Professional Documents

Culture Documents

Wellsafe

Uploaded by

Hendra JurbonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wellsafe

Uploaded by

Hendra JurbonCopyright:

Available Formats

Well Control Training & Assessment

Sample Driller-Level Questions

The questions in the document are a sample of Driller level questions that will

be included in the testing database.

These questions are still under review by an industry committee and may

therefore be revised.

Please use the Acronyms and Glossary of Terms document to assist with the

terminology in use.

Rev. 0 March 2015

IADC’s Well Control Training & Assessment

1. What is the correct definition of Porosity?

a. The ability of formation fluids to move through the rock.

b. The amount of solid rock in the formation.

c. The amount of pore space in the rock.

d. The pressure of the fluid in the pore space.

2. What is the correct definition of a kick?

a. An uncontrolled flow of formation fluids at the surface.

b. An influx of formation fluids downhole.

c. The increase in shut in pressure due to gas migration.

d. The increase in pressure on bottom when the pumps are

started.

3. Which of the following best describes fracture pressure?

a. The pressure in excess of mud hydrostatic that is likely to

cause losses at the casing shoe.

b. The total pressure applied at the shoe that is likely to cause

losses.

c. The maximum bottom hole pressure allowed during a kill

operation.

d. The maximum pressure allowed on the drillpipe gauge

during a kill operation.

4. Hydrostatic Pressure is:

a. The viscosity of a stationary column of fluid.

b. The force exerted by a column of fluid at rest.

c. The measured depth of a stationary column of fluid.

d. The force applied with Annular Pressure Loss.

5. When you shut in a well after a kick, it can take 5-10 minutes or

longer for the pressures to build-up. What affects the time of this

build-up?

a. The friction losses

b. Gas migration

c. The formation porosity

d. The formation permeability

Sample Driller-Level Questions, Rev. 0 2 March 2015

IADC’s Well Control Training & Assessment

6. What is the primary way to prevent a kick?

a. Close in the well with the BOPs.

b. Monitor the pit levels and flow rate to recognize a kick.

c. Take regular slow circulating rate pressures.

d. Use mud hydrostatic to balance the fluid pressure in the

formation.

7. The following information was recorded, while drilling ahead.

True Vertical Depth (TVD) Mud Weight - 10.5 ppg

- 13,205 feet

Measured Depth (MD) - Formation Fluid Gradient

13,970 feet at bottom of the hole -

0.5564 psi/foot

What is the situation at the bottom of the hole?

a. Overbalanced

b. Balanced

c. Underbalanced

8. What is the hydrostatic pressure of an 11.6-ppg fluid at 7,200 feet.

MD (6,250 feet. TVD)?

a. 4,343 psi

b. 3,007 psi

c. 3,770 psi

d. 4,200 psi

9. TVD = 6,700 ft. MD = 7,500 ft.

Mud weight = 9.4 ppg

Annular Pressure Loss = 210 psi

Calculate equivalent circulating density (ECD).

a. 10 ppg

b. 9.7 ppg

c. 9.5 ppg

d. 9.9 ppg

Sample Driller-Level Questions, Rev. 0 3 March 2015

IADC’s Well Control Training & Assessment

10. You circulate a light mud pill with the pumps running continuously.

When will the bottom hole pressure start to decrease? (Ignore the

dynamic pressure losses in the well.)

a. As soon as the pill starts to be pumped down the drill string.

b. After all the pill is pumped inside the drill string.

c. Once the pill starts to be displaced into the annulus.

d. After all the pill is in the annulus.

11. Before pulling out of the hole you pump a slug. After displacement

you line up on the trip tank.

Slug Size 25 bbls

Slug Weight 12 ppg

Mud Weight 10 ppg

Pipe Capacity .01776 bbls/ft.

Calculate how much mud would return to the trip tank.

a. 5 bbls

b. 10 bbls

c. 3 bbls

d. 6 bbls

12. During normal drilling operations 30 bbls of light mud is pumped

into the string followed by original mud. The Driller shuts down the

pump to observe the well with light mud still inside the drillpipe.

