Professional Documents

Culture Documents

Elzinc ASS V 4.1.02 Eng PDF

Elzinc ASS V 4.1.02 Eng PDF

Uploaded by

Dragoș Alexandru FodoreanuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Elzinc ASS V 4.1.02 Eng PDF

Elzinc ASS V 4.1.02 Eng PDF

Uploaded by

Dragoș Alexandru FodoreanuCopyright:

Available Formats

®

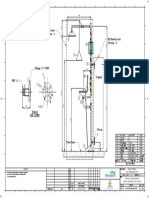

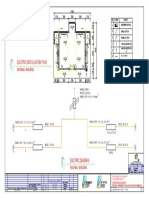

Traditional systems - Angle standing seam (vertical design) 01

ASS V 4.1.02 Front vented split capping - rear 'T' plate.

B

1 6

4

4

1

A

1 1 2 6

≥

4 60mm minimum

10

≥20mm

All dimensions are indicative unless specified on the drawing

Scale 1/5 Sheet thickness may be exaggerated for clarity

Notes:

· 'A' shows the top return fold for traditional 'sheet' cladding. 1. elZinc® cladding

· 'B' shows the top return fold for long strip cladding. 2. Membrane

· In the absence of local or national regulations, it is recommended that the 3. Structural underlay

coping overlap the cladding by a minimum of 60mm. 4. Folded galvanised steel profiles

· Generic structural details are given for indicative purposes only. 5. elZinc® perforated sheet

6. elZinc® retention profile

7. Insulation

8. Wooden batten

9. Wall bracket

10. Substrate

elZinc® Asturiana de Laminados S.A.

The information contained in this document-drawing- has a purely informative function and been elaborated with the

intention of assisting building professionals in regard to the installation of elZinc® cladding systems.It is the responsability of Tel. +34 984 116 332 Pol. Ind. de Olloniego, Parcela C1

the architect, building contractor and installer in any case to ensure the validity of the specific details employed on each

project. Asla-elZinc® rejects any responsibility due to direct or indirect damage that may arise from the use of the Institut Bauen Fax. +34 985 493 202 33660 Olloniego Asturias, Spain

information contained in this document SUD und Umwelt e.V.

www.elzinc.es elzinc@aslazinc.com

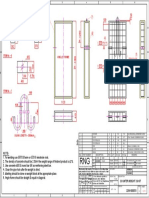

®

Traditional systems - Angle standing seam (vertical design) 01

ASS V 4.1.02 Front vented split capping - rear 'T' plate.

B

1 2 3 6

4

4

1

A

1 2 3 6

4 60mm minimum

10

≥20mm

All dimensions are indicative unless specified on the drawing

Scale 1/5 Sheet thickness may be exaggerated for clarity

Notes:

· 'A' shows the top return fold for traditional 'sheet' cladding. 1. elZinc® cladding

· 'B' shows the top return fold for long strip cladding. 2. Membrane

· In the absence of local or national regulations, it is recommended that the 3. Structural underlay

coping overlap the cladding by a minimum of 60mm. 4. Folded galvanised steel profiles

· Generic structural details are given for indicative purposes only. 5. elZinc® perforated sheet

6. elZinc® retention profile

7. Insulation

8. Wooden batten

9. Wall bracket

10. Substrate

elZinc® Asturiana de Laminados S.A.

The information contained in this document-drawing- has a purely informative function and been elaborated with the

intention of assisting building professionals in regard to the installation of elZinc® cladding systems.It is the responsability of Tel. +34 984 116 332 Pol. Ind. de Olloniego, Parcela C1

the architect, building contractor and installer in any case to ensure the validity of the specific details employed on each

project. Asla-elZinc® rejects any responsibility due to direct or indirect damage that may arise from the use of the Institut Bauen Fax. +34 985 493 202 33660 Olloniego Asturias, Spain

information contained in this document SUD und Umwelt e.V.

www.elzinc.es elzinc@aslazinc.com

You might also like

- Against NatureDocument6 pagesAgainst NatureAshly Shay100% (3)

- T 176Document9 pagesT 176ashkansoheylNo ratings yet

- Mini Project Report FinalDocument24 pagesMini Project Report FinalPrathamesh Parit100% (1)

- BackyardGardening (NSTP Project)Document66 pagesBackyardGardening (NSTP Project)Aireen Chavez100% (4)

- Elzinc ASS V 4.1.03 Eng PDFDocument2 pagesElzinc ASS V 4.1.03 Eng PDFDragoș Alexandru FodoreanuNo ratings yet

- Elzinc ASS V 4.1.04 Eng PDFDocument2 pagesElzinc ASS V 4.1.04 Eng PDFDragoș Alexandru FodoreanuNo ratings yet

