Professional Documents

Culture Documents

Aluminium Etching: Concentrations

Uploaded by

Fatih KsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aluminium Etching: Concentrations

Uploaded by

Fatih KsCopyright:

Available Formats

Aluminium

Etching

Revised: 2009-12-15

Source: www.microchemicals.eu/technical_information

Concentrations

All chemicals concentrations mentioned in this chapter with a * refer to a conventional concen-

tration listed in the last section of this document.

Aluminium

Aluminium has a density of 2.7 g/cm3 and therefore

belongs to the light metals. Its crystal structure is cu-

bic face centred.

Due to its high electric conductivity, aluminium is used

for conductors in microelectronics where it is often al-

loyed with copper in order to prevent electro migra-

tion, or with silicon in order to prevent the formation

of (silicon-consuming) aluminium-silicon alloys. Al: cubic face centred

With a standard potential of -1.66 V, aluminium does

not belong to the noble metals. However, the forma-

tion of a very thin (few nm) Al2O3 film makes it very inert in many substances. Therefore, Al

etchants require at least compounds for dissolving Al2O3 as well as for etching (or, respectively,

oxidizing) aluminium.

Aluminium Etching Mechanism

Typical Aluminium etchants contain mixtures of 1-5 % HNO3* (for Al oxidation), 65-75 %

H3PO4* (to dissolve the Al2O3), 5-10 % CH3COOH* (for wetting and buffering) and H2O dilution

to define the etch rate at given temperature.

Aluminium etching is highly exothermic, an (inevitable, since isotropic etching) underetching

of the resist mask causes local heating (increased etch rate) and super-proportional under-

etching of the mask as a consequence, if no agitation is performed.

Strong H2-bubbling reduces etch homogeneity. Improvements of the etch rate homogeneity

can be achieved if the etching will be interrupted every approx. 30 seconds by a short dip into

DI water. hereby, the H2 bubbles temporarily vanish.

Generally, etching starts after the dissolution (by H3PO4) of few nm Al2O3 film present on every

Al surface. For this reason, the pho-

Developer Attack toresist processing impacts on the

Entwicklerangriff Al etching: The alkaline developers

preferentially dissolve the Al 2 O 3

where the resist is primarily through-

developed (at regions with lower

resist film thickness, near the edges

of cleared structures, or below

cleared structures with larger fea-

Fotolack

Resist

tures).

Dependant on the extent of (desired

O or undesired) over-developing as

Al22O33 well as delay between development

Al

Al and Al-etching, the process param-

Substrat

Substrate eters may lead to a spatial inhomo-

geneous Al etching start.

Photoresists, developers, remover, adhesion promoters, etchants, and solvents ...

Phone: +49 731 36080-409 www.microchemicals.eu e-Mail: sales@microchemicals.eu

MicroChemicals GmbH - Aluminium Etching with Photoresists

Etch Rate and Selectivity

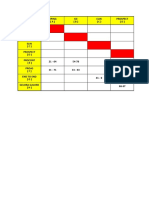

The Al etch rate of H3PO4/HNO3 mixtures 3.5

strongly depends on the temperature (fig. 74 ml H3PO4*

etch rate(10 Å/min)

right-hand for a certain composition, after 3.0 2.5 ml HNO3*

the removal of the Al2O3-layer on the Al

2.5 23.5 ml H2O

surface) and doubles approx. all 5 °C.

3

Aluminium alloyed with few % of Silicon 2.0

shows a comparable etch rate as compared

to pure Aluminium. 1.5

Most Al etchants attack copper significantly

more then aluminium. The nickel etch rate 1.0

is lower then the aluminium etch rate. Ti-

0.5

tanium, chromium and silver are hardly

etched, noble metals such as gold or plati- 20 24 28 32 36 40

num are not attacked.

etch temperature (°C)

Our Aluminium Etch

Our aluminium etchant ANPE 80/5/5/10 has the following composition:

H3PO4 : HNO3 : CH3COOH : H2O = 73 %: 3.1 % : 3.3 % : 20.6 %

We supply this mixture in 2.5 L sales volumes in VLSI quality. Other grades/sales volumes

available on request.

