Professional Documents

Culture Documents

Flow Measurement 83700-1-EN PDF

Uploaded by

Jagath PrasangaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flow Measurement 83700-1-EN PDF

Uploaded by

Jagath PrasangaCopyright:

Available Formats

NEW NEW NEW NEW NEW NEW NEW

NEW

Innovative Flow Measurement

Technology in Ventilation

WEINMANN Emergency sets new standards in modern ventilation MEDUMAT Standard 2 combined with the

technology with the unique FlowCheck sensor. Users demand FlowCheck sensor offers:

reliability and precision for continuous monitoring of inspiratory

and expiratory tidal and minute volume. • Display of expiratory tidal and minute volume

The robust construction of the new FlowCheck sensor satisfies and respiratory frequency for better ventilation

their needs. Under the toughest conditions during emergency monitoring

responses and hygienic reprocessing, the sensor withstands out-

• ASB (pressure support) in CPAP and SIMV modes

side influences and up to 50 reprocessing cycles. The unique chip

CPAP und SIMV for top results in Non Invasive

technology ensures delivery of highly precise measurements.

Ventilation

With low dead space of only 9 ml, the FlowCheck sensor is suit-

able for both children and adults. It is available as a disposable or • Pressure and flow curves displayed

reusable sensor to fulfill all requirements. for monitoring purposes

NEW NEW NEW NEW NEW NEW NEW

The Working Principle

of the FlowCheck Sensor

15254-EN-11/2015 © Copyright WEINMANN Emergency, Hamburg. Duplication of any kind only with the express permission of WEINMANN Emergency. All rights to design and specification modifications reserved.

The principle of thermal mass flow measurement has been used successfully in the exact measuring and dosing of gas flows for more

than 30 years. This process is now being applied for the first time in expiratory flow measurement during mechanical ventilation - in

MEDUMAT Standard².

Unlike conventional hot-wire processes, our sensor works without a fine wire. Flow measurement is not conducted by such sensitive

wires but rather by two temperature sensors - and that‘s what makes the FlowCheck sensor so robust.

Exactly how does flow measurement work?

Both temperature sensors and the heating element are mounted on a microchip. The heating element generates a thermal cloud

in the flow channel. The gas flow, which streams to or from the patient, causes the thermal cloud to shift towards one of the two

temperature sensors (see diagram).

FlowCheck sensor housing heating element thermal cloud

flow channel

gas flow microchip temperature sensors FlowCheck sensor housing

The size of the temperature difference measured between the two sensors determines the amount of flow. The higher the temperature

difference, the higher the flow and thus the displayed volume.

This technology is particularly advantageous because it delivers fast and accurate measurements even under changing environmental

conditions. An additional heating element on the sensor prevents condensation from forming in the sensor and thereby ensures that

measurements can be made without interference from moisture.

Technical Data/Operating Conditions

Temperature range -18° C to 70° C

Relative humidity 0 % RH to 95 % RH

Altitude -500 m to 5000 m

Displayed measurements Vte, MVe, f(fsp), Vleak

Tolerance of ±15 % over the entire

volume monitoring measurement range

WEINMANN-Emergency.com

You might also like

- Allthetimestudy Tenses in English LanguageDocument2 pagesAllthetimestudy Tenses in English LanguageJagath PrasangaNo ratings yet

- Allowed Charges CEBDocument7 pagesAllowed Charges CEBJagath PrasangaNo ratings yet

- Ceb Rates 2017Document7 pagesCeb Rates 2017Jagath PrasangaNo ratings yet

- 7SR11 and 7SR12 - Argus Complete Technical ManualDocument398 pages7SR11 and 7SR12 - Argus Complete Technical ManualJagath PrasangaNo ratings yet

- Distribution Design Standard - Underground SystemDocument69 pagesDistribution Design Standard - Underground SystemJagath PrasangaNo ratings yet

- Basics of SISDocument4 pagesBasics of SISJagath PrasangaNo ratings yet

- Fault Analysis Using Z BusDocument11 pagesFault Analysis Using Z BusJagath PrasangaNo ratings yet

- ADC and DAC Glossary: Application Note 641Document10 pagesADC and DAC Glossary: Application Note 641Jagath PrasangaNo ratings yet

- Earth Fault Distance Computation With Fundamental Frequency Signals Based On Measurements in Substation Supply BayDocument43 pagesEarth Fault Distance Computation With Fundamental Frequency Signals Based On Measurements in Substation Supply BayJagath PrasangaNo ratings yet

- Fault Analysis Using Z BusDocument11 pagesFault Analysis Using Z BusJagath PrasangaNo ratings yet

