Professional Documents

Culture Documents

Slab Design Wsd-Usd-Tanvir Edition PDF

Uploaded by

Tanvir Hossain TuhinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Slab Design Wsd-Usd-Tanvir Edition PDF

Uploaded by

Tanvir Hossain TuhinCopyright:

Available Formats

This method directs attention to stress conditions within the structural member under

working loads.

Working stress design is based on just such a stress distribution, on the grounds that elastic

stress limits are not exceeded at working loads.

By working-stress methods, allowable stresses are established as some fraction of the stress

capacities of the materials i.e. the yield strength of the steel and the cylinder strength of the

concrete.

Members are proportioned so that these allowable stresses are not exceeded when working

loads are applied.

Working load is defined as the sum of the actual dead load of the structure and an estimate of

the maximum live load, which will be superimposed at some time during its life.

This method focuses on the strength capacity of the member at conditions corresponding

to failure and is known as ultimate-strength design. This design is based on the nonlinear

compressive- stress variation, which is obtained before a member fails.

USD method, base the design of members on conditions just before failure. Members are

proportioned so that the lull strength of the cross-section is just utilized when the ultimate load is

applied.

The ultimate load is obtained by multiplying the actual dead load and the anticipated live load

by separate overload factors greater than unit.

[Date]

Priodeep Chowdhury;Lecturer;Dept. of CEE; Uttara University// Slab Design

In reinforced concrete structures, slabs are used to provide flat, useful

surfaces. A reinforced concrete slab is a broad, flat plate usually horizontal

with top and bottom surfaces parallel or nearly so. Reinforced concrete

beams, may support it by masonr y or reinforced concrete walls, by

structural steel members, directly by columns or continuously by the

ground.

Types of slab:

According to distribution of load along side, slabs are of two types –

1 . On e w ay slab

2 . T w o w ay slab

There are other types of slabs, such as flat plate slab, flat stab, folded plate slab, reinforced

brick slab, ribbed slab, hollow slab etc.

One Way Slab:

Slabs may be supported on two opposite sides only in which case, the structural action of

the slab is essentially one- way the loads being carried by the slab in the direction perpendicular to

the supporting beams, then the slab is called one way slab.

Slabs may be supported on all four sides in which case if the ratio of length to width of one slab

panel is larger than 2, most of the load is carried in short direction and to the supporting members

and one- way action is obtained. In one way, slab main reinforcement is placed in the shorter

direction.

Two way slab

If the slab in two directions is essentially in two ways and the load carrying the structural

action of the slab then the slab is called two- way slabs. If the ratio of length to width of one panel

is equal or smaller than 2 then the slab is two way. In two ways, slab main reinforcement is provided

in both the shorter and longer direction.

One way slab design formulae

Method: Working Stress Design (W S D)

1. Design data

» La = Clear span in short direction in ft

» Lb = Clear span in long direction in ft

» f’y = Yield strength of steel, psi

» f’c = Crushing strength of concrete, psi

» DL = Sum of all Dead Load [ excluding self weight ]

» LL = Live load, psf

[Date]

2. Condition:

Lb/La > 2 2

Priodeep Chowdhury;Lecturer;Dept. of CEE; Uttara University// Slab Design

3. Elastic constant calculation:

» Es = 29 x 106 psi » r = fs/fc

» Ec = 57000√ fc' » n = Es/Ec

» fs = 0.4f’y » k = n/(n+ r)

» fc = 0.45f’c » j = 1-k/3

4. Selection of slab thickness:

Minimum slab thickness from deflection point of view. (According to ACI Code)

» Assume, slab thickness = t inch

» Effective depth, d= t – 1

5. Load calculation:

o Calculation, self-weight, SW = t/12 x 150

o Total load W = DL+ LL+ SW

6. Moment calculation:

Moment from ACI code moment co-efficient

M = C x W x La2 (C = ACI code moment co-efficient)

7. Depth check:

𝐌

dreq = √𝐑𝐛 [ b = 12 inch]

d = t- 1

If, d> dreq. Hence; depth is ok.

[If, d<dreq. Change slab thickness and repeat from step (4) to (7)]

8. Steel calculation:

𝐌

As = ( )

𝐟𝐬𝐣𝐝

As m i n = 0.0025bt

If As< As m i n then As = As m i n

9. Distribution steel:

As = 0.002bt

[Date]

[*Specification: Maximum spacing = 2t.]