Suited Photoresists and their Processing for Al Etching

All AZ® and TI resists are suited and sufficiently stable as mask for etching few µm of Alu-

minium. Generally, we recommend the usage of resists with optimized adhesion such as the

AZ® 1500 series (resist film thickness range approx. 0.5-3 µm via the AZ® 1505, 1512 HS,

1514 H, and 1518), or the AZ® 4533 (3-5 µm).

The deeper Al has to be etched, the ticker the resist film should be. If this requires a high

aspect ratio, we recommend the high-resolution AZ® ECI 3000 series (resist film thickness

range approx. 0.5-4 µm).

Since most NaOH-, KOH-, or TMAH-based developers attack Aluminium at a rate of approx.

50-100 nm/min, sensitive processes require an Al-compatible developer such as the „AZ®

Developer“ with very low Al attack.

In order to improve the resist adhesion, a hardbake after development can be beneficial. We

recommend 140-145°C for 5-10 minutes. Since the resist film hereby embrittles, the cooling

down to room temperature should not take place abruptly in order to prevent the formation of

cracks.

For resist removal after etching, the „AZ® 100 Remover“ can be used as long as no dilution or

contamination with water (even in traces!) occurs, otherwise Al will strongly be attacked. In

case of sensitive processes, the pH-neutral organic solvents NMP or DMSO are more suited.

All resists and ancillaries mentioned in this section are distributed by us and more detailed in

the document Photoresists, Developers, and Removers.

Dilution Grade of the Substances Mentioned in this Document

HCl* = 37% HCl in H2O HNO3* = 70% HNO3 in H2O

H2SO4* = 98% H2SO4 in H2O HF* = 49% HF in H2O

H2O2* = 30% H2O2 in H2O H3PO4* = 85% H3PO4 in H2O

NH4OH* = 29% NH3 in H2O CH3COOH* = 99% CH3COOH in H2O

Photoresists, developers, remover, adhesion promoters, etchants, and solvents ...

Phone: +49 731 36080-409 www.microchemicals.eu e-Mail: sales@microchemicals.eu

-2-

MicroChemicals GmbH - Aluminium Etching with Photoresists

Disclaimer of Warranty

All information, process guides, recipes etc. given in this brochure have been added to the

best of our knowledge. However, we cannot issue any guarantee concerning the accuracy of

the information.

We assume no liability for any hazard for staff and equipment which might stem from the

information given in this brochure.

Generally speaking, it is in the responsibility of every staff member to inform herself/himself

about the processes to be performed in the appropriate (technical) literature, in order to

minimize any risk to man or machine.

AZ and the AZ logo are registered trademarks of AZ Electronic Materials (Germany) GmbH.

Photoresists, developers, remover, adhesion promoters, etchants, and solvents ...

Phone: +49 731 36080-409 www.microchemicals.eu e-Mail: sales@microchemicals.eu

-3-

You might also like

- Aluminium EtchingDocument3 pagesAluminium EtchingaliNo ratings yet

- Aluminium Etching MicroChemicals PDFDocument3 pagesAluminium Etching MicroChemicals PDFDaniela Silva MolinaNo ratings yet

- Wet Etching Metals Al Au Cu CR Ni Ti AgDocument7 pagesWet Etching Metals Al Au Cu CR Ni Ti AgArely Vazquez Jmnz'No ratings yet

- Compendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)From EverandCompendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)No ratings yet

- Show Brazing AluminiumDocument6 pagesShow Brazing Aluminiumneptuno97No ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Painting InspectionDocument62 pagesPainting InspectionbezzelNo ratings yet

- Afsa Corrosion Pocket GuideDocument36 pagesAfsa Corrosion Pocket GuideNuno PachecoNo ratings yet