- Real Power Optimization With Load Flow Using Adaptive Hopfield Neural NetworkDocument6 pagesReal Power Optimization With Load Flow Using Adaptive Hopfield Neural NetworkJagath PrasangaNo ratings yet

- Energy Market Impacts of A Clean Energy Portfolio Standard - Follow-UpDocument41 pagesEnergy Market Impacts of A Clean Energy Portfolio Standard - Follow-UpJagath PrasangaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- French Pharmacopoeia PDFDocument15 pagesFrench Pharmacopoeia PDFHasan Abu AlhabNo ratings yet

- Data NX 45-5-1800-4Document1 pageData NX 45-5-1800-4BHILLA TORRESNo ratings yet

- NWMP Data 2018Document56 pagesNWMP Data 2018Copper xNo ratings yet

- Cystostomy NewDocument32 pagesCystostomy Newkuncupcupu1368No ratings yet

- Anthropometric Article2Document11 pagesAnthropometric Article2Lakshita SainiNo ratings yet

- Clase No. 24 Nouns and Their Modifiers ExercisesDocument2 pagesClase No. 24 Nouns and Their Modifiers ExercisesenriquefisicoNo ratings yet

- Pamphlet InsideDocument1 pagePamphlet Insideapi-2408549370% (1)

- Amsoil Synthetic CVT Fluid (CVT)Document2 pagesAmsoil Synthetic CVT Fluid (CVT)amsoildealerNo ratings yet

- Bakery Business PlanDocument15 pagesBakery Business PlanGayu AishuNo ratings yet

- G1 CurvedDocument16 pagesG1 CurvedElbert Ryan OcampoNo ratings yet

- Case StudyDocument3 pagesCase StudyMarlon MagtibayNo ratings yet

- Anthropocene Working Group PDFDocument6 pagesAnthropocene Working Group PDFRuth Stacy EmmanuelNo ratings yet

- Cruz v. CA - G.R. No. 122445 - November 18, 1997 - DIGESTDocument2 pagesCruz v. CA - G.R. No. 122445 - November 18, 1997 - DIGESTAaron Ariston80% (5)

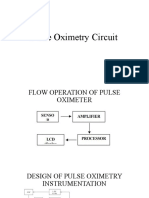

- Pulse Oximetry CircuitDocument19 pagesPulse Oximetry Circuitنواف الجهنيNo ratings yet

- Measurement LabDocument4 pagesMeasurement LabHenessa GumiranNo ratings yet

- Research Article Effects of PH On The Shape of Alginate Particles and Its Release BehaviorDocument10 pagesResearch Article Effects of PH On The Shape of Alginate Particles and Its Release BehaviorAmalia HanifaNo ratings yet

- @9negros Occidental Vs BezoreDocument3 pages@9negros Occidental Vs BezoreSimeon SuanNo ratings yet

- BRSM Form 009 - QMS MDD TPDDocument15 pagesBRSM Form 009 - QMS MDD TPDAnonymous q8lh3fldWMNo ratings yet

- SwivelDocument29 pagesSwivelluisedonossaNo ratings yet

- Two Drugs Are No More Effective Than One To Treat Common Kidney DiseaseDocument3 pagesTwo Drugs Are No More Effective Than One To Treat Common Kidney DiseaseGlogogeanu Cristina AndreeaNo ratings yet

- Research Paper CalamansiDocument7 pagesResearch Paper Calamansih040pass100% (1)

- Major Laishram Jyotin SinghDocument3 pagesMajor Laishram Jyotin SinghSpongebob SquarepantsNo ratings yet

- TableBookErrata PDFDocument4 pagesTableBookErrata PDFIbnuyusoff77No ratings yet

- Arc Welding Rod Chart byDocument1 pageArc Welding Rod Chart bytayyab aliNo ratings yet

- Real Time EvaluationDocument3 pagesReal Time Evaluationأيوب علاءNo ratings yet

- Wel-Come: Heat Treatment Process (TTT, CCT & CCR)Document14 pagesWel-Come: Heat Treatment Process (TTT, CCT & CCR)atulkumargaur26No ratings yet

- 7-13-1996 Joel Nance MDDocument3 pages7-13-1996 Joel Nance MDAnother AnonymomsNo ratings yet

- Problem Set in Power System 2Document3 pagesProblem Set in Power System 2Andrew AlterNo ratings yet

- TDS-PE-102-UB5502H (Provisional) 2019Document2 pagesTDS-PE-102-UB5502H (Provisional) 2019Oktaviandri SaputraNo ratings yet

- Importance of The On Board Crew Trainings and Drills For The Improvement of The Vessels' SafetyDocument8 pagesImportance of The On Board Crew Trainings and Drills For The Improvement of The Vessels' SafetyilgarNo ratings yet