Professional Documents

Culture Documents

Flanged Thermowells Model SF, RF and HF: Features

Uploaded by

wawanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flanged Thermowells Model SF, RF and HF: Features

Uploaded by

wawanCopyright:

Available Formats

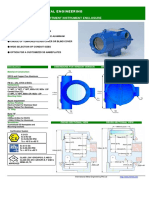

Flanged Thermowells

Model SF, RF and HF

According ANSI/ASME or DIN 43772

Features

• Solid bore construction

• Materials according ISO 15156/NACE MR 01-75

• Selection of materials

• Standard and customer specifications

• DIN and ANSI/ASME process connections

Ratings

DIN up to PN100

ANSI/ASME up to 2500 lb/sq. in.

Applications

Chemical and petrochemical industry

Machine and apparatus construction

Food and beverage industry

Pulp and paper industry

Technical specification SF LSF RF LRF HF LHF

Solid bore design

Shank solid bore, flange welded on shank standard. Optional one piece design, built up design or to cus-

tomer specification

Construction shank Straight Stepped Tapered

Lagging No Yes No Yes No Yes

Standard lengths 3” (75 mm), others on request

Standard U-length in inch 2 4 7 10 13 16 22

in mm 51 101,5 178 254 330 406,5 559

Optional to customer specification

1)

Bore diameter in inch 0,2600,385

1) 1) 1) 1)

in mm 6,6 8,5 9,8 10,5 not for types RF and LRF

Others on request, see coding table

Pressure rating Depending on flange rating

Process connection

DIN

Size DN25, DN40, DN50, DN80, DN100, others on request

Pressure class PN10, PN16, PN25, PN40, PN64, PN100, others on request

ANSI/ASME

Size in inch 1, 1½, 2, 3, 4, others on request

Pressure class in lb/sq. in. 150, 300, 600, 900, 1500, 2500

1) 1)

Facing R (raised face), F (flat face) , J (ring joint type) only for < 2500 lb/sq. in. and < 3”

Other forms, connections or standards are available on request

Instrument connection ½ NPSM female standard, optional ½ NPT female or G ½ female

Material Stainless steel 304 (1.4301), 304L (1.4306), 316 (1.4401), 316L (1.4404), 316Ti (1.4571)

Monel, Hastelloy B, Hastelloy C, Inconel, Tantalum, Duplex, Nickel

Other materials or coatings on request

Certifications & tests Material certificate DIN EN 10 204 3.1, Hydrostatic test, dye penetration test, X-ray, Hardness test,

ISO 15156/NACE certificate, stress calculation according to ASME Power Test Code 19.3 or Design

Memo No. T/115

Accessories, options Thermometers, Pt-100, thermocouples

All specifications are subject to change without notice.

G2.TWFLG/E Rev. E 06/02/2009

General dimensions in inch (mm)

Order information

1)

Process U-length Instrument Lagging Shank type Bore Material Flange Pressure Options

connection connection diameter facing rating

(10) 1" Inch All connec- (=) No (HF) Standard Inch (C) 304 ANSI ANSI (NH) Tagging stamped

dimen- tions are lagging with dimensions (1.4301) Flange Flange

(DN25) sion female Welded (2) Cap & chain

DN25 (L) With Flange (260) 0,260" (CL) 304L (R) 150 stainless steel

(0200) 2" (=) ½ NPSM lagging Tapered (6,6 mm) (1.4306) Raised 300 (BP) Buffed and

(15) 1 ½" (standard Shank face 600

3” (75mm), 1) polished

(0400) 4” (50) ½ NPT other

(385) 0,385" (S) 316 900

(SF) Welded (9,8 mm) (F) (FL.) Specify flange as

(DN40) lengths to (1.4401) 1) 1500

be speci- Flange Flat face per material code

DN40 (0700) 7” (51) G ½ 2500

fied in (e.g. FLM flange

[inch] or Straight (SL) 316L (J) material Monel)

