Professional Documents

Culture Documents

OCW BMM3643 Assessment Bulk Metal Deformation

Uploaded by

ramadan slim0 ratings0% found this document useful (0 votes)

61 views7 pagesocw

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentocw

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

61 views7 pagesOCW BMM3643 Assessment Bulk Metal Deformation

Uploaded by

ramadan slimocw

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

BMM3643 Manufacturing Processes

Bulk Metal Deformation

Individual Assignment 4

by

Dr Mas Ayu Bt Hassan

Faculty of Mechanical Engineering

masszee@ump.edu.my

BMM3643 Manufacturing Processes by Mas Ayu H.

Individual Assignment 4 - Bulk Metal

Deformation

• Aims

– Able to apply formulae depends on various types of forging force

– Able to analyze and apply true stress versus true strain graph in

forging force calculation

• Expected Outcomes

– Understand and able to apply the suitable formulae depends on

types of forging processes

BMM3643 Manufacturing Processes by Mas Ayu H.

Example 1: Open die forging force

1. A solid cylindrical slug made of 304 stainless steel is 150 mm in diameter

and 100 mm high. It is reduced in height by 50% at room temperature by

open-die forging with flat dies. Assuming that the coefficient of friction is

0.2, calculate the forging force at the end of the stroke.

Solution:

The forging force at the end of the stroke: F = Yfπr2 (1 + (2μr/3h))

Final dimensions: Final height, h = 100/2 = 50 mm,

To get the final radius, r

volume constancy: volumes before deformation = volumes after deformation

( )( 75 )^ 2 (100 ) ( )( r )^ 2 ( 50 ) r 106 mm

ln

100

50

0.69

BMM3643 Manufacturing Processes by Mas Ayu H.

Example 1: Open die forging force

(continue)

Solution:

From the graph, the flow stress for 304 stainless steel at a true strain of 0.69

is about 1000 MPa. (forging force must be in units N and m)

F = Yfπr2 (1 + (2μr/3h))

F 1000 106 0.106 1

2 20.20.106

30.050

4.5 107 N 45 MN

BMM3643 Manufacturing Processes by Mas Ayu H.

Example 2: Drawing force

1. A round wire made of a perfectly plastic material with a yield stress

of 200 MPa is being drawn from a diameter of 2.5 to 1.5 mm in a

draw die of 15°. Let the coefficient of friction be 0.1. Estimate the

drawing force required for both friction and frictionless conditions.

Solution:

𝜋

d0 = 2.5mm, so the initial cross-sectional area is 𝐴0 = 𝑑20 = 4.909 mm2

4

df = 1.5mm, Af = 1.767mm2, F = YavgAf In Ao/Af = 361 N

Therefore, µ = 0.1, α = 15° = 0.262 radians,

F = YavgAf [(1+ µ/α) In (Ao/Af) + (2/3)α]

= 560N

BMM3643 Manufacturing Processes by Mas Ayu H.

Individual Assignment 4

1. A round billet made of 70-30 brass is extruded at a temperature of 675°C.

The billet diameter is 125 mm and the diameter of the extrusion is 50

mm. Calculate the extrusion force required if extrusion constant, k, is 250

MPa.

2. Assume that a round slug of 10 mm in diameter and made of a metal

with Yavg = 350 MPa is reduced to a final diameter of 7 mm by cold

extrusion. Find the force F.

BMM3643 Manufacturing Processes by Mas Ayu H.

Individual Assignment 4 Format

Please remember to include the questions given in the

assignments. Cover page of the assignment should include:

1.Your Name & No. Matric

2.Section

3.Lecturer’s Name

4.Submission date

Late submission also will be penalized.

BMM3643 Manufacturing Processes by Mas Ayu H.

You might also like

- Tutorial 3 Bulk DeformationDocument2 pagesTutorial 3 Bulk DeformationSawai PariharNo ratings yet

- E.2.2 Sheet Metal WorkingDocument18 pagesE.2.2 Sheet Metal WorkingMesfin SisayNo ratings yet

- Assignment ProcessDocument2 pagesAssignment ProcessMuhammad Nazmul Hassan KhanNo ratings yet

- HW1Document3 pagesHW1peer highwayNo ratings yet

- r09222502 Mechanics of SolidsDocument9 pagesr09222502 Mechanics of SolidsNida Bagoyboy NatichoNo ratings yet

- CE411 Midterm ReviewDocument20 pagesCE411 Midterm ReviewVios, Allen Rafael M.No ratings yet

