Professional Documents

Culture Documents

Edible Oils Processing 2014 EN PDF

Uploaded by

WellfroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Edible Oils Processing 2014 EN PDF

Uploaded by

WellfroCopyright:

Available Formats

Sub-sectoral Environmental and Social

Guideline: Edible Oils Processing

Edible Oils Processing

This guideline is designed to be used by EBRD Financial Intermediaries (FIs) to understand

the nature of environmental and social (E&S) risks associated with existing operations in this

sector and suggested actions for businesses to manage these E&S risks. It also provides

guidance for FIs on potential due diligence questions to raise with management to understand

how their business is managing these E&S risks. This guideline focuses on material E&S

risks; it is not an exhaustive list. In managing E&S risks, all businesses should be compliant

with relevant E&S laws and regulations.1 Where applicable, this includes European Union

legislation, which may also be taken as a benchmark for good practice.

This guideline covers the production of edible oils through extraction from seeds, beans, fruits

and nuts. It does not cover the production of oils from animal-derived sources, or the

manufacture of biodiesel.

Reference NACE codes:

• 10.4: Manufacture of vegetable and animal oils and fats;

• 10.41: Manufacture of oils and fats;

• 10.42: Manufacture of margarine and similar edible fats.

Material risks

Below is an overview of the material environmental and social (E&S) risks present in edible

oils processing:

1 This guideline outlines some relevant legislation but does not provide an exhaustive list of applicable laws and regulations.

EBRD Sub Sector Environmental & Social Guideline 2014 Page 1

Edible Oils Processing

Sub-sectoral Environmental and Social

Guideline: Edible Oils Processing

E&S Risk Category Environment Health and Labour Community Page

Safety no.

Affect the natural Affect Affect the health and

environment Affect the workplace safety, livelihoods,

Key E&S Risks2 health or conditions and and environment of

safety of the treatment the community and

employees of employees wider public

Palm Oil/Biodiversity √ √ √ 4

Food Hygiene & √ √ √ 5

Product

Contamination

Odour √ √ 6

Solid Waste √ √ 6

Volatile Organic √ √ √ 7

Compounds (VOCs)

Hazardous Materials √ √ √ 8

Water Use √ √ 9

Wastewater √ √ 10

Energy Use √ √ 11

Air Emissions √ √ 11

Noise √ √ √ √ 12

Pesticides √ 13

Organic Products & √ √ 13

Labelling

Machine & Electrical √ 13

Safety

Manual Handling √ 14

Slips, Trips & Falls √ 14

PCBs & Asbestos √ √ √ 15

Temperature √ √ 15

Confined Space √ √ 15

Labour & Working √ 15

Conditions

Relations with Local √ 16

Communities

2Note: this table provides an indicative list of the EHS risks associated with the sub-sector; it is not meant to be an

exhaustive list and EHS risks will depend on the specific setting and scale of the operation or facility.

EBRD Sub Sector Environmental & Social Guideline 2014 Page 2

Edible Oils Processing

Sub-sectoral Environmental and Social

Guideline: Edible Oils Processing

Contents

Section Page No.

1. Process description 4

2. Key E&S Risks 4

3. Financial Implications 16

4. Suggested due diligence questions 17

5. References and additional sources 21

EBRD Sub Sector Environmental & Social Guideline 2014 Page 3

Edible Oils Processing

Sub-sectoral Environmental and Social

Guideline: Edible Oils Processing

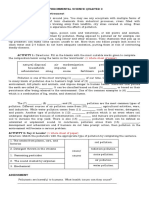

Vegetable oils and fats are an important

1. Process Description ingredient in a vast number of products

providing flavour, texture and structure.

Vegetable oils are extracted from seeds, They are used in food applications, animal

beans, fruits and nuts. The basic steps in the feed, cosmetics, detergents, paints, plastics,

process are shown in the Figure 1 below. candles, pharmaceuticals, biofuels and many

other technical applications.

Figure 1. Edible Oils Production

Seeds/ Beans

2. Key E&S Risks

Cleaning/Drying/

Sorting/Dehulling

Below are the material E&S risks associated

with this sector and key measures to manage

Crushing/Heating Filtration them. Where gaps are found in the

management of key E&S risks, the E&S risk

Solvent management measures may form part of a

Degumming

Extraction corrective E&S action plan agreed with your

customer.

Wet Cake Miscella*

Desolventing Solvent Removal Palm Oil/Biodiversity

Toasting by Distillation Pressed

Extracted Crude Oil

Crude Oil

Refining (Physical

Drying Cooling

or Chemical)

Palm oil plantations are under increasing

Semi-refined oil

scrutiny for their effects on the

Meals quality environment, including loss of carbon-

sequestering forest land.

Hydrogenation Interestification

There is also concern over displacement and

disruption of human and animal populations

Deodorisation due to palm oil cultivation.

Fully Refined Production of palm oil has been

Product controversial in recent years and could

*Miscella is a mixture of oil and solvent reflect on purchasers and processors of

these crops.

The extracted crude oil will be refined either

through chemical/alkali refining or through

physical means. The primary purpose is to

separate the free fatty acids and remove

other unwanted substances.

EBRD Sub Sector Environmental & Social Guideline 2014 Page 4

Edible Oils Processing

Sub-sectoral Environmental and Social

Guideline: Edible Oils Processing

Train staff in food safety issues and follow

How can a business manage this risk?

established procedures for hand washing,

Perform background checks on raw material working attire (clothes, shoe coverings,

suppliers to determine the origin of gloves and hair coverage), and how to

feedstocks. handle injuries and diseases;

Establish plant such that products move

from dirty to clean areas, to avoid

recontamination. Staff movement to be

Food Hygiene & Product Contamination

opposite to the manufacturing flow

direction of products (i.e. from ‘clean’

towards ‘dirty’ areas);

Contamination of product could result in ill Undertake regular cleaning and disinfection

health in the general public and may result in to maintain food safety and hygiene

product recall. Vegetable oils can become standards;

contaminated as a result of contamination of

the raw materials during processing, Process hygiene standards should prevent

packaging and transport. Screening of raw the spread of diseases such as salmonella,

materials will identify any incoming Escherichia coli (E. coli) and Legionnaires'

contaminated raw product and food hygiene disease beyond the factory boundaries, for

standards such as Hazard Analysis Critical example to the local surrounding

Control Points (HACCP)3 and Codex community and/or consumers;

Alimentarius4 will need to be considered in

order to reduce the risk of contamination. Consider implementing product traceability

systems that facilitate tracing of products

once released for sale;

How can a business manage this risk?