- Asset Integrity Management PDFDocument155 pagesAsset Integrity Management PDFBouazizizi MOHAMEDNo ratings yet

- Zincalume Galv Truecore MSDSDocument6 pagesZincalume Galv Truecore MSDScuongdcNo ratings yet

- Photoresist Removal: Dissolubility of Processed Photoresist FilmsDocument2 pagesPhotoresist Removal: Dissolubility of Processed Photoresist Filmswayan.wandira8122No ratings yet

- Alloys and PropertiesDocument8 pagesAlloys and PropertiesAna RivasNo ratings yet

- Imparting Resistance To Storage Stain: GalvinfonoteDocument3 pagesImparting Resistance To Storage Stain: GalvinfonoteSontosh BhattacharjeeNo ratings yet

- 3501Document15 pages3501Norisk NanungNo ratings yet

- Sermaloy J Diffused Slurry Aluminide Coating: AdvantagesDocument1 pageSermaloy J Diffused Slurry Aluminide Coating: Advantagesbigsteve9088No ratings yet

- Aluminium AnodisingDocument7 pagesAluminium AnodisingChinmay Bhuta100% (1)

- Aluminium Brazing 7 - StepsDocument6 pagesAluminium Brazing 7 - StepsPrashant NankarNo ratings yet

- Corrosion Performance of Aluminum Culvert: - MoreDocument18 pagesCorrosion Performance of Aluminum Culvert: - MoreMurali PokkunuriNo ratings yet

- ALUMON EN - MIES - NA - 201614 - 16jul18Document7 pagesALUMON EN - MIES - NA - 201614 - 16jul18Sarai Aracely melendez garciaNo ratings yet

- Marine PDFDocument578 pagesMarine PDFNizar BouchaalaNo ratings yet

- How To Use Anodizing Defects Catalogue Photo Gallery: 3.1 Acid CorrosionDocument21 pagesHow To Use Anodizing Defects Catalogue Photo Gallery: 3.1 Acid CorrosionSatyendra PandeyNo ratings yet

- Dental Amalgam: Rutika Pathrabe Roll No. 97Document57 pagesDental Amalgam: Rutika Pathrabe Roll No. 97sa100% (1)

- Jotun Solvalitt Alu 11A TDSDocument4 pagesJotun Solvalitt Alu 11A TDSSinan A AzizNo ratings yet

- BGas MaterialDocument65 pagesBGas Materialslxanto100% (4)

- Painting Inspection NotesDocument86 pagesPainting Inspection Notessandip singhNo ratings yet

- The Use of Aluminium Alloy in The Production of Ex ProductsDocument3 pagesThe Use of Aluminium Alloy in The Production of Ex ProductsSaber AbdelaalNo ratings yet

- Sampling Plan:: Testing A Certain NumberDocument23 pagesSampling Plan:: Testing A Certain NumberhariNo ratings yet

- Surlon KE Datasheet Hard Ceramic Hard Anodizing With Lubrication 29AUG17Document8 pagesSurlon KE Datasheet Hard Ceramic Hard Anodizing With Lubrication 29AUG17Giacomo ZammattioNo ratings yet

- Technical Bulletin 6-13 BrigDocument11 pagesTechnical Bulletin 6-13 Brigjulianpellegrini860No ratings yet

- Trivalent Passivation Systems PDFDocument2 pagesTrivalent Passivation Systems PDFMuthuswamyNo ratings yet

- Wall-Colmonoy Wallex-1 ENG January2021Document3 pagesWall-Colmonoy Wallex-1 ENG January2021pranav kariaNo ratings yet

- Introduction To Brazing of Aluminium Alloys: TALAT Lecture 4601Document24 pagesIntroduction To Brazing of Aluminium Alloys: TALAT Lecture 4601fedeloquiNo ratings yet

- Aluminium Electrode With 5%si: Size (MM) 2,5x350 3,2x350 4,0x350 Packets/Carton Kg/Packet Kg/CartonDocument1 pageAluminium Electrode With 5%si: Size (MM) 2,5x350 3,2x350 4,0x350 Packets/Carton Kg/Packet Kg/CartonAdel AbduoNo ratings yet

