratings yet

- Interim Relief Rates Table from 15% to 34Document2 pagesInterim Relief Rates Table from 15% to 34V Khasim SaidhaNo ratings yet

- Real Street PlotsDocument33 pagesReal Street PlotsSarmientoNo ratings yet

- Loadsheet b737Document1 pageLoadsheet b737David PlichtaNo ratings yet

- Hydraulic Torque Wrench Operation ManualDocument18 pagesHydraulic Torque Wrench Operation Manualahmad fahmeyNo ratings yet

- Polycab Price List 16th October 2021Document2 pagesPolycab Price List 16th October 2021Kushal DixitNo ratings yet

- (Eng) Advanced Concept Training - 2d Concrete Members en 1992 - 2017Document69 pages(Eng) Advanced Concept Training - 2d Concrete Members en 1992 - 2017Muscadin MakensonNo ratings yet

- School Canteen Satisfaction Survey ResultsDocument2 pagesSchool Canteen Satisfaction Survey ResultsElla PastorinNo ratings yet

- Reedisha Spinning LTD - Industrial ReportDocument112 pagesReedisha Spinning LTD - Industrial ReportShuvashish Chakma100% (4)

- Title of Training Presentation: Presented by Your NameDocument14 pagesTitle of Training Presentation: Presented by Your NameJudy UnreinNo ratings yet

- HypertensionDocument26 pagesHypertensionAbdalrhman Zaqqa100% (1)

- Cram v. The Fanatic Group - ComplaintDocument44 pagesCram v. The Fanatic Group - ComplaintSarah BursteinNo ratings yet

- Nouveau Document TexteDocument6 pagesNouveau Document Texteamal mallouliNo ratings yet

- Tracing Chronic Fatigue Syndrome Tsfunction Is Key To ME - CFS - B Day PDFDocument91 pagesTracing Chronic Fatigue Syndrome Tsfunction Is Key To ME - CFS - B Day PDFsanthigiNo ratings yet

- AIP Lab Manual - 012110050524 - 1Document11 pagesAIP Lab Manual - 012110050524 - 1Martin De Boras PragashNo ratings yet

- C++ Classes and ObjectsDocument4 pagesC++ Classes and ObjectsAll TvwnzNo ratings yet

- Generator System Fault Calculation Design GuideDocument22 pagesGenerator System Fault Calculation Design Guidedheerajdorlikar100% (2)

- Zenith 19M20 Sams 259 16Document26 pagesZenith 19M20 Sams 259 16dds94No ratings yet

- UntitledDocument39 pagesUntitledKaren CobachaNo ratings yet

- Attendance Challenge ToolkitDocument19 pagesAttendance Challenge Toolkitapi-197489652No ratings yet

- Calculating production costs and selling pricesDocument2 pagesCalculating production costs and selling pricesMitch BelmonteNo ratings yet

- CA ruling on fertilizer disputeDocument16 pagesCA ruling on fertilizer disputeRuby Anna TorresNo ratings yet

- Vocabulary - Vocabulario de Salud y de Sintomas en InglesDocument4 pagesVocabulary - Vocabulario de Salud y de Sintomas en InglesCarlos MiguelNo ratings yet

- Ruminations by Other PeopleDocument31 pagesRuminations by Other PeopledhultstromNo ratings yet

- Section 08500 - Windows: Whole Building Design Guide Federal Green Construction Guide For SpecifiersDocument7 pagesSection 08500 - Windows: Whole Building Design Guide Federal Green Construction Guide For SpecifiersAnonymous NMytbMiDNo ratings yet

- The Columbian Exchange ReadingDocument3 pagesThe Columbian Exchange Readingapi-286657372No ratings yet

- (Giao An Nay Duoc Chia Moi Tiet 1 File. Cac Tiet Khac Ko Duoc Hien Len, Nhung Co Day Du Khi Down Ve Va Giai Nen) Lesson Plan 1Document3 pages(Giao An Nay Duoc Chia Moi Tiet 1 File. Cac Tiet Khac Ko Duoc Hien Len, Nhung Co Day Du Khi Down Ve Va Giai Nen) Lesson Plan 1Hoai Ngoc NguyenNo ratings yet

- Benefits of sponge cities in managing urban stormwater and floodingDocument3 pagesBenefits of sponge cities in managing urban stormwater and floodingShivamNo ratings yet

- Blogger TemplateDocument15 pagesBlogger TemplateSteffi Jasmyn BelderolNo ratings yet

- 20170322190836toms CaseDocument9 pages20170322190836toms CaseJay SadNo ratings yet

- VAT Training Day 3Document42 pagesVAT Training Day 3iftekharul alamNo ratings yet

- Report On MinesDocument7 pagesReport On MinesYhaneNo ratings yet

- Quantum Computing CSDocument101 pagesQuantum Computing CSRaghavNo ratings yet

- ISC 2023 English Language Question PaperDocument5 pagesISC 2023 English Language Question PaperMohit JoshiNo ratings yet

- Ultra-compact Terrier drilling rig fits through standard doorwaysDocument8 pagesUltra-compact Terrier drilling rig fits through standard doorwaysjpantazis1975No ratings yet

- WME01 01 Que 20220510Document15 pagesWME01 01 Que 20220510muhammad awaisNo ratings yet