Professional Documents

Culture Documents

Manual Rod Tong

Uploaded by

Hendra Jurbon0 ratings0% found this document useful (0 votes)

164 views31 pagesP Tong

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentP Tong

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

164 views31 pagesManual Rod Tong

Uploaded by

Hendra JurbonP Tong

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 31

MODEL XQ29/1.8B HYDRAULIC SUCKER ROD TONG

OPERATION MANUAL

YANCHENG TEDA DRILLING AND PRODUCTION EQUIPMENT CO.,LTD.

Safety Instruction

1.Operators must read and know this manual well.

2.Operators must wear work uniform, safety shoes, safety helmet, safety gloves. etc.

3.Tie the back guy according to the instruction. Don’t tie it in the wrong direction,

4.Operate at the side of the tong body opening.

5.The safety door must be closed as making-up or breaking-out,

6.Don’t touch the running parts with hands when the tong is running.

7.Keep sundries out of the working area,

8.The pump should be off or the hydraulic tong power shut down as maint

Jaw plates, die seats or tong dies.

ig or changing the

9. Over-pressure and over-torque are forbidden.

10.Don’t add or dismount any parts to the tong.

11 Original parts made by EDD, should be used,

@ SAFETY FIRST, STANDARD OPERATION PROBLEMS MAY OCCUR IF BUGS ARE NOT

RID OF,

CONTENTS

1. Summary. oe

2.Technical Specification.

3.Unstallation..

4 Hydraulic Circuit.

5.Operation Explanation...

6 Maintenance and Lubrication.

7.Parts easy to be worn...

8.Troubles and Troubleshooting.

9.lustration and Parts Table...

9.1.Assembly and parts table,

9.2.Master tong and parts table

9.3 Shell accessory and parts table.

9.4.Tong head assembly anid part table...

9.5.Broking and centralizing mechanism andl pars table Oh

12

9.6:Transmission mechanism and parts table. FG esse 14

{9:7 Hand control valve and parts table. 16

98.Shifimechaniam essehly and pares ble 18

9.9 Safety assembly and parts table. 19

9.10.Backup tong and parts table 220

9.11.Backup tong head assembly and parts table, 21

9.12-Tong tail oil cylinder assembly and parts table, 2B

9.13 Fore guide pole and parts table, es 25

9.14.Rear guide pole and pars table...

S.1S.Lif as 9EMBLY. cs seeen

10.Trucking,storageand and after service.

Power To nu

3 as YDUCTION F TCOLID

1, Summary

“Model XQ29/1.8B Hydraulie power tong is an opening type power tong, which is used to make up and break out

sticker tod’s joint casing thread in well service. It has following features:

‘*The master tong is driven by low speed large torque hydraulic oil motor, control valve matches oil motor

directly its structure is simple, compact and portable.

‘*The new hydraulic backup tong atid the master tong form a combined tong, operate the control valve on the

‘master tong, the backup tong will automatically clip or simultaneously loosen the sucker rod joint.

‘*The method that both master tong and backup tong use are inner curved roller climbing and bi-direetion

clipping mechanism. It just needs to change the direction of knob on master tong and backup tong when

clipping.

‘*Change dies of different sizes, it can clip sucker rod’s joint or tubing of corresponding specifiation.

‘The tong has two speeds. It works with high efficiency when jerking and spinning at low speed or high speed.

2 Technical Parameter

‘© Application range Sucker Rod CYGI6, 19, 22, 25,29

Tubing OD 48-60 mm (S/8*=1 1/8")

‘¢High gear rated torque O7KN.m (S008 Ibs)

‘Low gear rated tore LBENm (1300. Ibs)

‘*Maximum speed at high gear 104RPM

‘¢Maximum speed at low gear 40RPM

‘*Opening dimension of Tong head 6mm Qs")

‘¢Oversll dimension of Combined Tong(L* WH) $43-334-404mm (21,4713.1"%15.9

“Weight 105kg 30h)

‘*Ratod system prossure loMPa —_(14S0PS1)

‘*Maximum oil supply 6sLimin (17GPM)

3. Installation

1) Hanging. Connect mechanical lift(I.8D7-0) and master tong’s suspension rod, Hang the power tong on the

‘master of work over rig. The suspension pulley should be above the ground more than 1Sm, Under free

hanging, power tong head’s center is about 0.5m above the well center. Hanging height is the best when die

pieces face sucker rod’s square section under the coupling. Adjusting the distance between master tong and.

backup tong so that die pieces face sucker rod” square section above the coupling.