- Svetsaren Vol 54-2 Troubleshooting in AluminiumDocument4 pagesSvetsaren Vol 54-2 Troubleshooting in AluminiumlvcuichanghuaNo ratings yet

- AlchromDocument1 pageAlchromnitin chauhanNo ratings yet

- ABB CorrosionDocument8 pagesABB CorrosionForexFFNo ratings yet

- Overview - Aerospace Anodize Finishes - Products FinishingDocument20 pagesOverview - Aerospace Anodize Finishes - Products FinishingVu NguyenNo ratings yet

- Chrome PlatingDocument11 pagesChrome PlatingMahesh Babu100% (1)

- 90-10 Copper-Nickel vs. Aluminum BrassDocument7 pages90-10 Copper-Nickel vs. Aluminum BrassMohamed AshfaqNo ratings yet

- Az 6600 Series (For HW 1)Document4 pagesAz 6600 Series (For HW 1)Max LiaoNo ratings yet

- Transolac Aluminium HR: Product DescriptionDocument3 pagesTransolac Aluminium HR: Product Descriptionshady yehiaNo ratings yet

- 03 ICT EtchDocument37 pages03 ICT EtchCyrille MagdiNo ratings yet

- Photoresist BakingDocument3 pagesPhotoresist BakingIgor_uhuNo ratings yet

- mc1696 PDFDocument4 pagesmc1696 PDFBala MuruganNo ratings yet

- Technical Bulletin - Acid EtchDocument4 pagesTechnical Bulletin - Acid EtchOla OlatunjiNo ratings yet

- Aluminium Alloy Specimens With High Edge RetentionDocument4 pagesAluminium Alloy Specimens With High Edge RetentionfotickNo ratings yet

- ObjectiveDocument12 pagesObjectivemasuma lovelyNo ratings yet

- Chrome Plating of Steel BarsDocument4 pagesChrome Plating of Steel BarsAmr BuhlakNo ratings yet

- Anodizing On AlDocument5 pagesAnodizing On AlKASHFI UDDINNo ratings yet

- 00 Preventing Corrosion in AluminumDocument1 page00 Preventing Corrosion in AluminumReylourd PunzalNo ratings yet

- B-Gas-Question & Answer PaparsDocument62 pagesB-Gas-Question & Answer PaparsSreedhar Patnaik.MNo ratings yet

- FROSIO - Flash QuesDocument4 pagesFROSIO - Flash QuesAnte BosancicNo ratings yet

- Berger Lumeros HR 123 Heat Resisting AluminiumDocument2 pagesBerger Lumeros HR 123 Heat Resisting AluminiumAvishek GuptaNo ratings yet

- Section 8. Aluminum and Aluminum AlloysDocument4 pagesSection 8. Aluminum and Aluminum AlloysblackhawkNo ratings yet

- Locating The Thinnest Spot in A Zinc (Galvanized) Coating On Iron or Steel ArticlesDocument4 pagesLocating The Thinnest Spot in A Zinc (Galvanized) Coating On Iron or Steel ArticlesDarwin DarmawanNo ratings yet

- TB 108 Anodised Aluminium Thickness Hardness MinDocument5 pagesTB 108 Anodised Aluminium Thickness Hardness MinKris T.No ratings yet

- Anderson CrackinginAluminumAlloysDocument35 pagesAnderson CrackinginAluminumAlloysamine100% (1)

- Recap Panahan HUT IKPT - 41Document3 pagesRecap Panahan HUT IKPT - 41Fatih KsNo ratings yet

- Olah Data Least SquareDocument2 pagesOlah Data Least SquareFatih KsNo ratings yet

- Olah Data Least SquareDocument2 pagesOlah Data Least SquareFatih KsNo ratings yet

