Professional Documents

Culture Documents

Why Use Duplex Stainless PDF

Why Use Duplex Stainless PDF

Uploaded by

Paolo VisentinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Why Use Duplex Stainless PDF

Why Use Duplex Stainless PDF

Uploaded by

Paolo VisentinCopyright:

Available Formats

TECHNICAL FEATURE l STAINLESS STEEL TANKS

WHY USE DUPLEX STAINLESS

STEELS FOR STORAGE TANKS

Tank manufacturers can reduce material weight and cut costs by specifying storage tanks made

from high-strength duplex stainless steel

S

teel storage tanks are vital for the of stainless steel, and therefore the welding CORROSION RESISTANCE

day-to-day operation of the biofuels and recommendations should be followed carefully The fact that duplex steels have excellent

chemical industries. However, there is to use the correct welding parameters, joint corrosion resistance also leads to low

a huge variety between the alloy content and configurations and fillers. maintenance requirements. To choose the

production of different types of steel – and the They are also available in wide sheets of optimal duplex steel grade, the corrosion

mechanical strength and corrosion resistance two meters (or 3.2 meters for special orders). environment needs to be considered both

can vary widely. Using plates that are wider, longer and for the inside and the outside of the tank.

thinner, tank manufacturers can save time on Normally the inside, with contact to the

COST EFFICIENCY preparation of the welding joint, reduce the chemical stored, sets the limitations, but

When specifying a tank, it’s important to amount of welding required and speed up sometimes it is the outside conditions that

choose the best material based on the tank’s delivery. Welding time and costs relate to the determine the grade. This is particularly

total lifecycle cost. Designers need to weigh size of the tank and the shell thickness. The important for tanks in ports, where a salty

up a whole range of factors when comparing thicker the shell, the more time needs to be environment and high temperatures can lead

tank options: material cost, welding, assembly dedicated to welding the tank. to a form of corrosion called ‘stress corrosion

and local labour costs, as well as the price for In countries where labour costs are low, cracking’.

applying and maintaining internal and external welding costs will be substantially lower A typical carbon steel tank needs a coating

surface treatments. It’s also important not to than many European countries, where labor to protect it from corrosion. That coating

overlook the value of scrap material at the end costs peak at around $72 per hour. However, needs regular inspection, maintenance and

of the tank’s life. welding cost also varies depending on the repair to ensure that it lasts the test of time. In

Looking at it holistically, the raw material grade of steel used. turn, maintenance activities represent safety

costs are only a fraction of the total lifecycle But for tank operators, these benefits risk to technicians working at height or in

cost of a tank. Therefore, it’s worth represent a long and trouble-free life. Greater confined spaces, as well as environmental risk

considering high-performance duplex stainless weldability and fewer welds mean that a tank when sandblasting and applying new layers of

steel as it may be more cost efficient in the will have fewer potential points of failure as it coating.

long term. ages. As a result, it will last longer and require In comparison, duplex stainless steel has

less maintenance. high natural resistance to corrosion over a

HIGH STRENGTH REDUCES RAW

MATERIAL USAGE

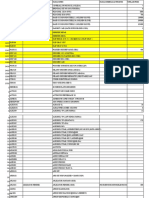

An excellent combination of

In comparison with other grades, duplex

stainless steel has high strength. This

high strength and corrosion resistance

is particularly attractive for storage tank 600 Forta SDX 2507

Forta LDX 2404 *) S32750/1.4410

manufacturers, as they can reduce the 550 Forta LDX 2101

S82441/1.4662

S32101/1.4162

Strength, Rp0.2 [MPa]

thickness of tank walls. 500

Forta SDX 100

Forta EDX 2304 S32760/1.4501

Not only does this reduce the size of the 450

S32304/1.4362

Forta DX 2304 Forta DX 2205

order for raw materials but it also simplifies 400 S32304/1.4362 S32205/1.4462 Ultra 654 SMO

transport and logistics when delivering a tank to 350 Ultra 4439

S32654/1.4652

S31726/1.4439 Ultra Alloy 825 Ultra 254 SMO

site. And it reduces handling requirements on 300 Ultra 317L N08825/2.4858 S32154/1.4547

S31703/1.4438

site when assembling and fabricating the tank. 250 Core 304L/4307

Ultra 6XN

N08926/

200 N08367/

Supra 316L/4404 Ultra 904L

MANUFACTURABILITY AND

1.4529

150 N08904/1.4539

DURABILITY

0 10 20 30 40 50 60 70 80 90

Values for hot rolled coil.