2) Adjustment. Adjust the serew(1.8.Z-33and1.8.Z-46 ) so that power tong keep horizontal. If it is not

horizontal, the clipping will be in faire,

3) Other end should be tied to on the back guide arm seat(1.8.Z-32)of the power tong. The back guy should be

able to bear one ton londs and be opposite to the operstor and keep vertical with power tong. Put up back

{guy in case there is an emergency in clipping sucker rod or tubing, It is also forthe safety of the operator

ho usually stands beside the operation handle.

4) Pipe tine connection. Please see illustration (see Fig. 9.1). Port “P” connects oil supply hose while port

“0” connects oil return hose. The nominal diameters of the oil supply hose and the oil return hose should

not be less than 20m,

Yodel

4 Hydraulic Cireuit

‘As shown in the drawing 1, control valve (3) control the changing of direction ofthe oil motor and atthe same

time it controls the changing of direction of backup tong. Rack plunger oi cylinder(2) of backup tong is used to

drive backup tong to clip rod string, Oil motor(!) is used to drive mater tong head to make up or break our rod or

tubing string. Pressure gauge(4) shows systematic pressure and it shows the torque of power tong indirectly at

the same time, Pressure and torque has corresponding relation shown in Drawing 2, Line A in the drawing shows.

low speed torque valve while line B stands for high speed torque valve.

Fig.t

(High Gear) (Low Gear)

SHigh Gear fiHLow Gear

KN. m

(ft Ibs)

0. §(370) 1..0(735) 1.5(1105) —-2.0(1478)

Fig2

5. Operation

1). Operation of shifting

Operation contol valve to make the power tong rotate slightly. Press shift fork it engages high speed. Pull

shift fork up it engages low speed. Shift must be carried out when power tong rotates in low speed avoiding

damaging gears

2) Make up

When the opening of master tong and backup tong’s head align propery, tur the rest knob (1.8.2.1-16) on

power tong and reset knob (1.8.B-2) on backup tong to the direction of makeup. Push power tong to suck

rod or tubing string. When master tong and jaw set of backup tong face the square section of joint or tubing,

itis ready for making up. When makeup is finshed, operate power tong to rotate in reverse direction until

the opening of master tong and backup tong align properly. Pull power tong avay from rod or tubing string,

thon makeup is over.

3). Break out

‘When the opening of master tong and backup tong align properly, turn reset knob(I.8.2.1-16) on master tong

and reset knob(1.8.B-2) on the backup tong t0 the direction of breakout. Push power tong to sucker rod

string. When master tong and jaw set of backup tong face the square section of joint, iti ready for breaking

out, When breakout is finished, operate power tong rotate in reverse diteetion until the opening of master

tong and backup ‘ong head align properly. Pull power tong away from rod string, then breakout is over.

4) Change Die Pieces

Push the jaw sets (1.8.Z.1-2)on master tong and backup tong to the center of tang head. Die pieces expose,

takedown the retaining pin( I 8.Z. 1-5) Ttis ready to take out die pieces and change them.

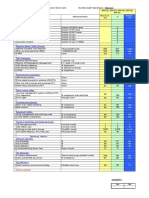

5). Selection of Jaw Plate

Jaw plate

16 | 193 2 2 | 48

identification, ee i SY

Appliable

cyais | cvais22 | cyG2s | cv029 | oitpipeoss. | Couptingoso

scape

6. Maintenance and Lubrication

‘Afr every transportation, itis necessary to wash master tong and backup tong with kerosene or diesel oil and

inject grease to oil cups (see part no(1.8.Z-16)) of machine body, jaw set and jaw set bracket on master tong and

backup tong, the surface of open gears

Every three months in work, remove the cover pate(|.8.2-45) and inject lubrication grease 1o gears’ surfaces.

