Professional Documents

Culture Documents

JJicable11 0009 Final PDF

Uploaded by

Mothafukin MorrisseyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JJicable11 0009 Final PDF

Uploaded by

Mothafukin MorrisseyCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/281295551

FIRST PRACTICAL UTILITY IMPLEMENTATIONS OF MONITORED WITHSTAND

DIAGNOSTICS IN THE USA

Conference Paper · June 2011

CITATIONS READS

3 49

8 authors, including:

Nigel Hampton Jean Carlos Hernandez Mejia

Georgia Institute of Technology Georgia Institute of Technology

47 PUBLICATIONS 240 CITATIONS 22 PUBLICATIONS 1,683 CITATIONS

SEE PROFILE SEE PROFILE

Joshua Perkel

Georgia Institute of Technology

38 PUBLICATIONS 109 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Cable Diagnostic Focused Initiative View project

ULA Research View project

All content following this page was uploaded by Jean Carlos Hernandez Mejia on 28 August 2015.

The user has requested enhancement of the downloaded file.

Close and Return

A.10.2 8th International Conference on Insulated Power Cables A.10.2

FIRST PRACTICAL UTILITY IMPLEMENTATIONS OF MONITORED WITHSTAND

DIAGNOSTICS IN THE USA

Chris L FLETCHER (1) Nigel HAMPTON (2), Jean Carlos HERNANDEZ (3), Jeff HESSE (4),

Michael G PEARMAN (5), Joshua PERKEL (2) C Tim WALL (6), Walter ZENGER (7)

1 - Duke, Charlotte, USA clfletcher@dukeenergy.com

2 - NEETRAC, Atlanta, GA, USA, nigel.hampton@neetrac.gatech.edu, josh.perkel@neetrac.gatech.edu

3 - Universidad de Los Andes, Mérida, Mérida, Venezuela, hmjeanc@ula.ve

4 - Duke, Cincinnatti, USA jeff.hesse@duke-energy.com

5 - Georgia Power, Atlanta, USA MGPEARMA@southernco.com

6 - Alabama Power, Birmingham, USA CTWALL@southernco.com

7 - Pacific Gas & Electric, San Francisco, USA WxZ2@pge.com

ABSTRACT Dielectric Loss does bring considerable and useful

information to the utility engineer.

Hipot or voltage proof tests have long been used to

assure the health of cable systems in the factory and This paper describes

when commissioning. One of the concerns with this • Background to Monitored Withstand approaches

approach is that there is no way to judge the quality of the • Differences associated with the metrics used for

Pass, ie did the system barely survive or was there a Monitored Withstands in comparison to the more

respectable margin. This paper shows how this problem

has been practically addressed in US utilities with an normal pure diagnostics

approach which is termed “Monitored Withstand”. The • Approaches for determining critical values for the

protocols and the test philosophies are discussed. A monitored features

number of case studies are discussed together which • Decision tools for interpretations

some reflections on future activities in this arena. • Utility and Laboratory Case Studies including follow

ups on system performance

KEYWORDS

Diagnostic Techniques, Very Low Frequency (VLF),

MONITORED WITHSTAND TESTS

Tan Delta, Decision Tools Simple Withstand tests are proof tests that apply voltage

above the normal operating voltage to stress the cable

INTRODUCTION system in a prescribed manner for a set time [1 - 5].

Monitoring a property during a withstand (or Proof) test These tests are similar to those applied to new

has been proposed as a more complete diagnostic over accessories or cables in the factory where they provide

simple non monitored withstand or single diagnostics the purchaser with assurance that the component can

(Leakage, PD, Tan Delta etc) [1 - 5]. This paper describes withstand a defined voltage. An alternative and more

some of the first practical implementations of this sophisticated implementation of the Simple Withstand

approach in the US and provides the collated results to approach requires that, in addition to its surviving the

date. voltage stress, a property of the system be measured and

monitored. This implementation of a withstand test, called

Proof or withstand tests have been used for a very long Monitored Withstand, is discussed in this section.

time in the cable industry and find their origins in the well

known routine tests carried out in accessory and cable One of the drawbacks of Simple Withstand tests is that

factories. Although this test continues to serve the there is no straightforward way to estimate the “Pass”

industry well, when a Simple Withstand is implemented in margin – once a test (say 30 min at 2 U0) is completed, it

the field users continue to be concerned by three issues: is impossible to differentiate among those passing

1. There is no way to estimate the quality of the cable segments. That is, it is impossible to distinguish the

system, and hence the risk of failure, prior to the segments that would survive 120 min from those that

application of the proof voltage. would have only survived 40 min. Thus, it is useful to

2. There is no way to adjust the extent of the test (either employ the concept of a Monitored Withstand Test

by decreasing or increasing) according to the quality whereby a dielectric property or discharge characteristic is

of the cable system monitored to provide additional data. There are four ways

3. There is no way to judge the quality of the pass these data are useful in making decisions during the test:

should the cable system support the proof voltage ie - Provide an estimate of the “Pass” margin.

was the pass a good one or a marginal one. - Enable a utility to stop a test after a short time if the

monitored property appeared close to imminent

It had been suggested that if a diagnostic parameter, such failure on test, thereby allowing the required

as dielectric loss, leakage or partial discharge, were remediation work to take place at a convenient

monitored during a proof test then all of the three issues (lowest cost) time.

noted above might be addressed. Consequently since - Enable a utility to stop a test early if the monitored

2008 the authors have been conducting Monitored property provided definitive evidence of good

Withstand tests on utility systems using very low performance, thereby increasing the number of tests

frequency (VLF) waveforms to assess the practicality of that could be completed and improving the overall

the initial hypothesis. Experience has shown that the efficiency of field testing.