Well Depth (TVD) = 9, 000 feet

Drill pipe capacity = 0.01776 bbls/ft

Original mud weight = 12 ppg

Light mud weight = 10 ppg

How does this operation affect bottom hole pressure?

a. Bottom hole pressure will remain the same.

b. Bottom hole pressure will increase 176 psi.

c. Bottom hole pressure will decrease by 176 psi.

13. The equivalent circulating density (ECD) determines the actual

bottom hole pressure while circulating.

Which part of the system pressure losses is used to calculate ECD?

a. The pressure loss in the annulus.

b. The pressure loss in the open hole section only.

c. The pressure loss across the nozzles.

d. The pressure loss in the drill string.

Sample Driller-Level Questions, Rev. 0 4 March 2015

IADC’s Well Control Training & Assessment

14. When pumping at 80 SPM the pump pressure = 4000 psi. What

would be approximate pump pressure if pumps were slowed to 40

SPM?

a. 500 psi

b. 800 psi

c. 1,000 psi

d. 2,000 psi

15. What is Bottom Hole Pressure (BHP) defined as?

a. The total pressure felt at the bottom of the hole when either

pumping or not pumping.

b. The total pressure felt at the bottom of the hole when either

pumping or not pumping.

c. The total pressure felt at the bottom of the hole when not

pumping.

d. The total pressure felt at the bottom of the hole when

pumping.

16. Why is it important to maintain the correct Bottom Hole Pressure

(BHP)?

a. If BHP decreases then the well can kick.

b. If BHP decreases the well may lose mud to the formation.

c. If BHP increases we increase the risk of a kick.

d. If BHP is not allowed to increase when drilling a transition

zone we increase the risk of losses.

17. What is the immediate effect of swabbing?

a. There is a reduction in bottom hole pressure.

b. There is a kick.

c. There are losses.

d. There is an increase in bottom hole pressure.

18. What can increase surge pressures when you are running in the

hole?

a. A small annular clearance.

b. Large bit nozzles.

c. Low gel strength mud.

d. A large annular clearance.

Sample Driller-Level Questions, Rev. 0 5 March 2015

IADC’s Well Control Training & Assessment

19. Given the following information, calculate the volume inside 100

stands of drill pipe

Drill Pipe OD 5.0 inches

Drill Pipe ID 4.276 inches

Drill pipe length 94 feet/stand

a. 228.4 bbls

b. 167.0 bbls

c. 6.6 bbls

d. 1.7 bbls

20. Give the following information; calculate the displacement if 5

stands of drill pipe are run in the hole with a solid float.

Drill Pipe OD 5 inches

Drill Pipe ID 4.276 inches

Drill pipe length 94 feet/stand

a. 2.3 bbls

b. 8.3 bbls

c. 11.4 bbls

d. 1.7 bbls

21. Which of the following is a definition of MAASP?

a. The pressure in excess of mud hydrostatic that, if exceeded,

is likely to cause losses at the shoe.

b. The maximum pressure allowed in the hole during a kill

operation.

c. The maximum pressure allowed on the drill pipe gauge

during a kill operation.

d. The total pressure applied at the shoe that is likely to cause

losses.

22. What will happen to Maximum Allowable Annular Surface Pressure

(MAASP) if Mud Weight is increased?

a. MAASP will stay the same.

b. MAASP will increase.

c. MAASP will decrease.

Sample Driller-Level Questions, Rev. 0 6 March 2015

IADC’s Well Control Training & Assessment

23. When should you do a Leak Off Test?

a. Before drilling out the casing shoe.

b. Before running the casing.

c. Immediately after running and cementing the casing.

d. After drilling out the casing shoe and 5-15 feet of new

formation.

24. When should you recalculate the Maximum Allowable Annular

Surface Pressure (MAASP)?

a. At the beginning of each tour.

b. Immediately before entering a reservoir.

c. After each bit change.

d. After changing the Mud Weight.