‘After every use, clear water and oil dustin tong immediately and keep the equipment clean,

‘Afr every use in well service, its necessary to inject lubricating grease to every rotary pin sha

‘Do not use vapor to clear tong in case the inner part loses eil or water enters into the inner part which may

cause damage to pars

‘The temperature of hydraulic oil should not be over 65°C. The over heat will make the seal of hydraulic

pressure system out of order.

‘Hydraulic oil must be kept clean and filter must be cleaned regularly. Ifthe hydraulic oil has been diy, it must

be changed without delay.

Hydraulic oi selected:

(1) Low solidifying point hydraulic oil YC-N46, application ambient temperature range: -20~ ~40"C

(2) Waterproof hydraulic oi! YB-N46,application ambient temperature range: -10~ +40°C

@) Ordinary hydraulic oil YA-N46, application ambient temperature range: 0 ~+40°C.

Users can take hydraulic oil, lubricating. grease and lubricating oil by themselves in accordance with Tocal

condition

‘7.Parts easy to be worn

NO._| Purchase number Part number Part name

1 [sz ¥QU8Z37 Iriction dise

2 fiszes XYQISZ-1A [Braking disc

3 [Laz RVQLEZ5 [Brake plate assembly

4 _[L.eB-s QUSBZIL jaw set (or die)

5 |isza7 YQURZ22A [Upper retaining roller shaft

6 (uae7 YQUB.Z-5 taining roller shat

7 |.sBa3 GBI235-76 ring 533.5

8 |L&B1S iB1235-76 -ring44<3.5

9 [L8B39 1B1235-76 o-ring22-2.4

‘Troubles and Troubleshooting

Troubles I ‘Cause analysis Remedies

1 Die pieces chose is not proper.

hhange corresponding dic pieces.

Die pieces'ecess is filed with | CTAMSE comesPonding dic p

Clear hard articles in die pieces’ recess.

a Change new die pieces.

Maaetonesie | Die wr eperae

| 4.Brake torque of tong head is too

| ‘small.

S.Tong is not horizontal.

Regulate brake shrink spring slightly

tight.

Adjust tong horizontal

t ;

Reset kacb's dietion 1s wi

Backup tong can't clip | RS eee

eee ay | except for causci,2.3,5 mentioned

a above.