Monitored Withstand whether using Partial Discharge or

Jicable’11 – 19 – 23 June 2011, Versailles - France

Close and Return

A.10.2 8th International Conference on Insulated Power Cables A.10.2

- Enable a utility to extend a test if the monitored the test it is clear that the loss increased right up to the

property provided indications that the “Pass” margin time of failure. The retest after repair shows much

was not sufficiently large, thereby focusing test improved (lowered) dielectric features in the ramp and

resources on sections that present the most concern. stable values in the hold period. In this case the utility was

able to implement a shortened test time. It is important to

In a Simple Withstand test, the applied voltage is raised to note that these data were one of the earliest collected and

a prescribed level, usually 1.5 to 2.5 times the nominal it has since become clear that the shortened time was too

circuit operating voltage for a prescribed time. The short and that the current minimum is 15 minutes; down

purpose is to cause weak points in the circuit to fail during from the 30 minutes clearly recommended by IEEE400.2

the elevated voltage application when the circuit is not [2, 5]. Furthermore it is instructive to note that although

supplying customers and when the available energy the dielectric performance is improved after the first failure

(which may be related to the safety risk) is considerably and repair, the remaining cable system is not returned to

lower. Testing occurs at a time when the impact of a the state of a new cable, where the loss and the voltage

failure (if it occurs) is low and repairs can be made quickly stability would be much better.

and cost effectively.

When performing a Monitored Withstand test, a dielectric 0 0

or discharge property is monitored during the withstand First Test Retest After Failure

period (Figure 1). The data and interpretation are

available in real time during the test so that the decisions 100

outlined above might be made. The dielectric or discharge

values monitored are similar to those described in earlier

Die le c t ric Lo s s [E- 3]

Cable Failure

sections. However, their implementation and interpretation

differs due to the requirement of a fixed voltage and a

relatively long period of voltage application. Within these 10 Voltage Ramp Voltage Hold

constraints, Leakage Current, Partial Discharge

(magnitude and repetition rate) and Tan δ (stability and

magnitude) might readily be used as monitors. Voltage

[pu]

0.5

1.0

1 1.5

1.7

Initial evaluation before Monitored Withstand test

-200 -100 0 100 200 -200 -100 0 100 200

Monit ored Propert y [A r b Units]

Time of Monitored Withstand (Secs)

A pplied Voltage [Uo]

Figure 2 Monitored Withstand (Dielectric Loss) on an

aged XLPE cable system before (left) and after (right)

failure.

1

REPORTING AND INTERPRETATION

Variable

Monitored Withstand results fall into two classes:

Voltage (Uo)

Monitor o Pass – no action required

0

0 5 10

o Not Pass – action required that may include “Further

Time (mins) Study”

Consequently, there are two ways a cable system might

“Not Pass” a Monitored Withstand:

Figure 1: Schematic of a Monitored Withstand Test

(black) with Optional Diagnostic Measurement (red) o Dielectric puncture

No dielectric puncture AND non-compliant

In Figure 2, the schematic also includes a commonly

information from the monitored property:

implemented Monitored Withstand test sequence – a

o Rapid increase anytime during the test

stepped increase in voltage and a hold period. The

Steady upward trend at a moderate level

critical part of the test is the measurement and

Instability (widely varying data)

interpretation during the withstand (constant voltage)

High magnitude

phase. The step / ramp in voltage allows an evaluation

before the start of the withstand test. This approach is

valuable in that it enables the field engineers to assess On the other hand, there is only one way in which a cable

the condition of the cable system before embarking on the system may “Pass” a Monitored Withstand test: no

Monitored Withstand test. dielectric puncture and compliant information from the

monitored property:

A Monitored Withstand (Dielectric Loss) test on an aged

XLPE cable system is shown by way of an example in o Stable (narrowly varying data)

Figure 2 before (left) and after (right) failure. Inspection of o Low magnitude

the Voltage Hold area shows the evolution of the loss. In

the first test the diectric loss features in the step already At this stage, it is instructive to examine the differences

showed that the cable system was degraded, but the between the interpretations of standard Dielectric Loss

utility elected to proceed to the withstand. In this opart of measurements compared to the assessment of the same

Jicable’11 – 19 – 23 June 2011, Versailles - France

Close and Return

A.10.2 8th International Conference on Insulated Power Cables A.10.2

property in a Monitored Withstand test. Work within the instability rather than the absolute value of the stability.

CDFI has suggested the following hierarchy for Dielectric

Loss measurement interpretation, when not used in the Feedback indicates that the approach detailed in Table 1

Monitored Withstand mode is (ranked from most important is quite a standard hierarchy for those using Monitored

to least important): Withstand programs employing Dielectric Loss. It is

o Stability within a voltage step. In the CDFI, stability is important to note that the attributes are similar for the

assessed by the standard deviation on Tan δ Ramp and Hold Phases but that the levels will be quite

measured during each step. Other methods for different due to the differences in the voltages and times

stability assessment methods may also be used. of application. Consequently, we believe it is likely that the

o Tip Up (difference in the mean value of Tan δ at two above hierarchy for assessment of Tan δ can be

selected voltages). generalized for any monitored property (such as Leakage

o Tan δ (mean value at U0). Current and PD for all voltage sources except Damped

AC):

o Trend within the monitored period. These are likely to

When used in the Monitoring mode, the constant voltage be categorical attributes: flat, upward trend,

employed does not permit the assessment of the Tip Up. downward trend, etc. Stability (by how much did it

However, this information can be available if a voltage change) within the monitored period.

ramp is used on the way to the withstand voltage level o Monitored property (mean value at withstand

(Figure 1). Otherwise, Tip Up cannot form part of the voltage).

standard hierarchy for Monitored Withstand.

