Professional Documents

Culture Documents

Important Information: Properties of Hdpe Pipe

Uploaded by

CRISTIAN EDER SILVA MACHUCAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Important Information: Properties of Hdpe Pipe

Uploaded by

CRISTIAN EDER SILVA MACHUCACopyright:

Available Formats

www.romac.

com • 1-800-426-9341 HDPE

IMPORTANT

MADE IN U.S.A.

INFORMATION

PROPERTIES OF HDPE PIPE

High density polyethylene pipe (HDPE) has several • Creep is continuous yield of material under

properties that make it very different from “tradi- stress. HDPE will creep if the stress placed on it

tional” water works pipe materials: gets above a certain level. If great care is not tak-

en when designing fittings for use on HDPE pipe,

• Coefficient of thermal expansion is over 10 this stress level can be exceeded and fittings

times that of DI and steel and 3 times that of that work great today may fail later as the HDPE

PVC. In practical terms, this means HDPE pipe creeps.

shrinks 10 times as much as DI and 3 times as

much as PVC when it gets cold. This can loosen • Low coefficient of friction means HDPE is very

any fittings installed on it. Also, it’s length shrinks “slick.” This makes it easy for fittings to rotate on

1 inch per 100 feet of pipe length with a 10° F the pipe or migrate along it.

temperature drop, making it likely to pull out of

unrestrained couplings. • Toe-in occurs when HDPE is cut. This can affect

tapping sleeves and saddles, and makes stiffeners

• Yield strength of HDPE is approximately 1/50 difficult to install in pipe ends.

that of DI or steel and 1/5 that of PVC.

HDPE

• Modulus of Elasticity of HDPE is much lower

than other pipe materials, which means it is not as

rigid.

LIMITATIONS OF ROMAC PRODUCTS FOR USE ON HDPE PIPE

HDPE has a lower modulus of elasticity and higher • Pipe systems must be designed to compensate

coefficient of thermal expansion than other pipe for pipe movement so as to prevent fittings from

materials. These properties cause HDPE pipe to migrating or rotating on the pipe.

expand and contract much more from changes in

temperature and/or pressure than other piping • Products are intended for use in underground

materials. Because of these and other properties, service only.

great care must be taken in choosing fittings and

repair products for use on HDPE pipe. Romac prod- • Romac internal pipe stiffeners must be used

ucts in this catalog section are designed to function when coupling pipe ends except for Alpha Re-

within the following limitations: strained Joint products on HDPE pipe

SDRs 9, 11, 13.5 and 17 (see Alpha installation

• Pipe must be manufactured in accordance with instructions for details).

AWWA Standard ANSI/AWWA C906 / with re-

spect to size. • Proper restraint must be used when coupling

pipe ends to prevent pullout from hydraulic forc-

• Operating temperatures are limited to 85° F max- es or temperature changes.

imum and 32° F minimum.

• Operating pressure is limited to 150 psi or the

rating of the pipe, whichever is less.

Romac cannot warrant products used in applications that are outside one or more of

these limitations. Contact Romac’s Engineering Department at 1-800-426-9341 if you have

questions about the use of our products on HDPE pipe.

JULY 01, 2017 9-1

HDPE www.romac.com • 1-800-426-9341

IMPORTANT

INFORMATION MADE IN U.S.A.

SPRING WASHERS

Spring washers are used with Romac products for HDPE

pipe to help counteract the problem of pipe contraction

during temperature and pressure changes. They are made

of a special “spring” grade of stainless steel.

The proper number of bolts have been provided for each

fitting based on the limitations on Page 9-1.

