Professional Documents

Culture Documents

Data Sheet P 550: Technical Information

Uploaded by

flasher_for_nokiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet P 550: Technical Information

Uploaded by

flasher_for_nokiaCopyright:

Available Formats

Technical Information

Approved Manufacturer acc. to

Data sheet P 550 Q

Revision 8 ISO 9001 and API-Spec. Q1

License No.

7-1-0234

1. CHEMICAL COMPOSITION

„P550“ is a special nonmagnetic, austenitic Mn-Cr-steel with a high nitrogen content.

C Mn Cr Mo N Ni

max. 0,06 20,50-21,60 18,30-20,00 min. 0,50 min. 0,60 min. 1,40

2. MECHANICAL PROPERTIES

Following mechanical properties (tested at room temperature) are achieved by a special

cold-working process over the full length of the collar:

Yield Strength (min.): OD up to 91/4“ 140 ksi 965 N/mm²

0,2%-offset method OD 91/2“ and larger 130 ksi 900 N/mm²

Tensile Strength (min.): 150 ksi 1035 N/mm²

Elongation (min.): 20% 20%

Reduction of area (min.): 50% 50%

Impact energy (min.): 60 ft.lb 82 J

Endurance Strength / N=105 (min.): ± 80 ksi ± 550 N/mm²

Hardness Brinell: 350-430 HB 350-430 HB

3. MAGNETIC PROPERTIES

Relative permeability: < 1,005.

4. CORROSION RESISTANCE

- Transgranular SCC: Prevented by special surface treatments (Hammer peening, roller

burnishing, shot peening).

- Intergranular SCC: The occurrence of material sensitization is prevented by quenching

after warmforging. Each collar is tested according to ASTM A 262, Pract.A and E, last edition.

- Pitting Corrosion: Due to a high chromium- and nitrogen content a high resistance to

pitting corrosion is given.

5. NON-DESTRUCTIVE TESTING

- Magnetic inspection: Drill collars are 100% tested by a proprietary probe-testing process

using a Förster Magnetomat 1.782. (“Hot Spot“-test). Magnetic permeability of each collar is

certified with the printout of probe-testing.

- Ultrasonic inspection: Each collar is ultrasonically inspected over 100% of the volume

according to ASTM E 114, last edition as a minimum level.

P550 Non-Magnetic Drill Collars meet all requirements of API Spec. 7.1, last edition.

All tests are carried out according to ASTM-Standards, last editions.

Prepared / released: B. Holper

Date: June, 2013

We provide the leading edge page 11

You might also like

- Data Sheet P 550: Technical InformationDocument1 pageData Sheet P 550: Technical InformationappoosdxbNo ratings yet

- 3500 LPM at 90 MTR - Diesel Engine Pump - DatasheetDocument1 page3500 LPM at 90 MTR - Diesel Engine Pump - Datasheetjaved777780No ratings yet

- CR Mo 4Document2 pagesCR Mo 4Mohsen ParpinchiNo ratings yet

- Wima FKP 4Document9 pagesWima FKP 4M-BasicNo ratings yet

- Documents PDFDocument22 pagesDocuments PDFwalid kawsarNo ratings yet

- Flush PB Black 1NO 1NCDocument2 pagesFlush PB Black 1NO 1NCLogan Marquez AguayoNo ratings yet

- Tai Tech HCB4532KF 800T90 - C357029Document21 pagesTai Tech HCB4532KF 800T90 - C357029otiapleNo ratings yet

- PIEZO BUZZER SPECIFICATION AND TESTINGDocument5 pagesPIEZO BUZZER SPECIFICATION AND TESTINGg_1234No ratings yet

- b41588 A3478 T - Ae4634ffc6Document12 pagesb41588 A3478 T - Ae4634ffc6kerusacba_2011No ratings yet

- Part Description AD500-9 TO Order # 3001380: First Sensor APD Data SheetDocument3 pagesPart Description AD500-9 TO Order # 3001380: First Sensor APD Data SheetAnish KumarNo ratings yet

- Wima FKP 1: Special Features Electrical DataDocument10 pagesWima FKP 1: Special Features Electrical DataАлексей АндрияшNo ratings yet

- Zhongyuan Internatoinal Material Specification: ZyicoDocument2 pagesZhongyuan Internatoinal Material Specification: ZyicoAbozar BilanNo ratings yet

