Professional Documents

Culture Documents

Articulo Ingles Demolicion Primera Parte

Uploaded by

Jhoner AlejandroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Articulo Ingles Demolicion Primera Parte

Uploaded by

Jhoner AlejandroCopyright:

Available Formats

Demolition of Structures Using Implosion

Technology

Amrutha Mary A1, Vasudev. R2

M.Tech Student, Dept of Civil Engineering, TIST, Kochi, Kerala, India

Associate Professor, Dept Civil Engineering, TIST, Kochi, Kerala, lndia

ABSTRACT: Demolition of any structure is the process of destroying down or collapsing down of large buildings

after is useful life period with the help of some equipment. For small buildings it is a simple process with light

equipment but in case of Larger buildings it may require the use of a wrecking ball, cranes etc. Explosive

demolition is the preferred method for safely and efficiently demolishing larger structures and skyscrapers. When

explosive are used for the demolition, it is known as Implosion. The various steps involved before the demolition

process such as surveying, removal of hazardous materials, preparation of demolition plan, stability report and

the precautionary safety measures that to be taken are presented in this paper. Demolition of structures using

Implosion technique is illustrated. The main explosives used for Implosion method such as dynamites and RDX

are highlighted. The methodology, merits and demerits of the demolition using implosion is explained.

KEYWORDS: Demolition, Explosive demolition method, implosion.

I. INTRODUCTION

Every structure is designed for a life period. After that service life period its existence become very dangerous to

its occupants and surrounding buildings. The building act usually contains provisions to control demolition works

for the protection of public safety and to ensure adjoining premises and the site are made good on completion of

the demolition.

When demolition of a building takes place, the owner must inform the council and permission for the same shall

be obtained. Greenhouses, conservatories, prefabricated garages and sheds do not require permission to be

demolished'

permission for demolition is not required if building to be demolished has a volume of less than 1750 cubic feet

(49.56 cubic meters) [4]. Demolition of any structure is a ground to earth technique which means destroying down

or falling down of a building with the help of equipment, machineries, explosives or with manual techniques

without affecting the surrounding. When explosives are used for this then the demolition process are called as an

implosion.

II. GENERAL STEPS IN DEMOLITION

A. Pre-Planning of Demolition Activity

pre-planning of the Demolition activity starts with Surveying of the site. Study of different parameters of the

structure and its surroundings with structural point of view is carried out in surveying. Two types of surveying are

mainly conducted.

They are Building Surveying and structural surveying which includes the (a)'Record Drawings and (b) structural

details of

the building to be demolished.

B. Stability Report: According to Building (Administration) Regulation, the Demolition Plan must accompanied by a

Stability Report with supporting calculations. The Stability Report shall include the following parts:

(1) A report on the stability of the building to be demolished during all stages of the process.

(2) In the case when powered mechanical plants or equipment are used. a report on the stability with supporting

calculations to demonstrate the use of the plants and equipment will not render inadequate the margin of safety

of, or cause damage to any building, structure, street, land and services

(3) In the case when powered mechanical plants or equipment are used. structural calculations for all temporary

supports and bracings should be done.

(4) A report on the stability of neighboring buildings and adjoining properties.

(5) In the case when temporary or permanent supports are required to neighboring buildings, adjoining

Properties and party walls, structural calculations for these temporary and permanent supports.

(6) A report with calculations demonstrating that the demolition work will not render inadequate the margin of

safety, or cause damage to any building, structure, street, land and services.

C. Safety Measures

(a) Training and Communication: Demolition workers. including plant or equipment operators shall go through

proper job safety training and be aware of the potential hazards by attending training sessions as on-the-job

training.

(b) Equipment Maintenance: All equipment shall be examined before use. They shall be properly tested, stored

and maintained. The equipment shall be inspected daily and results of the inspection shall be recorded. A

detailed safety instruction shall be provided to cater for specific situations of the project, if necessary.