Another important factor for tank Corrosion Resistance, CPT typical [°C] * Acc. to Outokumpu MDS-D35.

)

manufacturers is that duplex grades are

not difficult to weld. However, they do The Forta duplex grades of stainless steel represented by the color green are popular for building storage tanks.

Duplex steels have higher strength than the standard 304L, 316L grades, as well as mild or carbon steels

require a different approach to other types

100 JUNE/JULY 2019 VOLUME 15 ISSUE NO.3

TECHNICAL FEATURE l STAINLESS STEEL TANKS

long life. To ensure the best possible corrosion

resistance of the welds, the surface is usually

ground and pickled – and this cost must be

included when figuring out the most economic

approach to tank building.

The duplex microstructure also contributes

to high resistance to stress corrosion cracking,

which can be an important issue in storage

tanks.

As a result, tanks made from duplex do

not need a protective chemical coating. This Duplex stainless steel offers corrosion resistance for storage tanks in marine environments

eliminates the initial cost of a coating, as well

as the need for inspection, the logistics of The duplex materials are generally also the tank is raised again, and the process

handling chemicals and repair, lost availability more demanding to machine than conventional repeats until the tank is completed.

of tanks during maintenance, safety and austenitic grades – although the straightforward This required coils of stainless steel with

environmental issues. skirt construction of tanks means that this tightly-specified length as each layer of the tank

is not a significant point for tank storage uses one single coil to ensure that all tank skirts

DUPLEX STAINLESS STEEL applications. had only one vertical weld. Not only did this

During the manufacturing process, duplex CHEMICAL STORAGE FOR SPAIN’S minimise the number of welds but by providing

stainless steels require careful control to create ACIDEKA coils of exactly the right length, Outokumpu

an end product that in its microstructure is When chemical company Acideka added 12 minimised the amount of material wasted.

made up of equal measures of the two other new large-scale liquid storage tanks to its With the tank measuring 19 meters in

most important types of stainless steel: ferritic facility at the Port of Bilbao, Spain, it turned to diameter and 18 meters in height, Outokumpu

and austenitic. process equipment manufacturer De Dietrich provided 65 tonnes of hot rolled Forta DX 2205.

Compared with typical austenitic stainless Equipos Quimico (DDEQ). As a supplier of An important factor in its selection for Gpi

steels, duplex grades have higher chromium chemicals, Acideka relies on its port facility to was the 3.2 material certification. This verifies

and nitrogen content but less molybdenum and handle large volumes of corrosive chemicals to that the material has been inspected by the

nickel at corresponding corrosion resistance. As customers in industries from water treatment manufacturer as well as an independent third

a result, duplex grades are more price stable in to pulp and paper. party.

markets where nickel and molybdenum prices DDEQ initially requested a quote for 316L, a

fluctuate. grade of austenitic stainless steel that is often BIOGAS PLANT IN GERMANY

Their high chromium content tends to used for tank storage. A 13-hectare biogas park in Konnern, Germany

provide excellent resistance to uniform However, Outokumpu convinced the feeds biogas directly into the natural gas grid

corrosion. However, localised corrosion (or manufacturer that Forta DX 2304 would be to provide enough energy for around 10,000

pitting) can arise when they are exposed to preferable. The duplex stainless steel has homes.

solutions containing halides, such as chlorides. higher strength as well as excellent corrosion WELtec BioPower built the facility with

One way to rank different grades of stainless properties. biogas produced in 16 large digester tanks.

steel in chloride environments is to measure As a result, DDEQ was able to reduce the Each tank is 6.3 meters high and 25 meters in

the Critical Pitting Temperature (CPT). The shell thickness of the tank, reaping a 20% diameter and must be able to withstand expose

higher the CPT, the more resistant the steel saving in material. In addition, less handling and to corrosive biogas by-products such as sulphur

grade is to localised corrosion attack. The welding was required as Outokumpu were able and ammonia compounds. Corrosion resistance

diagram above shows which of the high to provide two-meter-wide plates. is particularly important for the site’s operators

strength Forta Duplex grades match the Elsewhere in Spain, Outokumpu provided as it is challenging to restart the digesters’

corrosion resistance of different austenitic duplex 2304 stainless steel for manufacturer process after an outage.

