Professional Documents

Culture Documents

Nitoprime 25 TDS PDF

Uploaded by

galih mahardikaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nitoprime 25 TDS PDF

Uploaded by

galih mahardikaCopyright:

Available Formats

Fosroc Nitoprime 25 constructive solutions

Epoxy resin primer for Fosroc flooring and coating range

Uses Application

Nitoprime 25 is a general purpose anti-corrosion primer for Equipment

concrete and steel surfaces (prepared by abrasive blast

Airless Spray

cleaning), for use with various Fosroc coatings and flooring

range. The product actively prevents corrosion and is tolerant wft wft

to application over manually prepared surfaces. 75-125mm 125-350mm

Nozzle Size : 0.33-0.38mm 0.38-0.46mm

Advantages (13-15thou) (15-18thou)

Fan Angle : 40°C 40°C

Active corrosion

control Operating Pressure : 155kg/cm² 155kg/cm°

(2200psi) (2200psi)

Formulated for use with Fosroc flooring and

coating systems The airless spray details given above are intended as a guide

only. Fluid hose length and diameter, paint temperature and

Description project complexity all have an effect on the choice of spray tip

and operating pressure. The operating pressure should be

Nitoprime 25 is a two pack epoxy primer, providing corrosion the lowest possible consistent with satisfactory atomization.

protection and improved adhesion. As conditions vary, it is the applicators’ responsibility to ensure

Properties that the equipment in use has been adjusted to give optimum

performance.

23°C 35°C

Pot Life : 2h 1h Conventional spray

Average Drying Times :

Nozzle Size : 1.27mm (50 thou)

Touch : 4-5h 3h

Atomizing Pressure : 2.8kg/cm² (40psi)

Recoat : 6-8h 4h

Fluid pressure : 0.4kg/cm² (6psi)

To handle : 9-10h 6h

The conventional spray details given above are intended as a

Instructions to use guide only. It may be found that in some circumstances, slight

variations in atomizing pressure, fluid pressure and alteration

Surface preparation of tip arrangements may provide optimum atomization.

Blast clean to SA2½ BS7079: Part A1:1989 (ISO 8501-1:1988). For application by conventional spray, thinning with up to 10%

Average surface profile should be in the range of 50-75m. Fosroc Solvent 102 may be required. Adjustment for wet film

Manually prepared surfaces should be to a minimum thickness should be allowed. Thinning will effect VOC

standard of St 3 BS7079: Part A1:1989 at the time of coating. compliance.

Ensure surfaces to be coated are dry and free from all traces

Brush and Roller

of surface contaminants.

The material is suitable for brush and roller application.

Application of more than one coat may be required to give the

equivalent dry film thickness to one spray appliced coat.

Application conditions

The application of Nitoprime 25 must take place immediately

to a dry steel surface after completion of the preparation work.

Good ventiallation is essential in conditions of high humidity,

i.e 80-85%.

Nitoprime 25

Fosroc Nitoprime 25

Limitations Precautions

Nitoprime 25 should not be applied when the substrate Health and safety

temperature is below 5°C or is 5°C and falling. If any doubt

Nitoprime 25 and Fosroc Solvent 102 should not come in

arises concerning temperature or applicationconditions,

contact with skin or eyes, or be swallowed. Ensure adequate

consult the local Fosroc office..

ventilation and avoid inhalation of vapours. Some people are

sensitive to resins, hardeners and solvents. Wear suitable

Estimating

protective clothing, gloves and eye protection.

Supply

If working in confined areas, suitable respiratory equipment

Nitoprime 25 : 4.5 litre units

must be used.

Fosroc Solvent 102 : 5 litre cans

The use of barrier creams provide additional skin protection.

Coverage In case of contact with skin, rinse with plenty of clean water,

Nitoprime 25 : 7.5m²/litre then cleanse with soap and water. In case of skin contact

@ 133microns wft with Nitoprime 25, remove immediately with resin removing

Note : The coverage figure of Nitoprime 25 is theorotical cream followed by washing with soap and water.

and may vary due to a variety of site conditions. Do not use solvent. In case of contact with eyes, rinse

immediately with plenty of clean water and seek medical

Storage advice. If swallowed, seek medical attention immediately -

do not induce vomiting.

Shelf life

Fire

Nitoprime 25has a shelf life of 12 months and Fosroc Solvent

102 has a shelf life of 12 months, if kept in a dry store in the Nitoprime 25 and Fosroc Solvent 102 are flammable. Keep

original unopened packs. away from sources of ignition. No smoking. In the event of

fire, extinguish with CO2 or foam. Do not use a water jet.