(20) 2" (1000) 10” [mm]) Shank (1.4404) Ring joint

type (CD5) certificate

(DN50) (1300) 13” (RF) Welded (M) Monel ISO 15156

DN50 Flange 1)

only for

Stepped (H) Hastel- (CDW2) Dye penetra-

(1600) 16” < 2500

(30) 3” Shank others on request loy C lbs and < 3” tion test

(2200) 22” (only bore MM DIN DIN

(CDRH) Rockwell

(DN80) 0,260 dimension (N) Nickel flange flange

(6,6mm)) hardness test

DN80 (... mm)

the flange fac- PN10 (X-RAY) X-ray photo

MM (DU)Duplex ing depends on

(40) 4” dimen- standard the process PN16

6,6 mm connection PN25 Material certificates

sion 1) acc. DIN EN 10 204

(DN100) (... mm) 8,5 mm (nominal size PN40

1) and nominal

DN100 length in 9,8 mm pressure) PN64 (CD2) 2.2

1)

mm 10,5 mm PN100

(CD3) 3.1

1)

flange material Hydrostatic internal

is the same as

the shank mate- pressure test

other construction 1) rial unless

such as: Solid not for type SM, specified with (CDW9) 100 bar 1 min.

machined, built up LSM, RT and code (FL.), see

and to customer LRT options (CDW4) To customer

others on others on specification on others on specification

request request others on request request others on request others on request request

Order example

Process Type U-length Instrument Lagging Shank type Bore Material Flange Pressure Options

connection connection diameter facing rating

10 W 0200 = L HF 260 SL R 150 2

Ashcroft Instruments GmbH Website: www.ashcroft.eu e-Mail: sales@ashcroft.com

Germany France United Kingdom

Max-Planck-Str. 1, D-52499 Baesweiler „206“ ZA du Mandinet, 1/3 Rue des Campanules Unit 5 William James House

P.O. Box 11 20, D-52490 Baesweiler F-77185 Lognes Cowley Road, Cambridge CB4 0WX

Tel.: +49 (0) 2401 808-0, Fax: +49 (0) 2401 808-125 Tel.: +33 (0) 1 60 37 25 30, Fax: +33 (0) 1 60 37 25 39 Tel.: +44 (0) 12 23 39 55 00, Fax: +44 (0) 12 23 39 55 01

You might also like

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Butt Weld Stainless Steel FittingsDocument16 pagesButt Weld Stainless Steel Fittingsbayu susiloNo ratings yet

- Pipe Chart PDFDocument2 pagesPipe Chart PDFCarlos Rivera0% (1)

- Fastener TrainingDocument20 pagesFastener TrainingJesus Barragán Ramos100% (2)

- Rate Analysis Programme MorthDocument376 pagesRate Analysis Programme Morthprashanth reddy sunki50% (2)

- 76 202Document8 pages76 202wawanNo ratings yet

- Flange BS10 AS2129 ANSIBS4504Document12 pagesFlange BS10 AS2129 ANSIBS4504윤병택No ratings yet

- Project Quality Assurance: Dep SpecificationDocument42 pagesProject Quality Assurance: Dep Specificationwawan100% (3)

- Stainless Steel Grades 2008 01 PDFDocument2 pagesStainless Steel Grades 2008 01 PDFRahul LavandNo ratings yet

- Techlok Product Range A4 V003 2014Document4 pagesTechlok Product Range A4 V003 2014alfreddieick1No ratings yet

- Dimensions, Sizes and Specification of DIN Flange & DIN Standard Flanges of Slip On Flanges, Blind Flanges, Welding FlangesDocument7 pagesDimensions, Sizes and Specification of DIN Flange & DIN Standard Flanges of Slip On Flanges, Blind Flanges, Welding FlangesSudhanshu67No ratings yet

- Condensate Tank - For 250Document3 pagesCondensate Tank - For 250Sakthi VelNo ratings yet

- List Shell Dep & Mesc SpeDocument9 pagesList Shell Dep & Mesc Spewawan80% (5)

- Report on Concrete Mix DesignDocument7 pagesReport on Concrete Mix DesignSnehashish BasuNo ratings yet

- Measure Flow with Orifice PlatesDocument18 pagesMeasure Flow with Orifice PlatesJhon AlfonsoNo ratings yet

- Bolted Connections 1Document45 pagesBolted Connections 1Nicole ReyesNo ratings yet

- API 510 QuestionsDocument8 pagesAPI 510 QuestionsTAYYAB FAROOQ100% (2)

- Surface Roughness Tester TR200 Features and SpecificationsDocument2 pagesSurface Roughness Tester TR200 Features and SpecificationsNGuga Van OnesusNo ratings yet

- SP-2041 2014Document19 pagesSP-2041 2014wawanNo ratings yet

- List Shell Dep Amp Mesc Spe PDFDocument9 pagesList Shell Dep Amp Mesc Spe PDFAzhar Ahmad100% (1)