Priodeep Chowdhury;Lecturer;Dept. of CEE; Uttara University// Slab Design

One way slab design formulae

Method: Ultimate Strength Design (U S D)

1. Design data: Mentioned as above

2. Condition: Lb/La> 2

3. Elastic constant calculation:

If f’c= 4000 psi then β1 = 0.85

If f’c> 4000 psi then β1 = 0.8

Balance steel ratio –

4. Selection of slab thickness: Mentioned as above.

5. Load calculation:

DL = Dead load (including self-weight)

LL = Live load

Total load, W = 1.4 x (DL+ SW) + 1.7 x LL

6. Moment calculation:

Moment from ACI code moment co-efficient

M = C x W x La2

C = ACI code moment co- efficient.

7. Depth check:

If d > dreq; Depth is OK.

If d < dreq; increase slab thickness.

8. Steel calculation:

[Date]

9. Temperature and shrinkage steel:

If f’y= 50000 psi then, Asmin = 0.002bt

If f’y=60,000 Asmin = 0.0018bt

4

If f’y> 60000 psi then Asmin = 0.0018 x 60000 x bt/fy

Priodeep Chowdhury;Lecturer;Dept. of CEE; Uttara University// Slab Design

Two way slab design formulae

Method: Ultimate Strength Design (U S D)

1. Selection of slab thickness:

Minimum slab thickness, tmin= 2(La + Lb) / 180 inch

Assume slab thickness = t

Effective depth in short direction; dsor = t-1 inch

Effective depth in long direction; dlon = t –1.5 inch

2. Load calculation:

Total load W = DL + LL + SW (Self weight) [ For WSD]

Total load W = DL x 1.4 + LL x 1.7 + SW x 1.4 (Self weight) [ For USD]

3. Moment calculation:

Panel ratio, m = La/Lb

(a) Negative moment at continuous edges:

Maneg = Caneg x W x La2

Mbneg = Cbneg x W x Lb2

Caneg, Cbneg = Co- efficient for negative moments in slabs from panel ratio and support condition.

(b) Positive moment at mid span:

Ma.pos.dl = Capdl x DL x La2

Ma.pos.ll = Capll x LL x La2

Ma.pos.tot = Mapos.dl + Mapos.ll

Mb.pos.dl = Cbpdl x DL x Lb2

Mb.pos.ll = Cbpll x LL x Lb2

Mb.pos.tot = Mbpos.dl + Mbpos.ll

» Ca.dl, Cbdl = Co- efficient for dead load positive moments.

» Ca.ll, Cbll = Co- efficient for live load positive moments.

(c) Negative moments at discontinuous ends:

Ma.neg = 1/3 x Mapos.tot

Mb.neg = 1/3 x Mb.pos.tot

4. Depth check:

Find Mmax

[Date]

Priodeep Chowdhury;Lecturer;Dept. of CEE; Uttara University// Slab Design

If, dreq.< dsor then depth is Ok.

If dreq.>dsor then increase the depth and repeat depth check

5. Steel calculation:

Calculate steel for long and short direction.

(a) For continuous ends

(b) For mid span

(c) For discontinuous ends

6. Temperature and shrinkage steel

[Date]

Priodeep Chowdhury;Lecturer;Dept. of CEE; Uttara University// Slab Design

You might also like

- LAB Design Procedure: 1. Decide The Type of Slab According To Aspect Ratio of Long and Short Side LengthsDocument20 pagesLAB Design Procedure: 1. Decide The Type of Slab According To Aspect Ratio of Long and Short Side Lengthsmollikamin100% (1)

- US Stair oDocument3 pagesUS Stair oRenvil PedernalNo ratings yet

- Geometry of Staircase: (Limit State Method As Per IS 456-2000) Design of Stair-CaseDocument2 pagesGeometry of Staircase: (Limit State Method As Per IS 456-2000) Design of Stair-CaseSujan SinghNo ratings yet

- Inspection Checklist for Masonry ConstructionDocument3 pagesInspection Checklist for Masonry Constructionrmm99rmm99No ratings yet

- CE315 Lecture NoteDocument96 pagesCE315 Lecture NoteHRNo ratings yet

- Ramp construction requirements and case studyDocument2 pagesRamp construction requirements and case studyJose EllisNo ratings yet

- Frame - Portal and Gable Rigid Plane Frame AnalysisDocument6 pagesFrame - Portal and Gable Rigid Plane Frame AnalysisCarlos Valverde PortillaNo ratings yet

- ACI 318M-11 Slab Punching StressDocument9 pagesACI 318M-11 Slab Punching StressIsprotec IngenieriaNo ratings yet

- M.K.Trading & M.K.Trading & M.K.Trading & M.K.Trading & Cont. Co.L.L.C Cont. Co.L.L.C Cont. Co.L.L.C Cont. Co.L.L.CDocument3 pagesM.K.Trading & M.K.Trading & M.K.Trading & M.K.Trading & Cont. Co.L.L.C Cont. Co.L.L.C Cont. Co.L.L.C Cont. Co.L.L.Ccheligp1981No ratings yet