25. If the well is flowing at a connection and you suspect the well is

“ballooning.” What is the first action that the Driller must take?

a. Measure the time it takes for 5 bbls of mud to flow into the

trip tank, and then shut in the well.

b. Complete the connection and go back to circulating speed to

stop the flow.

c. Shut in the well, call supervisor and record pressures and

pit gain.

d. Stop further drilling and circulate bottoms-up at the slow

pump rate.

26. In a well with gas-cut mud, when is the reduction in bottom hole

pressure greatest?

a. When the gas is at the Casing Shoe.

b. When the gas is at the bottom of the hole.

c. When the gas at the top of the well.

d. When the gas is half way up the open hole section.

27. Swabbed gas from a trip is allowed to expand as it is circulated up-

hole. What effect will this expansion have on bottom hole pressure?

a. Bottom hole pressure will stay constant as the gas is

circulated up-hole.

b. Bottom hole pressure will increase as the gas is circulated

up-hole.

c. Bottom hole pressure will decrease as the gas is circulated

up-hole.

d. Bottom hole pressure will decrease as the gas is circulated

up to the casing shoe, then it will stay constant.

Sample Driller-Level Questions, Rev. 0 7 March 2015

IADC’s Well Control Training & Assessment

28. What is the correct definition of ‘gas migration’?

a. The flow of gas through the Mud Gas Separator.

b. Formation gas that enters the well during a connection.

c. The process of gas expanding as it is circulated up-hole.

d. Uncontrolled movement of gas up-hole due to its low

density.

29. Why are gas kicks more difficult to detect in oil-based fluids than in

water-based fluids?

a. Oil is less dense than water.

b. Most gas is not soluble in water-based fluids.

c. The mud in the well has no effect on detecting a gas kick.

d. Gas is very soluble in oil-based fluids.

30. If the shut-in pressures are 600 psi SIDPP and 800 psi SICP and both

start rising slowly when weighting up the mud, what type of influx is

in the well?

a. Gas

b. Oil

c. Fresh water

d. Salt water

31. You are circulating bottoms-up due to swabbing from 8,000 feet.

Water Depth is 5000 feet. It is decided to shut in the Annular and

circulate up the choke line. What is the reason for this action?

a. To reduce risk of having gas in the Riser.

b. To prevent the gas from expanding as it is circulated up-

hole.

c. To allow SPM to be increased to reduce circulating time.

d. To minimize pressure on the casing shoe.

32. While drilling a long horizontal section of a well, a 10 bbl pit gain

was observed and the well was shut in. After shut in, it was noted

that SIDPP and SICP were approximately the same. What can we

determine from these pressures?

a. Influx is in the horizontal section of the well.

b. This is probably ballooning.

c. This is a salt-water influx.

d. This is probably a result of surging the well.

Sample Driller-Level Questions, Rev. 0 8 March 2015

IADC’s Well Control Training & Assessment

33. You are tripping a tapered string out of the well. The larger

diameter pipe is in the upper part of the string. What will happen to

the trip tank volume as the ‘slug’ is being displaced into the smaller

diameter pipe?

a. The Trip tank reading will indicate surging if the large

diameter pipe displacement is used on the trip sheet.

b. The Trip tank reading will indicate swabbing if the large

diameter pipe displacement is used on the trip sheet.

c. Trip tank will show same rate of change for both pipe

diameters.

d. There will be no change in trip tank level until all the slug

has been displaced into the small diameter pipe.

34. What affect does increasing temperature have on mud weight?

a. It will reduce the mud weight.

b. It will increase the mud weight of water base muds.

c. It will increase the mud weight of oil base muds.

d. There is no effect while drilling.

35. When out of the hole to change the Bit the mud in the Riser cools

due to sea temperature. How will the change in temperature affect

the mud weight?

a. The mud weight will probably increase.

b. The mud weight will probably decrease.

c. The mud weight will not be affected by temperature.

36. Your Shakerhand is taking oil-based mud weight readings with an

atmospheric Mud Balance. What would the mud weight readings be

if a pressurized mud balance were used?

a. Mud weight readings would be higher.

b. Mud weight readings would be lower.

c. Mud weight readings would be lower.