Regular, rigorous hygiene monitoring

Consider food hygiene under the programmes should be in place. All surfaces

requirements of EU food safety directives and equipment should be cleaned regularly

and legislation (e.g. Regulation No. to prevent the build-up of oil and fat and to

178/2002, Regulation on general principles reduce the risk of health hazards;

and requirements of food law, No.

882/2004 on general food safety, Regulation Ensure that appropriate clothing is provided

No. 2073/2005 on microbiological criteria to all facility visitors, that hygiene

for foods) in addition to local/national food requirements adhered to and that external

safety regulations; contact with the products is avoided.

3 ISO 2005

4 FAO and WHO (1962–2009).

EBRD Sub Sector Environmental & Social Guideline 2014 Page 5

Edible Oils Processing

Sub-sectoral Environmental and Social

Guideline: Edible Oils Processing

Odour Spent bleaching earth, activated clay,

silica and carbon are used in the

bleaching process and will contain

pigments and residues of other

undesirable substances such as gums and

Unpleasant odours may be generated during metals;

operations which heat the oil and involve

solvents. Sludge arising from wastewater treatment

which may be contaminated with

hazardous chemicals or have a high pH

How can a business manage this risk?

and therefore require appropriate

Reduce odour emissions from extraction disposal.

cookers, vacuum and pressurised systems by

using caustic, alkaline or ozone scrubber Extracted oil is typically packaged in plastic,

systems or by incinerating the gas; cans and glass. Waste may arise from the

Adopt odour management measures to packaging process in the form of discarded

prevent and minimise odour nuisance to local packaging offcuts.

communities and other receptors;

Control temperature and humidity to reduce

odour emissions. How can a business manage this risk?

Comply with national and EU regulations (as

Solid Waste applicable) for the safe disposal of waste;

Explore waste recovery measures such as:

o Use of waste vegetable matter as a soil

Edible oil processing can generate significant improver;

quantities of organic solid waste such as o Use of waste oils for biofuels;

empty fruit stalks and waste palm kernels. o Use of waste vegetable matter and free

Other solid wastes may include: fatty acids as fuel for steam and power

generation at refineries or for animal

Deodoriser distillate; feed;

o Use of free fatty acids as feedstock for

Mucilage5 from degumming; chemical industry;

o Use of uncontaminated wastewater

Spent catalysts and filtering aid from treatment sludge in agricultural

hardening; applications;

o Use of spent bleaching earth in

brick/block/cement manufacture,

fertiliser, anaerobic digestion;

Maintain an inventory of wastes generated

and minimise where possible;

5 Gelatinous substances secreted by plants.

EBRD Sub Sector Environmental & Social Guideline 2014 Page 6

Edible Oils Processing

Sub-sectoral Environmental and Social

Guideline: Edible Oils Processing

Store solid wastes in adequate containers and mild central nervous system (CNS)

segregate to encourage recycling; depression and irritation of the skin and

mucous membrane. Prolonged exposure

Dispose of wastes regularly to avoid odour, may cause serious health damage. Hexane is

litter, fly and rodent problems; also harmful in low concentrations to

aquatic organisms. Strict controls are

For wastes that cannot be recycled, due to required to prevent a build-up in working

biosecurity issues, dispose according to the areas and discharges to the environment.

requirements of local health authorities;

How can a business manage this risk?

Companies operating within the European

Union (either as a manufacturer or as a Consider solvent processes under the

supplier into European Union countries) will European Community Directive

be subject to the European Union Packaging 2008/112/EC on the limitation of emissions

and Packaging Waste Directive (94/62/EC of volatile organic compounds due to the use

as amended by 2005/20/EC), which aims to of organic solvents in certain activities and

reduce the amount of packaging that is being installations and the European Council

introduced into waste streams. Directive 88/344/EEC on the extraction of

solvents in foodstuffs. Further industry

Recover and reuse packaging material where guidance is available6;

possible or ensure that the packaging is easy

to recycle. Minimise solvent use by switching to physical

(rather than chemical) refining where the free

fatty acid content is >2%;

Volatile Organic Compounds (VOCs) Improve process design to increase solvent

recovery, e.g. distillation, reuse of vapours,

gravity separators etc.;

Consider the soil and groundwater

Solvent is used to separate oil from the contamination implications of the use and

vegetable matter. Solvent emissions arise storage of solvents

from several steps in the process such as the

solvent recovery plant, volatisation during

refining and leaks in piping and vents.

The most common solvent used is hexane,

which is a colourless, volatile liquid, soluble

6AEA Group Guidance on VOC Substitution and

in water and highly flammable and may Reduction for Activities Covered by the VOC

cause explosions due to the volatisation of Solvents Emissions Directive - Guidance 19:

the solvent dissolved in the oil. Exposure to Vegetable oil and animal fat extraction and vegetable

hexane may cause impaired fertility. Acute oil refining activities

inhalation of high levels of hexane can cause http://www.fediol.eu/data/VOC_Guidance.pdf

EBRD Sub Sector Environmental & Social Guideline 2014 Page 7

Edible Oils Processing

Sub-sectoral Environmental and Social

Guideline: Edible Oils Processing

Hazardous Materials Bulk storage facilities will be used for the

storage of oil seeds and beans, gas and liquid

chemicals used in the production process

and for cleaning and disinfection, and fuel

oils for energy production.

In addition to solvents, a range of other

potentially-hazardous materials may be used

during processing and cleaning, including: How can a business manage this risk?

Operations where pollution has occurred or

Phosphoric acid – used in degumming;

there is a threat of it occurring to water

resources, land and protected species and

Spent bleaching earth – this material

habitats may be liable under national

presents a fire risk;

legislation and EU legislation for preventing

and remedying environmental damage.