There are similar issues with the mean Tan δ. A mean ESTABLISHING CRITICAL LEVELS WITH

Tan δ can be computed for the entire withstand period of MULTIPLE FEATURES

the test. However, since this is a Monitored Withstand

test, testing occurs at voltages above U0, the voltage This section describes the preliminary effort to develop

commonly used for standard Tan δ assessments. The knowledge rules to help interpret Monitored Withstand /

concept of mean Tan δ is useful even at this higher Dielectric Loss results. This is accomplished in the same

voltage, but the critical values for assessment cannot be manner as that employed for Tan Delta measurements,

the same as those used for Tan δ at U0. In fact, these namely the collation and the interpretation of a wide range

values are likely to be higher than those used for the of data obtained from service measurements on utility

standard Tan δ assessment (Table 2). systems. Figure 3 shows the distributions (fitted – 3

parameter Weibull and empirical) for the Standard

In the approach detailed here the stability has been Deviation (overall for 30 minutes) for field tests on PILC

assessed by considering the difference between initial cables. In this figure the data are ranked from smallest

and 10 minute cases. 10 minutes has been chosen in that (best performers) to largers (poorest performers) and the

it is sufficiently long to determine the underlying trend, yet rank positions are plotted against the Standard Deviation.

sufficient time remains for the user to make an active In the same way as for the Tan Delta ramp data,

decision on whether they wish to curtail the test at 15 convenient percentiles such as 80 % and 90 % are

minutes. suggested as critical values. In practice, the values at

these percentiles can be rounded to 1.4 E-3 and 2.8 E-3.

Table 1 Comparison of Diagnostic Features (Tan

Delta) for Step (incl pure Tan Delta tests) and Hold

Portions of Monitored Withstand tests 100

Voltage Step Voltage Hold 90

Portion 80 80

(Withstand -

& Tan Delta Constant

Assessment Voltage)

60

Portion

Percent

Stability over 6 to 12 extended time

measurements at at IEEE400.2 40

(Standard Deviation) Uo voltage level

Voltage Dependence between 1.5Uo &

- 20

of Tan Delta (Tip Up) 0.5Uo

Tan Delta over 6 to 12 extended time

1.36

2.76

measurements at at IEEE400.2 0

(Mean) 0 1 2 3 4 5

Uo voltage level

Std Dev Tan Delta for Monitored Withstand (E-3)

Change in Tan Delta between 0 & 10

-

with time minutes Figure 3: Empirical Distribution of Standard Deviation

(Overall for 30 minutes) for Field Tests on PILC

Cables at IEEE Std. 400.2™ Voltage Levels

Generally, stability is the most useful of the three dielectric

loss features. Unfortunately, the use of standard deviation Table 2 shows a comparison of the criteria for stability in a

is not likely to be sufficient for this purpose. The need to standard Tan δ measurement and the resulting criteria

improve the approach is driven by the long times used for obtained from Figure 3 for the Monitored Withstand mode.

the monitored test and because the user is more likely to The limits are lower for the standard Tan δ measurements

be interested in the trend (increasing or decreasing) of the

Jicable’11 – 19 – 23 June 2011, Versailles - France

Close and Return

A.10.2 8th International Conference on Insulated Power Cables A.10.2

than the Monitored Withstand mode due to the higher Condition Assessments to suggest how the IEEE400.2

voltages and longer times employed for withstand tests. standard withstand test time might be modified by the

cable system condition, for example:

Table 2: Criteria for Condition Assessment Criteria of o No Action Required - - standard 30 minute test time

Paper Insulations (PILC) for Dielectric Loss and may be Reduced to 15 minutes

Monitored Withstand Modes o Further Study - - retain standard 30 minute test

Tan δ Tan δ Stability o Action Required - - standard 30 minute test time

Stability Measured should be increased to 60 minutes

Condition Measured @ IEEE Std. 400.2

Assessment @ U0 [E-3] Withstand levels [E-3] The approach outlined above may be replicated for the

(Dielectric (Monitored Withstand time evolution trend and the tan delta level to give

Loss Mode) Mode) insulation specific Decision Tools. These tools are

No Action

<0.3 <1.4 tabulated in Table 3.

Required

Further Study

Advised

0.3 to 0.4 1.4 to 2.8 SERVICE PERFORMANCE

Action

Required

>0.4 >2.8 Aged XLPE Cable

Table 3 Test Time Guidance and Condition

5.0 5

Assessment for Monitored Withstand tests on MV

cable systems

Tan Delta [E-3]

VLF-TD Stability (standard deviation)

Mean VLF-TD at Maintenance Level

Change in Tan Delta between 0 and

at Maintenance Level [10 ]

-3

Condition Assessment

Test Time Guidance

1.0

10 mins (E-3)

[10 ]

-3

0.5

0 5 10 15 20 25 30

Time [min]

Figure 4: Tan δ Monitored Withstand Data on service

aged XLPE cables

The results of a VLF AC - Sinusoidal Monitored Withstand

test in which the Tan δ was monitored continuously for the

PE-based Insulations (i.e. PE, XLPE, WTRXLPE) 30 minutes appear in Figure 4.

