Professional Documents

Culture Documents

C.7wy0.wh.71.11.01-E BMP001 S01 R00

Uploaded by

JC DC AcostaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C.7wy0.wh.71.11.01-E BMP001 S01 R00

Uploaded by

JC DC AcostaCopyright:

Available Formats

26°4

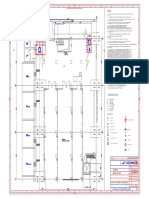

NOTES:

2'36''

N

- THE ELECTRICAL EQUIPMENT DISTRIBUTION MUST COMPLY WITH THE

ESTABLISHED IN NOM-001-SEDE-2012 AND WHAT IS SPECIFIED IN THE

ELECTRICAL DESIGN BASIS.

- THE DIMENSIONS OF THE ELECTRICAL PANELS ARE BASED ON THEIR

ELECTRICAL DRAWINGS.

- BEFORE INSTALLATION, EVERY WORK MUST BE COORDINATED WITH

CONTRACTORS OF PIPES, MECHANICAL AND CIVIL WORKS.

- THE ELECTRICAL CONTRACTOR SHALL SUPPLY ALL NUMBERS OF CERTIFICATES

OF ELECTRICAL MATERIALS USED IN THIS PLANE.

- THE ELECTRICAL PANELS SHALL BE INSTALLED ACCORDING TO THE INDICATED

IN THE BASE FRAME DRAWING.

- ALL HOLES FOR FUTURE ELECTRICAL PANELS MUST BE SEALED WITH THE

P1 P2 3A P3 P4 3B P5 CARBON STEEL ANTI-SKID PLATE, AS WELL AS THE NOT USED SPACE IN THE

INSTALLED ELECTRICAL PANELS.

SYMBOLOGY:

Y 1337.000

84

900 884 1316 600 816 ... xx INDICATES THE BEGINNING OF THE ELECTRICAL PANEL's SECTION

EQUIPMENT LIST

DIMENSIONS WEIGTH VOLTAGE

ID ITEM DESCRIPTION

A15a 1 +WH11S2P101/P105 P101/P105 MAIN CONTROL DESK

(HXWXD mm)

-*

(KG)

760

(V)

-*

833

1P 6

7

+WH11S2A01

+WH11S2A02

SPACE FOR NW PRINTER

NETWORK FOR CCTV & INTERCOM

-*

-*

-*

-*

-*

-*

8 +WH11S2A03 UPS DISTRIBUTION -* -* -*

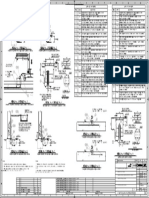

N.P.F = 2.600

9 +WH11S2A05 DP HVAC / FF -* -* -*

2167

15 +WH11S2A10 AUXILAR SERVICES ELECTRICAL PANEL 400x400x207 -* 220/127

"-*" Pending for PT's definition

A15

100

833

600 600 600 900

100

2P

600

6 7 8 9 40

1000

207

400

2542

15

N.P.F = 2.600

1074 1074

132

132

91

91

1

...101

33

3P

33

4

911

1

0

65

65

0

858

652

652

1650 1300

4P 250

B01 SLAB LOADING MAIN PULPIT's EQUIPMENT DISTRIBUTION

ESC. 1:50

Notes:

1. Dimensions in millimeters except where indicate otherwise Rev. Modification Contents Date Made By Checked By

2. Coordinates and levels in meters. A ISSUED FOR REVIEW 24/05/19 LEMA JESVC

00 APPROVED FOR CONSTRUCTION 31/05/19 LEMA JESVC

Reference plans:

C.7WY0.WH.71.11.01-SB_SLP001_S01_RB

C.7WY0.WH1-E_BMP_SUB_001 Customer Doc. No: CU-LOGO

WH.02.20201-E_DLZ001

C.S-C.7WY0

Project: Sub Supplier:

KEY PLAN AM LC Sub Supplier

Doc No.:

Plant: Date Name

HOT STRIP MILL

Made by 24/05/19 LEMA

26°4

Area:

2'36'

N

24/05/19 JLFP

X=666.00

Checked by

A25

'