- Model: A100: Flushing RingDocument2 pagesModel: A100: Flushing RingTÀi VÕNo ratings yet

- CAT114 A-Rev.2Document2 pagesCAT114 A-Rev.2Jordi Enjuanes BalaguerNo ratings yet

- Rosemount Seal m1199rtwDocument3 pagesRosemount Seal m1199rtwMiguel Jiménez FloresNo ratings yet

- TermopozoDocument4 pagesTermopozoLuis Guillermo Salinas CastilloNo ratings yet

- Access or LesDocument23 pagesAccess or LesAhmed KhairiNo ratings yet

- 11411.DS Heat Exchangers - Enquiry R1Document2 pages11411.DS Heat Exchangers - Enquiry R1Arjun SarkarNo ratings yet

- Gs01f06a00 50eDocument8 pagesGs01f06a00 50eDaniloNo ratings yet

- Alfa Laval Alfacond 400 - enDocument2 pagesAlfa Laval Alfacond 400 - enAjayNo ratings yet

- DS DSL990 FR en Us 16831Document2 pagesDS DSL990 FR en Us 16831Rahul JadhavNo ratings yet

- GI - Thermowell CatalogueDocument18 pagesGI - Thermowell CatalogueMahdy MazinyNo ratings yet

- Radiator Product CatalogDocument4 pagesRadiator Product CatalogSamer Abdulaziz SadaqaNo ratings yet

- Medium Sized Coriolis Mass Flowmeter: Measurement & ControlDocument8 pagesMedium Sized Coriolis Mass Flowmeter: Measurement & ControlTeknik GresikNo ratings yet

- Flushing Rings Quality MattersDocument1 pageFlushing Rings Quality Mattersmayur mahajanNo ratings yet

- Strainer Y TypeDocument2 pagesStrainer Y TypeJorgeNo ratings yet

- Fireking Y StrainerDocument1 pageFireking Y Strainermirdraco68No ratings yet

- Heat Exchanger DatasheetDocument4 pagesHeat Exchanger DatasheetWinsonLimHuiWahNo ratings yet

- Shin Nan Catalogue PDFDocument38 pagesShin Nan Catalogue PDFElan ChezhiyanNo ratings yet

- FPD190 - Differential Pressure - Restriction Orifice PlatesDocument12 pagesFPD190 - Differential Pressure - Restriction Orifice PlatesPeter MarkwellNo ratings yet

- Valve and SupportsDocument3 pagesValve and SupportsMohamed ArafaNo ratings yet

- Swing Check Valve - Flanged: Technical FeaturesDocument1 pageSwing Check Valve - Flanged: Technical FeaturesAhmed El MorsyNo ratings yet

- Appendix: Cross Reference BFTDocument7 pagesAppendix: Cross Reference BFTchauNo ratings yet

- Heat Exchanger Datasheet, PDFDocument1 pageHeat Exchanger Datasheet, PDFWinsonLimHuiWahNo ratings yet

- Blind Flange Design for 8-Inch PipeDocument2 pagesBlind Flange Design for 8-Inch PipeGohar ZamanNo ratings yet

- All Stainless Steel Process Gauge Open or Solid Front Model T5500 and T6500Document2 pagesAll Stainless Steel Process Gauge Open or Solid Front Model T5500 and T6500Ferdinand LizadaNo ratings yet

- CR StandardsDocument6 pagesCR Standardsalpha_beta48No ratings yet

- Blind Flange Design For 8", 600#, 15B Service LineDocument2 pagesBlind Flange Design For 8", 600#, 15B Service LineGohar ZamanNo ratings yet

- Diaphragm - Type Diaphragm SealType L990.10Document4 pagesDiaphragm - Type Diaphragm SealType L990.10harglugurNo ratings yet

- ISO 14540 Screw-to-Connect High Pressure Ball ValvesDocument4 pagesISO 14540 Screw-to-Connect High Pressure Ball ValvesJUANPANIAGUANo ratings yet

- Y Strainer Flanged PDFDocument1 pageY Strainer Flanged PDFmariuspiNo ratings yet

- 1 110 Gauge Shutoff ValveDocument2 pages1 110 Gauge Shutoff ValveAinayya alfatimahNo ratings yet

- 2020-06 AVA - ALMS - Stock - Product - RangeDocument4 pages2020-06 AVA - ALMS - Stock - Product - RangeDavid AlexandreNo ratings yet