Reduced

These results lead to the following assessment:

No

to 15 Action <0.25 <0.25 <5 1. Tested segment did not have a dielectric puncture

Mins Required 2. Change between 0 and 10 minutes: 0 E-3

and

and

>0.25 >0.25 >5 3. Stability (standard deviation on the mean at the

Retain 30 Further

Study and and and withstand voltage): 0.79E-3

Mins

Advised <17 <6 <45 4. Tan δ (mean at withstand voltage): 0.9E-3

Extended

to 60 Action >17 >6 >45 The Monitored Withstand assessment of this performance

or

or

Mins Required

would likely be “No Action Required” and test time may be

Paper Insulations (i.e. PILC) reduced to 15 minutes. In this case the utility chose not to

reduce the test time even though it was possible for them

Reduced No to do so.

to 15 Action <1.3 <0.7 <75

Mins Required PILC Cable System

and

and

>0.13 >0.7 >75 A three phase Paper Insulated Lead Cable (PILC) was

Retain 30 Further

Study and and and tested in late 2009. The protocol employed included a

Mins

Advised <4 <3.5 <135 Step Up and a Hold phase – first part of Figure 1. The

results from the Step Up phase are shown in Table 4 –

Extended

Action following the interpretation schemes in detailed in

to 60 >4 >3.5 >135

or

or

Mins Required references 5 & 6. As a consequence the utility involved

elected to follow these purely Tan δ measurements with a

Monitored Witshand In this case theye elected to conduct

In the context of a Monitored withstand test the Condition teh Monitored Withstand on all three phases rather than

Assessments (No Action Required etc) may also be used just Phase A which was shown to be the poorest

to determine real time guidance for the prosecution of the performer by the the step tests.

withstand test. The current approach is to use the

Results of a VLF AC - Sinusoidal Monitored Withstand

Jicable’11 – 19 – 23 June 2011, Versailles - France

Close and Return

A.10.2 8th International Conference on Insulated Power Cables A.10.2

test with Tan δ on PILC insulated cables appear in

110 10.0

110 10.0 100

90 A

100 60 Min

90 A 80 Difference 10 minute to 0 Extension

60 Min

minute Criteria

Difference 10 minute to 0 Extension

T D @ the Withstand Level [ E-3 ]

80 70

minute Criteria

T D @ the Withstand Level [ E-3 ]

70

Standard Deviation (E-3)

60

Standard Deviation (E-3)

60

50

1.0

50

1.0 15 Min

40 A Reduction

15 Min

B Criteria

40 A Reduction

C

B Criteria C

C 30

C Symbol size

B

30

Symbol size corresponds

B

corresponds to Tan Delta

to Tan Delta magnitude

20 0.1

magnitude 0 20 40 60 80 1 2 3 4 5 6 7

20 0.1 Measurement Sequence Difference 10 mins to 0 mins (E-3)

0 20 40 60 80 1 2 3 4 5 6 7

Measurement Sequence Difference 10 mins to 0 mins (E-3)

Figure 5. In these tests three phases were tested Figure 5: Tan δ Monitored Withstand Data (left) and

separately, If this test had been a Simple Withstand test Interpretation of Results (right) from Three Phases of

they would have been classified as Pass as none failed Service Aged PILC Insulated Cables

under voltage. However inspection clearly shows that

these phases perform quite differently in terms of change On this utility system it has been possible to follow the test

with time and level. The right most figure displays the and service performance. These data show that 6% of the

diagnostic features, change with time, stability and tan tests failed via a dielectric puncture in a simple withstand

delta level (represented by the size of the data points. The mode, whereas an additional 12% of tests could be

open symbols are graphical representations of the PILC addressed (18% in total) when the dielectric data were

criteria in Table 3. Comparison of the data points with the added to the assessment. Of these 18% No Passes, 7%

criteria enables interpretation of the test results, which is occurred during the ramp up and the remaining 11% in

shown in Table 4. the hold. The accumulated length and test time is on the

order of 450 conductor mile*years. Over this time the

Table 4 Interpretation of results for cables in “After Test” failure rate in service is of the order of 0.4 per

100 conductor miles per year. This compares very

Figure 5 favourably with system wide failure rate of 7 per 100

A B C conductor miles per year and shows the benefits that can

accrue. Equally valuable but less tangible is the benefit

Voltage Step Up that comes from a failure that occurs at in service which

carries a much larger energy in the fault than that from

Action

Std Dev Tan δ @ Uo Further Study test equipment.

Required

Mean Tan δ @ 1.5Uo – EPR Cable

No Action

Further Study A challenging example involving a 60 minute test on EPR

Mean Tan δ @ 0.5Uo Required

cable appears in Figure 6. In this case, the extended

Mean Tan δ @ Uo No Action Required period of monitoring reveals the instability in the standard

deviation and the median Dielectric Loss. It is useful to

Voltage Hold note that the use of non parametric estimates (median

and interquartile range) conveys the same information as

Dielectric Failure None the distribution based estimates (mean, standard

Change between 0 deviation) but without the potential interference from

and 10 minutes Action outlier data. The variability in these features would not

Required have been revealed by a standard diagnostic test – the

Stability No Action results from this test are represented by the initial open

Extend to 60 symbols in both plots.

(standard deviation at Required

minutes

withstand voltage) Reduce to 15

Tan δ Further Study minutes

(mean at withstand Retain 30

voltage) minutes

Examination of the results for Phase A after the Monitored

Withstand indicated that an appropriate final classification

(based on Change with Time, Stability and Tan δ) would

be Action Required.

Jicable’11 – 19 – 23 June 2011, Versailles - France

Close and Return

A.10.2 8th International Conference on Insulated Power Cables A.10.2

Median Tan Delta (E-3) Inter Quartile Range (E-3) 5 800

117 0.35 Tan Delta

PD Pulse Count

700

0.30 4

116

600

PD Pulse Rate [#/5 min]

0.25

Tan Delta [1e-3]

115 3 500

0.20

400

0.15

114 2

113.8 300

0.10

113 1 200

0.05

100

112 0.00

0 15 30 45 60 0 15 30 45 60 0

0

Time - mins 0 5 10 15 20 25 30

Time [min]

Figure 6: Tan δ Monitored Withstand Data on Service

Aged Cable with Filled Insulation Tested at IEEE Std.