TWO SPRING WASHERS THREE SPRING WASHERS FOUR SPRING WASHERS

HDPE

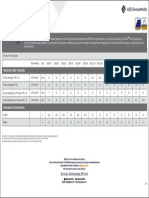

DIMENSIONS OF COMMON HDPE PIPE

SDR 21 SDR 17 SDR 13.5 SDR 11 SDR 9

PRESSURE CLASS 80 PRESSURE CLASS 100 PRESSURE CLASS 128 PRESSURE CLASS 160 PRESSURE CLASS 200

NOMINAL OUTSIDE INSIDE WALL INSIDE WALL INSIDE WALL INSIDE WALL INSIDE WALL

PIPE SIZE DIAMETER DIAMETER THICKNESS DIAMETER THICKNESS DIAMETER THICKNESS DIAMETER THICKNESS DIAMETER THICKNESS

3” 3.50 3.167 0.167 3.088 0.206 2.981 0.259 2.864 0.318 2.722 0.389

4.50 4.071 0.214 3.971 0.265 3.833 0.333 3.682 0.409 3.500 0.500

4” 4.80 4.343 0.229 4.235 0.282 4.089 0.356 3.927 0.436 3.733 0.533

5” 5.56 5.033 0.265 4.909 0.327 4.739 0.412 4.552 0.506 4.327 0.618

6.63 5.994 0.315 5.846 0.390 5.644 0.491 5.420 0.602 5.153 0.736

6” 6.90 6.243 0.329 6.088 0.406 5.878 0.511 5.645 0.627 5.367 0.767

8.63 7.804 0.411 7.610 0.507 7.347 0.639 7.057 0.784 6.708 0.958

8” 9.05 8.188 0.431 7.985 0.532 7.709 0.670 7.405 0.823 7.039 1.006

10.75 9.726 0.512 9.485 0.632 9.157 0.796 8.795 0.977 8.361 1.194

10” 11.10 10.043 0.529 9.794 0.653 9.456 0.822 9.082 1.009 8.633 1.233

12.75 11.536 0.607 11.250 0.750 10.861 0.944 10.432 1.159 9.917 1.417

12” 13.20 11.943 0.629 11.647 0.776 11.244 0.978 10.800 1.200 10.267 1.467

14” 14.00 12.667 0.667 12.353 0.824 11.926 1.037 11.455 1.273 10.889 1.556

16” 16.00 14.476 0.762 14.118 0.941 13.630 1.185 13.091 1.455 12.444 1.778

18” 18.00 16.286 0.857 15.882 1.059 15.333 1.333 14.727 1.636 14.000 2.000

20” 20.00 18.095 0.952 17.647 1.176 17.037 1.481 16.364 1.818 15.556 2.222

22” 22.00 19.905 1.048 19.412 1.294 18.741 1.630 18.000 2.000 17.111 2.444

24” 24.00 21.714 1.143 21.176 1.412 20.444 1.778 19.636 2.182 18.667 2.667

This chart is based on information in AWWA Standard ANSI/AWWA C906-90.

All dimensions are nominal and subject to manufacturing tolerances.

Only products listed in the HDPE Products section

are suitable for use with HDPE pipe. Do not use

products not listed in this section on HDPE!

Contact Romac’s Engineering Department at 1-800-426-9341 for sizes not listed in the catalog.

9-2 JULY 01, 2017 • REV. FEB. 13, 2018

You might also like

- 22 HDPE Pipe Oil GasDocument2 pages22 HDPE Pipe Oil GasArunkumar SelvamNo ratings yet

- NEISCO HDPE PIPES CatalougeDocument16 pagesNEISCO HDPE PIPES CatalougeAhmed HussienNo ratings yet

- HDPE Brochure (Lamson)Document6 pagesHDPE Brochure (Lamson)arkadjyothiprakashNo ratings yet

- Smith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureDocument8 pagesSmith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureWong Chung MengNo ratings yet

- CPVC Schedule 40 & Schedule 80 Pipe Specifications: ApplicationDocument11 pagesCPVC Schedule 40 & Schedule 80 Pipe Specifications: ApplicationRavikumarNo ratings yet

- HDPE Pipe: High Density Polyethylene PipeDocument4 pagesHDPE Pipe: High Density Polyethylene PipeDarshit VyasNo ratings yet

- CI2400ENG Bondstrand 2400 Product DataDocument6 pagesCI2400ENG Bondstrand 2400 Product DatachabibNo ratings yet

- DARC-051 Suministro e Instalacion Del Sistema Contraincendios.Document223 pagesDARC-051 Suministro e Instalacion Del Sistema Contraincendios.Raul H CastroNo ratings yet

- HDPE Pipe PresentationDocument17 pagesHDPE Pipe PresentationSiddiqui Muhammad AshfaqueNo ratings yet

- Chempro & UPVCDocument28 pagesChempro & UPVCcsdcw fqefqfNo ratings yet

- TUBOS PEAD PipelineDocument2 pagesTUBOS PEAD PipelineLuís Felipe Coimbra MinelloNo ratings yet