- PS Steel - Set 1Document4 pagesPS Steel - Set 1Jovanie CabanigNo ratings yet

- Draw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IDocument9 pagesDraw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IKomma Hema100% (1)

- TA202 AssignmentsDocument1 pageTA202 AssignmentsBrajesh kumarNo ratings yet

- Assignment 1Document1 pageAssignment 1Abdul RafayNo ratings yet

- Solution MPDocument5 pagesSolution MPSatheeskumarNo ratings yet

- ForgingDocument37 pagesForgingchris mushunjeNo ratings yet

- Question Bank: Module 1:design For Static StrengthDocument22 pagesQuestion Bank: Module 1:design For Static Strengthcrazy hjNo ratings yet

- Fum and A Mentals of Metal FormingDocument6 pagesFum and A Mentals of Metal Formingaksgupta24No ratings yet

- Manufacturing Processes - Assignment 2Document1 pageManufacturing Processes - Assignment 2Ahmed YaseenNo ratings yet

- Som Assignments PDFDocument12 pagesSom Assignments PDFLaxmi HattiholiNo ratings yet

- Beamsaet 1Document3 pagesBeamsaet 1omar_sool2No ratings yet

- 114 DM 052017Document2 pages114 DM 052017Ravindra JeeviNo ratings yet

- Assignment# 03: BlankingDocument1 pageAssignment# 03: BlankingengineerNo ratings yet

- Tension Members: Version 2 CE IIT, KharagpurDocument24 pagesTension Members: Version 2 CE IIT, KharagpurolomizanaNo ratings yet

- Answer The Stresses Are 69.92 Mpa and - 38.67 Mpa and The Neutral Axis Is 38.6 MM From The Tensile EdgeDocument3 pagesAnswer The Stresses Are 69.92 Mpa and - 38.67 Mpa and The Neutral Axis Is 38.6 MM From The Tensile Edgelayiro2No ratings yet

- 3 Hours / 70 Marks: Seat NoDocument5 pages3 Hours / 70 Marks: Seat NoMadao111No ratings yet

- ME 352 - All Problem Class - 14-18 BatchDocument125 pagesME 352 - All Problem Class - 14-18 BatchEntertainment GamingNo ratings yet

- Problems: Problem 1 Problem 2Document2 pagesProblems: Problem 1 Problem 2Lily Margareth ArrietaNo ratings yet

- WWW - Manaresults.Co - In: (Common To Me, MCT, MMT, Ae, Ame, MSNT)Document3 pagesWWW - Manaresults.Co - In: (Common To Me, MCT, MMT, Ae, Ame, MSNT)mahendra babu mekalaNo ratings yet

- AMD Tutorial ME CADCAM 2022-23Document6 pagesAMD Tutorial ME CADCAM 2022-23rip111176No ratings yet

- Final Exam Key AnswerDocument6 pagesFinal Exam Key Answergirma worku100% (1)

- Local PWHTDocument6 pagesLocal PWHTcmeshibu100% (1)

- Module 2 Full PDFDocument66 pagesModule 2 Full PDFDHEESHNA DILEEP 200545No ratings yet

- Production Conventional Question and AnswerDocument10 pagesProduction Conventional Question and AnswerRamesh ChandraNo ratings yet

- SOM3601 Assignment 2Document3 pagesSOM3601 Assignment 2Elendu Emmanuel ChigozieNo ratings yet

- Tutorial - 1: Dr. N.Gobinath SMEC, VIT ChennaiDocument11 pagesTutorial - 1: Dr. N.Gobinath SMEC, VIT Chennaishoovam123No ratings yet

- G For The Material Is 82 GN/m2. If The I-Section Is Replaced by A T-Section Made of TheDocument6 pagesG For The Material Is 82 GN/m2. If The I-Section Is Replaced by A T-Section Made of Theክበር ተመስጌንNo ratings yet

- ME 303 Study Set PDFDocument44 pagesME 303 Study Set PDFFajar RumantoNo ratings yet

- Problem 1 Ce Board Nov 2011, Nov 2013: Answer: 150mpa, 119.4mpa, 51.69mpaDocument4 pagesProblem 1 Ce Board Nov 2011, Nov 2013: Answer: 150mpa, 119.4mpa, 51.69mpaLester John Precillas100% (1)

- Amd Tutorial Me Cadcam 2017Document5 pagesAmd Tutorial Me Cadcam 2017rip111176No ratings yet