(c)Electrical Safety: A properly connected power source from a local electric utility supplier or a mobile electricity

generator shall be utilized in demolition sites. The safety requirements given in the Factories and Industrial

Undertakings (Electricity) Regulations shall be adhered to.

(d) Fire: All flammable goods shall be removed fi-om site unless they are necessary for the works involved. any

remaining flammable goods shall be stored in proper storage facilities. A11 furniture, timber, doors. etc. sha11 be

removed before any welding work is performed. Firefighting appliances shall be provided and maintained in

working conditions. The Construction Site (Safety) Regulations require the contractor to maintain in good

condition and free from defects all firefighting appliances provided in such construction site.

(e)Occupational Health: The health of workers on site shall be properly protected in accordance with the relevant

subsidiary regulations of the Factories and industrial Undertakings Ordinance and the Occupational Safety and

Health Ordinance with particular attention to areas such as: Exposure to Dust, Chemical Exposure, Heat Stress

and Ventilation, Noise Exposure, Medical and First Aid Facilities, Sanitation and Occupational Diseases.

(f) Emergency Exit Requirements in Demolition Sites: Emergency exits shall be provided during building

demolition. In case of any emergency evacuations, the emergency exit will serve as a lifeline for transportation of

injured workers. A minimum of one exit route shall be maintained and designated as the emergency exit at all

times during the demolition. Adequate lighting an<l fire extinguishing equipment shall be provided. Emergency

exit shall be properly protected, free of obstruction, and properly marked with exit signs or other indications to

clearly show the route. All workers shall be informed about the exit route.

(g) Vibration: Demolition work will cause vibration to neighboring buildings or structures to various extents,

depending on the method of demolition. The most serious vibration is caused by implosion. The effect of

vibration caused by implosion is categorized as follows: -

1.Permanent ground distortion produced by blast-induced gas pressures;

2. Vibratory settlement of foundation materials;

3. Projectile impact (blast fly rock)

4. Vibratory cracking from ground vibration or air blast. (h) Environmental Precautions

h) Air Pollution: Concrete breaking, handling of debris and hauling process are main sources of dust &om building

demolition. Dust mitigation measures complying with the Air Pollution Control (Construction Dust). Regulations

shall be adopted to minimize dust emissions. burning of waste shall not be allowed. Diesel fumes generated by

mechanical plant or equipment shall be subject to the control of the Air Pollution Control (Smoke) Regulations.

(b) Noise: Noise pollution arising from the demolition works including, but not limited to, the use of specified

powered mechanical equipment (SPME), powered mechanical equipment (PME), such as pneumatic breakers,

excavators and generators, etc., scaffolding, erection of temporary works, loading and transportation of debris,

etc. affects the workers, and the sensitive receivers in the vicinity of the demolition site. Silent type PME shall be

used to reduce noise impact as much as practicable. Demolition activity shall not be performed within the

restricted hours as established by Environmental Protection Division (EPD). Currently under the Noise Control

Ordinance, noise from the use of SPME and PME within restricted hours is governed by a Construction Noise

Permit (CNP) system.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ASTM 2493 Viscosidad - TemperaturaDocument5 pagesASTM 2493 Viscosidad - TemperaturaDiana Moscoso100% (1)

- Possibilities and ProbabilitiesDocument50 pagesPossibilities and ProbabilitiesChuckry Daligdig Maunes50% (2)

- NewTiger5 SkillsTrainer TeachersbookDocument48 pagesNewTiger5 SkillsTrainer TeachersbookA Legría F DezNo ratings yet

- II.a. Cell The Basic Unit of LifeDocument27 pagesII.a. Cell The Basic Unit of LifeDarwin NoolNo ratings yet

- Trip To Marine National Park - Narara, Jamnagar, GujratDocument5 pagesTrip To Marine National Park - Narara, Jamnagar, GujratanandnaregalNo ratings yet

- Adoption of Integrated Lean-Green-Agile Strategies For Modern Manufacturing SystemsDocument6 pagesAdoption of Integrated Lean-Green-Agile Strategies For Modern Manufacturing SystemsNuriaNo ratings yet