400.2 Voltage Level Figure 7: Simultaneous measurement of Tan δ and PD

data collected during a monitored withstand test on

In this case the results at 15 minutes would have shown 1970’s vintage XLPE cables

an increasing Tan Delta with high variability. Thus there

would have been insufficient evidence to curtail the test at

15 minutes. In fact the decision was taken at this point to FUTURE CHALLENGES

extend the test to 60 minutes (the maximum identified in This paper has shown that considerable progress has

IEEE400.2). Ultimately the Tan δ Monitored Withstand been made in quite a short time towards the practical

data would be classified as: implementation of Monitored Withstand tests for medium

1. No Dielectric Failure voltage (MV) cable systems. Nevertheless there are some

2. Trend: Unstable challenges that may be clearly identified:

3. Stability (Inter Quartile Range at the withstand There are very many features that can be derived in a

voltage): 0.125 E-3 (range of 0-0.3 E-3) monitored withstand test, thus there is a need to find a

4. Tan δ (median at withstand voltage): 113.8 E-3 way to combine them in a multivariate approach. Given

(range of 112.5-116.5 E-3). the success with Principal Component Analysis

5. Test Result : Action Required associated with Tan Delta tests [6] then this would likely

be a profitable approach to the analysis.

Dual Monitored Diagnostics Current embodiments of field measurement systems are

Figure 7 shows a monitored withstand test on a duct geared to pure Tan Delta assessments and provide real

based XLPE cable system which had been installed in the time representation of voltage effects with simple

mid 1980’s. In these tests PD and Tan Delta diagnostic factors (mean & standard deviation). Given the

measurements were carried out simultaneously. progress in the analysis presented here it is clear that the

Inspection of the results shows the usefulness of user would benefit from:

monitoring two properties as the Tan Delta might suggest • The calculation of more diagnostic features, for both

that the test could be truncated at 15 minutes, yet the PD Tan Delta and Capacitance

pulse rate was increasing. Consequently it was • A graphical representation of the Tan Delta &

determined to extend the time to 60 minutes; however as Capacitance evolution with time.

the PD rate had not reduced sufficiently the cables were

scheduled for replacement on the basis of the results at The progress evidenced in Table 3 shows that a series of

30 minutes. decision tools can be constructed to aid implementation in

the field. The authors are currently developing a number

of such tools, which currently take the form of printed

analysis sheets and data forms. The challenge is to find a

way to take the available test data and make it available in

a way to cover the wide range of situations that might

develop in the field. As an example, this paper has dealt

with the most common (80% of the time) case when the

standard 30 minute test could be curtailed at 15 minutes;

however the case of extension / curtailment at 30 minutes

has yet to be addressed. When this is done it will require

another level of features that although they are

computationally straightforward they are additional layers

of complexity.

ACKNOWLEDGEMENTS

The authors gratefully acknowledge the useful

discussions with many of the engineers involved within

Jicable’11 – 19 – 23 June 2011, Versailles - France

Close and Return

A.10.2 8th International Conference on Insulated Power Cables A.10.2

the Cable Diagnostic Focused Initiative and the financial

support of a large number of utilities in North America and

the US Department of Energy under award number DE-

FC02-04CH11237. They are especially endebted to the

utilities who took the time to contribute data from the field.

CONCLUSIONS

This paper has shown that Monitored Withstand is a

practical diagnostic approach that can be implemented by

utilities. The implementation is supported by automated

measurement equipment and a series of decision tools.

This combination empowers users at the local level and

provides a significant amount of support. Furthermore the

immediacy and transparency of the data acquisition and

interpretation processes builds ownership.

REFERENCES

1. IEEE Standard 400.2-2004™, IEEE Guide for Field

Testing of Shielded Power Cable Systems Using

Very Low Frequency (VLF), 2005.

2. IEEE Standard 400-2001™, IEEE Guide for Field

Testing and Evaluation of the Insulation of Shielded

Power Cable Systems,. 2002.

3. RN Hampton et al, “Experience of Withstand Testing

of Cable Systems in the USA”, CIGRE 2010 B1-

203.

4. J. Densley, “Aging Mechanisms and Diagnostics for

Power Cables - An Overview,” IEEE Electrical Ins

Mag, vol 17, no 1, pp 14-22, Jan/Feb 2001.

5. Diagnostic Testing of Underground Cable Systems

(Cable Diagnostic Focused Initiative), DOE Award

No. DE-FC02-04CH11237, December 2010

6. J Perkel et al, “Challenges associated with the

interpretation of dielectric loss data from power cable

system measurements”, JICABLE11, Versailles

France, June 2011

Jicable’11 – 19 – 23 June 2011, Versailles - France

View publication stats

You might also like

- Jicable19 67 VLF FinalDocument6 pagesJicable19 67 VLF FinalLucho RufoNo ratings yet

- Plant Engineering: Electrical Cable Test Applicability Matrix For Nuclear Power PlantsDocument138 pagesPlant Engineering: Electrical Cable Test Applicability Matrix For Nuclear Power PlantskatambarogersNo ratings yet

- Plant Engineering: Electrical Cable Test Applicability Matrix For Nuclear Power PlantsDocument138 pagesPlant Engineering: Electrical Cable Test Applicability Matrix For Nuclear Power PlantsDwi FitriantoNo ratings yet

- What Should You KnowDocument7 pagesWhat Should You KnowgabrielNo ratings yet

- Simultaneous PD and TD Testing - 0 PDFDocument5 pagesSimultaneous PD and TD Testing - 0 PDFDHARMENDRANo ratings yet