- HW2 ADocument2 pagesHW2 Ajambu99No ratings yet

- Smlab Manual - MechanicalDocument46 pagesSmlab Manual - MechanicalSwarnava MukherjeeNo ratings yet

- Stress and StrainDocument13 pagesStress and StrainMuruganandam RamadassNo ratings yet

- ME 338 Manufacturing Processes II HW#1Document3 pagesME 338 Manufacturing Processes II HW#1jambu99No ratings yet

- MA2004 - Manufacturing Processes: Tutorial 3 - Sheet Metalworking (Semester 1 AY2015-2016)Document4 pagesMA2004 - Manufacturing Processes: Tutorial 3 - Sheet Metalworking (Semester 1 AY2015-2016)Kok Keat TanNo ratings yet

- Problems in Fracture Mechanics: Problem: 1Document38 pagesProblems in Fracture Mechanics: Problem: 1andiNo ratings yet

- QUIZ (Each Question Carries 2 Marks, 5x2 10 Marks)Document1 pageQUIZ (Each Question Carries 2 Marks, 5x2 10 Marks)sutha_me20098282No ratings yet

- Assignment 6Document2 pagesAssignment 6Vasanth BhaskarNo ratings yet

- Metal Forming 2Document5 pagesMetal Forming 2aksgupta24No ratings yet

- Machines ElementsDocument72 pagesMachines ElementsAref ManicheNo ratings yet

- Bending PDFDocument1 pageBending PDFAhmed TarekNo ratings yet

- Tutorials 2Document3 pagesTutorials 2Daemaro Liv Guud BremmerNo ratings yet

- Extrusion and Drawing PDFDocument16 pagesExtrusion and Drawing PDFAravindhan AnbalaganNo ratings yet

- Mechanical Engineering DepartmentDocument2 pagesMechanical Engineering DepartmentArjit Goswami100% (1)

- Assignment3forming Solutions 121213110849 Phpapp02Document4 pagesAssignment3forming Solutions 121213110849 Phpapp02Renaldi Khaesar KumaraNo ratings yet

- Material Yr1 - Tutorial 6Document16 pagesMaterial Yr1 - Tutorial 6Ahmed TahaNo ratings yet

- PR Pembentukan 2-DikonversiDocument2 pagesPR Pembentukan 2-Dikonversivansyah 01No ratings yet

- Problems and Solutions in Fracture MechanicsDocument24 pagesProblems and Solutions in Fracture MechanicsKumar Saheb86% (109)

- HW3 ADocument2 pagesHW3 Ajambu99No ratings yet

- Torrico ReinforcedConcrete 01 PDFDocument8 pagesTorrico ReinforcedConcrete 01 PDFNajib A. CasanNo ratings yet

- Principal Stress and Strain TutorialDocument1 pagePrincipal Stress and Strain TutorialJay BhavsarNo ratings yet

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- 114 Gram 52 Gram: Editt1Document1 page114 Gram 52 Gram: Editt1ramadan slimNo ratings yet

- Edit 44Document1 pageEdit 44ramadan slimNo ratings yet

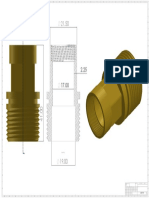

- Gas Ball Valve Part1Document1 pageGas Ball Valve Part1ramadan slimNo ratings yet

- 51 Gram 110 Gram: SCALE:5:1 Sheet 1 of 1 WeightDocument1 page51 Gram 110 Gram: SCALE:5:1 Sheet 1 of 1 Weightramadan slimNo ratings yet

- Gas Ball Valve Part 7Document1 pageGas Ball Valve Part 7ramadan slimNo ratings yet

- Material:: Drawn CHK'D Appv'D MFG Q.ADocument1 pageMaterial:: Drawn CHK'D Appv'D MFG Q.Aramadan slimNo ratings yet

- Gas Ball Valve Part 2Document1 pageGas Ball Valve Part 2ramadan slimNo ratings yet

- Speciality Graphite Materials: FOR Continuous CastingDocument6 pagesSpeciality Graphite Materials: FOR Continuous Castingramadan slimNo ratings yet

- Continuous Casting of Copper Compounds: Metall-RubrikDocument4 pagesContinuous Casting of Copper Compounds: Metall-Rubrikramadan slimNo ratings yet

- Determination of The Technological Parameters Process For Continuously Cast Brass IngotDocument7 pagesDetermination of The Technological Parameters Process For Continuously Cast Brass Ingotramadan slimNo ratings yet