- Elzinc DLSS 3.4.04 Eng PDFDocument2 pagesElzinc DLSS 3.4.04 Eng PDFDragoș Alexandru FodoreanuNo ratings yet

- CS-10030 - HDFS Assembly DetailsDocument1 pageCS-10030 - HDFS Assembly DetailsRoberto DiazNo ratings yet

- PFI Housing Filter Cartridge High FlowDocument3 pagesPFI Housing Filter Cartridge High Flowbennypartono407No ratings yet

- Wasabi 900E: Scale 1:1Document2 pagesWasabi 900E: Scale 1:1Роман ЛабаNo ratings yet

- Wasabi900e PDFDocument2 pagesWasabi900e PDFСергей КалгановNo ratings yet

- Wasabi900e PDFDocument2 pagesWasabi900e PDFСергей КалгановNo ratings yet

- P23-1072956-NWD-001 - NW TG Exhaust Ductings Shipping Skid + MTO - Rev 1Document13 pagesP23-1072956-NWD-001 - NW TG Exhaust Ductings Shipping Skid + MTO - Rev 1Anoop KavirajanNo ratings yet

- Civil - SOR - 2019 20 Pages 11 41Document484 pagesCivil - SOR - 2019 20 Pages 11 41jns 22495No ratings yet

- Aluminium 2Document1 pageAluminium 2Istvan DedeNo ratings yet

- Micrometer Heads Series 110 Differential Screw Translatorextra Fine Feeding TypeDocument1 pageMicrometer Heads Series 110 Differential Screw Translatorextra Fine Feeding TypeshahinNo ratings yet

- DEORE Rear Derailleur: Super Long CageDocument1 pageDEORE Rear Derailleur: Super Long CageFerhatNo ratings yet

- Wasabi 1300 FDocument5 pagesWasabi 1300 Fmerbiansyah7No ratings yet

- QT-22-00839807-1 Terminal Box Drawing 1HSE230057-251Document1 pageQT-22-00839807-1 Terminal Box Drawing 1HSE230057-251IVANNo ratings yet

- Volledige 2D TekeningDocument1 pageVolledige 2D TekeningGuidoNo ratings yet

- Knife DesignDocument4 pagesKnife DesignE. Manuel Cerrón AngelesNo ratings yet

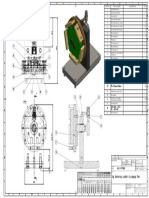

- Drawing Submission of AssemblyDocument1 pageDrawing Submission of AssemblyNirav MachhiNo ratings yet

- Serie-K EN 03 PDFDocument26 pagesSerie-K EN 03 PDFMarcinNo ratings yet

- 9750 RTL Saf DWG 0104 B Safety ShowerDocument1 page9750 RTL Saf DWG 0104 B Safety ShowerAgung PrasetyooNo ratings yet

- Alim Knit (BD) LTD.: Coagulation Tank With AgitatorDocument1 pageAlim Knit (BD) LTD.: Coagulation Tank With AgitatorKamrul HasanNo ratings yet

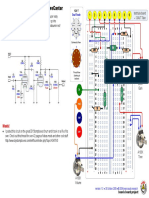

- TTB ValvecasterDocument1 pageTTB ValvecasterFernando de LuccaNo ratings yet

- Iff Mode S Iff Mode S: Mat. Acrylic, Black Matte 1eaDocument1 pageIff Mode S Iff Mode S: Mat. Acrylic, Black Matte 1eaAlfianti RizkyNo ratings yet

- Caja de Terminales Del Transformador de Corriente ABB IMB 145Document1 pageCaja de Terminales Del Transformador de Corriente ABB IMB 145Floyd MGNo ratings yet

- Elzinc ASS V 1.2.1.01a Beng PDFDocument1 pageElzinc ASS V 1.2.1.01a Beng PDFparhstudioNo ratings yet

- 09 G K2 01 REV00 General LayoutDocument1 page09 G K2 01 REV00 General LayoutSvetlana TNo ratings yet

- 153 Parts List 150Document16 pages153 Parts List 150silenkodmitrij33No ratings yet

- Counter Weight 3 - 3TDocument1 pageCounter Weight 3 - 3TsrijithNo ratings yet

- JSF-6011 Jiangsu Zhongtian Technology Co., LTD.: Indicate The Diameter of PoleDocument1 pageJSF-6011 Jiangsu Zhongtian Technology Co., LTD.: Indicate The Diameter of PoleRicardo RuizNo ratings yet

- OPen-Kinlong Window CatalogueDocument212 pagesOPen-Kinlong Window Cataloguesiju1974100% (1)