Hydrogen;

Within the EU, the Environmental Liability

Directive (ELD) (2004/35/EC) established a

Solvents;

framework of environmental liability, based

on the "polluter-pays" principle, to prevent

Cleaning agents such as detergents.

and remedy environmental damage;

Fuels - edible oils processing is a heat-

Compliance with the EU BREF Guidance

intensive process and can use

Note on Food, Milk and Drink Industries

hydrocarbon fuels (oil, diesel, coal) for

(2006) is required for ‘intensive’ facilities

heating processes. Underground storage

falling under the ELD; compliance with

tanks are a common source of

EBRD Performance Requirement 3 (whether

groundwater pollution unless contained,

the facility falls under the ‘intensive’

managed and tested regularly. Coal

definition or not;

storage can lead to soil contamination,

unless covered/contained appropriately.

Provide adequate secondary containment for

all hazardous fuels and oils etc.; install

Drain corrosion – edible oils processing

suitable shut-off and alarm systems;

processes commonly use

caustic/corrosive chemicals for cleaning

Maintain storage areas to ensure that they are

processes (including CIP). If discharged

organised, secure, clean and dry. Storage

to drainage systems, this can lead to

facilities should be properly designed with

corrosion of pipework and creation of

appropriate signage and ventilation and

new contaminant pathways.

should be locked and accessible only to

trained and approved personnel. Storage

The transport, storage and handling of such

facilities should be inspected on a regular

materials provide opportunities for spills and

basis to ensure that leaks and spillages do not

other releases to the environment and

occur;

present a risk of fire and explosion.

Record all hazardous materials held on site in

EBRD Sub Sector Environmental & Social Guideline 2014 Page 8

Edible Oils Processing

Sub-sectoral Environmental and Social

Guideline: Edible Oils Processing

an inventory with Materials Safety Data Washing and deodorisation;

Sheets (MSDSs) available in the appropriate

language; procedures should be prepared for Cleaning process areas;

their handling and treatment in the event of

spillage; Steam production.

Conduct regular inspection of all bulk Water can be wasted when much of it can be

containment facilities and effluent holding treated and reused in the process. It is

tanks to ensure integrity of storage; typical for abstraction or water use permits

to detail volumes of water abstraction

Provide personal protective equipment (PPE) allowed as over abstraction can impact local

that is fit for the task to prevent injury and communities. Whenever changes take place

maintain hygiene standards; in product volumes this should be reflected

in the permit.

Train staff in the correct selection, use and

maintenance of PPE. PPE should be

How can a business manage this risk?

inspected regularly and maintained or

replaced as necessary. Consider discharges and abstraction from

water resources under the requirements of

Maintain storage, transport and conveyance the EU Water Framework Directive

systems in good condition; (2000/60/EC) and local environmental

regulations and permitting requirements;

Protect raw materials storage from rain and

wind to prevent contaminated runoff and to Evaluate water supply and water efficiency

minimise wastage. measures (e.g. recycling, reuse, run-off

reduction, storage etc.) to reduce impacts on

surrounding resources and community

supplies;

Water Use

Separate cooling water from process water,

and recycle condensates and cooling waters;

Reduce cleaning water needs by ensuring that

Edible oil extraction can use a relatively solid waste is removed before rinsing and

large quantity of water throughout the washing, e.g. using scrapers, brooms and

process primarily for: vacuum cleaners;

Raw ingredient cleaning; Use taps with automatic shutoff valves;

Cooling water in crude oil production; Use high pressure hoses and optimised

nozzles to minimise water usage;

Chemical neutralisation;

Use hot water or steam as this can reduce

EBRD Sub Sector Environmental & Social Guideline 2014 Page 9

Edible Oils Processing

Sub-sectoral Environmental and Social

Guideline: Edible Oils Processing

water requirements;

How can a business manage this risk?

Consider adoption of equipment cleaning-in- Comply with national and international

place (CIP)7 methodologies to reduce regulations for edible oils processing; large

chemical, water and energy consumption. edible oils processing facilities in the EU,

with (capacity for greater than 300

tonnes/day of finished product), are subject

to national regulations under the Industrial

Wastewater Emissions Directive (IED) 2010/75/EU.

Other smaller facilities within the EU and

operations outside the EU will be subject to

local regulation;

Large volumes of wastewater containing Where feasible, use citric acid to replace

high organic loads, organic nitrogen, oils and phosphoric acid in degumming to reduce

fats, cleansing agents, solvents and phosphorous loading in effluent;

suspended solids may be produced.

Wastewater may also be contaminated with Use appropriate cleaning chemicals in the

pesticide residues. right dosage for the equipment to be cleaned,

e.g. caustics for polymerised fat and acids for

The main production processes producing lime deposits. Use hot water rather than

wastewater are the refinery, deodorisers and solvents to facilitate cleaning where possible;

boilers. Wastewater will typically require

treatment before it can be discharged to a Ensure that contaminated sludge is disposed

municipal wastewater treatment system or to of by incineration or landfill at permitted

the environment. Many facilities have on facilities;

site wastewater treatment plants, which may

utilise mechanical and chemical means of Install filters to collect sediment/debris

treatment. A permit with specific discharge before wastewater discharge;

parameters from the regulatory authorities

will normally be required. Install diversion drains to direct surface water

runoff away from waste areas;

Treat wastewater prior to discharge to

separate oils and fatty acids from the water

and discharge through a fat trap;

7CIP is a method of cleaning the interior surfaces of pipes,

vessels, process equipment, and associated fittings, without Install (or upgrade) wastewater treatment

disassembly using approved chemicals and/or detergents plant.

with minimal environmental impact and compatible with

subsequent wastewater treatment processes.

EBRD Sub Sector Environmental & Social Guideline 2014 Page 10

Edible Oils Processing

Sub-sectoral Environmental and Social

Guideline: Edible Oils Processing

Energy Use the use of compressed air and high-pressure

water for cleaning.

Workers may inhale or ingest the dust and

aerosols exposing them to biological hazards

Large quantities of energy are consumed in which present a risk of occupational lung

oil processing in two ways: disease. This may give rise to skin irritation

or allergic reactions.

Thermal energy in the form of steam and

hot water used for distillation, cleaning, A dust cloud of any flammable material will

and sterilising. Frequently an auxiliary explode where:

boiler is used to generate steam;

o The concentration of dust in air falls

Electricity for machinery operation, within the explosive limits;

refrigeration, lighting and production of

compressed air. Minimum refrigeration o There is a source of ignition.

requirements are normally determined by

regulation.

