Professional Documents

Culture Documents

Pulse Oximetry Circuit

Uploaded by

نواف الجهني0 ratings0% found this document useful (0 votes)

59 views19 pagesOriginal Title

3. Pulse Oximetry Circuit

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

59 views19 pagesPulse Oximetry Circuit

Uploaded by

نواف الجهنيCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 19

Pulse Oximetry Circuit

FLOW OPERATION OF PULSE

OXIMETER

DESIGN OF PULSE OXIMETRY

INSTRUMENTATION

DESIGN OF PULSE OXIMETRY

INSTRUMENTATION

• To build finger (or earlobe) probes which are small and unobtrusive

• miniature light sources and detectors. Light−emitting diodes (LEDs)

which work in the red and Near−Infra Red (NIR) part of the spectrum

are readily available.

• However, the average power which can be obtained from standard

LEDs is limited and a very sensitive detector (such as a

photomultiplier tube) would be required to detect the small amount

of light transmitted through the finger.

DESIGN OF PULSE OXIMETRY

INSTRUMENTATION

• special−purpose LEDs which have been developed:

• red LEDs are now being manufactured with internal lensing systems

to give high intensity outputs.

• Similarly, high current NIR LEDs are designed to be pulsed so that the

peak power available from them can be increased without increasing

the average power.

• This makes it possible to detect the light transmitted through the

finger with a simple, compact, solid−state photodetector such as a

photodiode.

DESIGN OF PULSE OXIMETRY

INSTRUMENTATION

• If we pulse both light sources, we can then use a single photodetector

in the finger probe, since silicon devices are responsive to light having

visible and NIR wavelengths. for example, use timing circuits to

supply, say, 50 µs pulses to the red and NIR LED drivers at a repetition

rate of 1 kHz, (a frequency of 1 kHz is suitable because such a

frequency is well above the maximum frequency present in the

arterial pulse). The maximum cardiac frequency is never going to

more than a few Hz

DESIGN OF PULSE OXIMETRY

INSTRUMENTATION

• In this mode of operation, high−intensity light outputs can be obtained with the NIR

LED with currents of up to 1A over a low duty cycle. The transmitted light detected

by the photodiode is amplified and converted to a voltage using an op−amp

configured as a current−to−voltage converter. At this point in the circuit the signal is

fed to two identical sections, one for each of the transmitted wavelengths.

• Since the light is pulsed, we need to use a sample−and−hold circuit to reconstitute

the waveforms at each of the two wavelengths. The same timing circuits which were

used to control the red and NIR LED drivers are also used to provide the the control

pulses for the corresponding sample−and−hold circuits. The outputs from these

circuits are then filtered with a band−pass filter (with 0.5 Hz and 5 Hz cut−off

frequencies) in order to remove primarily the d.c. component but also high

frequency noise. The resulting signals thus represent the cardiac−synchronous

information in the waveforms and these are further amplified before they are

converted to digital format for subsequent analysis by the microprocessor.

• It can be seen from the block diagram that the output from each sample−and− hold is

also passed to a low−pass filter. This is the first stage of an automatic gain control

(AGC) circuit which adjusts the light intensity from the corresponding LED so that the

d.c. level always remains at the same value (say 2V) whatever the thickness or skin

characteristics of the patient’s finger.

• There are two equally important reasons for deciding to use an AGC circuit: firstly, it

means that the amplitude of the a.c. signal (which may vary between 0.1% and 2% of

the total signal) is also within a pre−defined range and this makes the amplifier which

follows the band−pass filter easier to design. Secondly, the d.c. component of the

transmitted red and NIR signals can be set at the same value (2 V) in each case. Hence

it can be eliminated from the formula used by the microprocessor to calculate the

oxygen saturation. A new index, R’ = log I ac ' 1 / log I ac ' 2 is defined (compare with

Equation). In practice, it is not even necessary to convert the a.c. signal amplitudes at

the two wavelengths to their logarithmic equivalents: instead a look−up table can be

loaded into memory and this will contain the values of oxygen saturation

corresponding to each value of the (Red pulse amplitude)/(NIR pulse amplitude)

ratio.

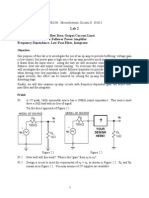

Constant current source for driving LEDs

• A simple potential circuit for achieving this is shown in Figure (next

slide) in which an op−amp is combined with a bipolar transistor. In

this circuit, the negative feedback forces ve = vin. Thus, Ie = Vin/R1.