- RRHBDocument1 pageRRHBEdwinDiane TandayuNo ratings yet

- Detail Pos C FixDocument1 pageDetail Pos C FixSAIFULLAHNo ratings yet

- Boundary Boundary: Builder CellarDocument1 pageBoundary Boundary: Builder CellarAnde BhanuNo ratings yet

- C13.02.20.00.0.00.B - Modification Set 50-72''Document1 pageC13.02.20.00.0.00.B - Modification Set 50-72''Ar ZanNo ratings yet

- Isometric 1:3: 242-45L Large Base Padlockable Detail Drawing Right Hand Shaft ProtrusionDocument1 pageIsometric 1:3: 242-45L Large Base Padlockable Detail Drawing Right Hand Shaft ProtrusionhakanNo ratings yet

- D-Me-Ms-152r0 Side Wheel of Spillway Service GateDocument1 pageD-Me-Ms-152r0 Side Wheel of Spillway Service Gateolalekan fatai RotimiNo ratings yet

- Pillai College of Engineering, New PanvelDocument1 pagePillai College of Engineering, New PanvelajayNo ratings yet

- Betonicon Katalogus 2017 - EN - 2Document52 pagesBetonicon Katalogus 2017 - EN - 2Tolcsvay CsabaNo ratings yet

- t2407 EngDocument5 pagest2407 Engd.store102No ratings yet

- B (1: 1) Typ.: Safety FencesDocument1 pageB (1: 1) Typ.: Safety Fencesphong viNo ratings yet

- Apollo: Mid-Tower Tempered Glass Gaming CaseDocument2 pagesApollo: Mid-Tower Tempered Glass Gaming CaseAlberto Fernandez PinillaNo ratings yet

- SMPS Half Bridge IR2153 2.0 - EsquemaDocument1 pageSMPS Half Bridge IR2153 2.0 - Esquemaleosedf0% (3)

- Assembly Jig PolygoneDocument1 pageAssembly Jig PolygoneClaudius Barenta BarusNo ratings yet

- 6906 001 Easy Glass Pro Fix Top Mount 2Document1 page6906 001 Easy Glass Pro Fix Top Mount 2mahmoud morsyNo ratings yet

- MUSHOLADocument1 pageMUSHOLAriogeskyNo ratings yet

- Plans BPC Toiture Zone LMPDocument11 pagesPlans BPC Toiture Zone LMPOwono owono OseeNo ratings yet

- elZinc-DLSS-3 2 1 04-Eng PDFDocument2 pageselZinc-DLSS-3 2 1 04-Eng PDFDragoș Alexandru FodoreanuNo ratings yet

- Part No. (2pcs) Part No. (4pcs) : 2. All Plate Minimum 6mm or AboveDocument1 pagePart No. (2pcs) Part No. (4pcs) : 2. All Plate Minimum 6mm or AboveIwan AbdurahmanNo ratings yet

- 6115 0049 PDFDocument1 page6115 0049 PDFErica CarolineNo ratings yet

- UntitledDocument18 pagesUntitledMuh Amin Alif100% (1)

- Scales and SheetsDocument4 pagesScales and SheetsbehrangarefNo ratings yet

- Canadian Solar-Datasheet-All-Black CS6K-MS v5.57 ENDocument2 pagesCanadian Solar-Datasheet-All-Black CS6K-MS v5.57 ENParamesh KumarNo ratings yet

- 03-GRP Mub BucketDocument1 page03-GRP Mub BucketNWA INT General Trading & ContractingNo ratings yet

- GF1 40x100 3 Buc: P.Th. Start Regional ProiectDocument1 pageGF1 40x100 3 Buc: P.Th. Start Regional ProiectPaius AdrianNo ratings yet

- Transformer Construction Assembly: JS ELDocument1 pageTransformer Construction Assembly: JS ELStephany PolinarNo ratings yet

- Canadian - Solar Datasheet CS6PP - Quartech 265 PDFDocument2 pagesCanadian - Solar Datasheet CS6PP - Quartech 265 PDFZelaoBonetsNo ratings yet

- Item 06Document1 pageItem 06Vasudev DabholkarNo ratings yet

- SXK 107 21261 Universal Antenna Support KitDocument1 pageSXK 107 21261 Universal Antenna Support Kitalexandra jahenNo ratings yet

- Www. Ser Ax. F R: Pali ER MonoblocDocument14 pagesWww. Ser Ax. F R: Pali ER MonoblocMuzammil AbbasNo ratings yet

- Fill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredFrom EverandFill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredNo ratings yet

- Elzinc ASS V 4.1.04 Eng PDFDocument2 pagesElzinc ASS V 4.1.04 Eng PDFDragoș Alexandru FodoreanuNo ratings yet