Flash points

Nitoprime 25 : 24°C

Fosroc Solvent 102 : 33°C

For further information, refer to the Product Material Safety

Data Sheet.

* Denotes the trademark of Fosroc International Limited

†

See separate data sheet

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions for

the Supply of Goods and Service. All Fosroc datasheets are updated on a regular basis. It is the user’s responsibility to

obtain the latest version.

Fosroc Kenya LTD

Po Box 78527-00507, Head Office

Mombasa rd near Syokimau telephone: +254 709 106 000 email: enquiry.kenya@fosroc.com

Railway station, Nairobi.

www.fosroc.com

You might also like

- Hi Pon 20 07 Epoxy Zinc Phosphate 70 Ver 13.0 PDFDocument4 pagesHi Pon 20 07 Epoxy Zinc Phosphate 70 Ver 13.0 PDFPushpendraNo ratings yet

- Intergard 740Document4 pagesIntergard 740Josevi Jiménez MerinoNo ratings yet

- Liquid Analysis v3 Powell-Cumming 2010 StanfordgwDocument28 pagesLiquid Analysis v3 Powell-Cumming 2010 StanfordgwErfanNo ratings yet

- Starting A Business Candle Making 2009Document2 pagesStarting A Business Candle Making 2009Carlo Fabros Junio100% (4)

- Nitoprime 25 TDS PDFDocument2 pagesNitoprime 25 TDS PDFgalih mahardikaNo ratings yet

- Fosroc Nitoprime 25: Constructive SolutionsDocument2 pagesFosroc Nitoprime 25: Constructive SolutionsVincent JavateNo ratings yet

- Protective & Marine Coatings: Zinc Clad Iv EuDocument2 pagesProtective & Marine Coatings: Zinc Clad Iv Eusrinath vNo ratings yet

- Macropoxy C88Document2 pagesMacropoxy C88nellyNo ratings yet

- Intertherm 79: Temporary Protective PrimerDocument4 pagesIntertherm 79: Temporary Protective PrimerNassim Ben AbdeddayemNo ratings yet

- 404 UkDocument4 pages404 UkAhmed IbrahimNo ratings yet

- Carboguard 703 PDSDocument2 pagesCarboguard 703 PDSMuthuKumar100% (2)

- Interchar 404 Fire GreyDocument4 pagesInterchar 404 Fire GreyaymanNo ratings yet

- Apcotherm Epn 200Document2 pagesApcotherm Epn 200Moin AltafNo ratings yet

- Characteristics: Japan's No.1Document2 pagesCharacteristics: Japan's No.1azam RazzaqNo ratings yet

- TDS-PDF-Interchar 1290 Eng A4 20170228Document4 pagesTDS-PDF-Interchar 1290 Eng A4 20170228shameelNo ratings yet

- Interchar 2090: Acrylic IntumescentDocument4 pagesInterchar 2090: Acrylic IntumescentEngTamerNo ratings yet

- Thor ZcepDocument2 pagesThor Zcepazam RazzaqNo ratings yet

- Interline 982+ds+eng PDFDocument4 pagesInterline 982+ds+eng PDFMohamed NouzerNo ratings yet

- Chartek 8 Epoxy IntumescentDocument4 pagesChartek 8 Epoxy IntumescentAhmed IbrahimNo ratings yet

- Nitoflor FC150 PDFDocument4 pagesNitoflor FC150 PDFSameera HerathNo ratings yet

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Intertherm - 3350 - Eng - A4 - 20150818Document4 pagesE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Intertherm - 3350 - Eng - A4 - 20150818vtnhoemNo ratings yet

- Nitoflor Tf120 UbDocument3 pagesNitoflor Tf120 UbtalatzahoorNo ratings yet

- SSIS TDS PDF Interline 982 EngDocument4 pagesSSIS TDS PDF Interline 982 EngAhmad BarriehNo ratings yet

- Polibrid 705 Data SheetDocument4 pagesPolibrid 705 Data SheetProject NiteksindoNo ratings yet

- Jotafloor EP SLDocument4 pagesJotafloor EP SLEduardo Vera portocarreroNo ratings yet

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Enviroline - 225 - Eng - A4 - 20190930Document4 pagesE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Enviroline - 225 - Eng - A4 - 20190930henryNo ratings yet

- Enviroline 373f+ds+eng PDFDocument4 pagesEnviroline 373f+ds+eng PDFMohamed NouzerNo ratings yet

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interchar - 1120 - Eng - A4 - 20201117Document4 pagesE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interchar - 1120 - Eng - A4 - 20201117Ramesh RathinamNo ratings yet

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interprime - 198 - Eng - Usa - LTR - 20150205Document4 pagesE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interprime - 198 - Eng - Usa - LTR - 20150205Roberta RamosNo ratings yet