stainless steels. Emypro for a 25-meter-high, 22 meter diameter Outokumpu supplied 1,500 tonnes of duplex

Another area where duplex stainless-steel tank in Tarragona. Completed in 2005, the tank stainless steel for the project. The high-strength

grades differ to austenitic ones is in formability was built for Terquimsa, Terminales Quimicos material enabled thinner tank walls with no loss

and machinability. The higher strength of duplex to hold pure acetic acid. Outokumpu provided of structural strength or stability.

means that higher forces are often required – 2-meter wide plates with thickness ranging

but this is often counteracted by the smaller from 6.5 – 12 mm. TANK DESIGN

gage thickness. Duplex stainless steels are used to store many

MINIMISING WELDS FOR GPI types of chemical and petrochemical products,

As a leading manufacturer of stainless-steel such as biodiesel, chemical feedstocks, marble

tanks and process equipment, Gpi won a slurry and other products. Several different

contract from Dow Chemical to build a 3,995 grades are ideally suited to tank building and

m3 tank to store demineralised water at the the choice depends on the specific properties

Port of Rotterdam. It selected a duplex grade of of the liquid to be stored.

stainless steel for its good corrosion resistance Their high mechanical strength and corrosion

and high mechanical strength. resistance mean that a duplex grade of

Gpi used a high-tech construction method stainless steel often offers the best value over

based on a coil building machine to fabricate a tank’s lifetime.

the tank from the top down. In this technique,

a coil of stainless steel is fed through the coil

building machine and welded in place as the FOR MORE INFORMATION

first layer of the tank body. Computer-controlled This article was written by Peder Claesson,

Duplex stainless steel eliminates the need for hydraulic jacks then lift the layer and feed a product manager at Outokumpu.

coatings

second coil into place below it. Once welded, www.outokumpu.com

JUNE/JULY 2019 VOLUME 15 ISSUE NO.3 101

You might also like

- Zecor PDFDocument7 pagesZecor PDFjavoidea696526100% (1)

- RoofDek Structural Roof Decking and Trays BrochureDocument24 pagesRoofDek Structural Roof Decking and Trays Brochuresiddharth vekariyaNo ratings yet

- Guidelines For Stainlesssteel WeldingDocument90 pagesGuidelines For Stainlesssteel Weldingquiron2010No ratings yet

- Welding of Offshore Structure 2012Document17 pagesWelding of Offshore Structure 2012ABDELOUAHEB HAMIDINo ratings yet

- Tai Chi and Qigong Yang-Sheng 2012-03 PDFDocument2 pagesTai Chi and Qigong Yang-Sheng 2012-03 PDFBudo MediaNo ratings yet

- Bourdon TubeDocument13 pagesBourdon TubeJamer Ian Mustapha100% (2)

- As3679 Material CatalogDocument5 pagesAs3679 Material CatalogEsapermana RiyanNo ratings yet

- Water StopsDocument12 pagesWater Stopstss13723No ratings yet

- Reduce Salt Corrosion Rates With Stronger Base AminesDocument4 pagesReduce Salt Corrosion Rates With Stronger Base AminesPaolo VisentinNo ratings yet

- IRM2500 Refractory Installation inDocument22 pagesIRM2500 Refractory Installation inmika cabelloNo ratings yet

- Si04253409 4 PDFDocument1 pageSi04253409 4 PDFclintNo ratings yet

- Cladding & Overlay - Ni InstituteDocument24 pagesCladding & Overlay - Ni Institutesajid aslamNo ratings yet

- Duplex Stainless SteelsDocument7 pagesDuplex Stainless SteelsRizalzi BachtiarNo ratings yet

- IRM2500 Refractory Installation inDocument22 pagesIRM2500 Refractory Installation inmika cabello100% (1)

- Shwerwin Williams Internal Lining PresentationDocument42 pagesShwerwin Williams Internal Lining PresentationPaolo Visentin0% (1)

- Outokumpu Duplex DatasheetDocument12 pagesOutokumpu Duplex DatasheetzosternatNo ratings yet

- Ceramic CompositesDocument29 pagesCeramic CompositesAbhey DograNo ratings yet

- TABELA - DUPLEX - Outokumpu Forta Range DatasheetDocument18 pagesTABELA - DUPLEX - Outokumpu Forta Range DatasheetRogerio VagoNo ratings yet