- SAMSON Globe 3241Document12 pagesSAMSON Globe 3241Shaheen HydrosNo ratings yet

- 1199 - Extended - Flange JOB 027Document3 pages1199 - Extended - Flange JOB 027brat.jose2023No ratings yet

- Temp. Control ValveDocument7 pagesTemp. Control Valvesaurabh kumarNo ratings yet

- Heat Exchanger DatasheetDocument5 pagesHeat Exchanger DatasheetWinsonLimHuiWahNo ratings yet

- Datasheet StrainerDocument4 pagesDatasheet StrainerTommy ArjanggiNo ratings yet

- DIN Version: T 8015 EN Series 240 Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveDocument8 pagesDIN Version: T 8015 EN Series 240 Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveLoander David GeronimoNo ratings yet

- Ongc WPS 1 of 2Document4 pagesOngc WPS 1 of 2Kiran NikateNo ratings yet

- Flow Indicator 1Document2 pagesFlow Indicator 1Vara PrasadNo ratings yet

- 2 Way Manifold - DatasheetDocument2 pages2 Way Manifold - DatasheetPUSHPENDRA SINGHNo ratings yet

- OSFDocument2 pagesOSFUyab100% (1)

- AAP S6 High Pressure Fittings E2 SDocument23 pagesAAP S6 High Pressure Fittings E2 SJusthyTaquiri0% (1)

- Iron Wafer Type Check Valve: Kitz Cast Iron ValvesDocument1 pageIron Wafer Type Check Valve: Kitz Cast Iron ValvesAndy SetyawanNo ratings yet

- Free Float Steam Trap: Model Ductile Cast Iron Cast IronDocument2 pagesFree Float Steam Trap: Model Ductile Cast Iron Cast IronSamerNo ratings yet

- ProductSerieSheet DF enDocument3 pagesProductSerieSheet DF enДаниил СторчеусNo ratings yet

- Flange DimensionsDocument30 pagesFlange DimensionshibhavuNo ratings yet

- ASHCROFT Diaphragm Seal Model 400-401Document2 pagesASHCROFT Diaphragm Seal Model 400-401HanzoNo ratings yet

- Model CR Commercial Riser: Table ADocument5 pagesModel CR Commercial Riser: Table ASpinu DanielNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Stamixco Brochure 2013 EDocument24 pagesStamixco Brochure 2013 EwawanNo ratings yet

- International Metal Engineering: Model 9080 Dual Compartment Instrument EnclosureDocument4 pagesInternational Metal Engineering: Model 9080 Dual Compartment Instrument EnclosurewawanNo ratings yet

- PDF N1301281618440Document2 pagesPDF N1301281618440wawanNo ratings yet

- Datalogger Battery LifetimeDocument1 pageDatalogger Battery LifetimewawanNo ratings yet

- Retriever Stroke Length Order & Service ValveDocument1 pageRetriever Stroke Length Order & Service ValvewawanNo ratings yet

- Material Selection Guide PDFDocument1 pageMaterial Selection Guide PDFwawanNo ratings yet

- Cata - Flange ANSI - pdf1299758077 PDFDocument48 pagesCata - Flange ANSI - pdf1299758077 PDFNikhil PanchalNo ratings yet

- Torqbolt Inc CatalogueDocument36 pagesTorqbolt Inc CataloguewawanNo ratings yet

- Material Data Sheet: Peek - PolyaryletherketoneDocument1 pageMaterial Data Sheet: Peek - PolyaryletherketonewawanNo ratings yet

- For Heat Treatment TestDocument4 pagesFor Heat Treatment TestwawanNo ratings yet

- Valve Seat Material GuideDocument1 pageValve Seat Material GuidewawanNo ratings yet

- FTTLVFLUO AEIA PTE- LTBDocument1 pageFTTLVFLUO AEIA PTE- LTBwawanNo ratings yet

- Habonim DBBDocument4 pagesHabonim DBB105034412No ratings yet

- Retriever Stroke Length Order & Service ValveDocument1 pageRetriever Stroke Length Order & Service ValvewawanNo ratings yet

- Answer Key TemplateDocument2 pagesAnswer Key TemplatewawanNo ratings yet

- Incoterms 2010 Quick Reference Chart 120610Document1 pageIncoterms 2010 Quick Reference Chart 120610Muhammad ShahbazNo ratings yet

- Incoterms 2010 Quick Reference Chart 120610Document1 pageIncoterms 2010 Quick Reference Chart 120610Muhammad ShahbazNo ratings yet