- Capacitores - WIMA - FKP - 1 Del VFDDocument12 pagesCapacitores - WIMA - FKP - 1 Del VFDAlex RamirezNo ratings yet

- CN-TDS-1911-03-S3110-OKDocument1 pageCN-TDS-1911-03-S3110-OKNelly DavedNo ratings yet

- TDC 09 - R1 - S690 QL & Weldox 700Document2 pagesTDC 09 - R1 - S690 QL & Weldox 700Thennarasu VelloreNo ratings yet

- Material 1.4057 PDFDocument3 pagesMaterial 1.4057 PDFengfaridmalkNo ratings yet

- Protect motors with NH DIN dual indication fuse linksDocument7 pagesProtect motors with NH DIN dual indication fuse linkschinwe njokanmaNo ratings yet

- Policarbonato Macizo Polygal Plazit PDFDocument4 pagesPolicarbonato Macizo Polygal Plazit PDFnicolas peraltaNo ratings yet

- Microsoft Word - SP - X21 - 485 - 480 - Ds - UK - A4 - TE - 539439ADocument1 pageMicrosoft Word - SP - X21 - 485 - 480 - Ds - UK - A4 - TE - 539439AJesus Alonso Camacho CastilloNo ratings yet

- ConnectorDocument6 pagesConnectorapiruck sukjingNo ratings yet

- Dbs50e S5ek00500Document6 pagesDbs50e S5ek00500ganiNo ratings yet

- 1PH8165-3FF13-0AC1 Datasheet enDocument1 page1PH8165-3FF13-0AC1 Datasheet enVictorNo ratings yet

- General-Purpose Limit Switch HL-5000: Ordering InformationDocument7 pagesGeneral-Purpose Limit Switch HL-5000: Ordering InformationBudKhNo ratings yet

- 1 N 56Document4 pages1 N 56Ankadi Sikari ReddyNo ratings yet

- Profile 45 250 Sandwich Panel Techincal DatasheetDocument2 pagesProfile 45 250 Sandwich Panel Techincal DatasheetEle SultanaNo ratings yet

- Material Specification Sheet Saarstahl - 27Mncrb5-2Document1 pageMaterial Specification Sheet Saarstahl - 27Mncrb5-2rakeshNo ratings yet

- 20NiMo9-7 - Liga MetálicaDocument4 pages20NiMo9-7 - Liga MetálicalutherblackNo ratings yet

- Wima CapacitorDocument11 pagesWima Capacitorchiranjib_kNo ratings yet

- TeSys Control Relays - CA3KN405FDDocument2 pagesTeSys Control Relays - CA3KN405FDsherub wangdiNo ratings yet

- 1 8550-34CrAlNi710Document2 pages1 8550-34CrAlNi710Michel PortalNo ratings yet

- PB 30.5Mm Enclosure Ss 3 Holes 3/4in Conduit Entry Catalogue NoDocument3 pagesPB 30.5Mm Enclosure Ss 3 Holes 3/4in Conduit Entry Catalogue NoLogan Marquez AguayoNo ratings yet

- OMEC - 11kW-4POLEDocument1 pageOMEC - 11kW-4POLETariq KhurshaidiNo ratings yet

- Baumer Tdp02 Tdpz02 Ds enDocument4 pagesBaumer Tdp02 Tdpz02 Ds enQamar ZiaNo ratings yet

- MKP-X2 interference suppression capacitorDocument2 pagesMKP-X2 interference suppression capacitorgunsakNo ratings yet

- Sick Pbt-Rb250sg1ssnuma0zDocument7 pagesSick Pbt-Rb250sg1ssnuma0zendangfarid hidayatNo ratings yet

- LC1DT60A6FD: Product DatasheetDocument3 pagesLC1DT60A6FD: Product DatasheetGiri BabuNo ratings yet

- Three Phase Induction Motor Data SheetDocument1 pageThree Phase Induction Motor Data SheetĐức NguyễnNo ratings yet

- Polim-H02sdDocument4 pagesPolim-H02sdkatak.chanNo ratings yet

- Copper Cu-Dhp / Sf-Cu: Page 1/2Document2 pagesCopper Cu-Dhp / Sf-Cu: Page 1/2gemilanglpNo ratings yet

