Professional Documents

Culture Documents

41 200

41 200

Uploaded by

Στέλιος Φλουρής0 ratings0% found this document useful (0 votes)

4 views6 pagesOriginal Title

41-200

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views6 pages41 200

41 200

Uploaded by

Στέλιος ΦλουρήςCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

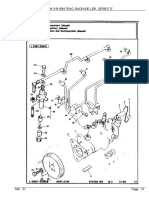

41-200 R and R centering sleeve

Model 126 starting 09/85

20

PAT OOS SS

remove and install (41-050).

screw off and on, M 10 = 45 Nm,

M12 = 65 Nm. Replace setflocking

hex. nuts (14),

‘mount and remove. Mark vibration damper and

flexible disc in relation to drive shaft. Loosen

fitted slaves with 10 mm dia. mandrel (steps 4,

5).

Centering sleeve (10)... ssss++ pull out of drive shaft, press-in,

Pay antendon to pressing-in dimensions, Wi

plastic bushings, grease cavity with Molykote

(grease and use multi-purpose grease with multi-

‘component bushings (quantity per sleeve

approx. 6 g 9).

11 Rear to factory approved service products list supplied with owner's erature or avaiable trough your local authorized

Meroodes-Bene Dealer

Drive shaft

Hex. head screws (11)

Flexible disc (12) and vibration damper (20)

(Chassis and Body Manus = Model 129 1029

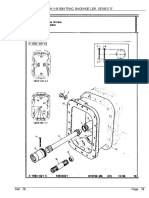

41-200 R and R centering sleeve

‘Special tool

(001 529.66 21 0]

Note

In the event of wear or damage to sealing lip in

centering sleeve (10) of front or rear drive shaft,

the centering sleeve can be individually replaced.

1 Front deve shat

10 Conterng sleave

32. Flexo ise

13° Washer

14 Sflocking hex. nut

48 Transmission univorea fango

20. Vibeation damper

Removal and installation

1 Remove drive shaft (41-050).

2 Unscrew hox. head screws with self-locking

hex. nuts.

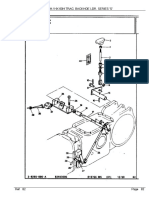

Drive shafts withaut vibratian damper

3 On this version, mark flexible disc (arrow) in

relation to three-legged flange of drive shaft.

rar-12086

(Chasse and Body Manuel - Model 129

41-200 R and R centering sleeve

Drive shafts with vibration damper

4 On this version, an identification mark on

nree-legged range (hump) and on vibration

damper (20) (vulcanized arrow) is in place.

Note

The installation position is correct, when the

arrow of vibration damper (20) points to hump of

three-logged flange (arrows).

Installation note

Reolace self-lockina hex. nuts.

Tightening torque M 10= 45 Nm,

M12=65 Nm.

Mount tangentially soft flexible discs (on vehicles

with engine 103) according to lettering "DIESE

SEITE ZUR OCLENKWCLLC” (T1NIe SIDE.

TOWARD DRIVE SHAFT).

5 On tangentially soft flexible discs (soft pull-

push) loosen the vulcanized fitted sleeves out of

throo loggod flango. For thio purpoce, woo a

cylindrical mandrel of 10 mm dia. and approx.

150 mm in length.

6 Remove flexible disc and, if installed,

vibration damper.

PHT BOOTTS

141-2695,

sa-24702

(Chassis and Body Menual - Model 128

1031

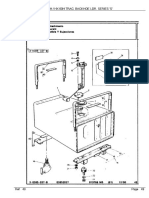

41-200 R and R centering sleeve

7 Separate front drive shaft from rear drive

shait.

Installation note

Front and rear drive shaft are marked in relation

to each other. When joined, make sure that the

hump on front drive shaft is located in center of

the two arrow-type humps of fork-type joint

(arows).

Removing centering sieeve

8 At low pulling force:

Knock centering sleeve uniformly out of dive

shaft hy maans of a flat chisel (arrows)

9. Athigh pulling force:

Drill an approx. 10 mm dia. hole at a right angle

trough sieeve 19 mm trom face of centering

sleeve.