- Domestic Gas Meter Accessories Data SheetDocument3 pagesDomestic Gas Meter Accessories Data Sheetramadan slimNo ratings yet

- Surge Analysis and Design - Case StudyDocument10 pagesSurge Analysis and Design - Case StudyRaghuveer Rao PallepatiNo ratings yet

- Petroleum Fluid Phase Behavior PDFDocument437 pagesPetroleum Fluid Phase Behavior PDFGeorge Meier100% (1)

- Ball Check Valve Numerical Simulation and Experimental Validation of The Cavitating FowDocument11 pagesBall Check Valve Numerical Simulation and Experimental Validation of The Cavitating FowpohanisirNo ratings yet

- Uponor Ecofl Ex Pre-Insulated Pipes: Technical InformationDocument128 pagesUponor Ecofl Ex Pre-Insulated Pipes: Technical Informationjamppajoo2No ratings yet

- Soal Pra PralaDocument20 pagesSoal Pra PralaYusud0% (1)

- IICHEDocument12 pagesIICHESuresh astroNo ratings yet

- Lecture 1 - Urban Drainage System ComponentDocument36 pagesLecture 1 - Urban Drainage System Componentsinatra DNo ratings yet

- Plunger ValveDocument5 pagesPlunger ValveVignesh TamilanNo ratings yet

- Super Fractionation CH 41Document10 pagesSuper Fractionation CH 41Abhimanyu SharmaNo ratings yet

- Lesson 5 Soil Aeration and TemperatureDocument34 pagesLesson 5 Soil Aeration and TemperatureJosue A. Sespene Jr.No ratings yet

- AC - System - Diagnostics - Poster - Loop Components TemperatureDocument1 pageAC - System - Diagnostics - Poster - Loop Components TemperatureKello jamesNo ratings yet

- Thermal Oil Heater1Document31 pagesThermal Oil Heater1Evans MandinyanyaNo ratings yet

- Heat Loss From A Pipe Calculator - Engineers EdgeDocument2 pagesHeat Loss From A Pipe Calculator - Engineers EdgeJA KNo ratings yet

- Practical Uses Kinetic Seperation in Sample System DesignDocument14 pagesPractical Uses Kinetic Seperation in Sample System DesignSamit ShaikhNo ratings yet

- Compressed Air Best Practice Guide For IndustryDocument22 pagesCompressed Air Best Practice Guide For IndustrySharon LambertNo ratings yet

- 006 API610 PumpsDocument110 pages006 API610 Pumpskaveh fadaeiNo ratings yet

- Catalogo de Filtros Separador de Aire (Mann+hummel) PDFDocument64 pagesCatalogo de Filtros Separador de Aire (Mann+hummel) PDFMikel10200% (1)

- Course Outline Detail 2016Document2 pagesCourse Outline Detail 2016Chong Cherng WongNo ratings yet

- Liquid PumpsDocument16 pagesLiquid PumpsBruno BrepohlNo ratings yet

- Refrigeration CycleDocument19 pagesRefrigeration CycleCherryl De Asis-PanesNo ratings yet

- Flood Mitigation Project Area of Angoori River Cross SectionDocument8 pagesFlood Mitigation Project Area of Angoori River Cross SectionankitNo ratings yet

- Stik in SlowDocument12 pagesStik in SlowSofiane SophianeNo ratings yet

- F.J. Gutiérrez Ortiz, A. Serrera, S. Galera, P. Ollero: Sciverse SciencedirectDocument13 pagesF.J. Gutiérrez Ortiz, A. Serrera, S. Galera, P. Ollero: Sciverse SciencedirectJuanPabloGuerreroNo ratings yet

- Tutorial 1Document3 pagesTutorial 1Muhammad AriffNo ratings yet

- 12th PhysucsvipDocument3 pages12th Physucsvipphysics a2No ratings yet

- Sheet - 01 - FluidDocument66 pagesSheet - 01 - FluidMayank kr. jhaNo ratings yet

- FM-I. Lect 11Document6 pagesFM-I. Lect 11Hassan ZahidNo ratings yet

- r32 PT ChartDocument2 pagesr32 PT ChartnadaNo ratings yet

- A Rational Approach To The Hydraulic Design of Pipe ConduitsDocument15 pagesA Rational Approach To The Hydraulic Design of Pipe ConduitsZeBocaoNo ratings yet

- Rainwater Infiltration: by Norma Khoury-NoldeDocument8 pagesRainwater Infiltration: by Norma Khoury-NoldeNiong DavidNo ratings yet