Since the collector current is almost equal to the emitter current (Ic is

equal to Ie + Ib), the LED current is therefore also given by ILED =

Vin/R1. However, this current source is slightly imperfect because the

small base current, Ib, may vary with Vce. This arises because the

op−amp stabilises the emitter current whereas the load sees the

collector current.

• By using a FET instead of a bipolar transistor, this problem can be

avoided as shown in breviouse Figure . Since the FET draws no gate

current, the output is sampled at the source resistance without error,

eliminating the base current error of the bipolar transistor. Any

departures from ideal behaviour are due to non−linearities in the

current sampling resistor and to errors in the op−amp input circuit,

such as offsets and drifts. Note, however, that the load current is

limited by the IDS(on) of the MOSFET. If a bipolar power supply is

available, the circuits in breviouse Figure can be further simplified by

omitting Vin and tying the non−inverting input of the op−amp to

ground as shown in next Figures. in both of which ILED = 12 V/R1.

Timing circuit

• In this application, the accuracy of the timing is not of paramount importance, hence

the timing circuit can be built around the 555 timer integrated circuit. From the data

sheet for this i.c., it can easily be worked out that the circuit given in Figure 41 can be

configured, for example by setting C = 22 nF, Ra = 56kΩ and Rb = 3.3kΩ, to give a 50 µs

pulse approximately every millisecond, as intended.

Pulsing the light output from the LEDs

• The output from the LED can be pulsed by

connecting an n−channel enhancement−mode

MOSFET across it as shown in Figure 42. The pulses

from the output pin of the 555 timer (pin 3) are

taken to the gate of the transistor. The FET needs

to be an enhancement−mode MOSFET for it to be

turned fully off and on by the gate pulses. The

MOSFET chosen for this task should also be

capable of handling the maximum current flowing

through the LED.

Receiver circuit

• The simplest solid−state optical detector is the photodiode.

Photodiode detectors normally operate with reverse bias applied to

the p−n junction (photoconductive mode). When light falls on the

junction region of the photodiode, an electron−hole pair is created;

under the influence of the junction (or built−in) field, the hole is

swept towards the p−material and the electron towards the

n−material. The resulting light current is seen as a large increase in

the reverse current.

• For the purposes of signal amplification, the photocurrent must be

transformed into a voltage with moderate output impedance; this is

achieved with the circuit shown in Figure 43, the op−amp being

configured as a current−to−voltage converter. Because of the high

junction resistance of the reverse−biased photodiode, the op−amp

should be an FET type with a very high input impedance. Since the

negative input of the op−amp acts like a virtual earth, the output

voltage of the circuit is vo = −I RL. A very large feedback resistance

may be used, values as high as several tens of MΩ being typical in

practice.

Sample−and−hold circuit

• In the sample mode, the output of an ideal sample−and−hold circuit is equal to the input

signal at that particular instant. When switched to the hold mode, the output should

remain constant at that value of the input signal which existed at the instant of switching.

This circuit uses a FET switch which passes the signal through during the sample period

and disconnects it during the hold period. Whatever signal was present at the time the

FET is turned off is then held on the capacitor C. The choice of a value for C is a

compromise between two conflicting requirements: " Leakage currents in the FET and the

op−amp cause the capacitor voltage to droop during the hold period according to the

equation dV/ dt - I/ l C where Il is the leakage current. Thus C should be as large as

possible in order to minimise droop. " The resistance of the FET when turned on (typically

tens of ohms) forms a low−pass filter in combination with C and so C should be small if

high speed signals are to be followed accurately. Ready−built sample−and−hold circuits

are also available as monolithic integrated circuits which simply require the connection of

an external hold capacitor.

Automatic gain control circuit

• The output from the sample−and−hold circuit, as indicated in the

general description of the block diagram, is fed to a band−pass filter

which extracts the pulsatile signal prior to its further amplification

and analysis. The same output is also taken to a low−pass filter with a

cut−off frequency of, say, 0.1 Hz, which extracts the d.c. value of the

transmitted signal. There are then several ways of implementing the

AGC function. One of the simplest ways is to feed the d.c. signal to

one input of a differential amplifier whose other input is a constant,

reference voltage (from a zener diode, for example). The difference

between these two voltages is then used to generate the voltage vin

in Figure 39 which sets the value of the LED current

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Optocouplers: Electrical Isolation and Transfer CharacteristicsDocument7 pagesOptocouplers: Electrical Isolation and Transfer CharacteristicsKainat MalikNo ratings yet

- Bmen3120 Project1 Frequency Selective Circuit 1Document12 pagesBmen3120 Project1 Frequency Selective Circuit 1api-3139933760% (2)