- SalerioDocument28 pagesSalerioRizqaFebrilianyNo ratings yet

- hp8154b 8155aDocument2 pageshp8154b 8155adspa123No ratings yet

- 5 Wire Heater Tap DrawingDocument1 page5 Wire Heater Tap Drawingnaymyozaw zawNo ratings yet

- Jurnal Skripsi Fadhil WigunoDocument5 pagesJurnal Skripsi Fadhil WigunoFadhil WigunoNo ratings yet

- Techno Eleq3 enDocument74 pagesTechno Eleq3 eneugeni madaNo ratings yet

- Service ManualDocument105 pagesService ManualSlaughterGirlNo ratings yet

- CSC-1321 Gateway User Guide: Downloaded From Manuals Search EngineDocument48 pagesCSC-1321 Gateway User Guide: Downloaded From Manuals Search EngineKislan MislaNo ratings yet

- LO - Precision Optics - Helios Series - Technical DataDocument1 pageLO - Precision Optics - Helios Series - Technical DataFranco TerrazasNo ratings yet

- Building Utilities 2: Casulla, Cristine T. Bs in Architecture 3 University of LuzonDocument20 pagesBuilding Utilities 2: Casulla, Cristine T. Bs in Architecture 3 University of LuzonEreca NavarroNo ratings yet

- PLC ListDocument28 pagesPLC ListIshfaqAhmedMayoNo ratings yet

- Everflo User Manual International EnglishDocument17 pagesEverflo User Manual International EnglishCiuca DeliaNo ratings yet

- Semi-Automated Agriculture Robot For Seeding FunctionDocument4 pagesSemi-Automated Agriculture Robot For Seeding FunctionShubman GillNo ratings yet

- DHI ASL8112X W - DatasheetDocument2 pagesDHI ASL8112X W - DatasheetLeonel cadenas hernandezNo ratings yet

- DC PWM Motor Speed Controller: Circuit DiagramDocument2 pagesDC PWM Motor Speed Controller: Circuit DiagramarminNo ratings yet

- KBP201 THRU KBP207: FeaturesDocument2 pagesKBP201 THRU KBP207: FeaturesHadi BarakNo ratings yet

- ELEC353 Practice Problem Set #6: R R Z R ZDocument14 pagesELEC353 Practice Problem Set #6: R R Z R Zabdolrahman altamimeNo ratings yet

- qpd0005-pk020 Rev (G)Document15 pagesqpd0005-pk020 Rev (G)rasoolNo ratings yet

- Digital Signal Processing Lecture-03: Arnisha Akhter Lecturer, Dept. of CSE Jagannath UniversityDocument44 pagesDigital Signal Processing Lecture-03: Arnisha Akhter Lecturer, Dept. of CSE Jagannath UniversityKashfi ShormitaNo ratings yet

- MANY0730A.GB AirMaster P1 - Positive Displacement ApplicationDocument11 pagesMANY0730A.GB AirMaster P1 - Positive Displacement Applicationsebastian100% (4)

- Capacitor EL-Intelcond AY-2019Document7 pagesCapacitor EL-Intelcond AY-2019Gabriel AlfaroNo ratings yet

- B.tech 4th Year SyllabusDocument61 pagesB.tech 4th Year SyllabusInsta WorldNo ratings yet

- NX-3000 Series: User ManualDocument70 pagesNX-3000 Series: User ManualJulio Cesar Huachaca RodriguezNo ratings yet

- Exercises With Finite State Machines: CS 64: Computer Organization and Design Logic Lecture #17 Winter 2019Document17 pagesExercises With Finite State Machines: CS 64: Computer Organization and Design Logic Lecture #17 Winter 2019Gabriel CañadasNo ratings yet

- PVIV Test Solution: Typical I-V Test Configuration With Optional Equipment Shown. Solar Simulator Is Sold SeparatelyDocument4 pagesPVIV Test Solution: Typical I-V Test Configuration With Optional Equipment Shown. Solar Simulator Is Sold Separatelyluciano_gularteNo ratings yet