- Elzinc ASS V 4.1.03 Eng PDFDocument2 pagesElzinc ASS V 4.1.03 Eng PDFDragoș Alexandru FodoreanuNo ratings yet

- Elzinc DLSS 3.4.04 Eng PDFDocument2 pagesElzinc DLSS 3.4.04 Eng PDFDragoș Alexandru FodoreanuNo ratings yet

- elZinc-DLSS-3 2 1 04-Eng PDFDocument2 pageselZinc-DLSS-3 2 1 04-Eng PDFDragoș Alexandru FodoreanuNo ratings yet

- GOLD/Strip Au-1: A Peroxide/Bifluoride Based Gold StripperDocument3 pagesGOLD/Strip Au-1: A Peroxide/Bifluoride Based Gold StripperAbu NahlNo ratings yet

- General Pumps - Firefighting RangeDocument32 pagesGeneral Pumps - Firefighting RangeSigma MansorNo ratings yet

- Earth Moving Machines-A GlanceDocument27 pagesEarth Moving Machines-A GlanceVinod YbNo ratings yet

- Presentasi Indolakto Ahu Dan ChillerDocument16 pagesPresentasi Indolakto Ahu Dan ChillerVincent JonathanNo ratings yet

- JyothishaPrakaasham MeenaVijayaDocument52 pagesJyothishaPrakaasham MeenaVijayaAnonymous 5mSMeP2j100% (1)

- Asera - BKM Id CardDocument35 pagesAsera - BKM Id CardYos JagusNo ratings yet

- ece轮胎文件Document37 pagesece轮胎文件张正No ratings yet

- Iofi Code of Practice 5th RevisionDocument60 pagesIofi Code of Practice 5th RevisionVALERIA HERRERA CHALARCANo ratings yet

- Farkhanda Anwar W/O Muhammad Farooq 43 Iqbal Block Ittifaq Town LHRDocument1 pageFarkhanda Anwar W/O Muhammad Farooq 43 Iqbal Block Ittifaq Town LHRFoad AhmedNo ratings yet

- 2019 May MA202-E - Ktu QbankDocument2 pages2019 May MA202-E - Ktu QbankThe WolfNo ratings yet

- Waiting For GodotDocument2 pagesWaiting For GodotIoana OlteanuNo ratings yet

- Fluffy Hair - Recherche GoogleDocument1 pageFluffy Hair - Recherche GoogleEliot MaillouxNo ratings yet

- Efficiency, Economy Polymer Metering SystemDocument12 pagesEfficiency, Economy Polymer Metering Systemjuanper01No ratings yet

- Workshop On PCB EtchingDocument2 pagesWorkshop On PCB EtchingBhaskar RaminiNo ratings yet

- 湖北省武汉外国语学校2023 2024学年高一上学期阶段性诊断测试英语试卷Document9 pages湖北省武汉外国语学校2023 2024学年高一上学期阶段性诊断测试英语试卷yun xingNo ratings yet

- EDITED Health9 q1 Mod1Document17 pagesEDITED Health9 q1 Mod1Mary CrisNo ratings yet

- "A Highly Skilled Workforce Is A Must ... ": - Rohan Gulati, Projects Director, Sundex Process Engineers Pvt. LTDDocument2 pages"A Highly Skilled Workforce Is A Must ... ": - Rohan Gulati, Projects Director, Sundex Process Engineers Pvt. LTDPrashant Bansod100% (1)

- Airlaw and Airworthiness Reviewer SheetDocument16 pagesAirlaw and Airworthiness Reviewer SheetJose MercadoNo ratings yet

- Switch Box SbuDocument3 pagesSwitch Box SbuJOHNNo ratings yet

- Attachment 1 PDFDocument2 pagesAttachment 1 PDFHuy DoanNo ratings yet

- Hyperglycemia in Pregnant Ladies and Its Outcome Out in The Opd, Labor Ward, Gynecology and Obstetrics, Lady Atichison Hospital, LahoreDocument7 pagesHyperglycemia in Pregnant Ladies and Its Outcome Out in The Opd, Labor Ward, Gynecology and Obstetrics, Lady Atichison Hospital, LahoreiajpsNo ratings yet

- Korg Pa1X Service ManualDocument81 pagesKorg Pa1X Service Manualdougcobb100% (3)

- MY20 Lexus UX BrochureDocument25 pagesMY20 Lexus UX BrochureEddwim BeltranNo ratings yet

- Thesis About Zero Waste ManagementDocument6 pagesThesis About Zero Waste Managementpattyjosephpittsburgh100% (2)

- Katalog KLINGER Sight GlassDocument8 pagesKatalog KLINGER Sight GlassismailadmfNo ratings yet

- Business PlanDocument46 pagesBusiness PlanJhon Fernan MadolidNo ratings yet