- F3294 Phe840mDocument2 pagesF3294 Phe840msdancer75No ratings yet

- Specification For Galvanized Steel: Raw Material SpecificationsDocument2 pagesSpecification For Galvanized Steel: Raw Material SpecificationsAnonymous aBZfewNo ratings yet

- LED Street Light Spec T1B Series 40w-120wDocument10 pagesLED Street Light Spec T1B Series 40w-120wLuminhomeLightingNo ratings yet

- Vishay Dale: FeaturesDocument4 pagesVishay Dale: FeaturesFouquetNo ratings yet

- 36NiCrMo16 PDFDocument2 pages36NiCrMo16 PDFAmy GriffinNo ratings yet

- GroupCataloguePage 1303Document4 pagesGroupCataloguePage 1303DhairyaNo ratings yet

- Sanyou Relays: Miniature High Power RelayDocument3 pagesSanyou Relays: Miniature High Power RelayTV Cinaqui ContiNo ratings yet

- Saarstahl 58CrV4 steel sheetDocument1 pageSaarstahl 58CrV4 steel sheetAndy HuffNo ratings yet

- Datasheet Interruptor SchneiderDocument2 pagesDatasheet Interruptor SchneideraarmanjcNo ratings yet

- Industrial Relays of Small Dimensions: Contact DataDocument10 pagesIndustrial Relays of Small Dimensions: Contact DataNelson VillalbaNo ratings yet

- 4340f51215cab87d59552f746c22a108Document2 pages4340f51215cab87d59552f746c22a108Azad ArashhaNo ratings yet

- Miniature Circuit Breaker - S200 - 4P - C - 10 Ampere: Product-DetailsDocument6 pagesMiniature Circuit Breaker - S200 - 4P - C - 10 Ampere: Product-DetailsbilalNo ratings yet

- TechnicalSpecification OPGW-24G652DDocument6 pagesTechnicalSpecification OPGW-24G652DMrugesh Samsung.m31sNo ratings yet

- MCS 0402, MCT 0603, MCU 0805, MCA 1206 - Professional: Vishay BeyschlagDocument13 pagesMCS 0402, MCT 0603, MCU 0805, MCA 1206 - Professional: Vishay BeyschlaglalithkumartNo ratings yet

- T20B and Piranha T20 Dose Probes Technical SpecsDocument4 pagesT20B and Piranha T20 Dose Probes Technical SpecsDhoy GaviolaNo ratings yet

- Product Data Sheet 6FX2001-2GB00: Date: 08/06/2014 Subject To ModificationsDocument3 pagesProduct Data Sheet 6FX2001-2GB00: Date: 08/06/2014 Subject To ModificationsNhatQuangNguyenNo ratings yet

- WEG 132kW SpecificationDocument8 pagesWEG 132kW Specificationbonginkosi mathunjwaNo ratings yet

- Attachment A - 4 Circuit Breakers 150 KV 3150 - 40 KaDocument3 pagesAttachment A - 4 Circuit Breakers 150 KV 3150 - 40 KaSouth ParkNo ratings yet

- PA66-GF30LANXESS Durethan AKV30 000000 ISO ENDocument3 pagesPA66-GF30LANXESS Durethan AKV30 000000 ISO ENKalipse FerreiraNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Electronics – From Theory Into Practice: Applied Electricity and Electronics DivisionFrom EverandElectronics – From Theory Into Practice: Applied Electricity and Electronics DivisionRating: 5 out of 5 stars5/5 (1)

- LC1D115P7: Product Data SheetDocument3 pagesLC1D115P7: Product Data Sheetflasher_for_nokiaNo ratings yet

- Hydril Annular BOP1Document2 pagesHydril Annular BOP1Abde EsselamNo ratings yet

- Astm A479Document7 pagesAstm A479Martin RomeroNo ratings yet

- TD 670 676 680 8PG BW Oct2015Document8 pagesTD 670 676 680 8PG BW Oct2015flasher_for_nokiaNo ratings yet

- CX1020 - Basic CPU Module: CX1020-0xxx CX1020-0xxx CX1020-0xxxDocument2 pagesCX1020 - Basic CPU Module: CX1020-0xxx CX1020-0xxx CX1020-0xxxflasher_for_nokiaNo ratings yet

- Choke and Kill Manifold Brochure PDFDocument12 pagesChoke and Kill Manifold Brochure PDFtaloslamomia9417100% (1)

