0% found this document useful (0 votes)

311 views4 pagesPFD

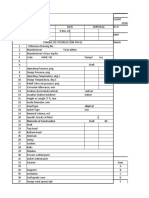

A process flow diagram (PFD) shows the general flow of processes and major equipment in a plant without minor details. It identifies equipment, flow paths, and design operating conditions like temperatures and pressures. A PFD aims to document the basic process design. A piping and instrumentation diagram (P&ID) includes more piping and instrumentation details than a PFD. A mass balance diagram (MBD) applies the law of conservation of mass to analyze physical systems and identify unknown mass flows. The Factories Act of 1948 in India aims to ensure safety, health, and well-being of workers in factories.

Uploaded by

GaneshCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

311 views4 pagesPFD

A process flow diagram (PFD) shows the general flow of processes and major equipment in a plant without minor details. It identifies equipment, flow paths, and design operating conditions like temperatures and pressures. A PFD aims to document the basic process design. A piping and instrumentation diagram (P&ID) includes more piping and instrumentation details than a PFD. A mass balance diagram (MBD) applies the law of conservation of mass to analyze physical systems and identify unknown mass flows. The Factories Act of 1948 in India aims to ensure safety, health, and well-being of workers in factories.

Uploaded by

GaneshCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

- Process Flow Diagram: Presents an overview of process flow diagrams, their purpose, and common elements involved in plant operations.

- Piping and Instrumentation Diagram (P&ID): Describes piping and instrumentation diagrams, illustrating how they map out control and monitoring instruments in plant design.

- Mass Balance: Explains the concept of mass balance, its applications to calculation of material inputs and outputs, and maintaining equilibrium in processes.

- Guidelines of Factories Act: Provides guidelines from the Factories Act focused on workers' safety, health, and operational efficiency within industrial contexts.