- Trench Sheeting BrochureDocument8 pagesTrench Sheeting BrochurehameedNo ratings yet

- Duplex SSDocument12 pagesDuplex SSTushar PatilNo ratings yet

- Structural Steels PDFDocument2 pagesStructural Steels PDFvigneshNo ratings yet

- Structural Stainless Steel PDFDocument5 pagesStructural Stainless Steel PDFGiri DharanNo ratings yet

- TAM600 Insulation and CorrosionDocument18 pagesTAM600 Insulation and CorrosionAleem QureshiNo ratings yet

- 101 (2006)Document2 pages101 (2006)Eng-Mahmoud AtiaNo ratings yet

- DuplexSellSheet 01 12Document2 pagesDuplexSellSheet 01 12rickthetrickstertrickyNo ratings yet

- CoreTreatment IEEE YungDocument10 pagesCoreTreatment IEEE YungAli HashemiNo ratings yet

- Forta FDX 27 - Duplex Stainless Steel For High Strength Gasket Plate Heat ExchangersDocument9 pagesForta FDX 27 - Duplex Stainless Steel For High Strength Gasket Plate Heat Exchangerszbigniew3brytanNo ratings yet

- TB29 - Deckform Sept 02Document2 pagesTB29 - Deckform Sept 02Ravinesh SinghNo ratings yet

- Galvanize 83Document13 pagesGalvanize 83accountsNo ratings yet

- Effect of Fiber Laser Welding On The Fatigue Properties of Dissimilar Welded Joints Between DP980 and HSLA SteelsDocument7 pagesEffect of Fiber Laser Welding On The Fatigue Properties of Dissimilar Welded Joints Between DP980 and HSLA SteelsSripriyan K 100507No ratings yet

- Shell Corena S2 P - TDS PDFDocument3 pagesShell Corena S2 P - TDS PDFAnonymous oAbjbl4H100% (1)

- Sika - Ferrogard Anode Range Brochure 0314 NZDocument8 pagesSika - Ferrogard Anode Range Brochure 0314 NZTHODOROS TSAKONASNo ratings yet

- Vafly000295 en AqDocument2 pagesVafly000295 en AqMike PowerNo ratings yet

- Design: Where Continuous Operation Is Required, Speeds May Be Limited To 107Mpm and Pressure Maximum To 240 KpaDocument30 pagesDesign: Where Continuous Operation Is Required, Speeds May Be Limited To 107Mpm and Pressure Maximum To 240 KpaglobalindosparepartsNo ratings yet

- Materials Fact Sheet No 02 Selection of Stainless Steels For Use in The Water IndustryDocument6 pagesMaterials Fact Sheet No 02 Selection of Stainless Steels For Use in The Water IndustrydipankarbasakNo ratings yet

- Aming Members Sept 04Document16 pagesAming Members Sept 04Edison BecerraNo ratings yet

- Austempered Ductile Iron (Adi) 1Document20 pagesAustempered Ductile Iron (Adi) 1Ashutosh GuptaNo ratings yet

- Choice of Specifications and Design Codes For Duplex Stainless SteelsDocument12 pagesChoice of Specifications and Design Codes For Duplex Stainless SteelsRonald Leyva GiraldoNo ratings yet

- Duplex Stainless Steels - A Simple Guide: How The Austenite/Ferrite Balance Is AchievedDocument4 pagesDuplex Stainless Steels - A Simple Guide: How The Austenite/Ferrite Balance Is AchievedAndy PhoenixNo ratings yet

- Tuf Strand SFDocument2 pagesTuf Strand SFlavekushNo ratings yet

- 1.4462 Duplex PropertiesDocument2 pages1.4462 Duplex PropertiesEROL30No ratings yet

- Steel in Stadium EgineeringDocument4 pagesSteel in Stadium EgineeringFrans HeidelooNo ratings yet

- Sika® Carboshear L: Product Data SheetDocument3 pagesSika® Carboshear L: Product Data Sheetmeldi suhatrilNo ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelBo WangNo ratings yet

- WWF Paper PDFDocument7 pagesWWF Paper PDFniharNo ratings yet

- Bake Hardening SteelDocument15 pagesBake Hardening SteelAnoop KizhakathNo ratings yet