- Laboport: Mini Diaphragm Vacuum Pumps and CompressorsDocument2 pagesLaboport: Mini Diaphragm Vacuum Pumps and Compressorsflasher_for_nokiaNo ratings yet

- Bimetal Thermometer For The Process Industry Per EN 13190, Premium Version Model 55Document13 pagesBimetal Thermometer For The Process Industry Per EN 13190, Premium Version Model 55flasher_for_nokiaNo ratings yet

- Bill of Materials for Gate ValveDocument6 pagesBill of Materials for Gate Valveflasher_for_nokiaNo ratings yet

- HDLS Series Switches: Installation Instructions For TheDocument4 pagesHDLS Series Switches: Installation Instructions For Theflasher_for_nokiaNo ratings yet

- ANSI Flanges Dimensions Specs Grades ClassesDocument23 pagesANSI Flanges Dimensions Specs Grades ClassesVenkatesh GangadharNo ratings yet

- 5.000 HWDP With NC50 (4.5IF) (6.625 X 3.000 TJ) Integral SpiralDocument1 page5.000 HWDP With NC50 (4.5IF) (6.625 X 3.000 TJ) Integral SpiralFranklin Jose Almera AcostaNo ratings yet

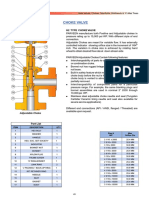

- Choke ParveenDocument3 pagesChoke ParveenYM Edwin Gil BeltranNo ratings yet

- Astm A479Document7 pagesAstm A479Martin RomeroNo ratings yet

- Hydril Annular BOP1Document2 pagesHydril Annular BOP1Abde EsselamNo ratings yet

- USDA Engineering Classification of Rock MaterialsDocument61 pagesUSDA Engineering Classification of Rock MaterialsTanNo ratings yet

- Thermowell For Thermometers ManualDocument40 pagesThermowell For Thermometers Manualflasher_for_nokiaNo ratings yet

- 5.000 HWDP With NC50 (4.5IF) (6.625 X 3.000 TJ) Integral SpiralDocument1 page5.000 HWDP With NC50 (4.5IF) (6.625 X 3.000 TJ) Integral SpiralFranklin Jose Almera AcostaNo ratings yet

- API 7K Certified Mud Pump Parts ListDocument23 pagesAPI 7K Certified Mud Pump Parts Listflasher_for_nokiaNo ratings yet

- Doniflon 2010: Properties Appropriate Industries & ApplicationsDocument2 pagesDoniflon 2010: Properties Appropriate Industries & Applicationsflasher_for_nokiaNo ratings yet

- Rfb7 - de - en Triple Mas 6000Document2 pagesRfb7 - de - en Triple Mas 6000Miguel GonzalezNo ratings yet

- rfb7 de en PDFDocument2 pagesrfb7 de en PDFflasher_for_nokiaNo ratings yet

- Manual Bomba de LodosDocument37 pagesManual Bomba de LodosJuan RuizNo ratings yet

- Assessing Rock Compressive Strength and Predicting Formation Drillability Using Sonic, Gamma & Density LogsDocument7 pagesAssessing Rock Compressive Strength and Predicting Formation Drillability Using Sonic, Gamma & Density Logsflasher_for_nokiaNo ratings yet

- Ifi 115Document1 pageIfi 115Vinay PawarNo ratings yet

- Rfb7 - de - en Triple Mas 6000Document2 pagesRfb7 - de - en Triple Mas 6000Miguel GonzalezNo ratings yet

- Mud Pump Consumables - enDocument24 pagesMud Pump Consumables - enflasher_for_nokia100% (1)

- Duraflo Composite Oemduea Mongoose PsDocument2 pagesDuraflo Composite Oemduea Mongoose Psflasher_for_nokiaNo ratings yet

- 12 Point Flange Screws Technical SpecificationsDocument1 page12 Point Flange Screws Technical Specificationsflasher_for_nokiaNo ratings yet

- uPVC Pressure Fittings GuideDocument17 pagesuPVC Pressure Fittings GuidepubudunishanthaNo ratings yet

- Home Assignment PV 4 2010Document1 pageHome Assignment PV 4 2010Chaitanya GodseNo ratings yet

- Selectrode: Chromium Carbide Manufacturers of Custom Welding Lines For ResaleDocument3 pagesSelectrode: Chromium Carbide Manufacturers of Custom Welding Lines For ResalesareddytejaaeNo ratings yet