- DHT-DHC OverviewDocument39 pagesDHT-DHC OverviewTaras ByloNo ratings yet

- Gray UPVC Pipes & FittingsDocument28 pagesGray UPVC Pipes & FittingsAli Osman100% (3)

- FI Brochure HDPE FM CatalogDocument66 pagesFI Brochure HDPE FM CatalogCOORDINACION DISEÑONo ratings yet

- Jfetiger BrochureDocument8 pagesJfetiger BrochureAquila Q MNo ratings yet

- Seal King® Secondary Seal: Protecting Your World, One Tank at A TimeDocument2 pagesSeal King® Secondary Seal: Protecting Your World, One Tank at A TimerustyNo ratings yet

- FT - AWWA C900 - Tubería Enterrada C900Document3 pagesFT - AWWA C900 - Tubería Enterrada C900Jimmy Fernández B.No ratings yet

- 720 Pipette Puller ManualDocument22 pages720 Pipette Puller ManualPaulo CamargoNo ratings yet

- Plain End Piping System For High Density Polyethylene Pipe: Product DescriptionDocument1 pagePlain End Piping System For High Density Polyethylene Pipe: Product DescriptionAbbas RizviNo ratings yet

- Hydraulic Stage Tool: Model 754PD With 854BS Liner Plug SetDocument6 pagesHydraulic Stage Tool: Model 754PD With 854BS Liner Plug SetAli AlakariNo ratings yet

- DS Ipex Pipe SCH40 & SCH80Document3 pagesDS Ipex Pipe SCH40 & SCH80KPHMXNo ratings yet

- Mechanical Seals JohnCraneDocument6 pagesMechanical Seals JohnCranevalikka100% (3)

- HDPE 4710 FM Pipe SpecificationDocument2 pagesHDPE 4710 FM Pipe SpecificationJulio CongonaNo ratings yet

- Tubería AWWA C900Document3 pagesTubería AWWA C900ErickNo ratings yet

- M-LOK Specification ManualDocument18 pagesM-LOK Specification ManualLorin LaverdureNo ratings yet

- A New Era In: Filtration Performance and InnovationDocument6 pagesA New Era In: Filtration Performance and InnovationCARLOS SARMIENTONo ratings yet

- Put An ACE in The Hole: Vam Top Vam Top HC Vam Top HT Vam Top Fe New VamDocument8 pagesPut An ACE in The Hole: Vam Top Vam Top HC Vam Top HT Vam Top Fe New VamjoseNo ratings yet

- Instrumentation Cable BSDocument42 pagesInstrumentation Cable BSShivaniNo ratings yet

- Specifications: Typical ApplicationsDocument4 pagesSpecifications: Typical ApplicationsMahmoud Al HomranNo ratings yet

- Ficha Tecnica Tuberias Viega Pureflow - TDPF - 0120 - Pureflow - Pex - TubingDocument4 pagesFicha Tecnica Tuberias Viega Pureflow - TDPF - 0120 - Pureflow - Pex - TubingDaniella GarciaNo ratings yet

- Hydratight Morgrip Swivel Ring Flyer PDFDocument2 pagesHydratight Morgrip Swivel Ring Flyer PDFSenthil KumarNo ratings yet

- Design Flow PE Pipe ChartDocument2 pagesDesign Flow PE Pipe ChartBinodh DanielNo ratings yet

- Xceeder Lambda Chain BrochureDocument8 pagesXceeder Lambda Chain BrochurebrunoborogdNo ratings yet

- Tuberias Schedule 40 Fittings, Unions & SaddlesDocument74 pagesTuberias Schedule 40 Fittings, Unions & SaddlesFelix SanchezNo ratings yet

- Xylan CoatDocument9 pagesXylan CoatTran NguyenNo ratings yet

- TD-4615 HRDocument8 pagesTD-4615 HRjosfwangNo ratings yet

- Pipe Sizing & Specifications Methods For Joining Pipe Pipe Representation Pipe Fittings Buttwelded Branch Fittings Flanges Screwed FittingsDocument27 pagesPipe Sizing & Specifications Methods For Joining Pipe Pipe Representation Pipe Fittings Buttwelded Branch Fittings Flanges Screwed Fittingsrodhiba1No ratings yet

- WDS Series: Air/Steam Moisture Separator Cast Iron or Carbon SteelDocument2 pagesWDS Series: Air/Steam Moisture Separator Cast Iron or Carbon SteelDiego HernandezNo ratings yet