- Fasteners For PlywoodDocument11 pagesFasteners For PlywoodfordesignNo ratings yet

- White Paper - Mitigating Corrosion and Erosion in Waste To Energy and Biomass BoilersDocument20 pagesWhite Paper - Mitigating Corrosion and Erosion in Waste To Energy and Biomass BoilersmostafaNo ratings yet

- And Steel Framing: Pressure Treated WoodDocument2 pagesAnd Steel Framing: Pressure Treated WoodGopi KrishnanNo ratings yet

- Background: Table 1. Some Standard Designations For Duplex Stainless SteelalloysDocument3 pagesBackground: Table 1. Some Standard Designations For Duplex Stainless SteelalloysBharat TailorNo ratings yet

- Materials ProjectDocument4 pagesMaterials Projectxtopherus124No ratings yet

- Delta Protekt KL120Document1 pageDelta Protekt KL120GavinNo ratings yet

- Storage Calorifier Profile HrsfunkeDocument12 pagesStorage Calorifier Profile HrsfunkePKP MECHNo ratings yet

- PDS Shell GadusDocument2 pagesPDS Shell GadusTaufik BinasrNo ratings yet

- A Techno Economic Balance For ZonalDocument6 pagesA Techno Economic Balance For ZonalBagas Prasetyawan Adi NugrohoNo ratings yet

- Steela-'07: Duplex Stainless A Review After DSS Held in GradoDocument11 pagesSteela-'07: Duplex Stainless A Review After DSS Held in GradoVinay MaisuriyaNo ratings yet

- Table Corrosion FastenerDocument4 pagesTable Corrosion FastenerGiuseppe FerrariNo ratings yet

- TB26 - Weathering Steels Sept 02Document2 pagesTB26 - Weathering Steels Sept 02Ravinesh SinghNo ratings yet

- 25CR20NIDocument2 pages25CR20NIShariq KhanNo ratings yet

- Fertilizer Industry Valve Solutions: Upstream Midstream Downstream Chemical Valve ApplicationsDocument20 pagesFertilizer Industry Valve Solutions: Upstream Midstream Downstream Chemical Valve ApplicationsSyed Zayne Syed KadirNo ratings yet

- Applications of ADI in High Strength Thin Wall Automotive PartsDocument6 pagesApplications of ADI in High Strength Thin Wall Automotive PartsalgobozkurtNo ratings yet

- Rexnord Addax Composite Couplings ManualDocument7 pagesRexnord Addax Composite Couplings ManualAjmal ArshadNo ratings yet

- UALT Page4Document1 pageUALT Page4Syed AsadullahNo ratings yet

- Untitled Extract PagesDocument11 pagesUntitled Extract PagesMohammedIrfanNo ratings yet

- New Products From Pmi: Talent & Technology Virtual SymposiumDocument17 pagesNew Products From Pmi: Talent & Technology Virtual SymposiumPaolo Visentin0% (1)

- Lessons Learned Program: Pollo Hallenger OlumbiaDocument39 pagesLessons Learned Program: Pollo Hallenger OlumbiaPaolo VisentinNo ratings yet

- Custom Learning Solutions: Guide For Companies and OrganizationsDocument16 pagesCustom Learning Solutions: Guide For Companies and OrganizationsPaolo VisentinNo ratings yet

- Webinar 200528 Botox Resume and LinkedInDocument19 pagesWebinar 200528 Botox Resume and LinkedInPaolo VisentinNo ratings yet

- Smart Electronics: Thailand Investment ReviewDocument12 pagesSmart Electronics: Thailand Investment ReviewPaolo VisentinNo ratings yet

- Abs SustaDocument6 pagesAbs SustaPaolo VisentinNo ratings yet

- Oil Marketing During COVID-19 Report UpdateDocument10 pagesOil Marketing During COVID-19 Report UpdatePaolo VisentinNo ratings yet

- COVID-19:: Career Navigation Through A Global PandemicDocument1 pageCOVID-19:: Career Navigation Through A Global PandemicPaolo VisentinNo ratings yet

- Clean Fuel Project (CFP), Thaioil Public Company Limited: Objective and Project Information Project LocationDocument1 pageClean Fuel Project (CFP), Thaioil Public Company Limited: Objective and Project Information Project LocationPaolo VisentinNo ratings yet