Check teset knob and turn it to right

direction except for remedies

‘mentioned above,

‘Master or backup tong’s | Retaining pin or set pin is out

Tum reset knob 180 degree to realign

strength is too weak,

openings can't align | rset knob of kao when |

properly. | resetting. eee

Engsgemcat i aot

‘Add edjuing vsber” stengiben

psitve and easy. to| Lock srengh is too weak ee

| pwestueeffortot mriog

taltpes |

aa ae

Taw set do not extend, por Brake | Cranes beaie div

el xQ29

a5 3s

9, Mlustration and parts list

9.1 Assembly and parts table

‘9.2.Master tong and parts table

9.3 Shell accessory and parts table

9.4.Tong head assembly and parts table

9.5.Braking and centralizing mechanism and pars table

9.6.Transmission mechanism and parts table

‘9.7.Hand control valve and parts table

9.8.Shifling mechanism assembly and parts table

9.9.Safety assembly and parts table

9.10.Backup tong and parts table

9.11,Backup tong head assembly and parts table

9.12-Tong til oil eylinder assembly and parts table

9.13.Fore guide pole and pasts sable

9.14 Rear guide pole and parts table

THON BOUL

HOD

ef

33 3tS

9.1 Assembly and parts list(Fig.3,Table 1)

Fig. 3 Assembly

Table 1 Assembly parts list

Item, PIN, Part number Part name Qry

1_[iapro XYQI8.DTO Lif assembly 1

2 |18ep0 XYQ18.QD.0 Fore guide rod assembly a

3__| isp. XQI8BZ.0 Master tong 1

4 |isp2 XQL8BB.0 Backup tong 2

s_[isupo XYQLS.HDO Rear guide pole 1

Dp,

335 Sos

Fig.4 Master tong

Table 2 Master tong parts list

Item PIN, Part number Part name Qry,

1 |isz78 XYQU8.Z4 (1A) Safety door assembly 1

2 | reps XQ18B.Z.1 Tong head assembly 1

3 [i8z79 Braking and centralizing mechanism 1

4 [taz09 Shell and accessory 1

3_[isz7i XYQIEZS Hydraulic hand control valve 1

6 [18726 XYQU8Z3 Shifiing gear assembly 1

eo

9.3 Shell accessory and parts list (Fig 5,Table 3)

~=

Moa

Fig.S Shell and accessory

& PRODUCTION EQ

Table 3 Shell and accessory parts list

Part number Part name QTY

[X¥Q18.2-27, [Hanger rod 1

[opir70.1 [Hexagon socket head cap screw MBx25-8.8 1

5B/T70.1 Hexagon socket head cap serew M8*20-8.8 5

KKYQ18Z28 langing seat 1

kvQ1.82-7 (2a) shen 1

YO1S.B-15 [Unper suppor: seat 2

(anrr70.1 Hexagon socket head cap screw MIOXIG-8.8 4

[eprT70.1 fienagon socket head cap screw MI280-8.8 4

xvqnaz21 [pin shaft 1

(carr otter pind30 1

yeloid hydraulic motor BMS-250 1

[XYQU.8.2-30 [Motor sleeve 1

lanrT276 [Single row deep groove bal bearing 6208 1

¥QI8Z29 [Morar connecting seat i

(GB/T1152 \Straight hydraulic grease nipple M8 1

IX¥Q1.8.2-26 |Hole cover, 2

YQL8Z34 [Name plate 1

kvorsz.20 ail rope pin L

lonrra (Coter pin3-25 1

fewrr70.1 [Hexagon socket head cap screw M10*30-8.8 4

loarr9s ‘Standraded spring washer10 4

VOLE Z-19 Rear guide pole seat 1

YQICZ21 Spring 1

¥Q6B.Z-17, ste 1

BITS [Hexagon socket head cap screw M6x16-8.8 6

xyqoaz-15 IBonom cover 1

XYQL.8z-35 [pressure and torque corresponding plate 1

BITS Slotted cheese head serews M6x10-5.8 8

Pa a

9.4 Tong head assembly and parts list (Fig. 6,Table 4)

14.15 16

|

|

|

|

|

|

|

Fig.6 Tong head assembly

1. 8B Power Manua

ae Ste

Table 4 Head assembly parts list

Them PN, Part number Parename oy

1 [iszite [xvenszits | Konb 1

2 [isziis [xverazs-t4 | spring 1

3 [iszisa [xveraz.t-13 | Konb shan 1

4 [razor | xvoisz36 Spline connection plate 1

5 [iszias [eversziiza | Retaining pin 1

6 [isziiz | xvoiezi-t1a | Open gear cover 1

7 fiszia | xvorsziia | Jaw bracket 1

8 | 1821-8 XYQLEZA-8 Spring 2

9 | taps Jaw assembly 2

to fiszino | xvorszi9 Ramp 4

u_fisziat [evei8Zi0A | Open gear 1

2 [ispts [carne Cylindrical pin 4-20 1

3 [az GBATOA Hexagon socket head cap serewsMi-20-8.8 [13

ia _[iszes | xvqiazis Retaining pin Fi

1s fiazi2 | xvquazi2 Jaw body 2

ie _[iazia [xveiazi3 Roller shaft 2

7 fiszia | xvqiazi4 Roller 2

is fiazi7 | xvqrazi7 Spring seat 2

19 _[1.8Bs XQI.ABZ.1-1 Jaw set (or die) 2

20 [iazias | opr. Hexayon sockethead cap serewaMO=14-88 | 4

a _[iszi9 [ors Hexagon socket head cap serewsMBx16-88 | 4

n

aS 3as"