- Jicable19 67 VLF FinalDocument6 pagesJicable19 67 VLF FinalUguru-Okorie DavidNo ratings yet

- High-Resolution Subjective Testing Using: A Double-Blind ComparatorDocument9 pagesHigh-Resolution Subjective Testing Using: A Double-Blind ComparatorLucio BianchiNo ratings yet

- B.Milovic - Substation Maintenance Improving Best Practices For Greater Success - Electricity Today MagazineDocument5 pagesB.Milovic - Substation Maintenance Improving Best Practices For Greater Success - Electricity Today MagazineMartin FabianNo ratings yet

- No 1-30-33 Trends in Transformer Failure Analysis WBDocument4 pagesNo 1-30-33 Trends in Transformer Failure Analysis WBDimitar MarkovNo ratings yet

- No Fault Found, Retest Ok, Cannot Duplicate or Fault Not Found? Towards A Standardised TaxonomyDocument9 pagesNo Fault Found, Retest Ok, Cannot Duplicate or Fault Not Found? Towards A Standardised TaxonomyPaul WatkinsNo ratings yet

- Validating Surge TestDocument9 pagesValidating Surge Testquality10No ratings yet

- 1 46Document5 pages1 46Dedit Gunarso PutroNo ratings yet

- Mv-105 Cable - Field Acceptance Testing - A Cable Manufacturer'S PerspectiveDocument7 pagesMv-105 Cable - Field Acceptance Testing - A Cable Manufacturer'S PerspectiveMarcelo Gomes PlanteirNo ratings yet

- State of The Art Predictive Maintenance TechniquesDocument11 pagesState of The Art Predictive Maintenance TechniquesMIGUEL ANGEL DURON SAAVEDRA100% (1)

- 15 Brochures - With Copyright PDFDocument11 pages15 Brochures - With Copyright PDFTung Nguyen AnhNo ratings yet

- Robustness Valdiation Step by StepDocument36 pagesRobustness Valdiation Step by StepGreenheart OussamaNo ratings yet

- Cables - Power Plant Practices To Ensure Cable OperabilityDocument223 pagesCables - Power Plant Practices To Ensure Cable OperabilitycadtilNo ratings yet

- Partial Discharge Analysis and Asset Management: Experiences On Monitoring of Power ApparatusDocument7 pagesPartial Discharge Analysis and Asset Management: Experiences On Monitoring of Power Apparatusduong nguyenNo ratings yet

- Relay-Performance - Estados Del SEPDocument3 pagesRelay-Performance - Estados Del SEPquisi123No ratings yet

- Partial Discharge Testing of Defective Three-PhaseDocument7 pagesPartial Discharge Testing of Defective Three-PhaseAlejandro MaturanoNo ratings yet

- Reliability and Quality TestingDocument4 pagesReliability and Quality TestingveficilNo ratings yet

- Omicron 2Document4 pagesOmicron 2kegiw15659No ratings yet

- VLF Sine 0.1 HZ - Universal Voltage Source For Test-Ing and Diagnostics of Medium-Voltage CablesDocument9 pagesVLF Sine 0.1 HZ - Universal Voltage Source For Test-Ing and Diagnostics of Medium-Voltage CablesVictor HCNo ratings yet

- Duct Leakage Repeatability Testing: LBNL 175563rev2Document26 pagesDuct Leakage Repeatability Testing: LBNL 175563rev2Bagus BayuNo ratings yet

- Is Fault Locating Killing Our Cable SystemsDocument5 pagesIs Fault Locating Killing Our Cable SystemsJIGSNo ratings yet

- PD Analysis in MonitoringDocument6 pagesPD Analysis in MonitoringZakaria BelloulaNo ratings yet

- Extruded Cable Reliability-Life Estimation and Life ExtensionDocument6 pagesExtruded Cable Reliability-Life Estimation and Life Extensionromany italianoNo ratings yet

- Electrical Inspection and ToolsDocument4 pagesElectrical Inspection and ToolsJuan AraqueNo ratings yet

- Relay Testing Results Using TransientsDocument7 pagesRelay Testing Results Using TransientsMohamed Daw HamoudaNo ratings yet

- Utilizing Validation Experience For SystDocument5 pagesUtilizing Validation Experience For Systsilvio luizNo ratings yet

- Reliability Prediction from Burn-In Data Fit to Reliability ModelsFrom EverandReliability Prediction from Burn-In Data Fit to Reliability ModelsRating: 3 out of 5 stars3/5 (2)

- IPC2018-78522-Krieg-Nestleroth-Hennig-Haines Final 6-29-2018Document10 pagesIPC2018-78522-Krieg-Nestleroth-Hennig-Haines Final 6-29-2018Martin Chimenti - ARO SANo ratings yet

- Electrical System TestingDocument10 pagesElectrical System TestingoritasNo ratings yet

- Electrical & Electronic Systems: Analysis of Power Reduction Techniques Used in Testing of VLSI CircuitsDocument3 pagesElectrical & Electronic Systems: Analysis of Power Reduction Techniques Used in Testing of VLSI CircuitsAbhinava DeepakNo ratings yet

- Using Cross-Correlation Coefficients To Analyze Transformer Sweep Frequency Response Analysis (SFRA) TracesDocument6 pagesUsing Cross-Correlation Coefficients To Analyze Transformer Sweep Frequency Response Analysis (SFRA) TracesSandeep PhagariaNo ratings yet

- Glossary: Nigel Hampton and Jean Carlos Hernandez-MejiaDocument13 pagesGlossary: Nigel Hampton and Jean Carlos Hernandez-MejiaTung Nguyen AnhNo ratings yet