- Ricoh MPC 3002 Parts CatalogDocument221 pagesRicoh MPC 3002 Parts CatalogДмитрий Разуваев100% (1)

- Calculate Lighting Fixture's Beam Angle and Lumen - Electrical Notes & ArticlesDocument5 pagesCalculate Lighting Fixture's Beam Angle and Lumen - Electrical Notes & ArticlesRahul ItaliyaNo ratings yet

- Water Temp Sensor DatasheetDocument1 pageWater Temp Sensor DatasheetOgnjen GalićNo ratings yet

- Reciprocity MixersDocument48 pagesReciprocity MixersMax MarkNo ratings yet

- Dearborn Protocol Adapter (Dpa) and PLC Testcon Pinouts Industry Connectors Reference GuideDocument26 pagesDearborn Protocol Adapter (Dpa) and PLC Testcon Pinouts Industry Connectors Reference GuideMateo VelezNo ratings yet

- Catalogo Adorne 2020Document39 pagesCatalogo Adorne 2020Batzi LudNo ratings yet

- RP 280F Spec SheetDocument1 pageRP 280F Spec SheetAmita PatelNo ratings yet

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessFrom EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessNo ratings yet

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionFrom EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionRating: 4 out of 5 stars4/5 (811)

- The Other End of the Leash: Why We Do What We Do Around DogsFrom EverandThe Other End of the Leash: Why We Do What We Do Around DogsRating: 5 out of 5 stars5/5 (64)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 3.5 out of 5 stars3.5/5 (33)

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseFrom EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseRating: 3.5 out of 5 stars3.5/5 (69)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 5 out of 5 stars5/5 (5)

- Fire Season: Field Notes from a Wilderness LookoutFrom EverandFire Season: Field Notes from a Wilderness LookoutRating: 4 out of 5 stars4/5 (142)

- Why Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeFrom EverandWhy Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeRating: 4.5 out of 5 stars4.5/5 (699)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldFrom EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldRating: 4.5 out of 5 stars4.5/5 (18)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsFrom EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsRating: 4 out of 5 stars4/5 (223)

- The Lives of Bees: The Untold Story of the Honey Bee in the WildFrom EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildRating: 4.5 out of 5 stars4.5/5 (44)

- The Secret Life of Lobsters: How Fishermen and Scientists Are Unraveling the Mysteries of Our Favorite CrustaceanFrom EverandThe Secret Life of Lobsters: How Fishermen and Scientists Are Unraveling the Mysteries of Our Favorite CrustaceanNo ratings yet

- Spoiled Rotten America: Outrages of Everyday LifeFrom EverandSpoiled Rotten America: Outrages of Everyday LifeRating: 3 out of 5 stars3/5 (19)

- Come Back, Como: Winning the Heart of a Reluctant DogFrom EverandCome Back, Como: Winning the Heart of a Reluctant DogRating: 3.5 out of 5 stars3.5/5 (10)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsFrom EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsRating: 3.5 out of 5 stars3.5/5 (13)

- The Mind of Plants: Narratives of Vegetal IntelligenceFrom EverandThe Mind of Plants: Narratives of Vegetal IntelligenceRating: 4.5 out of 5 stars4.5/5 (11)

- The Big, Bad Book of Botany: The World's Most Fascinating FloraFrom EverandThe Big, Bad Book of Botany: The World's Most Fascinating FloraRating: 3 out of 5 stars3/5 (10)

- When the Sahara Was Green: How Our Greatest Desert Came to BeFrom EverandWhen the Sahara Was Green: How Our Greatest Desert Came to BeRating: 4.5 out of 5 stars4.5/5 (5)

- Braiding Sweetgrass: Indigenous Wisdom, Scientific Knowledge and the Teachings of PlantsFrom EverandBraiding Sweetgrass: Indigenous Wisdom, Scientific Knowledge and the Teachings of PlantsRating: 4.5 out of 5 stars4.5/5 (1423)