141-2866

PaTBOES

1032

(Chasts and Body Manual - Model 129

41-200 R and R centering sleeve

10 Insert a mandrel through bore and pull

ccontering sleeve out of drive shaft by means of

two assembly levers.

11. Prass-in naw cantaring slaave with suitable

mandrel. Pay attention to pressing-in dimension

‘of centering sleeve (refer to table).

Model Dimension "a" from face of

centering sleeve to three-legged

flange

front rear

198.02 an 249

126,09/04

20.4 23.9

Chassis and Body Manus ~ Mode! 129 1033,

41-200 R and R centering sleeve

12 With bronze bushing, grease cavity of

centering sleeve with Molykote grease and use

‘mutti-purpose arease with multi-component

bushing (refer to factory approved service

products list,

‘quantity per slaeve approx. 6 g)

13 For furthor installation proceed vice versa as

of stop 7,

141-12500,

1034

+ Model 129

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- KBA Rapida 72K Web PDFDocument11 pagesKBA Rapida 72K Web PDFΣτέλιος ΦλουρήςNo ratings yet

- ΝόμοςτουHooke-ΔυνάμειςDocument2 pagesΝόμοςτουHooke-ΔυνάμειςΣτέλιος ΦλουρήςNo ratings yet

- 50H 50H / / HX HX 60H 60H TRAC. Trac. Backhoe Backhoe Ldr. Ldr. Series Series 'S' 'S'Document2 pages50H 50H / / HX HX 60H 60H TRAC. Trac. Backhoe Backhoe Ldr. Ldr. Series Series 'S' 'S'Στέλιος ΦλουρήςNo ratings yet

- Ap Deiktes Eparkeias Epitychias Fysiki A Lyk Kat PDFDocument17 pagesAp Deiktes Eparkeias Epitychias Fysiki A Lyk Kat PDFΣτέλιος ΦλουρήςNo ratings yet

- AGCO 819766 106 PageDocument2 pagesAGCO 819766 106 PageΣτέλιος ΦλουρήςNo ratings yet

- AGCO 819766 78 PageDocument2 pagesAGCO 819766 78 PageΣτέλιος ΦλουρήςNo ratings yet

- AGCO 819766 82 PageDocument2 pagesAGCO 819766 82 PageΣτέλιος ΦλουρήςNo ratings yet

- AGCO 819766 49 PageDocument2 pagesAGCO 819766 49 PageΣτέλιος ΦλουρήςNo ratings yet

- Caterpillar 2Document3 pagesCaterpillar 2Στέλιος ΦλουρήςNo ratings yet

- Chevron Europe PDFDocument4 pagesChevron Europe PDFΣτέλιος ΦλουρήςNo ratings yet

- Oils and Lubricants: Homepage LanguagesDocument4 pagesOils and Lubricants: Homepage LanguagesΣτέλιος ΦλουρήςNo ratings yet

- 50H 50H / / HX HX 60H 60H TRAC. Trac. Backhoe Backhoe Ldr. Ldr. Series Series 'S' 'S'Document2 pages50H 50H / / HX HX 60H 60H TRAC. Trac. Backhoe Backhoe Ldr. Ldr. Series Series 'S' 'S'Στέλιος ΦλουρήςNo ratings yet

- 50H 50H / / HX HX 60H 60H TRAC. Trac. Backhoe Backhoe Ldr. Ldr. Series Series 'S' 'S'Document2 pages50H 50H / / HX HX 60H 60H TRAC. Trac. Backhoe Backhoe Ldr. Ldr. Series Series 'S' 'S'Στέλιος ΦλουρήςNo ratings yet

- Steering Geometry Rig Data V2Document2 pagesSteering Geometry Rig Data V2Στέλιος ΦλουρήςNo ratings yet

- 2012-06-25 043538 Transmission 428b PDFDocument5 pages2012-06-25 043538 Transmission 428b PDFΣτέλιος ΦλουρήςNo ratings yet

- David Brown Tractor Technical Engine SpecificationsDocument1 pageDavid Brown Tractor Technical Engine SpecificationsΣτέλιος ΦλουρήςNo ratings yet

- 2012-06-25 043538 Transmission 428b PDFDocument5 pages2012-06-25 043538 Transmission 428b PDFΣτέλιος ΦλουρήςNo ratings yet