37. Why is it important to inform the Driller when starting or stopping

the De-Sander or De-Silter?

a. Pit volume will change.

b. Mud viscosity will be reduced.

c. Shakers will need to be by-passed.

d. Flow Rate will increase from the well.

Sample Driller-Level Questions, Rev. 0 9 March 2015

IADC’s Well Control Training & Assessment

38. Why is it important to measure the weight and viscosity of the fluid

at the shakers?

a. It provides information about mud properties and the

general well condition.

b. It informs Mud Engineer when to do mud tests.

c. It makes sure the well plan’s mud program is followed.

d. It is more important to measure the weight and viscosity

after the Shakers.

39. There are four (4) Mud Pits, each measuring 9 feet x 12 feet x 8 feet

deep.

Fluid depth is 6 feet in each pit.

Volume = (Length x Width x Depth) / 5.615

How many barrels of mud in the surface tanks?

a. 462 bbls

b. 154 bbls

c. 411 bbls

d. 137 bbls

40. Why is it important for the Driller to know when mud is being

transferred into or out of the active system?

a. To recognize if there are gains and losses due to a kick or

lost circulation.

b. To know when to operate the pit agitators to prevent Barite

falling out of the mud.

c. To line up returns through the Desilters to improve mud

mixing.

d. To start bottoms-up circulation to clean the hole before new

mud is pumped.

41. You are drilling ahead with a 12¼-inch Bit with an average ROP of

95 feet/hour. For the last 20 minutes there has been no change to

the pit level. What action would you take?

a. Continue drilling all is good.

b. Prepare to mix LCM as you may be losing some mud to the

formation.

c. Increase WOB now that ROP is stable.

d. Consider making a flow check to check why pit volume is

stable.

Sample Driller-Level Questions, Rev. 0 10 March 2015

IADC’s Well Control Training & Assessment

42. Why do we kill the well at a slower SPM (strokes per minute)?

a. To kill the well in a short time.

b. To prevent bursting the casing.

c. To allow choke operator time to react during a well kill.

d. To determine pump rate to displace cement.

43. Where do you record Slow Circulating Rate (SCR) pressure?

a. Record pressure at the mud pump gauge.

b. Circulate through the Choke Manifold with a fully open

choke.

c. With one mud pump only.

d. Record pressure at the Choke control panel.

44. Why do we take Choke Line Friction (CLF) pressure?

a. To calculate increase in Initial Circulating Pressure (ICP).

b. To calculate Kill Mud Weight.

c. To calculate Initial and Final Circulating Pressures

(ICP/FCP).

d. To help compensate for choke line friction when starting to

a well kill.

45. How do you take a Choke Line Friction (CLF) pressure?

a. Circulate the well through a full open choke with the BOP

open and record the pressure on the static kill line.

b. Circulate down the choke line and up the riser with the BOP

open and record the pressure.

c. Circulate down the kill line and up the choke line. The CLF is

twice the recorded pressure.

d. Circulate down Riser Boost line and up the choke line.

46. What are typical Slow Circulating Rates (SCR’s)?

a. Between 1 and 4 barrels per minute.

b. 75% of drilling pump rate.

c. Same as drilling pump rate.

d. Between 75 and 95 strokes per minute (SPM).

Sample Driller-Level Questions, Rev. 0 11 March 2015

IADC’s Well Control Training & Assessment

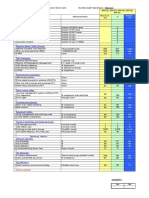

47. Well Data:

Hole Dimensions

Depth (TVD) 12,090 feet

9 5/8" Casing shoe 8,800 feet

Hole size 8½ inch

Current mud weight 13.5 ppg

Internal Capacities

6 1/2" Drill collars (length 900 feet) 0.00768 bbl/foot

5" Drill pipe - capacity 0.01776 bbl/foot

5" Drill pipe - metal displacement 0.00650 bbl/foot

5" Drill pipe- closed end displacement 0.02426 bbl/foot

Annular Capacities

Open hole / Drill collar 0.0292 bbl/foot

Open hole / Drill pipe 0.0459 bbl/foot

Casing / Drill pipe 0.0505 bbl/foot

LOT

Mud weight 12 ppg

Leak off pressure 2700 psi

Pump Details

Pump Output 0.109 bbl/stk

SCR at 40 SPM 550 psi

Shut in data

SIDPP 200 psi

SICP 600 psi

Pit gain 15 bbls

Calculate:

a. Maximum allowable mud weight ppg

prior to kick

b. MAASP prior to kick psi

c. Strokes from surface to bit strokes

d. Strokes from bit to shoe strokes

e. Strokes from Bit to Surface strokes

f. Kill mud weight ppg

Sample Driller-Level Questions, Rev. 0 12 March 2015

IADC’s Well Control Training & Assessment

48. Well Data:

Hole Dimensions

Depth (TVD) 12,090 feet

9 5/8" Casing shoe 8,800 feet

Hole size 8½ inch

Current mud weight 13.5 ppg

Air gap 80 feet

Water depth 740 feet

Internal Capacities

6 ½ " Drill collars (length 900 feet) 0.00768 bbl/foot

5" Drill pipe - capacity 0.01776 bbl/foot

5" Drill pipe - metal displacement 0.00650 bbl/foot

5" Drill pipe- closed end displacement 0.02426 bbl/foot

Choke line 0.006 bbl/foot

Marine riser 0.39 bbl/foot

Annular Capacities

Open hole / Drill collar 0.0292 bbl/foot

Open hole / Drill pipe 0.0459 bbl/foot

Casing / Drill pipe 0.0505 bbl/foot

LOT

Mud weight 12 ppg

Leak off pressure 2700 psi

Pump Details

Pump output 0.109 bbl/stk

SCR (riser) at 40 SPM 550 psi

SCR (choke line) at 40 SPM 850 psi

Shut in data

SIDPP 200 psi

SICP 600 psi

Pit gain 15 bbls

Calculate:

a. Maximum allowable mud ppg

weight prior to kick

b. MAASP prior to kick psi

c. Strokes from surface to bit strokes

d. Strokes from bit to shoe strokes

e. Strokes from Bit to Surface strokes

f. Kill mud weight ppg

Sample Driller-Level Questions, Rev. 0 13 March 2015

IADC’s Well Control Training & Assessment

49. What is the main reason for flushing the choke and kill lines?

a. To measure the slow circulating rate.

b. To prevent blockages due to settling of mud solids.

c. To help read accurate shut in pressure during a well kill

operation.

d. To lubricate the failsafe valves.

50. What is meant by abnormal pressure?

a. The excess pressure due to circulating mud at high rates.

b. The excess pressure that needs to be applied to cause “leak-

off.”

c. Heavy weight mud used to give an overbalance.

d. The formation fluid pressure is greater than formation

water hydrostatic pressure.

51. What must the drill-crew member in the pits or shakers do if they

see a change in mud weight, viscosity or mud level?

a. Inform the Driller immediately of the changes.

b. Continue monitoring the mud to see if the change continues.

c. Inform the Mud Engineer when he makes his normal checks.

d. Add base-oil or water to the mud system.

52. How could the Driller recognize if a lighter mud weight is being

pumped into the well?

a. Decrease in Hook Load.

b. Gradual increase in pump pressure as mud is pumped down

the drill string.

c. Gradual decrease in pump pressure as mud is pumped down

the drill string.

d. Increased flow rate at a connection due to u-tube effect.

53. You are pumping a heavy mud pill into the drillstring. When will

bottom hole pressure start to increase (ignore dynamic pressure

losses in the well)?

a. Once all the pill is in the annulus.

b. Once the pill starts to be displaced into the annulus.

c. As soon as the pill is pumped into the drillstring.

d. Once all the pill is inside the drillstring.