- Acoustic Emission TestingDocument6 pagesAcoustic Emission TestingJaneswar PrabhakarNo ratings yet

- Transformer Testing Techniques and Standard Development PDFDocument4 pagesTransformer Testing Techniques and Standard Development PDFthientranNo ratings yet

- 10gbase-Kr PMD Testsuite v1.1Document21 pages10gbase-Kr PMD Testsuite v1.1flyoxyNo ratings yet

- Cables - NETA Power Cable Diagnostics Field Application & Case StudiesDocument15 pagesCables - NETA Power Cable Diagnostics Field Application & Case StudiescadtilNo ratings yet

- CompressionDocument45 pagesCompressionRajesh DurisalaNo ratings yet

- SOCRATES 2010 VTCFall PresentationDocument50 pagesSOCRATES 2010 VTCFall Presentationwest zoneNo ratings yet

- IEEE Tutorial Course - High Impedance FaultsDocument48 pagesIEEE Tutorial Course - High Impedance FaultsJosé Rubens Macedo JuniorNo ratings yet

- Cigre Tf21-05id44ver24Document10 pagesCigre Tf21-05id44ver24salekojic5332No ratings yet

- Reliability of Electrical Insulating Systems - Statistical Approach To Empirical Endurance ModelsDocument5 pagesReliability of Electrical Insulating Systems - Statistical Approach To Empirical Endurance Modelsostojic007No ratings yet

- Accelerated Life Testing For ElectronicsDocument9 pagesAccelerated Life Testing For Electronicsvitor_silverio100% (1)

- New Testing Paradigm Virtual PrototypingDocument5 pagesNew Testing Paradigm Virtual Prototypinguamiranda3518No ratings yet

- Shortening Burn-In Test: Application of Weibull Statistical Analysis & HVSTDocument21 pagesShortening Burn-In Test: Application of Weibull Statistical Analysis & HVSTd35_4everNo ratings yet

- Condition Assessment of Substation Ground GridsDocument62 pagesCondition Assessment of Substation Ground GridsDeputy Manager P&I Division PeshawarNo ratings yet

- 6156 WPRC DynamicSimulations 20031002 WebDocument34 pages6156 WPRC DynamicSimulations 20031002 WebYM6BNo ratings yet

- Development of Power System Protection Laboratory Through Senior Design ProjectsDocument6 pagesDevelopment of Power System Protection Laboratory Through Senior Design ProjectsMrrajesh RajeshNo ratings yet

- Jansen.M - Harmonics - PaperDocument8 pagesJansen.M - Harmonics - PaperdenfordmuNo ratings yet

- Advancements in Integrity Testing 26 R0 PDFDocument2 pagesAdvancements in Integrity Testing 26 R0 PDFHung nguyen manhNo ratings yet

- Analysis and Optimization of 132KV Grid Using ETAP PDFDocument6 pagesAnalysis and Optimization of 132KV Grid Using ETAP PDFAlejandro PalaciosNo ratings yet

- PA IEEE PES 2014 BAUR Combined VLF and MWT ENDocument5 pagesPA IEEE PES 2014 BAUR Combined VLF and MWT ENMarcelo Gomes PlanteirNo ratings yet

- Engineering Failure Analysis: Ricardo Manuel Arias Velásquez, Jennifer Vanessa Mejía Lara, Andrés Melgar TDocument25 pagesEngineering Failure Analysis: Ricardo Manuel Arias Velásquez, Jennifer Vanessa Mejía Lara, Andrés Melgar TI Wayan ArimbawaNo ratings yet

- A Multi-Dimensional Diagnostic Fingerprint For Power TransformersDocument4 pagesA Multi-Dimensional Diagnostic Fingerprint For Power TransformersRicardo RampersadNo ratings yet

- L1 2 HvpaDocument58 pagesL1 2 HvpaMayur IsameNo ratings yet

- Reliability of High-Power Mechatronic Systems 2: Aerospace and Automotive Applications: Issues,Testing and AnalysisFrom EverandReliability of High-Power Mechatronic Systems 2: Aerospace and Automotive Applications: Issues,Testing and AnalysisNo ratings yet

- Smart-UPS SMC2000IDocument3 pagesSmart-UPS SMC2000IMothafukin MorrisseyNo ratings yet

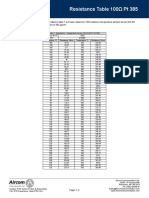

- Resistance Table 100Ω Pt 385 Temperature SensorsDocument1 pageResistance Table 100Ω Pt 385 Temperature SensorsMothafukin MorrisseyNo ratings yet

- Device Coordination PDFDocument89 pagesDevice Coordination PDFMothafukin MorrisseyNo ratings yet

- Three-Phase-Inductionmotor With Squirrel Cage Rotor: Operationing and Installation DataDocument4 pagesThree-Phase-Inductionmotor With Squirrel Cage Rotor: Operationing and Installation DataMothafukin MorrisseyNo ratings yet

- JJicable11 0009 Final PDFDocument8 pagesJJicable11 0009 Final PDFMothafukin MorrisseyNo ratings yet

- Calculation of Power Transformers Health IndexesDocument7 pagesCalculation of Power Transformers Health IndexesMothafukin MorrisseyNo ratings yet

- TUV Module PerformanceDocument6 pagesTUV Module PerformanceMothafukin MorrisseyNo ratings yet

- M. F. Bukhina, S. K. Kurlyand - Low-Temperature Behaviour of Elastomers (New Concepts in Polymer Science) - Brill Academic Publishers (2007)Document197 pagesM. F. Bukhina, S. K. Kurlyand - Low-Temperature Behaviour of Elastomers (New Concepts in Polymer Science) - Brill Academic Publishers (2007)Mothafukin MorrisseyNo ratings yet

