Date:19/02/2016

OCTG DIVISION

Reference: MD-15-XXX Rev 0

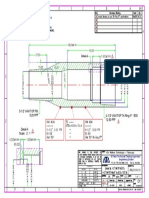

Introducing VAM® 21

VAM® 21 is the latest generation of Threaded & Coupled (T&C) premium connection introducing

an innovative and revolutionary design. Confidence thanks to ISO 13679 CAL-IV compliance

within the full pipe body envelope extends the opportunities for your well designs.

VAM® 21 is the highest performing and most reliable VAM® connection to date with excellent

gas tight sealing under combined loads, extreme compression resistance (100%) and innovative

VAM® Effect with the VAM® Stabilizer™. Seal and shoulder functions are separated so that

torque and compression have no affect on the sealing performance.

Product range

• VAM® 21 is currently available in sizes from 4 ½" to 14". Others sizes are available

upon request

• VAM® 21 HT, the high torque version, is available from 5” to 9 5/8”

• Carbon, Martensitic stainless steel (13%Cr & Super 13%Cr), Duplex, Super Duplex and

Nickel base Alloys. Yield strengths from 80 ksi to 140ksi.

Application

Suitable for any kind of application, from conventional to extreme HP/HT well design:

• Production casing, Liner, Tie-back

• Production tubing

• Drilling with Casing

VAM® 21 technical features - Innovative, simple and robust design

• Threaded and coupled (T&C) premium connection.

• Seal independent from shoulder : sealability is not affected by torque or

compression

• Multigrooving avoids dope pressure build-up to provide clean and repeatable make-

up graphs

• Cylindrical thread crests and roots to reduce the risk of cross threading

• All performances validated through tests

Performances

• Qualified to ISO13679 FDIS-2011 CAL-IV, the most stringent connection

qualification procedure to date and upcoming API 5C5:2013

• Extreme compression resistance (100% of Pipe Body Yield Strength)

• Bending validated up to 65°/100ft

• Sealability validated up to 240°C (464°F).

• 100% Tensile efficiency

• 100% PBYS compression

• 100% API 5C3 / ISO and validated for High collapse grades

under combined load

Options

• Available with high torque option: VAM® 21 HT.

o Provides even more torque for dedicated applications:

rotating liner, drilling with casing, ERD, multilateral

wells, horizontal sections

o VAM® 21 and VAM® 21 HT are interchangeable

• Available with clearance option VAM® 21 SC.

• Available for Steam well applications VAM® 21 SW.

• VAM® 21 SL: slim-line tailor made designs available upon request to fit in the most unique well designs.

• Available with CLEANWELL® option.

Page: 1 of 2

� Date:19/02/2016

OCTG DIVISION

Reference: MD-15-XXX Rev 0

VAM® 21 product line availability

Nominal Nominal Nominal Nominal Nominal

Size (OD) Size (OD) Size (OD) Size (OD) Size (OD)

weight weight weight weight weight

in. lb/ft in. lb/ft in. lb/ft in. lb/ft in. lb/ft

11.6 18.0 23.0 62.8 61.0

12.6 5 21.4 26.0 65.3 68.0

4 1/2 13 3/8

13.5 23.2 29.0 9 7/8 66.4 72.0

15.1 17.0 32.0 66.9 77.0

7

20.0 35.0 68.9 13 5/8 88.2

5 1/2 23.0 38.0 10 73.9 82.5

26.0 41.0 45.5 86.0

26.8 42.7 51.0 93.0

18.6 29.7 55.5 14 96.9

6

30.9 33.7 10 3/4 60.7 100.0

23.2 7 5/8 35.8 65.7 106.0

24.0 39.0 71.1 114.0

28.0 47.1 73.2

6 5/8

32.0 8 5/8 44.0 54.0

34.5 8 3/4 57.5 60.0

11 3/4

36.7 40.0 65.0

43.5 71.0

9 5/8 47.0 67.8

11 7/8

53.5 71.8

58.4

VAM® 21 HT also available in these sizes

Benefits

• Simple, reliable and easy running

• Easy stabbing and self-alignment feature: running speed increased 15% compared to VAM® TOP

reduce rig operational costs

• Seal protected from rough handling

• Suitable for automated rig handling systems

• Clear and repeatable make-up charts

• Performances preserved when increasing torque (Maximum Torque with Sealability value)

• Performance preserved after fatigue

• Reduced drilling wear susceptibility.

• 75 Licensees and plants qualified to thread VAM® 21 as of Nov.2015

Field record

VAM® 21 has been used in the most critical / high profile fields worldwide. More than 100 operators are currently using

VAM® 21.

VAM® 21 worldwide pareto by size (# joints)

90 000

80 000

70 000

60 000

50 000

40 000

30 000

20 000

10 000

0

9 5/8 HT

10 3/4

13 3/8

13 5/8

5 1/2

6 5/8

7 5/8

7 3/4

9 5/8

9 7/8

10

14

5

More than 1 million feet of VAM® 21 joints have been run downhole

More details available on www.vallourec.com

Page: 2 of 2