- Adi Design SolutionDocument7 pagesAdi Design SolutionMark John Servado AgsalogNo ratings yet

- Ultra-low Power Charge-Pump PLL with High Temperature StabilityDocument4 pagesUltra-low Power Charge-Pump PLL with High Temperature Stabilityhawking1122No ratings yet

- Implementation of Frequency Demodulator Using The PLL Demodulation MethodDocument4 pagesImplementation of Frequency Demodulator Using The PLL Demodulation MethodasmonovNo ratings yet

- Self Oscillating Class-D Audio Amplifier Circuit DesignDocument29 pagesSelf Oscillating Class-D Audio Amplifier Circuit DesignnicchioNo ratings yet

- LIC Question BankDocument7 pagesLIC Question BankParvathy S ParvathyNo ratings yet

- 1) Wireless Headphone ReceiverDocument28 pages1) Wireless Headphone ReceiverPetarPetrovicNo ratings yet

- Interpretation Spectre SCDocument13 pagesInterpretation Spectre SCFrederic DelmarcheNo ratings yet

- Lab Manual Analog Electronics-B.tech-Eee-3rdDocument32 pagesLab Manual Analog Electronics-B.tech-Eee-3rdKiranmai KonduruNo ratings yet

- Practical 2P12 Semiconductor Devices: What You Should Learn From This PracticalDocument11 pagesPractical 2P12 Semiconductor Devices: What You Should Learn From This PracticalDevesh GargNo ratings yet

- Lem In2000 Paper v4b SroDocument9 pagesLem In2000 Paper v4b SromarinkokNo ratings yet

- Current Sensor Ic 4017Document55 pagesCurrent Sensor Ic 4017Alan RejiNo ratings yet

- Full Report - E1Document13 pagesFull Report - E1Naddy MohdNo ratings yet

- Lab3Document5 pagesLab3معتصم الكاملNo ratings yet

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1From EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Rating: 4.5 out of 5 stars4.5/5 (3)

- Lic May-June 2017Document15 pagesLic May-June 2017santhosh sekarNo ratings yet

- Wave SapingDocument43 pagesWave SapinglsrinivasnteceNo ratings yet

- Capacimetre FemtoDocument30 pagesCapacimetre FemtoJean-Marie ChaputNo ratings yet

- Unit 4 NotesDocument9 pagesUnit 4 NotesPrathamesh BhavsarNo ratings yet

- ECE3204 D2013 Lab2Document9 pagesECE3204 D2013 Lab2Khalil2097No ratings yet

- Iia Module Iii PDFDocument13 pagesIia Module Iii PDFgayathri vishnuNo ratings yet

- Amateur Radio Electronics on Your MobileFrom EverandAmateur Radio Electronics on Your MobileRating: 5 out of 5 stars5/5 (1)

- EDN's Best of Design Ideas - Volume 1Document24 pagesEDN's Best of Design Ideas - Volume 1ableseaman100% (4)

- Optocoupler Input Drive CircuitsDocument7 pagesOptocoupler Input Drive CircuitsLuis Armando Reyes Cardoso100% (1)

- Presentation - On-Chip Current Sensing Technique For Cmos Monolithic Switch-ModeDocument30 pagesPresentation - On-Chip Current Sensing Technique For Cmos Monolithic Switch-Modesohailasghar_tNo ratings yet

- PLL 4Document9 pagesPLL 4vermavikki97No ratings yet

- Analog and Digital Ic'S Short Questions With AnswersDocument41 pagesAnalog and Digital Ic'S Short Questions With Answerspriya adhavanNo ratings yet

- Integrator Circuits: 7.0.1 ReadingDocument5 pagesIntegrator Circuits: 7.0.1 Readingnaveenkv10_105528408No ratings yet

- Digitally Controlled Oscillator ReportDocument18 pagesDigitally Controlled Oscillator ReportVinidhra ShivakumarNo ratings yet

- A Low Power, and Low Signal 5-Bit 25msamples/s Pipelined ADC For Monolithic Active PixelsDocument5 pagesA Low Power, and Low Signal 5-Bit 25msamples/s Pipelined ADC For Monolithic Active Pixelstajmjcet_123No ratings yet

- That You Read All The Background Information of This Laboratory BEFORE Proceding With The ExperimentDocument14 pagesThat You Read All The Background Information of This Laboratory BEFORE Proceding With The ExperimentRajith MohananNo ratings yet