- Hi Pon 20 01 Epoxy Primer Ver 8.0Document4 pagesHi Pon 20 01 Epoxy Primer Ver 8.0PushpendraNo ratings yet

- Sherwin Williams Macropoxy M262 PDS Promain 05 09 2022Document2 pagesSherwin Williams Macropoxy M262 PDS Promain 05 09 2022paNo ratings yet

- KAN-TAURUS High Build Epoxy Finish: CharacteristicsDocument2 pagesKAN-TAURUS High Build Epoxy Finish: Characteristicsazam RazzaqNo ratings yet

- EPILUX 850 SF VOC Jan-2017Document2 pagesEPILUX 850 SF VOC Jan-2017PraveenNo ratings yet

- Interchar 1190: Water Borne Intumescent CoatingDocument4 pagesInterchar 1190: Water Borne Intumescent Coatingsubham sahuNo ratings yet

- Interchar 963: Acrylic IntumescentDocument4 pagesInterchar 963: Acrylic IntumescentImran MulaniNo ratings yet

- Hipon 20 DechloDocument3 pagesHipon 20 DechloLopez GardoNo ratings yet

- 312 UkDocument4 pages312 UkAhmed IbrahimNo ratings yet

- Enviroline 224+ds+eng PDFDocument4 pagesEnviroline 224+ds+eng PDFMohamed NouzerNo ratings yet

- Interzone 954Document0 pagesInterzone 954hennawijayaNo ratings yet

- Intercure 99Document4 pagesIntercure 99Doby YuniardiNo ratings yet

- Interplate 11: Zinc SilicateDocument4 pagesInterplate 11: Zinc SilicateMohamed NouzerNo ratings yet

- Epilux 155Document2 pagesEpilux 155Allana100% (1)

- Annex 1 TDS Nitoprime Zincrich Saudi ArabiaDocument3 pagesAnnex 1 TDS Nitoprime Zincrich Saudi ArabiaMdShahbazAhmedNo ratings yet

- Interchar 1190 (2 Hour) DatasheetDocument4 pagesInterchar 1190 (2 Hour) DatasheetCongson JeffNo ratings yet

- Fosroc Nitoflor FC150: Constructive SolutionsDocument4 pagesFosroc Nitoflor FC150: Constructive SolutionsABHI MITRANo ratings yet

- Intercure 420: Rapid Recoat EpoxyDocument4 pagesIntercure 420: Rapid Recoat EpoxyA. FauziNo ratings yet

- Nitoprime ZincrichDocument3 pagesNitoprime ZincrichtalatzahoorNo ratings yet

- TDS Intergard® 269epoxyDocument4 pagesTDS Intergard® 269epoxySyamsul MaripNo ratings yet

- 306 UkDocument4 pages306 UkAhmed IbrahimNo ratings yet

- Hardtop XP: Technical Data SheetDocument5 pagesHardtop XP: Technical Data SheetMohd YusriNo ratings yet

- High Build Epoxy Anti-Corrosive Primer SpecsDocument2 pagesHigh Build Epoxy Anti-Corrosive Primer SpecsMuthuKumar100% (1)

- Interzone 1000: Glass Flake EpoxyDocument4 pagesInterzone 1000: Glass Flake EpoxyAnindya Aulia PratiwiNo ratings yet

- Chartek 8E: Epoxy IntumescentDocument4 pagesChartek 8E: Epoxy IntumescentSubham SahuNo ratings yet

- Fosroc Nitoflor SL4000 Heavy Duty Epoxy Floor ToppingDocument4 pagesFosroc Nitoflor SL4000 Heavy Duty Epoxy Floor ToppingVincent JavateNo ratings yet

- Interzone954TdsEng PDFDocument4 pagesInterzone954TdsEng PDFÖzgür TuştaşNo ratings yet

- k1) Luxatherm1600 3171Document2 pagesk1) Luxatherm1600 3171Syed FaridNo ratings yet

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 pagesB B B Berger Erger Erger Erger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- HEMPADUR ZINC 15360 15360 en-GB PDFDocument2 pagesHEMPADUR ZINC 15360 15360 en-GB PDFErwin MalmsteinNo ratings yet

- Ficha GP3477 Epoxy Water EmulsionDocument2 pagesFicha GP3477 Epoxy Water EmulsionMarina AvNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

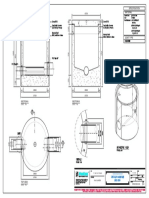

- Manhole Shaft Dia. 600 HibwDocument1 pageManhole Shaft Dia. 600 Hibwgalih mahardikaNo ratings yet