- Myanmar - Business - Guide 5th Edition PDFDocument92 pagesMyanmar - Business - Guide 5th Edition PDFPaolo VisentinNo ratings yet

- HGV Scunthorpe 0317 Bridge-Heights All-RoutesDocument1 pageHGV Scunthorpe 0317 Bridge-Heights All-RoutesPaolo VisentinNo ratings yet

- Cool Future For G: Frontiers December 2001Document8 pagesCool Future For G: Frontiers December 2001Paolo VisentinNo ratings yet

- 2016 4Q Seperate Interim Financial StatementsDocument101 pages2016 4Q Seperate Interim Financial StatementsPaolo VisentinNo ratings yet

- YS Hardness RelationDocument5 pagesYS Hardness RelationPaolo VisentinNo ratings yet

- Abstract: The New Compounds of Salicylic Acid Derivatives, 2 - (3 - (Chloromethyl) Benzoyloxy) Benzoic AcidDocument8 pagesAbstract: The New Compounds of Salicylic Acid Derivatives, 2 - (3 - (Chloromethyl) Benzoyloxy) Benzoic AcidFebria AnggraeniNo ratings yet

- Renal TraumaDocument59 pagesRenal TraumaDewi Yukinohana50% (2)

- JAN 2013 Mancount ConcentratingDocument63 pagesJAN 2013 Mancount Concentratingyogi wahidhasyimNo ratings yet

- The Rich North and Poor SouthDocument1 pageThe Rich North and Poor SouthChris SmithNo ratings yet

- 190 Johanne Marie Nielsen Vibbert Larsen ChapterDocument8 pages190 Johanne Marie Nielsen Vibbert Larsen ChapterjohnmarjwNo ratings yet

- Thesis 1988Document52 pagesThesis 1988RamkatNo ratings yet

- Manual: Personal ComputersDocument60 pagesManual: Personal ComputersLOBOMAN_55555No ratings yet

- Records m3Document1 pageRecords m3Kobe pacquiaoNo ratings yet

- AGP-LMD End Market AnalysisDocument83 pagesAGP-LMD End Market AnalysisKedirNo ratings yet

- Adapt IfDocument157 pagesAdapt IfCahyoNo ratings yet

- Just Already Yet - 20647Document1 pageJust Already Yet - 20647Hush AmeenNo ratings yet

- Homi BhabhaDocument2 pagesHomi BhabhaAmey Teke69% (16)

- Science Form 4 Chapter 5 5.6Document17 pagesScience Form 4 Chapter 5 5.6KSSM TSE100% (1)

- Case of A.H. and Others v. RussiaDocument90 pagesCase of A.H. and Others v. RussiaLa LeyNo ratings yet

- Percentage Differential Protection For TransformersDocument6 pagesPercentage Differential Protection For TransformersPragya JainNo ratings yet

- NCERT Questions - Financial Statements (Final Accounts) - Evero PDFDocument53 pagesNCERT Questions - Financial Statements (Final Accounts) - Evero PDFYogendra PatelNo ratings yet

- Control of Industrial Major Hazard (Cimah) Regulations 1996: Nurlita Irfiani MKK152014Document34 pagesControl of Industrial Major Hazard (Cimah) Regulations 1996: Nurlita Irfiani MKK152014jeey irisNo ratings yet

- 2020 Ohio Medical Marijuana Patient and Caregiver SurveyDocument267 pages2020 Ohio Medical Marijuana Patient and Caregiver SurveyCincinnatiEnquirerNo ratings yet

- Bimco Standard War Risks Clause For Voyage ChartersDocument2 pagesBimco Standard War Risks Clause For Voyage ChartersRomet RuseNo ratings yet

- Devatkal ReportDocument9 pagesDevatkal ReportpraveenNo ratings yet

- Ink MsdsDocument4 pagesInk MsdsRahulNo ratings yet

- SO MaterialDocument112 pagesSO MaterialkinkinNo ratings yet

- Lss-A286 Astm A453 PDFDocument2 pagesLss-A286 Astm A453 PDFmazolasboNo ratings yet

- Annex SL White Paper 6.29.18Document20 pagesAnnex SL White Paper 6.29.18Miljan Savic100% (1)

- Kidz Lab Academy: Importance of Plants To PeopleDocument8 pagesKidz Lab Academy: Importance of Plants To PeopleElaine Claire Gorospe PanchoNo ratings yet