- Data Ir2153Document6 pagesData Ir2153mdkadryNo ratings yet

- A Beam-Forming Transmit ASIC For Driving Ultrasonic Arrays: John V. Hat®eld, Kwet Seng ChaiDocument7 pagesA Beam-Forming Transmit ASIC For Driving Ultrasonic Arrays: John V. Hat®eld, Kwet Seng ChaitoloiceNo ratings yet

- AC Circuits PDFDocument6 pagesAC Circuits PDFRANDOLPHENo ratings yet

- Dioda AplicationDocument5 pagesDioda AplicationRahmatbasukiNo ratings yet

- Magnetic field meter circuit design and constructionDocument7 pagesMagnetic field meter circuit design and constructionJohurul IslamNo ratings yet

- Measuring Total Power of AM TransmitterDocument44 pagesMeasuring Total Power of AM TransmitterNikhil KolheNo ratings yet

- Unit 4 FOCDocument26 pagesUnit 4 FOCNAGASWATHI NIDAMANURINo ratings yet

- 130nm CMOS Technology Design of Passive UHF RFID Tag inDocument4 pages130nm CMOS Technology Design of Passive UHF RFID Tag inDuc DucNo ratings yet

- Mit Aec Labmanula 10esl37Document45 pagesMit Aec Labmanula 10esl37anon_70724250No ratings yet

- Remake LCR Meter - Elektor Magazine PDFDocument12 pagesRemake LCR Meter - Elektor Magazine PDFMiguel ClementeNo ratings yet

- MS Project ReportDocument11 pagesMS Project ReportArnab Jyoti BaruahNo ratings yet

- 25638-Acquire Images With A Sensor and A Micro Controller PDFDocument5 pages25638-Acquire Images With A Sensor and A Micro Controller PDFSzilagyi SebaNo ratings yet

- Function GeneratorDocument78 pagesFunction GeneratorVishali Chowdary100% (1)

- BJT Pulse PDFDocument6 pagesBJT Pulse PDFmenguemengueNo ratings yet

- CE Amplifier Using PNP Transistor CircuitDocument13 pagesCE Amplifier Using PNP Transistor CircuitAtharv KulkarniNo ratings yet

- An Electronic Ballast With Power Factor Correction For Fluorescent LampsDocument5 pagesAn Electronic Ballast With Power Factor Correction For Fluorescent Lampsjeeva_ebookNo ratings yet

- Ultrasonic Distance Meter MicrocontrollerDocument11 pagesUltrasonic Distance Meter MicrocontrollerHafiz Murtaza100% (3)

- Analog Communication Lab ManualDocument30 pagesAnalog Communication Lab ManualANIRUDDHA PAULNo ratings yet

- Edn Design Ideas IIIDocument5 pagesEdn Design Ideas IIIagmnm1962100% (2)

- AM Modulation and Demodulation LabDocument8 pagesAM Modulation and Demodulation LabAhmadAkhbariNo ratings yet

- Design and Construction of A Remote Controlled Power Supply UnitDocument10 pagesDesign and Construction of A Remote Controlled Power Supply Unitzungeru01No ratings yet

- Am ModulationDocument9 pagesAm ModulationBrzata PticaNo ratings yet

- DipIt 1 2UKDocument28 pagesDipIt 1 2UKMos CraciunNo ratings yet

- EEET434 - Module03-Design Signal ConditioningDocument15 pagesEEET434 - Module03-Design Signal Conditioningنواف الجهنيNo ratings yet

- EEET434 - Module02-Signals and TransducersDocument60 pagesEEET434 - Module02-Signals and Transducersنواف الجهنيNo ratings yet

- Data Acquisition and Control: Signal ConditioningDocument58 pagesData Acquisition and Control: Signal Conditioningنواف الجهنيNo ratings yet

- EEET434 - Module02 - Signals and Transducers - Part 2Document41 pagesEEET434 - Module02 - Signals and Transducers - Part 2نواف الجهنيNo ratings yet

- EEET434 - Module02 - Signals and Transducers - Part 1Document39 pagesEEET434 - Module02 - Signals and Transducers - Part 1نواف الجهنيNo ratings yet

- Data Acquisition and Control: EEET 434Document38 pagesData Acquisition and Control: EEET 434نواف الجهنيNo ratings yet

- Lab Manual ELET 437Document124 pagesLab Manual ELET 437نواف الجهنيNo ratings yet

- Blood Presure Cct2Document13 pagesBlood Presure Cct2نواف الجهنيNo ratings yet

- Pulse Oximetry Circuit2 FuzzyDocument23 pagesPulse Oximetry Circuit2 Fuzzyنواف الجهنيNo ratings yet

- Blood Pressure Using Oscillometric MethodDocument25 pagesBlood Pressure Using Oscillometric Methodنواف الجهنيNo ratings yet