- Round Bar Astm A694 f65 Dia.130mm, Nace Mr0175 Hn.76289Document2 pagesRound Bar Astm A694 f65 Dia.130mm, Nace Mr0175 Hn.76289wawanNo ratings yet

- SRG LPG Float Gauge Type 487: Container Connection Mounting Head MaterialsDocument1 pageSRG LPG Float Gauge Type 487: Container Connection Mounting Head Materialsalvaro_arcvNo ratings yet

- SAF-FRO - Welding Consumables CatalogueDocument194 pagesSAF-FRO - Welding Consumables CatalogueLLNo ratings yet

- Refractory Properties of Indian Sea-Water MagnesiaDocument6 pagesRefractory Properties of Indian Sea-Water Magnesiaakanksha kumariNo ratings yet

- Mục 64 Keo dán nguội băng tải Devcon R flex 15565Document2 pagesMục 64 Keo dán nguội băng tải Devcon R flex 15565Việt Hùng NghiêmNo ratings yet

- Usa Astm C936 (M) 13 PDFDocument3 pagesUsa Astm C936 (M) 13 PDFAzisMiftakhulPutraNo ratings yet

- SUS316 Compression Fitting SafetyDocument7 pagesSUS316 Compression Fitting SafetysunanNo ratings yet

- Valves, pipes, supports and air eliminators equipment listDocument275 pagesValves, pipes, supports and air eliminators equipment listEdgar Alejandro Barajas RuizNo ratings yet

- Module 1Document47 pagesModule 1greatrijuvanNo ratings yet

- Flyash Bricks: Profile No.: 17 NIC CodeDocument6 pagesFlyash Bricks: Profile No.: 17 NIC Codeesha108No ratings yet

- ASTM F593 Fasteners: Stainless Steel Bolts, Nuts, Washers & MoreDocument7 pagesASTM F593 Fasteners: Stainless Steel Bolts, Nuts, Washers & MoreProcurement MCCLNo ratings yet

- The Early History of PVC PipeDocument2 pagesThe Early History of PVC Pipeb1gm3nNo ratings yet

- Ufgs 07 41 13.16 Metal Roof PanelsDocument12 pagesUfgs 07 41 13.16 Metal Roof PanelssharethefilesNo ratings yet

- Katalog Techniczny ENG PDFDocument136 pagesKatalog Techniczny ENG PDFJoseph Cloyd L. LamberteNo ratings yet

- Handbook On Plumbing Installation For Buildings: June 2017Document75 pagesHandbook On Plumbing Installation For Buildings: June 2017NIRANo ratings yet

- Bucket Teeth CASEDocument9 pagesBucket Teeth CASEnemez1zNo ratings yet

- Calculated Fire Resistance RatingsDocument8 pagesCalculated Fire Resistance RatingsRameshNayakaNo ratings yet

- Essentials of Civil EnggDocument6 pagesEssentials of Civil EnggAkhilesh KumarNo ratings yet

- Design Jacking Pipa Australia STDDocument10 pagesDesign Jacking Pipa Australia STDDaniel SalehNo ratings yet

- BRC Machine Design ProblemsDocument19 pagesBRC Machine Design ProblemsBrilliantJohnMalandacRubiaNo ratings yet

- Brochure HYDRAULIC Hose Quick Camlock Valve HIC India 04Document4 pagesBrochure HYDRAULIC Hose Quick Camlock Valve HIC India 04Tithi Kuldeep ChauhanNo ratings yet

- 5.method Statement Shuttering and Form WorkDocument4 pages5.method Statement Shuttering and Form Workشاز إياس100% (1)

- Kestopour PL 15Document1 pageKestopour PL 15Mantas ButrimaviciusNo ratings yet

- Equivalent Frame Method Applied To Concrete Shear Walls by Angelo MattacchioneDocument8 pagesEquivalent Frame Method Applied To Concrete Shear Walls by Angelo Mattacchionegulilero100% (1)

- Advances in Wood Composites II: Polymers July 2020Document5 pagesAdvances in Wood Composites II: Polymers July 2020Hari BudiartoNo ratings yet

- Pavement Design Report (PK 50 - PK 61.3) - Rev.1 05 May 2021Document94 pagesPavement Design Report (PK 50 - PK 61.3) - Rev.1 05 May 2021Adrian FrantescuNo ratings yet

- Pu Exterior Paint - NovotaDocument2 pagesPu Exterior Paint - NovotasamirNo ratings yet