How can a business manage this risk?

How can a business manage this risk? Many countries are signatories to the Kyoto

Protocol and have adopted targets for the

Use heat recovery to heat incoming oil with reduction of CO2 emissions. Where

the outgoing oil thereby reducing energy Governments have set up carbon emission

demand and water demand for steam; reduction programmes, industrial processes

like edible oils processing are required to

Examine other options for heat recovery and reduce their CO2 emissions through setting

insulation, to reduce/supplement energy targets. This can result in a need for

usage; substantial investment in new/clean

technologies to achieve the emission targets

Examine options for increasing energy set. These targets can be reflected in

efficiency through modifying work practices environmental permits;

and installing energy efficient

devices/equipment. Consider air emissions under the

requirements of EU air quality and emissions

directives (e.g. Directive 2008/50/EC on

ambient air quality also Industrial Emissions

Air Emissions Directive (IED) 2010/75/EU) and local

environmental regulations and permitting

requirements;

Reduce dust emissions through:

Dust may arise from storage, handling and

drying activities; aerosols typically arise from o Ensuring proper maintenance of all

EBRD Sub Sector Environmental & Social Guideline 2014 Page 11

Edible Oils Processing

Sub-sectoral Environmental and Social

Guideline: Edible Oils Processing

cleaning, screening and crushing of intrinsically safe electrical equipment;

equipment to prevent fugitive emissions;

o Ensuring vessels and tanks have sufficient

o Enclosing and sealing plant and emergency venting capacity to relieve

equipment to prevent escape and excessive internal pressure in the event of

accumulation of dust; fire; if the silo is contained within a plant,

evacuate gases outside.

o Using doors/plastic strip curtains on

building access points; Install dust and solvent emissions monitoring

equipment at sensitive points;

o Redesigning processes to reduce free-fall

distances and speed of movement for dry Inventory all GHG emissions associated with

products; the edible oils processing process and its

value chain , as well as the GHG emissions

o Replacing external bulk storage areas with associated with life cycles of its products; this

silos, fitted with alarms to prevent information can be used in the reporting

overfilling; processes where necessary, and to set

effective reduction targets/initiatives.

o Installing a centralised piped vacuum

cleaning systems;

o Installing dust extractors e.g. cyclones and Noise

fabric filters;

o Improving ventilation within buildings;

o Maintaining a slight negative pressure The noise generated by equipment and

within storage vessels such as bins and processes such as steam generation,

silos. condensers, ventilation, and pressurised air

equipment as well as trucks can be a

Reduce the risk of fire and explosion by: nuisance if the site is located close to

residential areas and other sensitive

o Reducing dust emissions as above; receptors.

o Locating equipment within a lightweight Noise induced hearing loss can occur from

building so that the roof and wall cladding working in noisy areas, e.g. internal

panels can act as explosion relief; transport, conveyors, boilers, pumps, fans,

and steam and air leaks.

o Fitting silos and bins with explosion relief;

o Assessing explosion potential by zoning

hazards within the facility and installation

EBRD Sub Sector Environmental & Social Guideline 2014 Page 12

Edible Oils Processing

Sub-sectoral Environmental and Social

Guideline: Edible Oils Processing

aprons etc.;

How can a business manage this risk?

Locate and design facilities to avoid sensitive Train staff in the correct selection, use and

receptors to noise; maintenance of PPE;

Enclose noisy machinery to isolate people Implement worker management plans to

from noise where practicable and reduce ensure that workers with allergic reactions are

noise exposure through the hierarchy of not working with substances that cause a

controls; reaction;

Provide hearing protection as required. Conduct health screening of new staff and

regular health monitoring of existing staff.

Pesticides

Organic Products and Labelling

Chemicals including pesticides and

insecticides may be applied to raw materials Processing and production of organic

and/or physical structures to control pests. products that are sold and labelled as

Pesticides are potential pollutants which may organic must meet a number of

cause environmental and health impacts. requirements under Council Regulation (EC)

No 834/2007 of 28 June 2007 on organic

Toxic pesticides which biodegrade slowly, production and labelling of organic

can accumulate in body tissues and be products.

harmful to ecosystems and human health.

Accidental exposure to hazardous

How can a business manage this risk?

substances (e.g. pesticides) can result in

dermal contact and inhalation. Contact can Follow EU guidelines (834/2007/EC) which

lead to burns or inflammation of skin or introduce requirements for production and

allergy. Inhalation can lead to respiratory labelling of organic products

difficulties.

Machine & Electrical Safety

How can a business manage this risk?

Provide personal protective equipment (PPE)

that is fit for the task to prevent

exposure/risk and maintain hygiene

standards, e.g. gloves overalls, respirators, In a busy processing environment, injuries

involving machinery or equipment are

common. Conveyors, packaging machines

EBRD Sub Sector Environmental & Social Guideline 2014 Page 13

Edible Oils Processing

Sub-sectoral Environmental and Social

Guideline: Edible Oils Processing

and palletisers or operating fork lift trucks awkward shaped items, and manoeuvring

and delivery vehicles/trucks are commonly carts/manual forklifts.

used in edible oil processing.

Repetitive tasks such as the operation of

Over a quarter of all manufacturing injuries slicing and vacuum-packing machines can

occur in the food processing industries8. lead to musculoskeletal injuries and work-

related upper limb disorders (WRULDs).

How can a business manage this risk?

How can a business manage this risk?

Within the EU, machinery purchased after 1

January 1995 must comply with the Redesign manual processes and rotate work

Machinery Directive 98/37/EC; tasks to avoid heavy lifting and repetitive

activities;

Assess machine safety in consultation with

machine operators, reduce hazards Install mechanical lifting aids where possible.

according to the hierarchy of controls and

undertake modifications/install guards and

interlocks as required;

Slips, Trips and Falls

Assess electrical installations and ensure that

appropriate insulation, earthing and residual

current devices (RCDs) are in place;

Separate people from vehicle movement to Food preparation processes may require

ensure the safety of workers, the community access to elevated areas such as gantries, vats

and the public; and storage silos. These activities may

require working at height.