- 04E83326B1B9406B9D2130DE77817D12Document717 pages04E83326B1B9406B9D2130DE77817D12chemikas8389No ratings yet

- Stability Requirements: EM 1110-2-2100 1 Dec 05Document20 pagesStability Requirements: EM 1110-2-2100 1 Dec 05Edson HuertaNo ratings yet

- Ec - 1110 2 6066Document540 pagesEc - 1110 2 6066path967No ratings yet

- RCD-DeSIGN Engr. Mark ChristianDocument9 pagesRCD-DeSIGN Engr. Mark ChristianTaki TachibanaNo ratings yet

- One Way & 2way Slab Desi̇gnDocument24 pagesOne Way & 2way Slab Desi̇gnObsii W Busha LaloNo ratings yet

- SSE Retaining - Wall - ACI Sheet v1.02Document1 pageSSE Retaining - Wall - ACI Sheet v1.02SES DESIGNNo ratings yet

- RECTBEAMDocument16 pagesRECTBEAMselva84No ratings yet

- Circular Column Design Based On ACI 318-14: Project: Client: Design By: Job No.: Date: Review byDocument1 pageCircular Column Design Based On ACI 318-14: Project: Client: Design By: Job No.: Date: Review byJuanAlfaroRodríguezNo ratings yet

- Geotechnical Engineering - IIDocument5 pagesGeotechnical Engineering - IIMohammed Zoheb NawazNo ratings yet

- Rectbeam (318-05)Document16 pagesRectbeam (318-05)Tayyab ZafarNo ratings yet

- Guidelines Design Example 1Document7 pagesGuidelines Design Example 1pigpig6No ratings yet

- Toe QuestDocument4 pagesToe Questrameshbabu_1979No ratings yet

- Bracing PDFDocument2 pagesBracing PDFmsn722005No ratings yet

- Free Standing Masonry Wall Design Based On ACI 530-05 & ACI 318-05Document9 pagesFree Standing Masonry Wall Design Based On ACI 530-05 & ACI 318-05SadatcharaMoorthi NNo ratings yet

- 425 Serviceability CHP 6 S11Document76 pages425 Serviceability CHP 6 S11aomareltayeb100% (1)

- Two-Way Slab Design Parameters and ChecksDocument2 pagesTwo-Way Slab Design Parameters and ChecksmayphyoNo ratings yet

- From Vice President: MessageDocument36 pagesFrom Vice President: MessageThaung Myint OoNo ratings yet

- 9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 2Document2 pages9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 2Ahmad Badsha QuadriNo ratings yet

- Fundamental Properties of Soil Particle SizeDocument56 pagesFundamental Properties of Soil Particle SizeAnagen PabecaNo ratings yet

- Reinforcing Bar Development and Splice Lengths Per ACI 318-05Document8 pagesReinforcing Bar Development and Splice Lengths Per ACI 318-05cengizNo ratings yet

- Combined Footing Design PDFDocument2 pagesCombined Footing Design PDFRenee100% (1)

- Calculate Ultimate Moment Capacity of Beam SectionDocument11 pagesCalculate Ultimate Moment Capacity of Beam SectionImam Nazmus SalehinNo ratings yet

- Slabs Problem PDFDocument23 pagesSlabs Problem PDFChesley MoralesNo ratings yet

- Advanced RC Week2Document41 pagesAdvanced RC Week2haloNo ratings yet

- Concrete Beam Design, For New or Existing, Based On ACI 318-14Document2 pagesConcrete Beam Design, For New or Existing, Based On ACI 318-14JuanAlfaroRodríguezNo ratings yet

- RC Stair SlabsDocument3 pagesRC Stair SlabsAssad Mohammed AliNo ratings yet

- Analysis and Design of One Way SlabsDocument9 pagesAnalysis and Design of One Way Slabsسيف جمال مدين عبداللهNo ratings yet

- "Rectbeam" - Rectangular Concrete Beam Analysis/Design: Program DescriptionDocument46 pages"Rectbeam" - Rectangular Concrete Beam Analysis/Design: Program DescriptionOswaldo SuarezNo ratings yet

- Beams (SFD & BMD)Document18 pagesBeams (SFD & BMD)yenebeb tariku100% (1)

- CE 470-Lect-3 (Analysis of Biaxially Loaded Columns) (Read-Only)Document22 pagesCE 470-Lect-3 (Analysis of Biaxially Loaded Columns) (Read-Only)Jamal RkhNo ratings yet