- Manhole Shaft Dia. 600 HibwDocument1 pageManhole Shaft Dia. 600 Hibwgalih mahardikaNo ratings yet

- Manhole Shaft Dia. 600 HibwDocument1 pageManhole Shaft Dia. 600 Hibwgalih mahardikaNo ratings yet

- Understanding Concrete Pipe StandardsDocument29 pagesUnderstanding Concrete Pipe Standardsgalih mahardikaNo ratings yet

- Ketchikan Shipyard Improvements Plan CompleteDocument230 pagesKetchikan Shipyard Improvements Plan CompleteOpó Ishak Bawias Adare100% (1)

- INVENTORY MANAGEMENT TechniquesDocument24 pagesINVENTORY MANAGEMENT TechniquesWessal100% (1)

- Technology Consulting: Amruta Kulkarni Anu Abraham Rajat JainDocument9 pagesTechnology Consulting: Amruta Kulkarni Anu Abraham Rajat JainRajat JainNo ratings yet

- PediculosisDocument14 pagesPediculosisREYMARK HACOSTA100% (1)

- Manual Handling Risk Assessment ProcedureDocument6 pagesManual Handling Risk Assessment ProcedureSarfraz RandhawaNo ratings yet

- Winkens Et Al 2009Document8 pagesWinkens Et Al 2009Marta SanchezNo ratings yet

- Chronological OrderDocument5 pagesChronological OrderDharWin d'Wing-Wing d'AriestBoyzNo ratings yet

- Sample QuestionsDocument70 pagesSample QuestionsBushra MaryamNo ratings yet

- ProjectDocument86 pagesProjectrajuNo ratings yet

- College of Physical Therapy Produces Skilled ProfessionalsDocument6 pagesCollege of Physical Therapy Produces Skilled ProfessionalsRia Mae Abellar SalvadorNo ratings yet

- Tuberculin Skin Test: Facilitator GuideDocument31 pagesTuberculin Skin Test: Facilitator GuideTiwi NaloleNo ratings yet

- Eagle Test ReportDocument25 pagesEagle Test ReportMuhammad FahadNo ratings yet

- Grade 8 Lily ExamDocument3 pagesGrade 8 Lily ExamApril DingalNo ratings yet

- Building and Enhancing New Literacies Across The CurriculumDocument119 pagesBuilding and Enhancing New Literacies Across The CurriculumLowela Kasandra100% (3)

- Integrating Therapeutic Play Into Nursing and Allied Health PracticeDocument214 pagesIntegrating Therapeutic Play Into Nursing and Allied Health PracticeIbrahim SabraNo ratings yet

- 10 Tips To Support ChildrenDocument20 pages10 Tips To Support ChildrenRhe jane AbucejoNo ratings yet

- 03 - 42 STCP-Ahm AssetDocument46 pages03 - 42 STCP-Ahm AssetARP MEILNo ratings yet

- Rotational Equilibrium SimulationDocument3 pagesRotational Equilibrium SimulationCamille ManlongatNo ratings yet

- Service Positioning and DesignDocument3 pagesService Positioning and DesignSaurabh SinhaNo ratings yet

- Cell Selection ReselectionDocument35 pagesCell Selection ReselectionThiaguNo ratings yet

- Kennedy 1945 Bibliography of Indonesian Peoples and CulturesDocument12 pagesKennedy 1945 Bibliography of Indonesian Peoples and CulturesJennifer Williams NourseNo ratings yet

- Omobonike 1Document13 pagesOmobonike 1ODHIAMBO DENNISNo ratings yet

- Proposed Panel Antenna: Globe Telecom ProprietaryDocument2 pagesProposed Panel Antenna: Globe Telecom ProprietaryJason QuibanNo ratings yet

- Delhi (The Capital of India) : Ebook by Ssac InstituteDocument27 pagesDelhi (The Capital of India) : Ebook by Ssac InstituteAnanjay ChawlaNo ratings yet

- SMEs, Trade Finance and New TechnologyDocument34 pagesSMEs, Trade Finance and New TechnologyADBI EventsNo ratings yet

- Durand Et Al JHRC 1997 Experimental Design Optimization of The Analysis of Gasoline by Capillary Gas ChromatographyDocument6 pagesDurand Et Al JHRC 1997 Experimental Design Optimization of The Analysis of Gasoline by Capillary Gas ChromatographyCatalinaSalamancaNo ratings yet

- GastrectomyDocument19 pagesGastrectomyCyrus GarciaNo ratings yet

- Masterbatch Buyers Guide PDFDocument8 pagesMasterbatch Buyers Guide PDFgurver55No ratings yet