- BioMedical InstrumentationDocument10 pagesBioMedical Instrumentationنواف الجهنيNo ratings yet

- Pulse Oximetry (Autosaved)Document13 pagesPulse Oximetry (Autosaved)نواف الجهنيNo ratings yet

- LCD221SD Service ManualDocument41 pagesLCD221SD Service Manual1cvbnmNo ratings yet

- Sanyo Integrated Circuits For TV-VCR UseDocument34 pagesSanyo Integrated Circuits For TV-VCR UseИгорь КремковNo ratings yet

- Unit 4Document76 pagesUnit 4Hemant TulsaniNo ratings yet

- Construction of A Microcontroller Based Security Door Using Smart CardDocument95 pagesConstruction of A Microcontroller Based Security Door Using Smart CardBless Ugbong100% (1)

- High-resolution baby scale service manualDocument17 pagesHigh-resolution baby scale service manualSergio PérezNo ratings yet

- Introduction To MechatronicsDocument150 pagesIntroduction To MechatronicsAdebola oluwadamilare prosperNo ratings yet

- Biasing Circuits for Transistors ExplainedDocument65 pagesBiasing Circuits for Transistors Explainedsai ineshNo ratings yet

- Lect0 IntroDocument60 pagesLect0 IntroRofyda SaadNo ratings yet

- Field Strength MeterDocument9 pagesField Strength MeterVinod JagdaleNo ratings yet

- B.tech VguDocument86 pagesB.tech VguNeeraj SharmaNo ratings yet

- Economical Electric Wheelchair Design for BangladeshDocument6 pagesEconomical Electric Wheelchair Design for BangladeshMohit ChaliaNo ratings yet

- MCFT - Electronic Material Devices, Devices and Fabrication - Parasuram SwaminathanDocument219 pagesMCFT - Electronic Material Devices, Devices and Fabrication - Parasuram Swaminathankomal udaiNo ratings yet

- BUX48ADocument8 pagesBUX48AroozbehxoxNo ratings yet

- Fundamentals of Automotive Electricity & ElectronicsDocument81 pagesFundamentals of Automotive Electricity & ElectronicsJohnny YmNo ratings yet

- Intel Moores Law Investor Meeting Paper FinalDocument4 pagesIntel Moores Law Investor Meeting Paper FinalVale Ignacia TapiaNo ratings yet

- 200W Leach AmpDocument12 pages200W Leach AmpАлексей Андрияш100% (1)

- The Effect of The Inversion Channel at The Aln/Si Interface On The Vertical Breakdown Characteristics of Gan-Based DevicesDocument7 pagesThe Effect of The Inversion Channel at The Aln/Si Interface On The Vertical Breakdown Characteristics of Gan-Based DevicesA Mohan BabuNo ratings yet

- IJBTDocument15 pagesIJBTAlberto Aduvire RafaelNo ratings yet

- Assignment 2 - ELEXDocument4 pagesAssignment 2 - ELEXKaizerEvonyNo ratings yet

- Project Proposal Triggering Circuit For ThyristorsDocument9 pagesProject Proposal Triggering Circuit For Thyristorsmohsin AwanNo ratings yet

- Try Simple FET Preamplifier Circuit (Very High Impedance) - ElecCircuitDocument8 pagesTry Simple FET Preamplifier Circuit (Very High Impedance) - ElecCircuitABHINo ratings yet

- Gate Level Design FundamentalsDocument34 pagesGate Level Design FundamentalsYOGESWARI TOLIANo ratings yet

- PSIM User ManualDocument271 pagesPSIM User Manuallutti68No ratings yet

- Complementary Push-Pull Amplifier Designs for Active AntennasDocument12 pagesComplementary Push-Pull Amplifier Designs for Active AntennasmplennaNo ratings yet

- The Soul of A New MachineDocument308 pagesThe Soul of A New MachineDaniel Melo100% (2)

- EE - ANALOG and DIGITAL ELECTRONICS PDFDocument75 pagesEE - ANALOG and DIGITAL ELECTRONICS PDFHariShankarSharmaNo ratings yet

- Semiconductor 200Document29 pagesSemiconductor 200Vikash PalNo ratings yet

- Course Handout KannanDocument3 pagesCourse Handout KannanJulie JacksonNo ratings yet

- 2SB616 SavantICDocument3 pages2SB616 SavantICMrGC1964No ratings yet

- Presentation On Transistor: Pradnya P. MoonDocument11 pagesPresentation On Transistor: Pradnya P. MoonpradnyamoonNo ratings yet