- Detailed Composite Beam Design AISCDocument20 pagesDetailed Composite Beam Design AISCRaveendra Babu CherukuriNo ratings yet

- Tedds Foundation DesignDocument7 pagesTedds Foundation DesignMasaba SolomonNo ratings yet

- Notching On BeamsDocument5 pagesNotching On BeamsRRussel CastroNo ratings yet

- Design of Continuous Column & Beams According To ACI-codeDocument11 pagesDesign of Continuous Column & Beams According To ACI-codeShanker Lal Meghwar100% (2)

- Add An Extra DL and Revise - 0.15 PSFDocument1 pageAdd An Extra DL and Revise - 0.15 PSFsharif uddinNo ratings yet

- Two Way Slab-ACI - Code - Good USED IN DESIGN - VerifiedDocument18 pagesTwo Way Slab-ACI - Code - Good USED IN DESIGN - VerifiedbiniamNo ratings yet

- Sample Design Calculations For A 5 Story BuildingDocument14 pagesSample Design Calculations For A 5 Story BuildinglonerstarNo ratings yet

- Design of roof slab, beam and column for houseDocument18 pagesDesign of roof slab, beam and column for housekkhan_451062No ratings yet

- TSTRUC1 Notes - Beam Deflections - Area-MomentDocument8 pagesTSTRUC1 Notes - Beam Deflections - Area-MomentAndy OretaNo ratings yet

- CIV 3164-Design of Reinforced Concrete Structures-I: Department of Civil, Environmental and Geomatics EngineeringDocument52 pagesCIV 3164-Design of Reinforced Concrete Structures-I: Department of Civil, Environmental and Geomatics EngineeringHakuna MatataNo ratings yet

- Design Considerations for Prestressed ConcreteDocument23 pagesDesign Considerations for Prestressed ConcreteglaydelleNo ratings yet

- ch12 PDFDocument30 pagesch12 PDFRadhika VeeralaNo ratings yet

- Slab Design Wsd-Usd-Tanvir Edition PDFDocument6 pagesSlab Design Wsd-Usd-Tanvir Edition PDFTanvir Hossain TuhinNo ratings yet

- Slab DesignDocument7 pagesSlab DesignSA023No ratings yet

- Method of Design - SLAB & BEAMDocument19 pagesMethod of Design - SLAB & BEAMসামিউলইসলামNo ratings yet

- Reinforced Concrete Beam DesignDocument21 pagesReinforced Concrete Beam DesignNiel John BaquilarNo ratings yet

- Machine design review: gears, shafts, fatigueDocument80 pagesMachine design review: gears, shafts, fatiguevenkatNo ratings yet

- RC 2Document19 pagesRC 2AyaNo ratings yet

- ONE-WAY SLABS DESIGNDocument26 pagesONE-WAY SLABS DESIGNJohn Mejia50% (4)

- One Way Solid SlabDocument26 pagesOne Way Solid SlabalaajabbarNo ratings yet

- Desalination Unit Drawing ListDocument22 pagesDesalination Unit Drawing ListTanvir Hossain TuhinNo ratings yet

- Envelop of Loads - Contineous Beam AnalysisDocument6 pagesEnvelop of Loads - Contineous Beam AnalysisTanvir Hossain TuhinNo ratings yet

- Structural calculations for a desalination unit buildingDocument26 pagesStructural calculations for a desalination unit buildingTanvir Hossain TuhinNo ratings yet

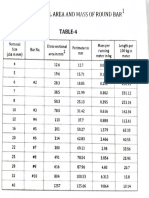

- Bar Area & Mass Unit Weight ChartDocument1 pageBar Area & Mass Unit Weight ChartTanvir Hossain TuhinNo ratings yet

- Effects of Diaphragm Discontinuity - TheisisDocument42 pagesEffects of Diaphragm Discontinuity - TheisisTanvir Hossain TuhinNo ratings yet

- Slab Design Wsd-Usd-Tanvir Edition PDFDocument6 pagesSlab Design Wsd-Usd-Tanvir Edition PDFTanvir Hossain TuhinNo ratings yet

- Constructino Joint An OverviewDocument1 pageConstructino Joint An OverviewTanvir Hossain TuhinNo ratings yet

- Axially Loaded RC Column DesignDocument17 pagesAxially Loaded RC Column DesignBert EngNo ratings yet

- Foundation Design Lecture NoteDocument35 pagesFoundation Design Lecture NoteTanvir Hossain TuhinNo ratings yet

- Load Combo Sample As Per BNBCDocument2 pagesLoad Combo Sample As Per BNBCTanvir Hossain TuhinNo ratings yet