Train vehicle and forklift drivers to properly

operate the machinery and equipment

How can a business manage this risk?

Effective design can often eliminate the need

Manual Handling to work at height but in the event that it is

necessary, such work should be carefully

managed and controlled;

Install correct fall arrest systems (guarding

Lifting, repetitive work and posture injuries and harnesses attached to fixed anchor points

can occur from lifting and carrying heavy or etc.).

8 United Kingdom Health and Safety Executive 2014

http://www.hse.gov.uk/food/hse.htm.

EBRD Sub Sector Environmental & Social Guideline 2014 Page 14

Edible Oils Processing

Sub-sectoral Environmental and Social

Guideline: Edible Oils Processing

Polychlorinated Biphenyls (PCBs) & Confined Spaces

Asbestos

Edible oils processing facilities contain

PCBs may be present in electrical vessels such as tanks and pits which may

switchgear, transformers and fluorescent require entry by staff during maintenance

light starters. and cleaning activities. Entry to confined

spaces without effective management and

Asbestos may be present in fire proofing control can result in engulfment and

and insulation material, including as asbestos asphyxiation.

cement boards, as fire retardant gaskets in

pipe work and as fire retardant insulation

around boilers and furnaces, particularly in How can a business manage this risk?

older buildings.

Implement confined space procedures,

provide training, equipment and control

Both materials give rise to risks to the

systems if confined space entry is necessary.

environment and health and safety.

How can a business manage this risk?

Labour & Working Conditions

Where the presence of asbestos or PCBs is

known or suspected, seek professional advice

Temperature Edible oils processing operations may use

casual and contract labour. Poor working

conditions for casual labourers in the food

processing sector is a key labour risk.

High temperatures can lead to collapse Child labour is a prevalent risk particularly in

through heat exhaustion and contact burns. relation to smaller-scale family run

operations.

How can a business manage this risk? Worker accommodation standards,

Minimise time needed for staff to access high particularly for temporary/casual labourers,

temperature areas, issue protective clothing may not reach the standard required for

and ensure that regular breaks and hydration permanent employees.

takes place

EBRD Sub Sector Environmental & Social Guideline 2014 Page 15

Edible Oils Processing

Sub-sectoral Environmental and Social

Guideline: Edible Oils Processing

Stakeholder Engagement Plan (SEP);

How can a business manage this risk?

Comply with International Labour Manage traffic flows with

Organisation (ILO) requirements on working consideration of local communities.

hours, pay, overtime, etc.;

Include all ILO prohibitions on child labour

into contracting agreements;

3. Financial

Provide appropriate worker accommodation Implications

which meets, at a minimum, the basic needs

of workers, national legislation and Outlined below are key financial implications of

international good practice9. management of E&S risks related to edible oils

processing.

Product recall can have a significant impact,

Relations with Local Communities e.g. compensation claims, loss of reputation,

loss of contracts and in terms of export

markets. Significant upgrades in hygiene

standards may be required at the production

facility in order to reduce the risk of

Having good relationships with contamination during processing and to

neighbouring communities reduces the risk satisfy national and European food hygiene

of local opposition to food processing standards. A system of product traceability is

activities. Opposition may arise from odour required to facilitate product recall;

emissions and increased traffic.

If oil and solvents are allowed to enter the

effluent stream, the cost of treatment

How can a business manage this

increases and this represents the loss of

risk? valuable by-products;

Engage with the local community and

Significant capital expenditure might be

assess opportunities for their

required to maintain environmental, health,

involvement in employment or in

safety and hygiene standards;

provision of goods and services;

Capital and operational investments to obtain

For large-scale intensive facilities, or in

and maintain industrial emissions permits

highly populated areas, prepare a

and, where applicable, achieve compliance

with Best Available Techniques (BAT);

9Workers’ accommodation: processes and standards:

Capital and operational investments to

A guidance note by IFC and the EBRD; August 2009 prevent and minimise the risk of

contamination of soil, surface water and

EBRD Sub Sector Environmental & Social Guideline 2014 Page 16

Edible Oils Processing

Sub-sectoral Environmental and Social

Guideline: Edible Oils Processing

groundwater resources from edible oils

processing waste;

4. Suggested Due

Diligence Questions

Injuries may lead to increased payroll costs to

replaced workers;

Fines, penalties and third party claims may be When assessing E&S risks, it is important to

incurred for non-compliance with engage the customer on how these risks are

environment, health and safety regulations; managed.

Capital expenditure for installing or Perform a complete tour of the facility,

upgrading wastewater and waste treatment accompanied by someone knowledgeable about

facilities; all the activities at the site.

Capital expenditure for installing or Confirm organisational responsibilities and

upgrading storage facilities for chemicals, systems for environment, health, safety and

fuels and oils; social matters and that these systems cover both

employees employed directly and sub-

Product contamination issues may result in contractors.

restrictions on price and demand, and export

markets (e.g. EU); During the initial site visit, the issues will vary

according to the type of edible oils processing

Inadequate health and safety provisions and the level of environment, health and safety

(including risk assessments, training, and hygiene management already introduced.

infection control and provision of Personal While visiting the site it is important to discuss

Protective Equipment (PPE) etc.) for and review the following:

workers (permanent, temporary and/or

casual) may lead to absenteeism, health care General Housekeeping

costs or health and safety incidents and

claims; Check the condition and containment

arrangements of raw and finished product

Community health and safety impacts from storage facilities;

edible oils processing (e.g. exposure to

contaminated drinking water and/or living in What is the standard of general house-

proximity to infectious diseases) may lead to keeping on site? Do areas look clean and

reputation damage, legal tidy? Look for localised spills, leaking pipes

challenges/prosecutions and/or etc.;

compensation claims.

Check the age and condition of buildings and

equipment.

EBRD Sub Sector Environmental & Social Guideline 2014 Page 17

Edible Oils Processing

Sub-sectoral Environmental and Social

Guideline: Edible Oils Processing

Health and Safety source and origin of Oil Palm if used in the

process?