- Corrosion Above Ground Brochure EnglishDocument6 pagesCorrosion Above Ground Brochure EnglishsyammohansNo ratings yet

- Hdpe Ips Submittal PDFDocument2 pagesHdpe Ips Submittal PDFJESUS HUAMANINo ratings yet

- The PE4710 - PE 100 Is A Special Black Polyethylene Material For The Pipe IndustryDocument2 pagesThe PE4710 - PE 100 Is A Special Black Polyethylene Material For The Pipe IndustrysreeNo ratings yet

- Lit Circpac HP DataDocument2 pagesLit Circpac HP Databillel limaneNo ratings yet

- Redox Breaker + Hour MeterDocument6 pagesRedox Breaker + Hour Meterhenry vegaNo ratings yet

- Wall Mount & Box Mount Fan - 600 & 700 Series CatalogDocument12 pagesWall Mount & Box Mount Fan - 600 & 700 Series CatalogRodrigo Regla MuñozNo ratings yet

- Ptfe Wedge Seals: Applications Operating ConditionsDocument6 pagesPtfe Wedge Seals: Applications Operating ConditionsMarcos Marcandali de JesusNo ratings yet

- SCH 80Document9 pagesSCH 80Ahmad AnthonyNo ratings yet

- Type 11j Ds Feb18Document3 pagesType 11j Ds Feb18Suresh KumarNo ratings yet

- Jfebear BrochureDocument12 pagesJfebear BrochurebabuNo ratings yet

- Ptfe Lined Pipe CatalogDocument24 pagesPtfe Lined Pipe CatalogchabibNo ratings yet

- B 4600Document6 pagesB 4600sergioarrayaNo ratings yet

- SV60 Safety Valves: For Use With Steam, Gas and LiquidsDocument8 pagesSV60 Safety Valves: For Use With Steam, Gas and LiquidscmpuckNo ratings yet

- PVC Fittings WebDocument80 pagesPVC Fittings WebRasmy NaamyNo ratings yet

- Sur Club Quote PDFDocument18 pagesSur Club Quote PDFsamanthaNo ratings yet

- Spiraline Grooved Casing and LinerDocument4 pagesSpiraline Grooved Casing and Linerhuyenhvtc252No ratings yet

- Ideal DAF: Dissolved Air FlotationDocument4 pagesIdeal DAF: Dissolved Air FlotationblondtumbalaNo ratings yet

- Tubi Parker 692Document2 pagesTubi Parker 692Chiara FratiNo ratings yet

- 3 WO Copper NickelDocument78 pages3 WO Copper NickelAnonymous Kr13NEBNo ratings yet

- 15-16 Inst Lampu Dan Stop Kontak Kabel TR Nya, Nyy, Nym, Nyfgby (KABELINDO)Document7 pages15-16 Inst Lampu Dan Stop Kontak Kabel TR Nya, Nyy, Nym, Nyfgby (KABELINDO)hafinNo ratings yet

- Geothermal Exchange Pipe and Fittings: Quality and Service That SoarsDocument4 pagesGeothermal Exchange Pipe and Fittings: Quality and Service That SoarsIbrahim DanishNo ratings yet

- Wavin HDPE Soil Waste and Vent ApplicationsDocument48 pagesWavin HDPE Soil Waste and Vent ApplicationsGeorge Uche Anijah-obiNo ratings yet

- (2018) Estimation of The Generation Rate of Different Types of Plastic Wastes and Possible Revenue Recovery From Informal Recycling - AGUNGDocument10 pages(2018) Estimation of The Generation Rate of Different Types of Plastic Wastes and Possible Revenue Recovery From Informal Recycling - AGUNGachmad bahauddinNo ratings yet

- Geomembrane Technical DataDocument1 pageGeomembrane Technical DataYusufAliMuktiNo ratings yet

- DELTA-DRAIN Technical DataDocument1 pageDELTA-DRAIN Technical DataMauricio Barajas BacaNo ratings yet

- Polymer Notes 1Document23 pagesPolymer Notes 1catotheophilus18No ratings yet

- Effects of Disinfection On Newly Constructed Polyethylene Water Mains TR-34 / 2001 BDocument14 pagesEffects of Disinfection On Newly Constructed Polyethylene Water Mains TR-34 / 2001 BToBert100% (1)

