Professional Documents

Culture Documents

Inventory Management - 1448289399 PDF

Uploaded by

Hardik Panchal0 ratings0% found this document useful (0 votes)

7 views4 pagesOriginal Title

Inventory Management_1448289399.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views4 pagesInventory Management - 1448289399 PDF

Uploaded by

Hardik PanchalCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

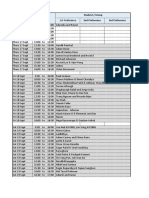

Inventory

Management

1. Demand Forecasting

1.1. Parts with planned and unplanned demands

1.1.1. Historical data

1.1.1.1. Stock Value

1.1.1.2. Parts price

1.1.1.3. Usage Number

1.1.1.4. Purchasing Number

1.1.2. Parts Classification

1.1.2.1. Maintenance schedule

1.1.2.1.1. Predictive maintenane

1.1.2.1.2. Preventive Maintenance

1.1.2.1.3. Corrective Maintenance

1.1.2.2. Price

1.1.2.2.1. High

1.1.2.2.2. Medium

1.1.2.2.3. Low

1.1.2.3. Critical part

1.1.2.3.1. Critical

1.1.2.3.2. Partially critical

1.1.2.3.3. Non-critical

1.1.2.4. Consumption of part

1.1.2.4.1. fast moving

1.1.2.4.2. Slow moving

1.1.2.4.3. Dead stock

2. Supply Management

2.1. Supplier availability

2.1.1. Multiple supply source for parts

2.1.2. Contracts with external suppliers

2.1.2.1. Contract setting up in cost efficient

2.1.2.2. Parts can be replenished at any time

2.2. Supply parameters

2.2.1. Repair lead time

2.2.1.1. Picking

2.2.1.2. Transport

2.2.1.3. Storage

2.2.2. Procurement lead time

2.2.2.1. Picking

2.2.2.2. Transport

2.2.2.3. Storage

3. Maintaining minimum and maximum quantity

3.1. Parts classification

3.1.1. Parts consumption

3.1.1.1. Develop minimum and maximum stocks list

3.1.1.1.1. Automatically place order if stock less than

minimum order

3.1.2. Critical

3.1.2.1. Develop mimimum and maximjm stocks list

3.1.2.1.1. Automatically place order if stock less than

minimum order

4. Inventory control

4.1. Stocking strategy

4.1.1. Based on supply characteristic

4.1.1.1. Critical parts

4.1.1.2. Cost

4.1.1.3. Parts consumption

4.2. Replishment policy

4.2.1. Determine frequency for placing order

4.2.2. Selection of warehouse for replishment ordered

4.2.2.1. Plant warehouse

4.2.2.2. Main storage warehouse

4.3. Replishment policy parameters

4.3.1. Order quantity

4.3.2. Discounts

4.3.3. Uncertain in demand and cost

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Assessment Item 1 v4.0Document2 pagesAssessment Item 1 v4.0Hardik PanchalNo ratings yet

- Improve Rural Public Transport IndiaDocument16 pagesImprove Rural Public Transport IndiaHardik PanchalNo ratings yet

- Improve Rural Public Transport IndiaDocument16 pagesImprove Rural Public Transport IndiaHardik PanchalNo ratings yet

- 1.1 Make-or-Buy Decision: PMN605 Strategic Project ProcurementDocument43 pages1.1 Make-or-Buy Decision: PMN605 Strategic Project ProcurementHardik PanchalNo ratings yet

- Strategic Plan by SameerDocument12 pagesStrategic Plan by SameerHardik PanchalNo ratings yet

- Case Study Report On Redevelopment of Wankhede Cricket StadiumDocument16 pagesCase Study Report On Redevelopment of Wankhede Cricket StadiumHardik PanchalNo ratings yet

- Group 8 Heat Excahnger ReportDocument35 pagesGroup 8 Heat Excahnger ReportHardik PanchalNo ratings yet

- Assessment Item 1 v4.0Document2 pagesAssessment Item 1 v4.0Hardik PanchalNo ratings yet

- Case Study Report - Statue of Unity - Assessment - 2cDocument24 pagesCase Study Report - Statue of Unity - Assessment - 2cHardik Panchal100% (1)

- Case Study Report On Redevelopment of Wankhede Cricket StadiumDocument7 pagesCase Study Report On Redevelopment of Wankhede Cricket StadiumHardik PanchalNo ratings yet

- Day Time Student / Group 2nd Preference 3rd PreferenceDocument2 pagesDay Time Student / Group 2nd Preference 3rd PreferenceHardik PanchalNo ratings yet

- Research Topic - Investigation Via The Literature: Assessment Item 1ADocument9 pagesResearch Topic - Investigation Via The Literature: Assessment Item 1AHardik PanchalNo ratings yet

- Group 8 Heat Excahnger ReportDocument35 pagesGroup 8 Heat Excahnger ReportHardik PanchalNo ratings yet

- Wankhede PDFDocument8 pagesWankhede PDFShubham BhandariNo ratings yet

- Strategic Plan by SameerDocument12 pagesStrategic Plan by SameerHardik PanchalNo ratings yet

- PMN605 Assessment 2 Brief 2019 S2 v20190712Document7 pagesPMN605 Assessment 2 Brief 2019 S2 v20190712Hardik PanchalNo ratings yet

- Inventory Management Practices and Productivity of Large Manufacturing FirmsDocument92 pagesInventory Management Practices and Productivity of Large Manufacturing FirmsHardik PanchalNo ratings yet

- Project ProposalDocument10 pagesProject ProposalHardik PanchalNo ratings yet

- Inventory Management - 1448289399 PDFDocument4 pagesInventory Management - 1448289399 PDFHardik PanchalNo ratings yet

- Con Ict Resolution To Project Performance: Procedia - Social and Behavioral Sciences July 2015Document11 pagesCon Ict Resolution To Project Performance: Procedia - Social and Behavioral Sciences July 2015Hardik PanchalNo ratings yet

- GapsDocument1 pageGapsHardik PanchalNo ratings yet

- 4 1aDocument226 pages4 1ahydroturbinesNo ratings yet

- Project ProposalDocument10 pagesProject ProposalHardik PanchalNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)