Check whether Health and Safety risks have

been systematically assessed, documented Does the organisation have insurance in

and addressed; place to cover product contamination? Have

there been any recent incidents? Has the

Check whether efforts have been made to company any other insurances and have there

reduce hazards through application of the been any claims against these policies?

hierarchy of controls i.e. eliminate, substitute,

engineer, administer then issue personal Is the facility subject to any audits by

protective equipment PPE as a last resort customers? What was the outcome of these

(e.g. install noise reduction equipment before audits?

resorting to issuing hearing protection);

Waste Management

If PPE is required, check that it is being

supplied by the employer, is used effectively Check that waste disposal takes place on a

and maintained/checked regularly; regular basis;

Note the signage around the site, does it Check that waste storage areas are clear of

convey what health & safety risks might exist debris and that skips are covered to prevent

in areas? waste escaping; for example, check that waste

containers have lids or are stored in an area

Check whether an asbestos survey has been with a roof;

undertaken at the facility, have the costs for

management/removal been assessed, and if Wastewater and Surface water Management

asbestos exists, is an asbestos management

plan in place? Check whether drainage systems lead to

wastewater treatment systems or discharge

Check whether fire-fighting and first aid directly to surface waters;

equipment is available, and is it

checked/maintained regularly? Check whether the routing of wastewater

drainage systems within the facility are well

Have the premises been inspected recently understood; has the facility undertaken dye

(within the past 2 years) by the regulatory tracing and/or video surveying of drain

authorities for health, hygiene and systems?

environment? What were their findings?

Check that the routing of surface water

Edible Oils Processing Management drainage systems from the facility are well

Practices understood (and are separate to the

wastewater drainage system); has the facility

Check the source of raw materials. Are the been the subject of surface water pollution

levels of pesticides and other contaminants incidents; is any system in place to capture

quantified and within guidelines? What is the surface water in the event of a release, or a

EBRD Sub Sector Environmental & Social Guideline 2014 Page 18

Edible Oils Processing

Sub-sectoral Environmental and Social

Guideline: Edible Oils Processing

first flush system to capture an initial penalties, fines, major recommendations or

washdown? corrective action plans?

Check the extent of treatment/capture Does the organisation have a grievance

systems for the different types of wastewater, mechanism which allows employees to raise

workplace concerns?

including process water, surface water runoff

and cleaning water;

Are employees free to form, or join, a

workers’ organisation of their choosing?

Check if monitoring and testing is

undertaken as a requirement of operating

Check worker accommodation.

licences and the extent of compliance in

recent years;

Incident Management

Note the colour and appearance of adjacent

Check if any recent incidents have taken

water courses.

place on site involving serious injuries,

fatalities, fires/explosions, spills or gas

Pollution Control releases of ammonia or chlorine. Note

whether these incidents were investigated and

Is the facility next to any vulnerable water

staff trained.

bodies, sited in a floodplain, or close to

groundwater sources which may be

Community Complaints/Grievances

contaminated by activities?

Is a grievance mechanism in place to allow

Check the location and condition of oil and

the community to raise concerns regarding

chemical storage areas. Are these well

farming operations?

controlled, appropriately constructed and is

containment / spill clean-up equipment

Note any history of public complaints

provided?

relating to the facilities operation.

Labour Management

Investment

Check that labour standards, contracting and

Check if the business has budgeted line items

remuneration are in line with national law

and are consistent with the average for the for environment, health and safety

sector; improvements - check whether there are any

high value improvements in the business plan

Check that hours worked, including for E, H & S issues in the coming

overtime, are recorded and staff should months/years.

receive written details of hours worked and

payment received; Regulatory Compliance

Has the Company received inspections from Check if the Company has received

the local labour inspectorate in the previous inspections from the local labour, H&S or

three years? Have these resulted in any Environmental inspectorate in the previous

EBRD Sub Sector Environmental & Social Guideline 2014 Page 19

Edible Oils Processing

Sub-sectoral Environmental and Social

Guideline: Edible Oils Processing

three years and whether these have resulted o Food safety management plans;

in any penalties, fines, major

recommendations or corrective action plans. o Environmental, Health, Safety and Food

Safety audits of its operations conducted

Establish whether the company has via a third party;

undertaken a systematic, documented review

of operations against national legal o Demonstrable involvement of senior

requirements relevant to Environmental, management in environment, health &

Health, Safety and Social performance and safety, and hygiene management and

the extent of compliance with that legislation. leadership.

Management Plans

Review the operational procedures and

management plans available regarding the

control of risks. As a minimum any

business should have the following in place:

o Environmental, Health & Safety

management systems which include

operational procedures that are

communicated, implemented and

regularly reviewed (i.e. ‘live’ systems that

are used in practice, not just kept as an

office manual);

o Monitoring programmes to monitor

environmental, health & safety, and

hygiene risks (and where necessary,

testing of water, air, noise, waste

emissions etc.);

o Improvement objectives, targets and

project plans;

o A training plan for personnel to include

environmental and health and safety

issues;

o Emergency plans for environment,

occupation & community health & safety,

and food safety incidents and site security;

EBRD Sub Sector Environmental & Social Guideline 2014 Page 20

Edible Oils Processing

Sub-sectoral Environmental and Social

Guideline: Edible Oils Processing

5. References and Additional Sources

European Bank for Reconstruction and Development (EBRD). Environmental and Social Policy

May 2008. Performance Requirement 2: Labour and Working Conditions. Performance

Requirement 3: Pollution Prevention and Abatement

International Finance Corporation (IFC), Environment, Health and Safety Guidelines. Vegetable

Oil Processing, April 2007.

http://www.ifc.org/ifcext/enviro.nsf/Content/EnvironmentalGuidelines

European Union 2004, Directive 2004/35/CE of the European Parliament and of the Council of

21 April 2004 on environmental liability with regard to the prevention and remedying of

environmental damage, http://eur-lex.europa.eu/legal-

content/EN/TXT/?uri=CELEX:32004L0035

European Union 2010, Directive 2010/75/EU of the European Parliament and of the Council of

24 November 2010 on industrial emissions (integrated pollution prevention and control,

http://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32010L0075

European Union 2005, Directive 2005/20/EC of the European Parliament and of the Council of

9 March 2005 amending Directive 94/62/EC on packaging and packaging waste, http://eur-

lex.europa.eu/legal-content/EN/ALL/?uri=CELEX:32005L0020

European Union 2014, Directive 2014/52/EU of the European Parliament and of the Council of