9.5 Braking and centralizing mechanism and parts list (Fig.7,Table 5)

Fig. 7 Braking and centralizing mechanism

Bee RAE VANCHUNG THDA DRILLING & PRODUCTION FQUT

Table 5 Braking and centralizing mechanism pars list

Tem | _PN Part number Par name ory

1 1.8.2-70 [Steel wire2*700_ 1

2 hazes [esrra2 liexagon bots with sot on head MIOx45-8.8 8

3 fisz29 kkvescz21 [Spring 3

4 hiszs bvorszs lprake disc assembly 1

Ss |18z-82 YQ8.Z-37 [Friction dise 2

6 fiszs3 (xvOLaZ1A [Brake plate 1

7_|ispss [opr lexagon socket head cap serowsM%25-8.8 4

8 fiezao _hevoiaz24 [rong head nandte ei

9 [i839 bevol.s.2-23 (A) [Tong head cover 1

10 fiszar (kvQi82-7 a) _|shen 1

his YQU8Z3 [surponine rate 1

2 iazin (Garros [cross recessed countersunk flathead serew MS-8-5,8 | 13

3 tazs_lapites [cross reessed countersunk fla head serew MS*10-5.8 | 25

14 [i.8z4s foparzo. Hexagon socket head cap screws MB%20-8,8 Z

1s [18237 ikvo1.ez-220 _|Upper centralizing roller stat B

is fiaza. fkvoraz2 [centralizing roller 25

17 [18736 fGprre9ai [citelip for shat 12 B

ig_ [1.8.27 YQU8.Z-5 [Centralizing roller shaft 12

eee |

as”

9.6Transmission mechanism and parts list (Fig.8,Table 6)

Fig. 8 Transmission mechanism

Q29/1.8 wer To Manua

aS Sas DRILLING & PRODUCTION EO)