Sample Driller-Level Questions, Rev. 0 14 March 2015

IADC’s Well Control Training & Assessment

54. The flow sensor shows a total loss of returns and the mud level

cannot be seen in the annulus. What immediate action should the

Driller take?

a. Shut the well in and pump lost circulation material.

b. Fill the annulus with water (or lightest mud available) and

record volume.

c. Pump at reduced rate adding lost circulation material.

d. Continue drilling ahead cautiously.

55. You are tripping out without filling the hole. How does this affect

mud level and bottom hole pressure (BHP)?

a. Mud level will drop and BHP will decrease.

b. Mud level will drop and BHP will increase.

c. Mud level and BHP will stay constant.

d. Mud level will rise and BHP will drop.

56. You are ready to pull out of the hole “dry” and shall monitor the trip.

How much mud should be added to the well?

a. A volume of mud to replace the volume of metal pipe

removed.

b. A volume of mud to replace the internal capacity of the pipe

removed.

c. A volume of mud to replace the open hole volume of an

equal length of pipe.

d. One barrel per stand of drill pipe and two barrels per stand

of collars.

57. You have tripped 10 stands into the well. The volume of mud that

has entered the trip tank is 5 bbls greater than the displacement you

calculated. What does this indicate?

a. An influx of formation fluid has entered the well.

b. You are losing drilling fluid to the formation.

c. This is not an indication of any downhole problem.

d. You should increase your trip speed.

58. What is a definition of swabbing?

a. Increase in bottom hole pressure when the pipe is raised.

b. Decrease in bottom hole pressure when the pipe is raised.

c. Increase in bottom hole pressure when the pipe is lowered.

d. Decrease in bottom hole pressure when the pipe is lowered.

Sample Driller-Level Questions, Rev. 0 15 March 2015

IADC’s Well Control Training & Assessment

59. On the following sample trip sheet, identify the first abnormal fill-up

that occurred (Each Stand Group pulled = 5 stands and has a

calculated displacement of 3.78 bbls).

Stand Trip Measured Calculated Difference Cumulative

Group Tank Hole Fill Hole Fill Difference

# Volume (bbls) (bbls) (bbls) (bbls)

(bbls)

1 51 3.8 3.78 + .02 + .02

2 47.2 3.9 3.78 + .12 + .14

3 43.3 3.5 3.78 - .28 - .14

4 39.8 3.5 3.78 - .28 - .42

5 36.3 3.2 3.78 - .58 - 1.0

6 33.1 3.0 3.78 - .78 - 1.78

a. Stand Group 1

b. Stand Group 2

c. Stand Group 3

d. Stand Group 4

e. Stand Group 5

60. Casing is run in the hole with a non-return float assembly without

being filled. With the Shoe at 3000 feet the float assembly fails and

mud u-tubes up inside the casing. What will happen to the BHP?

a. BHP will decrease.

b. BHP will increase.

c. BHP will stay the same due to the u-tube effect.

61. You are running casing with a self-fill float assembly. How would

you know that the self-fill assembly was plugged and the casing was

not filling?

a. Trip monitoring would show increased returns from the

well.

b. Trip monitoring would show decreased returns from the

well.

c. Hook load would increase by buoyed weight of the steel run

in the hole.

d. You would not be able to rotate the casing.

Sample Driller-Level Questions, Rev. 0 16 March 2015

IADC’s Well Control Training & Assessment

62. The well is full of 12.2ppg mud. A 500-foot cement plug is set and

tested. If the mud above the plug is replaced with 10.2 ppg Brine

what will happen to the differential pressure across the cement

plug?

a. Pressure differential will increase.

b. Pressure differential will decrease.

c. Pressure differential will be zero.

63. The well is full of 12.2ppg mud. A 500-foot cement plug is set and

tested. The mud above the plug is replaced with 10.2 ppg Brine. If

the cement plug failed, what direction would fluid move across the

cement plug?

a. Pressure from below would cause fluid to move up.

b. Pressure from above would cause fluid to move down.

c. Fluid would not move across the plug as the pressure

differential is zero.

64. You are drilling ahead on a floating rig and the wellhead connector

is accidently unlatched.