16 April 2014 amending Directive 2011/92/EU on the assessment of the effects of certain public

and private projects on the environment, http://eur-lex.europa.eu/legal-

content/EN/TXT/?uri=CELEX:32014L0052

European Union 2000, Directive 2000/60/EC of the European Parliament and of the Council of

23 October 2000 establishing a framework for Community action in the field of water policy,

http://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32000L0060

European Union 2008, Directive 2008/50/EC of the European Parliament and of the Council of

21 May 2008 on ambient air quality and cleaner air for Europe, http://eur-

lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2008:152:0001:0044:EN:PDF

European Community 1988, Council Directive 88/344/EEC of 13 June 1988 on the

approximation of the laws of the Member States on extraction solvents used in the production of

foodstuffs and food ingredients, http://eur-

lex.europa.eu/LexUriServ/LexUriServ.do?uri=CELEX:31988L0344:EN:HTML

EBRD Sub Sector Environmental & Social Guideline 2014 Page 21

Edible Oils Processing

Sub-sectoral Environmental and Social

Guideline: Edible Oils Processing

European Union 2006, Directive 2006/42/EC of the European Parliament and of the council of

17 May 2006 on machinery, and amending Directive 95/16/EC, http://eur-

lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2006:157:0024:0086:EN:PDF

European Community 1998, Directive 98/37/EC of the European Parliament and of the

Council of 22 June 1998 on the approximation of the laws of the Member States relating to

machinery, http://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX:31998L0037

European Commission 2006, Integrated Pollution Prevention and Control, Reference Document

on Best Available Techniques in the Food, Drink and Milk Industries, August 2006,

http://eippcb.jrc.ec.europa.eu/reference/fdm.html

European Community 1992, Council Directive 92/43/EEC of 21 May 1992 on the conservation

of natural habitats and of wild fauna and flora, http://eur-

lex.europa.eu/LexUriServ/LexUriServ.do?uri=CELEX:31992L0043:EN:HTML as amended by

Council Directive 97/62/EC of 27 October 1997 adapting to technical and scientific progress

Directive 92/43/EEC on the conservation of natural habitats and of wild fauna and fauna

http://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX:31997L0062

European Union 2008, Directive 2008/112/EC of the European Parliament and of the Council

of 16 December 2008 amending Council Directives 76/768/EEC, 88/378/EEC, 1999/13/EC

and Directives 2000/53/EC, 2002/96/EC and 2004/42/EC of the European Parliament and of

the Council in order to adapt them to Regulation (EC) No 1272/2008 on classification, labelling

and packaging of substances and mixtures, http://eur-

lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2008:345:0068:0074:EN:PDF

European Community 1999, Council Directive 1999/13/EC on the limitation of emissions of

volatile organic compounds due to the use of organic solvents in certain activities and

installations, http://eur-

lex.europa.eu/LexUriServ/LexUriServ.do?uri=CONSLEG:1999L0013:19990329:EN:PDF as

amended by Directive 2004/42/CE and Directive 2008/112/EC))

European Union 2007, Council Regulation (EC) No 834/2007 of 28 June 2007 on organic

production and labelling of organic products and repealing Regulation (EEC) No 2092/91,

http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2007:189:0001:0023:EN:PDF

European Union 2002, Regulation (EC) No 178/2002 laying down the general principles and

requirements of food law, establishing the European Food Safety Authority and laying down

procedures in matters of food safety, http://eur-lex.europa.eu/legal-

content/EN/ALL/?uri=CELEX:32002R0178

EBRD Sub Sector Environmental & Social Guideline 2014 Page 22

Edible Oils Processing

Sub-sectoral Environmental and Social

Guideline: Edible Oils Processing

European Union 2007, Commission Regulation No. 1441/2007 of 5 December 2007 amending

Regulation (EC) No 273/2005 on microbiological criteria for foodstuffs, http://eur-

lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2007:322:0012:0029:EN:PDF

European Union, Regulation (EC) No 882/2004 of the European Parliament and of the Council

of 29 April 2004 on official controls performed to ensure the verification of compliance with

feed and food law, animal health and animal welfare rules, http://eur-

lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2004:165:0001:0141:EN:PDF

International Organisation for Standardisation (ISO) www.iso.org ISO14001:2004:

Environmental Management Systems – Requirements with Guidance for use. Geneva: ISO

FAO and WHO (Food and Agriculture Organization and World Health Organization).1962–

2009. Codex Alimentarius. Geneva: FAO and WHO,

http://www.codexalimentarius.net/web/index_en.jsp

ISO22000:2005: Food Safety Management System – Requirements for any organisation in the

food chain. Geneva ISO

AEA Group 2008: Guidance on VOC Substitution and Reduction for Activities Covered by the

VOC Solvents Emissions Directive - Guidance 19: Vegetable oil and animal fat extraction and

vegetable oil refining activities http://www.fediol.eu/data/VOC_Guidance.pdf

EBRD Sub Sector Environmental & Social Guideline 2014 Page 23

Edible Oils Processing

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Law of AntiquitiesDocument9 pagesLaw of AntiquitiesWellfroNo ratings yet

- ProjectClosureReport-v1 0Document83 pagesProjectClosureReport-v1 0WellfroNo ratings yet

- Environmental Impacts of MiningDocument8 pagesEnvironmental Impacts of MiningEl Shaira Rizzo100% (1)

- Urban PlanningDocument10 pagesUrban Planninghckfn aquinoNo ratings yet

- Asian PaintsDocument22 pagesAsian Paintsardiab100% (1)

- Mapeh Grade 9 First Quarter Pre-Assessment TestDocument4 pagesMapeh Grade 9 First Quarter Pre-Assessment TestDW7 EYHNo ratings yet

- Climate Report Saudi Arabia 2017Document5 pagesClimate Report Saudi Arabia 2017WellfroNo ratings yet

- San Francisco-Oakland Bay Bridge East Span Seismic Safety ProjectDocument18 pagesSan Francisco-Oakland Bay Bridge East Span Seismic Safety ProjectWellfroNo ratings yet

- 1704 New Ectoin Anti-Pollution SummaryDocument27 pages1704 New Ectoin Anti-Pollution SummaryIlham Abinya LatifNo ratings yet