- PE PipesDocument28 pagesPE Pipesmanar rafikNo ratings yet

- 2020 0427 Acegrid GdeDocument1 page2020 0427 Acegrid GdeanitakuttyNo ratings yet

- Cribandmatco Cribbing Jacking Catalogue PDFDocument16 pagesCribandmatco Cribbing Jacking Catalogue PDFHanzo BestNo ratings yet

- Plastic Recycling Business PlanDocument36 pagesPlastic Recycling Business PlanAnkur Verma98% (42)

- Easyliner HDD: HDPE Geomembrane Bonded With Geotextiles On Both SidesDocument7 pagesEasyliner HDD: HDPE Geomembrane Bonded With Geotextiles On Both SidesAnonymous CQ4rbzLVENo ratings yet

- Turning Low-Density Polyethylene Plastic Waste Into Plastics Bricks For Sustainable DevelopmentDocument7 pagesTurning Low-Density Polyethylene Plastic Waste Into Plastics Bricks For Sustainable DevelopmentAbdelrahman Ashmawy100% (1)

- Astm - Standard Practice For PVC PipesDocument3 pagesAstm - Standard Practice For PVC PipesrassdriverNo ratings yet

- SP-2379 Ver 1 Mar-21 Pipeline External CoatingsDocument15 pagesSP-2379 Ver 1 Mar-21 Pipeline External CoatingsDevam RajNo ratings yet

- Tr-33 Generic Butt Fusion Joining Gas PipeDocument32 pagesTr-33 Generic Butt Fusion Joining Gas PipeLuis QuinoNo ratings yet

- Evalene HDPE Grade SlateDocument1 pageEvalene HDPE Grade Slatepalani.djpNo ratings yet

- Sabic Hdpe P6006N: High Density Polyethylene For PipeDocument2 pagesSabic Hdpe P6006N: High Density Polyethylene For PipePercyArgomedoNo ratings yet

- Recycled Paper Box To BagDocument6 pagesRecycled Paper Box To BagDem Gualvert TismoNo ratings yet

- Project Report - Plastic Moulded Jerry CansDocument39 pagesProject Report - Plastic Moulded Jerry Canstechnocrat_vsp100% (3)

- HdpeeDocument38 pagesHdpeeSamet BelliNo ratings yet

- Cook's Illustrated 070Document36 pagesCook's Illustrated 070vicky610100% (2)

- MS-PIPING-002ev.a, Laying & Jointing HDPE PipingDocument12 pagesMS-PIPING-002ev.a, Laying & Jointing HDPE PipingBiswasNo ratings yet

- 2024 DPWH Standard List of Pay Items Volume III DO 6 s2023Document68 pages2024 DPWH Standard List of Pay Items Volume III DO 6 s2023Alaiza Mae GumbaNo ratings yet

- Plastic WareDocument6 pagesPlastic WareMuhamad AfidinNo ratings yet

- Abu Dhabi Sewerage Services Company (Adssc) : Adssc/Gscw Section 02600 Sewer Rehabilitation Rev: 02 Jan. 2011 Page 1 of 34Document34 pagesAbu Dhabi Sewerage Services Company (Adssc) : Adssc/Gscw Section 02600 Sewer Rehabilitation Rev: 02 Jan. 2011 Page 1 of 34MȜtaz HammadNo ratings yet

- Brosur Floaton MT - Modular Reservoir Steel HDPE ClosedcellDocument8 pagesBrosur Floaton MT - Modular Reservoir Steel HDPE ClosedcellAnindra Ahmad FarrasNo ratings yet

- SABIC® HDPE M200056 (MFR 20 DG - Min 2.16 KG)Document2 pagesSABIC® HDPE M200056 (MFR 20 DG - Min 2.16 KG)SENADJKI AHMEDNo ratings yet

- RTP PIPE FOR Co2 CAPTUREDocument8 pagesRTP PIPE FOR Co2 CAPTUREIBRAHIMNo ratings yet

- Quality Assurance and Quality Control Practices For Rehabilitation of Sewer and Water MainsDocument68 pagesQuality Assurance and Quality Control Practices For Rehabilitation of Sewer and Water MainsVasaNo ratings yet

- Composite Sleepers 1Document14 pagesComposite Sleepers 1Suprit MagadumNo ratings yet