Rig Floor to Mudline = 2,450 feet

Water Depth = 2,390 feet

What will happen to the bottom hole pressure?

a. BHP will decrease by seawater hydrostatic.

b. BHP will decrease by Riser mud hydrostatic.

c. BHP will stay the same as seawater will balance riser mud

weight.

d. BHP will decrease by Riser mud hydrostatic minus seawater

hydrostatic.

65. You are circulating bottoms up after a trip through a gas reservoir.

Oil-based mud is in the well. Water Depth = 6570 feet. What can

affect bottom hole pressure during the circulation?

a. Break-out of gas in the Riser causing mud to unload.

b. Increase in pressure as gas breaks-out of the mud in the

Riser.

c. Increase in pressure as cuttings are circulated out of the

well.

d. Risk of Riser burst allowing seawater to reduce hydrostatic.

Sample Driller-Level Questions, Rev. 0 17 March 2015

IADC’s Well Control Training & Assessment

66. Which one of the following is NOT classed as a ‘barrier’?

a. Pipe Ram

b. Mud hydrostatic pressure

c. Drill string Float

d. Full Opening Safety valve

67. Before cutting the drilling line, with the bit at the casing shoe, which

item of equipment must be installed to make the operation safe?

a. Circulating head.

b. Full opening safety valve.

c. Inside blowout preventer.

d. Full opening safety valve and an inside blowout preventer.

68. What is a “negative” test?

a. A test on a barrier where the pressure on the formation side

of the barrier is greater than the pressure on the upstream

wellbore.

b. A test on a barrier where the pressure on the formation side

of the barrier is less than the pressure on the upstream

wellbore.

c. A test on a barrier where the pressure on the formation side

of the barrier is equal to the pressure on the upstream

wellbore.

69. Which two-barrier combination is not considered independent?

a. A tubing plug set downhole and a backpressure valve in the

hanger.

b. Kill weight mud in the well and the blow out preventer.

c. An Annular and a Ram on a BOP stack.

d. A cemented shoe track over a non-hydrocarbon bearing

zone and a casing bridge plug.

70. You are killing a well on a floating rig. How do you monitor the

pressure integrity of the closed BOP?

a. Monitor the mud level in the Riser with the Trip Tank.

b. Lock the BOP and monitor closing pressure.

c. Close Diverter and monitor for flow overboard.

d. Circulate Riser to kill mud weight and monitor for changes

in pit level.

Sample Driller-Level Questions, Rev. 0 18 March 2015

IADC’s Well Control Training & Assessment

71. What can cause the well to go underbalance in top-hole formations?

a. Normally pressured formations.

b. High pressure shallow gas formations.

c. Pumping out of the hole on trips.

d. Regularly pumping high viscosity ‘sweeps’ to keep the hole

clean.

72. What is the definition of the term ‘shallow water flow’?

a. Water or water and sand entering the well from top-hole

formations.

b. Increase in mud chlorides measured at the Shakers.

c. Density of seawater acting on the wellbore.

d. A warning sign of a shallow gas flow entering the wellbore.

73. The drawing shows a basic diverter system. The wind direction is

from starboard to port (right to left). Items B and C are normally

closed when drilling. Select the correct operating sequence for

safely diverting the well.

Wind Direction

a. Open C: Close D: Close A

b. Close D: Close A: Open B

c. Open B: Close D: Close A

d. Open C: Close A: Close D

Sample Driller-Level Questions, Rev. 0 19 March 2015

IADC’s Well Control Training & Assessment

74. Formation strengths are generally weak when you drill top hole and

you may get total losses. How can you minimize this risk?

a. By pumping slowly to reduce the drill string pressure loss.

b. By keeping a high overbalance.

c. By controlling the penetration rate to prevent loading the

annulus with cuttings.

d. By circulating returns up the choke line.

75. Which of the following is a ‘bottoms-up’ warning sign that the

formation pressure is increasing?

a. Drilling break.

b. Change in torque or drag.

c. Decrease in circulating pressure with an increase in pump

rate.

d. Increase in connection, trip, or background gas.