- Mat Mock Test Duration 40 MinsDocument4 pagesMat Mock Test Duration 40 MinsKundan JhaNo ratings yet

- Gis Based Groundwater Recharge Estimation The Case of Shinile Sub-Basin, EthiopiaDocument27 pagesGis Based Groundwater Recharge Estimation The Case of Shinile Sub-Basin, EthiopiaseidNo ratings yet

- Earth Sci 2 SG Unit 2 PDFDocument28 pagesEarth Sci 2 SG Unit 2 PDFbaileyNo ratings yet

- Courseplan OoadDocument3 pagesCourseplan OoadbazilabanuNo ratings yet

- A. B /C S 9 U: Urriculum NitsDocument2 pagesA. B /C S 9 U: Urriculum NitsBenjamin Joel BreboneriaNo ratings yet

- Booklet For of Florence NightingaleDocument3 pagesBooklet For of Florence NightingaleSopan ShindeNo ratings yet

- Unit-Iv-Memory and ForgettingDocument20 pagesUnit-Iv-Memory and ForgettingGaurav RajNo ratings yet

- Peer Tutoring Survey QuestionnaireDocument1 pagePeer Tutoring Survey QuestionnairekcapuzNo ratings yet

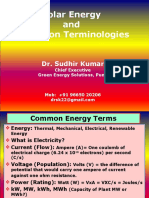

- Solar Energy and Radiation Terminologies: Dr. Sudhir KumarDocument24 pagesSolar Energy and Radiation Terminologies: Dr. Sudhir KumarAyman OsamaNo ratings yet

- Electromagnetic Lock: Application ScenarioDocument2 pagesElectromagnetic Lock: Application ScenarioZizeuPaperuNo ratings yet

- DHA Suffa University: Faculty Employment Application FormDocument5 pagesDHA Suffa University: Faculty Employment Application FormMajid KhanNo ratings yet

- Extraction and Isolation of Saponins PDFDocument2 pagesExtraction and Isolation of Saponins PDFMikeNo ratings yet

- Chinese Bench - A Research On Multi-Function Furniture DesignDocument34 pagesChinese Bench - A Research On Multi-Function Furniture Designiezhariaizi100% (1)

- ASP QuestionsDocument25 pagesASP QuestionsMudassar Bin ZaheerNo ratings yet

- 1..write A Python Program To Swap Two Numbers Using A Third VariableDocument5 pages1..write A Python Program To Swap Two Numbers Using A Third VariablesainaveenNo ratings yet

- Readings in Managerial PsychologyDocument22 pagesReadings in Managerial PsychologyHENDRIK2011No ratings yet

- 11th Physics Practical Guide Study Material English MediumDocument33 pages11th Physics Practical Guide Study Material English Mediumjeysonbegin4No ratings yet

- 44 Hemmings 2020-Owners Corporation Meeting SGM - 7064187-7064561-81S-200714 PDFDocument51 pages44 Hemmings 2020-Owners Corporation Meeting SGM - 7064187-7064561-81S-200714 PDFRayner MihailovNo ratings yet

- MSC In: Machine Learning, Systems and ControlDocument2 pagesMSC In: Machine Learning, Systems and ControlMirza HassanNo ratings yet

- Grade 6 Life Skills Exam Nov 2021Document6 pagesGrade 6 Life Skills Exam Nov 2021Siphokazi NxusaniNo ratings yet

- DLP VMVDocument4 pagesDLP VMVnoera angel montemayorNo ratings yet

- Bio 1Document4 pagesBio 1XYRUS MARAMOTNo ratings yet

- In Depth Knowledge. (See Example Question 4) Section B Is Worth 30 Out of 100 MarksDocument3 pagesIn Depth Knowledge. (See Example Question 4) Section B Is Worth 30 Out of 100 MarksCallMeSplittzNo ratings yet

- Normally Consolidated Clay Report ScriptDocument2 pagesNormally Consolidated Clay Report ScriptJames Kyle Apa-apNo ratings yet