Table 6 Transmission mechanism parts list

item [PN Part number Par name QTY

_[iszi | xveisz7 Ga) | shen 1

2 |iszss | xvoisz25 K a

3_[iszis | xvoi.8z-10 Shaft 3

4_iszs7 | xvqiazs2 Sleeve 2

s_|iszs [cers cross recessed countersunk head sorewMSx10-5.8 | 24

6 _[iszss_[xvoisz33 Nevdle cover 6

7_[iszi3 _[oprrsos Needle 4425.8 132,

&_|iszss | xvoi87-31 Idle gear 2

9_|isz22 _|xvai.sz-t6 Washer 4

io [182-16 | Gprriis2 Straight hydraulic grease nipples M6 3

u_fiszi2 [xvoiaze Duplex Gear 1

2 |isz14 | xvoisz9 Spacer ring 1

13 [isz2s [xvoiszis ower input shaft 1

14 | us217 | xveisz-i1 Shifting gear 1

1s_[aszis [xvQiszi2 Inner gear sleeve 1

16 [18200 “| XVoLaz14 Spline gear 1

v7 _[iszi9 | xveieza Clutching Geer Assembly 1

is_[1sz23 | xvqiszi7 Support plate 1

i _[isz24 [opr Single row deep groove ball bearings 6204 1

lel

a 3as VANCHE

LING & PR

9.7 Hand Control Valve and parts list (Fig.9,Table 7)

Fig.9 Hand Control Valve

Table 7 Hand Control Valve parts list

Item PIN Part number Part name ind

1 |18zs510 | xv@ezs-1 Valve Body 1

2 [18255-8 | 6B1235-76 O-Ring3o3.5 2

3 [iazss7 [xvqezsi Combination Valve Core 5

4 [18255-6 | X¥Q3025-7 Support Seat L

5 [1879 GBIT70 “Hexagon Socket Head ScrewM6x16 4

6 [8255-5 [xvQieZ.5-84 Fork i

7 [18DT9. GBITOL Cotter Pin3.2%20 BI

8 [187552 [oprres2 Pin Shaftl0~40 1

9 [1azss1 | GBrraa Pin Shafi 2x45. L

10 _[i8.B8 GBITS3 Spring Washer 12 1

n_[iszssa [oprrei70 Hexagon NutMi2 L

12 | 18255-3 [ XVQCZ59 Gontroi Lever 1

1B [18z3-10 [| X¥QICZ5-10 Ball Knob 1

14 [8zss16 | RvQICZ 512 Hex head plug 1

LEZ-47 Pressure GageO~16MPa 1

is [iezss-17 [xvoiez5a8 Copper Washer 1

16 | 18259, GBIN35-76 ‘O-Ring2O24 2

17_|i8Z-60 XYQICZ.24 Tail Connector Z

18 [18z55-9 | GBrT70 Hexagon Socket Head Screw M1235 4

19 _[i8zss-is | xveicz52 Valve Tail Seat 1

20 [iazssia | xvQIczs-6 Restricting Ring 1

2_[iszssi3 | xveezs-5 Spring Seat(2) 1

22_ [182-5512 | X¥QC.Z54 Spring 1

2B [iszssi [xveiczs3 Spring Seat(l) 1

7

Fig.10 Shifting mechanism assembly

Table 8 Shifting mechanism assembly parts list

item PIN Part nomber Part name Qry

1 [1823-1 XYQU8Z3-1 Sleeve 2

2 [1823-2 XYQU8.Z.3-2 Shift Fork 1

3. | 1823-9 XYQI8.Z3-5 Sliding Block 2

4 [1823-7 XYQI8Z3-3, Key 1

5 [1823-8 XYQUEZ3-4 Shift Fork Shaft 1

6 [1823-10 XYQ3C.Z.5-10 Ball knob 1

7 [182z34 XYQ3CZ.6-4 Roller Shaft 1

8 [1823-5 GBITOL Cotter Pin 210 1

9 [1823-3 XYQICZ.6-3 Roller 1

10 [1823-6 XYQ3C.Z.6-5 Roller seat 1

1

Fig.11 Safety door assembly

Table 9 Safety door assembly parts list

Item:

PIN

Part number Part name gry,

1 fiz ulling spring(@2.5@15%65) 1

2 |rezai YQI.BZACLA).L ety door 1

3 |iaza4 YQIRZA(IAY4 in shafh(2) 1

4 |ez7s sBIT859 {standard spring washer 14 1

5 hezas YQIB.ZA(1A)3 [pin shatt¢1) 1

6 |iszs YOI8Z.5 [Braking plate assembly 1

7 hsezn IX¥QL8.Z-7(2A) [shett 1

8 lisz42 X¥Q18.Z.4(14)2 [Shaft seelve 1

4a Gots

9.10 Backup tong and parts list (Fig.12, Table 10)

Fig.12 Backup tong.

Table 10 Backup tong parts list

tem PN Part number Part name:

ary,

1 [LBs [Backup tong head

2 |sB46 [Tong til oil eylinder assembly

=

20

Fig.13 Backup head assembly

a

Table LL

Backup head assembly parts list

tem PN Part number Part name Qry

_|ispa3 [opis Hexagon socket head cap serew M8%25-8.8. 4

2 |isz4o | xvoi8z24 | Tong head handle 2

3 [iss XYQ1.8B-02 | Backup tong head cover a

4 | ise7 XQ18B.B-1 Jaw set bracket 1

s_[iszie | xvoigzis ing 2

6 | 1.8B-4 Jaw set assembly eB

7_|isza-io | xvqisz1-9 | Ramp 4

s_|18B8 XQI.8BB2. Backup tong head body U

9 {isp XYQI8B-12 | Backup tong front seat 2

1o_ [182-31 GBT70.1 Hexagon socket head cap screw M10x3048.8 4

[18230 | @prr93 ‘Standard spring washer 10 4

12 _|18B2 XVQIC.B2 Backup tong reset knob 1

13 _ [1.861 GETS Cylindrical pin 418 1

4 ispas | xvescpio | spring z

is [i8p42 | aprr308 Steel ball 4.5 i,

16 [18246 | Gprr701 Hexagon socket head cap serew M3*20-8.8 8

v7 [ips xVQ1.8B.01__| Knob shatt 1

is [18z120 | xvgi8z1-12 | Retaining pin 1

19 [iszis [xveiszis | soppin 2

20 [iazi2 | xveiszi2 | Jawsetbody 2

a_|iszis | xvo1.8z13 | Rollershatt 2

22 |iszis [xvoiszia | Roller 2

23 [18217 [xvgi.8z17 | Spring seat 2

24_| 1.8.5 XQU8BZ.1-1 | Jaw set (or die) 2

2s_| 1821-18 | GBr701 Hexagon socket head cap screw M8 14-88 4

26 |iszio [opr1 Hexagon socket head cap screw M8x16-8.8, 4

Fig.14 Tong tal oil cylinder assembly

a ote N &

Table 12 Tong tail oil cylinder assembly parts list

Trem PN Part number Pat name Qry

1_[ 182.9 GBrrT0.1 Hexagon socket head cap serews MOx1688 | 5

2 GB/T70.4 Hexagon socket head cap screws MOx1088 | 1

3 | 18BS X¥QI.8B.05 Gear cover 1

4 |1sB6 XYQLAB-03 Shif shat 1

5 [tsps XYQLAB-O4 Duplex gear 1

6 18.B47 GBIT1096, Key 12*28 1

7 | 18B-11 XYQI.8.B-0TA Tong tail oil cylinder 1

8 [ispi2 | xvo1.8p08 | Rackplonger 1

9 | t8B0 | xvoia B06 Cylinder liner 2

10 [186-13 [opi23s.76 O-Ring 353.5 a

11 | tsBs | oni2ss76 O-Ring 43.5 2

2 [isp | xvorsso Cylinder cover 2

3 [18833 [opr Hexagon socket head cap seraws MB-2588 | 8

i [isis | Gorrs Standrad spring washer 12 4

15 [18617 | apr Hexagon socket head cap sorewsMIZ25-88 | 4

16 _[t8B40 | xvoiab-13 Stop pin 1

17 [18B48 | epaes Standrad spring washer 8 4

tx [1841 XYOLS.B-14 ‘Backup tong til 1

19 [18839 | Gp1235-76 O-Ring 2252.4 7

20 | 188-50 “Hose 8 1-500 (MI8>1.5/018 ball) 2

21 | 18Bs1 XYQ3CB-22 Longer adapter 1

» [ise [xvece21 a) |oitor ez

4

aS ios

9.13Fore guide pole and parts list (Fig.15,

9.14Rear guide pole and parts list (Fig.16,

Fig.tS Fore guide pole

Table 13)

Table 14)

Fig.16 Rear guide pole

Table 13. Front guide pole parts list

Tem PN Part number Part name gry,

1_|isep-s XYQ18.0D-4 Fore guide rod sleeve 2

2_|isep4 XYQI8.QD-3 Spring 2

3_|isep2 GBIT91 Cotter 420 a

4_|18.0p.3 XYQL8.QD-2 Fore guide rod 2

s_[18qp1 XYQL8.QD-1 Fore guide rod seat 2

Table 14 Rear guide pole parts list

Them Part number Part name Qry,

1 XYQUHD.L Back guide rod sleeve i

2 XYQL8.HD-3 Spring L

3 GBITOL Cotter 5*35 i

4 XYQUS.HD-2 Back guide rod 1

5 XYQL8.HD-1 End cover, 1

6 GBT Slotted cone end fastening screw M6*10 | _1

2s

Fig.17 Lift assembly

Table 15 Lift assembly parts list

hem PIN Part number Partname ‘gry

1_[iapra XYQL8DT-I Lifting tug 1

2__[ispra XYQLS.DT2 Spring seat 1

3_[ispr6 XYQI.SDT3 Spring 1

4 [ispri GBITS82 Pin shaft B4x40 H

s_[isprs GBiT9L Cotter pin 3.2*20 2

6 _[isprs XYQLEDTI Lift 1

7_|18pr4 GB/TLIS Cylindrical pind20 1

8 |1spr7 XYQURDT2 Hanger rod 1

9 [isprs GBITS82 Din shaft 16~45 1

26

aS ifs

10.Trucking, Storage and After Service

10.1 Trucking

‘When you move hydraulic power tong, you should move it smoothly and keep it from wet, and don’t put it

upside to downside and also keep it from damage. When it is lifted, use stee! wire rope with the diameter 12mm

ot bigger, and to keep it in balance, Don't incline and swing it too much, to keep it fom attacking other things

avoiding damaged.

10.2 Storage

XYQ3C hydraulic power tong should be placed in where is no sunshine, prevent rain, wet proof, good airing and

the environment temperature below 45 Oc. Don’t storage itn a muddy place or outdoors. Protect oil inlet and

outlet well to prevent some sundries in. The storage period is general one year for new hydraulic power tong. It

can be used after one-year storage but all the sealing parts and hoses must be changed.