- Stakeholder SeminarDocument80 pagesStakeholder SeminarWellfro100% (1)

- AirbaseDocument48 pagesAirbaseimepsystems100% (1)

- PDFDocument450 pagesPDFNodge Holanda100% (1)

- The 2021 Report of The Lancet Countdown On Health and Climate Change: Code Red For A Healthy FutureDocument44 pagesThe 2021 Report of The Lancet Countdown On Health and Climate Change: Code Red For A Healthy FutureFOX 17 NewsNo ratings yet

- Otto Andersen Auth. Unintended Consequences of Renewable Energy Problems To Be SolvedDocument103 pagesOtto Andersen Auth. Unintended Consequences of Renewable Energy Problems To Be Solvedkareem_opoNo ratings yet

- Risk Assessment Example - Mobile Offshore Unit (MOU) Relocation Operations PDFDocument18 pagesRisk Assessment Example - Mobile Offshore Unit (MOU) Relocation Operations PDFWellfro0% (1)

- Control of Resuspended Sediments in Dredging ProjectsDocument12 pagesControl of Resuspended Sediments in Dredging ProjectsWellfroNo ratings yet

- Dubai_Creek_from_commercial_dock_to_straDocument4 pagesDubai_Creek_from_commercial_dock_to_straWellfroNo ratings yet

- Ambient air quality and exposure assessment study of the Gulf Cooperation Council countries_ A critical review (Science of The Total Environment, vol. 636) (2018)Document8 pagesAmbient air quality and exposure assessment study of the Gulf Cooperation Council countries_ A critical review (Science of The Total Environment, vol. 636) (2018)WellfroNo ratings yet

- Jones_etal2015Document26 pagesJones_etal2015WellfroNo ratings yet

- Artificial Lighting at Night in Estuaries PDFDocument22 pagesArtificial Lighting at Night in Estuaries PDFWellfroNo ratings yet

- Silt Curtain Selection GuideDocument6 pagesSilt Curtain Selection GuideWellfroNo ratings yet

- Silt Curtain EffectivenessDocument2 pagesSilt Curtain EffectivenessWellfroNo ratings yet

- Project Description and MethodologyDocument14 pagesProject Description and MethodologyWellfroNo ratings yet

- Marpol Suplement 2015Document48 pagesMarpol Suplement 2015CvitaCvitićNo ratings yet

- Stakeholder Analysis ToolDocument8 pagesStakeholder Analysis ToolRichard Thodé JrNo ratings yet

- Ozone Depleting SubstancesDocument7 pagesOzone Depleting SubstancesWellfroNo ratings yet

- Brief Note - BCA Green Mark Criteria For Residential BuildingDocument23 pagesBrief Note - BCA Green Mark Criteria For Residential BuildingnsiongloongNo ratings yet

- 2nd Quarter. w4 d2 EngDocument12 pages2nd Quarter. w4 d2 EngLorenzo YapNo ratings yet

- Form 59: Vehicle Photo With Registration Plate 60 MM X 30 MMDocument1 pageForm 59: Vehicle Photo With Registration Plate 60 MM X 30 MMgyalsteenNo ratings yet

- Impact of Aviation Industry To EnvironmentDocument8 pagesImpact of Aviation Industry To EnvironmentShubham MauryaNo ratings yet

- Sciencedirect: Katarzyna Szymczyk, Marta Kadłubek Katarzyna Szymczyk, Marta KadłubekDocument9 pagesSciencedirect: Katarzyna Szymczyk, Marta Kadłubek Katarzyna Szymczyk, Marta KadłubekSevilNo ratings yet

- Acid Rain OriginalDocument6 pagesAcid Rain OriginalAvikPandeyNo ratings yet

- Evaluating The Effectiveness of Air Quality Regulations A Review of Accountability Studies and FrameworksDocument30 pagesEvaluating The Effectiveness of Air Quality Regulations A Review of Accountability Studies and FrameworksdindaNo ratings yet

- Proper Waste Management and Rate of Dengue Cases in The Residence of Barangay Malvar 7-A, Davao CityDocument36 pagesProper Waste Management and Rate of Dengue Cases in The Residence of Barangay Malvar 7-A, Davao CityLea MeaNo ratings yet

- Fenvs 10 934885Document11 pagesFenvs 10 934885Iyad GuiaNo ratings yet

- UNIT 1 Introduction To Water and Water PollutionDocument19 pagesUNIT 1 Introduction To Water and Water PollutionRG SegaranNo ratings yet

- Regulatory Impact Analysis A Primer ImpDocument16 pagesRegulatory Impact Analysis A Primer Impjavert99No ratings yet

- Air Resources Board: 20 Day of December 2008Document2 pagesAir Resources Board: 20 Day of December 2008David J SandersNo ratings yet

- Eia PDFDocument177 pagesEia PDFTengLiJinNo ratings yet

- Lynas EIA Assessment Report NTN April 13 Ok BaguihDocument30 pagesLynas EIA Assessment Report NTN April 13 Ok BaguihSyahmi Jaafar100% (1)

- Evs Notes - Rejinpaul PDFDocument261 pagesEvs Notes - Rejinpaul PDFMani100% (3)

- Vijeta 15-July2022-1Document219 pagesVijeta 15-July2022-1Danish HusainNo ratings yet

- IAN BRANDON GWAZE MSOM507 Assignment 2 MIGRAT PDFDocument12 pagesIAN BRANDON GWAZE MSOM507 Assignment 2 MIGRAT PDFIsheanesu HungweNo ratings yet

- Guideline ForDetermination of Good Engineering Practice Stacl Height (Technical Support Document For The Stack Height Regulations)Document100 pagesGuideline ForDetermination of Good Engineering Practice Stacl Height (Technical Support Document For The Stack Height Regulations)kangsungjin100% (1)

- Environmental Science Quarter 3 ModuleDocument4 pagesEnvironmental Science Quarter 3 ModuleAlexis AguilarNo ratings yet

- The Unhealthiest Places in The WorldDocument3 pagesThe Unhealthiest Places in The WorldКоцюбайло МаксимNo ratings yet

- 9 DONE Air PollutantsDocument8 pages9 DONE Air PollutantsSumaiya ImamNo ratings yet