18H

ELECTRICAL ENGINEERING

17H

Approved by 24/05/19 JESVC

CL FURNACE

16H

15H

14H

13H

Equipment: Material

CL CHARGING

A15a

A14

12H

11H 2K

10H

3K 4K 5K 6K 7K

SLAB CHARGING AREA & REHEATING FURNACE Mass (Kg)

X=812.20 9H

HB

A13

Ca Cb 8H

Sub-Group:

X=831.00 A12

B4 B4

A11

A10

4E

3E

7H

6H

HA

J1

Security Level

B01 SLAB LOADING MAIN PULPIT

X=856.00 1K

B3 B3

2E 5H

CL 1E

MILL 4H

B2

X=884.50

B1b

B2

B1b

3H

2H

J2

Status

1H

B1

X=919.60

22 23 24 25 26 27 28 29 30 31 32

B1

33 34 35 36 37 38 39 40 41 42 43 44 45

RA

46

RB RC

1J 61J

Drawing Name: Document

B01 SLAB LOADING MAIN PULPIT's EQUIPMENT DISTRIBUTION

I1

A1 X=958.00

Type

Y=1255.00

Y=1295.00

Y=1335.00

Y=1391.50

Y=1393.50

Y=1449.00

Y=1499.00

Y=1556.50

Y=1566.50

12

Material No:

1 2 3a 4 5a 5b 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

1I 83I

Version Scale 1:50 Size

Sheet 01 N° of sheets 01

Dwg. No. PLM-D: Revision

ESC: 1:50

0 500 1250 2500 5000

C.7WY0.WH.71.11.01-E_BMP001 00

You might also like

- C.7wy0.ih.74.8244-Uag Eiz250 S01 R00Document1 pageC.7wy0.ih.74.8244-Uag Eiz250 S01 R00JC DC AcostaNo ratings yet

- Notes: Fluid and Utility Facilities Hvac Chilled Water Plant IsometricDocument1 pageNotes: Fluid and Utility Facilities Hvac Chilled Water Plant IsometricJC DC AcostaNo ratings yet

- C.7wy0.ih.74.86.1.uag Eiz100 S01 R00Document1 pageC.7wy0.ih.74.86.1.uag Eiz100 S01 R00JC DC AcostaNo ratings yet

- C.7wy0.wh.74.31.20201.uag Eiz100 S01 R00Document1 pageC.7wy0.wh.74.31.20201.uag Eiz100 S01 R00JC DC AcostaNo ratings yet

- SF-32 WTP D.S. 2,660 L/S EF-22 D.S. 2,660 L/S: NotesDocument1 pageSF-32 WTP D.S. 2,660 L/S EF-22 D.S. 2,660 L/S: NotesJC DC AcostaNo ratings yet

- C.7wy0.wh.74.22.20205.uag Eiz102 S01 R00Document1 pageC.7wy0.wh.74.22.20205.uag Eiz102 S01 R00JC DC AcostaNo ratings yet

- UMA-50 4 TR UMA-51 4 TR: 1 R.R 23"x23" 1 R.R (508x304 MM) 1 R.R 23"x23" 1 R.R (508x304 MM)Document1 pageUMA-50 4 TR UMA-51 4 TR: 1 R.R 23"x23" 1 R.R (508x304 MM) 1 R.R 23"x23" 1 R.R (508x304 MM)JC DC AcostaNo ratings yet

- Hueco en Losa de Azotea de 600MM X 650MM Hueco en Losa de Azotea de 980MM X 980MMDocument1 pageHueco en Losa de Azotea de 600MM X 650MM Hueco en Losa de Azotea de 980MM X 980MMJC DC AcostaNo ratings yet

- C.7wy0.ih.74.82.42.uag Eiz100 S01 R00Document1 pageC.7wy0.ih.74.82.42.uag Eiz100 S01 R00JC DC AcostaNo ratings yet

- C 7WY0 XA 96 11-E9900 ERD002 S01 R0 DetallesDocument1 pageC 7WY0 XA 96 11-E9900 ERD002 S01 R0 DetallesJC DC AcostaNo ratings yet

- Plant Arrangement Level + 0.00Document1 pagePlant Arrangement Level + 0.00JC DC AcostaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Study On Working of Filler Materials in Bituminous ConcreteDocument72 pagesStudy On Working of Filler Materials in Bituminous ConcreteChand Basha Shaik0% (1)