- Usiten 375-1Document6 pagesUsiten 375-1Gerardo Rodríguez100% (2)

- U.S. NRC Guide on ASME Code Case Acceptability for Nuclear Power Plant ComponentsDocument59 pagesU.S. NRC Guide on ASME Code Case Acceptability for Nuclear Power Plant ComponentsSivadol VongmongkolNo ratings yet

- IS: 4984 Wall Thickness & Weight Chart of Pipes For Material Grade PE-100Document1 pageIS: 4984 Wall Thickness & Weight Chart of Pipes For Material Grade PE-100Deputy Executive Engineeer RWS & S Nrpm100% (2)

- Document2015 09 21 - 169Document22 pagesDocument2015 09 21 - 169PreethamNo ratings yet

- Fpso - Specifications For Topsides Piping SystemsDocument25 pagesFpso - Specifications For Topsides Piping Systemsdndudc100% (1)

- MAURER Elastomeric BearingsDocument2 pagesMAURER Elastomeric Bearingsabdelrahman emadNo ratings yet

- A 957 - A 957M - 15aDocument9 pagesA 957 - A 957M - 15aPavan KumarNo ratings yet

- Polyolefin ElastomerDocument6 pagesPolyolefin ElastomerHari SuthanNo ratings yet

- Plot No - C-98 SEC-NSG FINAL-ModelDocument1 pagePlot No - C-98 SEC-NSG FINAL-ModelSAKET TYAGINo ratings yet

- Compressive and Shear Strengths of Straw Log Bearing WallDocument21 pagesCompressive and Shear Strengths of Straw Log Bearing WallPatti StouterNo ratings yet

- Performance of Geopolymer Concrete Reinforced With FRP Rebars - A ReviewDocument7 pagesPerformance of Geopolymer Concrete Reinforced With FRP Rebars - A ReviewSushil Singh BAGHELNo ratings yet

- Leakage Acceptance Rates Comparison Metal & Soft Seated Valves Api 598/api 6D/Mss Sp-61/Fci 70-2Document5 pagesLeakage Acceptance Rates Comparison Metal & Soft Seated Valves Api 598/api 6D/Mss Sp-61/Fci 70-2Ashfaq AnwerNo ratings yet

- Milling Time CalculationDocument16 pagesMilling Time CalculationJaka Sembung Bawa GolokNo ratings yet

- Transparent ConcreteDocument26 pagesTransparent Concretekapil more67% (3)

- Grinding Machine Operation: Arranged byDocument12 pagesGrinding Machine Operation: Arranged byMhmmd Adam100% (1)

- PPO SlideDocument29 pagesPPO SlideRadhashyam GiriNo ratings yet

- 167 PDFDocument11 pages167 PDFFlorin CosarcaNo ratings yet

- Metal Working in The Ancient WorldDocument39 pagesMetal Working in The Ancient WorldDavor100% (2)

- Cast Iron Price Calculator - Gray Iron, Ductile IronDocument4 pagesCast Iron Price Calculator - Gray Iron, Ductile IronKrishna Mohan T.RNo ratings yet

- 06 Eurocodes Steel Workshop WALDDocument136 pages06 Eurocodes Steel Workshop WALDTiago Cunha100% (1)

- Applications of Recycled and Waste MaterialsDocument17 pagesApplications of Recycled and Waste MaterialsanonymNo ratings yet

- 914 Rotisserie PlansDocument8 pages914 Rotisserie Planskenfish1No ratings yet

- Bolt Grade Markings and Strength Chart - Head Markings, Material, Proof, Yield, Tensile StrengthDocument2 pagesBolt Grade Markings and Strength Chart - Head Markings, Material, Proof, Yield, Tensile StrengthHamilton Fábio Borges50% (2)

- Bitumode APP P 180,200,250Document2 pagesBitumode APP P 180,200,250Raha Trading and ContactingNo ratings yet

- EIE Students Presentation on Corrosion Types & ProtectionDocument9 pagesEIE Students Presentation on Corrosion Types & ProtectionVenkatamarnidiNo ratings yet

- 4 Types of Heat Exchanger Failures ArticleDocument6 pages4 Types of Heat Exchanger Failures ArticleAamir KhanNo ratings yet

- Cost Material CalculatorDocument10 pagesCost Material Calculatoranamik00180% (5)