- Load Combo Sample As Per BNBCDocument2 pagesLoad Combo Sample As Per BNBCTanvir Hossain TuhinNo ratings yet

- 2013 KTM 350 EXC Shop-Repair ManualDocument310 pages2013 KTM 350 EXC Shop-Repair ManualTre100% (7)

- Science in VedasDocument42 pagesScience in VedasPratyush NahakNo ratings yet

- Chapter 3 of LPL Textbook PDFDocument26 pagesChapter 3 of LPL Textbook PDFandreaNo ratings yet

- How The Voice Works HandoutDocument7 pagesHow The Voice Works HandoutMatthew ColleyNo ratings yet

- Processing, Handling and Storage of Agricultural Product 2Document6 pagesProcessing, Handling and Storage of Agricultural Product 2LittleagleNo ratings yet

- On Healing Powers: Asclepius, Caduceus and AntibodiesDocument4 pagesOn Healing Powers: Asclepius, Caduceus and AntibodiesasclepiuspdfsNo ratings yet

- Chapter 3 Professional Practices in Nepal ADocument20 pagesChapter 3 Professional Practices in Nepal Amunna smithNo ratings yet

- A Text-Book of Colloquial Japanese, Based On The Lehrbuch Der Japanischen Umgangssprache by Dr. Rudolf Lange (1907)Document634 pagesA Text-Book of Colloquial Japanese, Based On The Lehrbuch Der Japanischen Umgangssprache by Dr. Rudolf Lange (1907)asdf123123100% (1)

- Italy, Through A Gothic GlassDocument26 pagesItaly, Through A Gothic GlassPino Blasone100% (1)

- Types of Motivation in Language LearningDocument8 pagesTypes of Motivation in Language LearningAlya IrmasyahNo ratings yet

- Australian Securities and Investments Commission V KingDocument47 pagesAustralian Securities and Investments Commission V KingCourtni HolderNo ratings yet

- Section 5 - Triangles - Part 1 Answer KeyDocument48 pagesSection 5 - Triangles - Part 1 Answer KeyErryn Lowe100% (2)

- Dell in India Targeting SMB Markets - The Differentiation Strategy PDFDocument16 pagesDell in India Targeting SMB Markets - The Differentiation Strategy PDFJatinNo ratings yet

- Afro Asian LiteratureDocument62 pagesAfro Asian LiteratureNicsyumulNo ratings yet

- National Geographic USA - 01 2019Document145 pagesNational Geographic USA - 01 2019Minh ThuNo ratings yet

- Row and Cluster Housing Building Codes and Bye LawsDocument1 pageRow and Cluster Housing Building Codes and Bye Lawssadhana illaNo ratings yet

- CV HannahDocument3 pagesCV HannahRoxan DosdosNo ratings yet

- Bread and Pastry Production NC II 1st Edition 2016Document454 pagesBread and Pastry Production NC II 1st Edition 2016Brian Jade CadizNo ratings yet

- Talent Level 3 Grammar Tests Unit 2Document2 pagesTalent Level 3 Grammar Tests Unit 2ana maria csalinasNo ratings yet

- CartridgeDocument26 pagesCartridgeMnavya SaiNo ratings yet

- Recording of Dying DeclarationDocument6 pagesRecording of Dying DeclarationsarayusindhuNo ratings yet

- L.G.B.T. Fiction: Book ReviewDocument4 pagesL.G.B.T. Fiction: Book ReviewDejana KosticNo ratings yet

- NBCC Green ViewDocument12 pagesNBCC Green Views_baishyaNo ratings yet

- PCC 3300 PDFDocument6 pagesPCC 3300 PDFdelangenico4No ratings yet

- Differentiated Lesson PlanningDocument2 pagesDifferentiated Lesson Planningapi-398854125No ratings yet

- Phaser 6510WC6515 Brochure EnglishDocument4 pagesPhaser 6510WC6515 Brochure EnglishToma ObretenovNo ratings yet

- Researching Indian culture and spirituality at Auroville's Centre for Research in Indian CultureDocument1 pageResearching Indian culture and spirituality at Auroville's Centre for Research in Indian CultureJithin gtNo ratings yet

- 1967 Painting Israeli VallejoDocument1 page1967 Painting Israeli VallejoMiloš CiniburkNo ratings yet

- Marine Clastic Reservoir Examples and Analogues (Cant 1993) PDFDocument321 pagesMarine Clastic Reservoir Examples and Analogues (Cant 1993) PDFAlberto MysterioNo ratings yet

- Criteria For Judging MR and Ms UNDocument9 pagesCriteria For Judging MR and Ms UNRexon ChanNo ratings yet