10.3 Unpacking

Check the appearance of hydraulic power tong and check and accept it as packing list.

10.4 After Service

Our company has special professional service team and customer service Internet,

SERVICE PROMISE: Reply in Time, Main tenance and Repairing in Work Site, fre service,

‘TELEPHONE: 086-0515-86582548; 086-0515-86583024

FAX: 086-015-86582386

E-mail: ¢@chinateda.com

»

Hengji Town, Jianhu county, Jiangsu Province, China

224763

+86 (0)515-86582548

+86 (0)515-86582386

td@chinateda.com

http://www.en-teda.com

You might also like

- Highland Hotel: MR Rio Molex Butar Butar SPRTDocument6 pagesHighland Hotel: MR Rio Molex Butar Butar SPRTHendra JurbonNo ratings yet

- Perhitungan Dasar Well ControlDocument6 pagesPerhitungan Dasar Well ControlHendra JurbonNo ratings yet

- Liner TailDocument1 pageLiner TailHendra JurbonNo ratings yet

- Kepala KudaDocument9 pagesKepala KudaHendra JurbonNo ratings yet

- Kepala KudaDocument9 pagesKepala KudaHendra JurbonNo ratings yet

- Cat 3406 Engine Parts ManualDocument78 pagesCat 3406 Engine Parts ManualCarlos Manzoni100% (6)

- WellsafeDocument34 pagesWellsafeHendra Jurbon0% (1)

- Manual TransmissionDocument31 pagesManual TransmissionHendra Jurbon100% (1)

- Perhitungan Dasar Well ControlDocument6 pagesPerhitungan Dasar Well ControlHendra JurbonNo ratings yet

- Pipe Wrench Use GuideDocument4 pagesPipe Wrench Use GuideHendra JurbonNo ratings yet

- Wcbop CatalogDocument82 pagesWcbop Catalogwolfy1234100% (2)

- Drilling Progrm PDFDocument5 pagesDrilling Progrm PDFHendra JurbonNo ratings yet

- Form Pengambilan Hand GloveDocument8 pagesForm Pengambilan Hand GloveHendra JurbonNo ratings yet

- EX-0035 Drilling - English API Forumla SheetDocument4 pagesEX-0035 Drilling - English API Forumla Sheetmohamed abbasNo ratings yet

- Wcbop CatalogDocument82 pagesWcbop Catalogwolfy1234100% (2)

- Formation PressureDocument79 pagesFormation PressureRian MonterryNo ratings yet

- Pressure Traverse Galih 2 InchDocument4 pagesPressure Traverse Galih 2 InchHendra JurbonNo ratings yet

- Wcbop CatalogDocument82 pagesWcbop Catalogwolfy1234100% (2)

- Daftar PustakaDocument1 pageDaftar PustakaHendra JurbonNo ratings yet

- PT ManualDocument28 pagesPT ManualLuis Alberto IzarraNo ratings yet

- NWW BP - Spa Metric Rig 07Document3 pagesNWW BP - Spa Metric Rig 07Hendra JurbonNo ratings yet

- Blow OutDocument1 pageBlow OutHendra JurbonNo ratings yet

- Bab IiDocument601 pagesBab IiHendra JurbonNo ratings yet

- Formation PressureDocument79 pagesFormation PressureRian MonterryNo ratings yet

- 10.75” 40.5 # Casing @ 101’ and 7”20# Prod. Casing Installed in WellDocument1 page10.75” 40.5 # Casing @ 101’ and 7”20# Prod. Casing Installed in WellHendra JurbonNo ratings yet

- Nafta Gaz 2013 02 01Document9 pagesNafta Gaz 2013 02 01salomonmelcanoNo ratings yet

- Bab IiDocument601 pagesBab IiHendra JurbonNo ratings yet

- Well Head Casing DiagramsDocument2 pagesWell Head Casing DiagramsHendra JurbonNo ratings yet

- Kepala KudaDocument9 pagesKepala KudaHendra Jurbon Butar-ButarNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)