- Precast-Handbook-Dayton Superior PDFDocument163 pagesPrecast-Handbook-Dayton Superior PDFJulio Eder LopezNo ratings yet

- 04 Footing DesignDocument29 pages04 Footing DesignJoshua OrcalesNo ratings yet

- Heat Transfer Area For Fin Tube Heat Exchanger For FBDDocument8 pagesHeat Transfer Area For Fin Tube Heat Exchanger For FBDPrathmesh GujaratiNo ratings yet

- Weekly Report No. 27Document16 pagesWeekly Report No. 27Karl ToddNo ratings yet

- List Komponen Jembatan Gantung Bentang 120 M Kelas I Type RigidDocument1 pageList Komponen Jembatan Gantung Bentang 120 M Kelas I Type RigidIlham Fadel MNo ratings yet

- Structural Design of Concrete Block PavementsDocument11 pagesStructural Design of Concrete Block PavementsOso OsoNo ratings yet

- BoefDocument6 pagesBoefmetroroadNo ratings yet

- Optimized Alkali Activated Slag Based CoDocument27 pagesOptimized Alkali Activated Slag Based CoMILON KUMAR HORENo ratings yet

- Analyses and Use of Software Ansys and Franc2d For Fracture MechanicsDocument8 pagesAnalyses and Use of Software Ansys and Franc2d For Fracture MechanicsPradeep KunduNo ratings yet

- A 826 - A826m - 95 Qtgyni05nqDocument5 pagesA 826 - A826m - 95 Qtgyni05nqsachinguptachdNo ratings yet

- Plastic Material SelectionDocument62 pagesPlastic Material SelectiondarshanmrNo ratings yet

- Jute Fiber-Reinforced Polymer Composites: A Comprehensive ReviewDocument21 pagesJute Fiber-Reinforced Polymer Composites: A Comprehensive ReviewbiniyamNo ratings yet

- Tappi Tip 0402-19Document21 pagesTappi Tip 0402-19GTpianomanNo ratings yet

- Lebow2006 Catalog PDFDocument118 pagesLebow2006 Catalog PDFAlif RizqiNo ratings yet

- Coal SlagDocument4 pagesCoal SlagSivaratnam NavatharanNo ratings yet

- 1Document2 pages1Sameer Satpute100% (1)

- Welding Consumables-Cast IronDocument9 pagesWelding Consumables-Cast Ironshabbir626No ratings yet

- Boiler Input/Output List: REV Date Decription BY ApprvdDocument26 pagesBoiler Input/Output List: REV Date Decription BY ApprvdJKKNo ratings yet

- Epicon F.S. Mortar: Technical DatasheetDocument3 pagesEpicon F.S. Mortar: Technical DatasheetBogdanBNo ratings yet

- Eca PutrajayaDocument188 pagesEca PutrajayaHannan Ruslim50% (2)

- AAN016 V1 U StructFluidsDocument18 pagesAAN016 V1 U StructFluidspaularibNo ratings yet

- Coat Defects PDFDocument72 pagesCoat Defects PDFkirubha_karan2000100% (1)

- Kidney Palasa-WO-2022.12.06Document8 pagesKidney Palasa-WO-2022.12.06Kanul RiyazNo ratings yet

- Thermosel BrochureDocument2 pagesThermosel BrochuremegacobNo ratings yet

- Sardar Vallabhai Patel Indoor StadiumDocument3 pagesSardar Vallabhai Patel Indoor StadiumRájDèép TrìpâţhíNo ratings yet

- Shaftwall PD and UL DesignsDocument57 pagesShaftwall PD and UL DesignsBlake FicklingNo ratings yet

- Poldi Impact Hardness Tester PoldihammerDocument2 pagesPoldi Impact Hardness Tester PoldihammerPedro SilvaNo ratings yet

- SX002a-En-EU-Example - Buckling Resistance of A Pinned Column With Intermediate RestraintsDocument5 pagesSX002a-En-EU-Example - Buckling Resistance of A Pinned Column With Intermediate RestraintsWNo ratings yet

- Puentes Norma LFRDDocument1,218 pagesPuentes Norma LFRDElber Cervantes LopezNo ratings yet