- M. F. Bukhina, S. K. Kurlyand - Low-Temperature Behaviour of Elastomers (New Concepts in Polymer Science) - Brill Academic Publishers (2007)Document197 pagesM. F. Bukhina, S. K. Kurlyand - Low-Temperature Behaviour of Elastomers (New Concepts in Polymer Science) - Brill Academic Publishers (2007)Mothafukin MorrisseyNo ratings yet

- Dew Point For Compressed AirDocument2 pagesDew Point For Compressed AirMothafukin MorrisseyNo ratings yet

- MV Cable Derating Factors NF C 13-200 (France)Document4 pagesMV Cable Derating Factors NF C 13-200 (France)Mothafukin MorrisseyNo ratings yet

- LV Cable Derating Factors IEC 60364 (Europe)Document8 pagesLV Cable Derating Factors IEC 60364 (Europe)Mothafukin MorrisseyNo ratings yet

- Dewpoint Compressed Air Application NoteDocument4 pagesDewpoint Compressed Air Application NoteKarthick Velayutham100% (1)

- IPC-TM-650 Contact Resistance Test Methods ManualDocument2 pagesIPC-TM-650 Contact Resistance Test Methods ManualMothafukin MorrisseyNo ratings yet

- D1653Document5 pagesD1653manox007No ratings yet

- Sifat Bahan Pangan dan Hasil PertanianDocument39 pagesSifat Bahan Pangan dan Hasil PertanianStefanus Bayu Sindhu WijayaNo ratings yet

- Phy QBDocument25 pagesPhy QBManav MehtaNo ratings yet

- Android: Uni-Stroke Touch Gesture Recognition Using $1 Gesture ReconigizerDocument13 pagesAndroid: Uni-Stroke Touch Gesture Recognition Using $1 Gesture Reconigizerpi194043No ratings yet

- Ms7820 ManualDocument64 pagesMs7820 ManualJesus Velazquez AriasNo ratings yet

- A1512 Panasonic SemiconductorDocument2 pagesA1512 Panasonic SemiconductorbrneiNo ratings yet

- The Foundations of NetworkingDocument3 pagesThe Foundations of NetworkingSergeyNo ratings yet

- Lightweight AP - Registration To WLC PDFDocument15 pagesLightweight AP - Registration To WLC PDFAnasham TegegnNo ratings yet

- Samsung CAC Duct S Brochure 20140729 0Document16 pagesSamsung CAC Duct S Brochure 20140729 0Callany AnycallNo ratings yet

- XPS Insulation ASTM - C578 - Types PDFDocument1 pageXPS Insulation ASTM - C578 - Types PDFSushil KumarNo ratings yet

- Factory Overhead Analysis and VariancesDocument13 pagesFactory Overhead Analysis and Variancesjgfjhf arwtrNo ratings yet

- Manual de Servicio Colimador Ge Sentry 3Document247 pagesManual de Servicio Colimador Ge Sentry 3Jairo Manzaneda100% (1)

- Food Groups Intake in Relation To Stunting Among Exceptional ChildrenDocument8 pagesFood Groups Intake in Relation To Stunting Among Exceptional ChildrenAriqah GinaNo ratings yet

- Factor Analysis PresentationDocument158 pagesFactor Analysis PresentationAnonymous pnYfWvNo ratings yet

- Fractional Distillation of Ginebra San Miguel GinDocument6 pagesFractional Distillation of Ginebra San Miguel GinHajime NakaegawaNo ratings yet

- Ds1307 Application NoteDocument17 pagesDs1307 Application NoteShamsunder31No ratings yet

- KCA-201 Online PUE Theory of Automata & Formal Languages MCA 2nd SemDocument13 pagesKCA-201 Online PUE Theory of Automata & Formal Languages MCA 2nd SemakttripathiNo ratings yet

- Tanque: Equipment Data SheetDocument1 pageTanque: Equipment Data SheetAlonso DIAZNo ratings yet

- CDB 4323 Assignment 1Document2 pagesCDB 4323 Assignment 1Muhammad AnwarNo ratings yet

- TMS470 Assembly Language Tools User' S GuideDocument336 pagesTMS470 Assembly Language Tools User' S GuideMadhu CkNo ratings yet

- Ramsey Mercury Free Tilt Sensor 8054.0514 CODocument4 pagesRamsey Mercury Free Tilt Sensor 8054.0514 COlf123No ratings yet

- Advanced Process Modeling 1Document41 pagesAdvanced Process Modeling 1mtahir777945No ratings yet

- Answer Ndeb Released Questions 2013 AfkDocument1 pageAnswer Ndeb Released Questions 2013 AfkKareem Shawa33% (6)

- Introduction to Weibull Analysis for Reliability ImprovementDocument2 pagesIntroduction to Weibull Analysis for Reliability ImprovementCesar ChpNo ratings yet

- ACE Brochure - Final - June - 4 - 2013 PDFDocument16 pagesACE Brochure - Final - June - 4 - 2013 PDFOrlando FloresNo ratings yet

- Introduction To Photogrammetry With UAVDocument107 pagesIntroduction To Photogrammetry With UAVut4ulu100% (1)

- PU11 Computer Science Notes - ExcelDocument4 pagesPU11 Computer Science Notes - Excelgautham28No ratings yet

- Agile Testing Methods Guide: Scrum, Crystal, DSDM, FDD, Lean, XP & MoreDocument19 pagesAgile Testing Methods Guide: Scrum, Crystal, DSDM, FDD, Lean, XP & Moreangelica campuedNo ratings yet

- Whoqol: User ManualDocument59 pagesWhoqol: User ManualDina AuliyaNo ratings yet