76. Which of the following is a ‘real time’ warning sign that the

formation pressure may have increased?

a. Drilling break.

b. Increase in connection, trip, or background gas.

c. Change in cutting size, volume, or shape.

d. Changes in mud properties.

77. What must a Driller do after a drilling break?

a. The Driller must reduce the weight on the bit.

b. The Driller must circulate bottoms-up.

c. The Driller must flow check.

d. The Driller must reduce the pump speed.

78. What drilling practice should be considered when connection gas is

recorded?

a. Increase the mud viscosity.

b. Reduce mud weight by a small amount.

c. Control ROP to keep only one slug of connection gas in the

annulus.

d. Pull out of hole and change the Bit.

79. What is a positive drilling break?

a. An increase in rate of penetration.

b. A decrease in rate of penetration.

c. A washout in the drill string.

d. The penetration of a harder formation.

Sample Driller-Level Questions, Rev. 0 20 March 2015

IADC’s Well Control Training & Assessment

80. What is the main reason for a pit drill?

a. To test the pit and flow alarms.

b. To see how fast the Driller can line up on the trip tank.

c. To ensure the crew is able to effectively react to a kick.

d. To ensure the crew is trained to kill the well.

81. Who has the authority to shut in the well without waiting for

permission?

a. Derrickhand

b. Floorhand

c. Mud engineer

d. Driller

82. The Derrickman informs you that there has been a 10 bbl increase

in the pits over the last 30 minutes. What action should you take?

a. Carry out a flow check.

b. Ask the Derrickman to check for any mud transfers.

c. Call the Toolpusher for advice.

d. Inform the Mud Engineer.

83. Which kick indicator is normally detected first?

a. Pit gain increase.

b. Trip Tank increase.

c. Flow rate increase.

d. Pump pressure increase.

84. You run back to the shoe and carry out a slip-and-cut on the drilling

line. The operation normally takes 60 minutes. What is the best way

to monitor the well?

a. Install a FOSV, line up to trip tank, and set the alarms.

b. Line up to trip tank and set the alarms to + 2 bbls.

c. Line up to mud pits and inform Mud Logger to monitor for

gains.

d. Shut in well and record pressure every 15 minutes.

Sample Driller-Level Questions, Rev. 0 21 March 2015

IADC’s Well Control Training & Assessment

85. Which of the following situations make it more difficult to detect a

kick with the PVT?

a. When you allow mud to overflow the shakers.

b. When you reduce the pit level alarm settings from 10 bbls to

5 bbls.

c. When you keep active mud system transfers to a minimum

whilst drilling ahead.

d. When you by-pass the solids control pits.

86. Which operations or situations on a floating rig may influence the

pit level readings when monitoring an open well?

a. Assignment of generators

b. Rig pitch and roll

c. Sea water depth

d. Riser tension

87. You have run back to the float shoe after a casing and cement job.

The instructions are to circulate the hole clean before drilling out

the shoe. Why should you monitor the pit and flow levels during this

operation?

a. The well could still flow up through the shoe.

b. To monitor for losses as any extra cement is cleaned out of

the well.

c. To determine when bottoms-up circulation is complete.

d. To monitor for thermal expansion of the cement.

88. When should the well be monitored with pit level and flow rate

instrumentation?

a. Any time there is a potential for a barrier to fail

b. Only when drilling open hole

c. During connections

d. When running in the hole

89. Which practice would lead to a bigger influx when you are shutting-

in the well?

a. Regular training for the Derrickman on the duties for

monitoring pit level.

b. Testing stab in valves during BOP tests.

c. Regular pit drills for the drill crew.

d. Calling the Toolpusher to the floor before shutting in the

well.

Sample Driller-Level Questions, Rev. 0 22 March 2015

IADC’s Well Control Training & Assessment

90. While tripping into the hole, at 6,000 feet. a flow check proves

positive. Policy is to shut the well in using hard shut in procedure.

What is the correct procedure to shut in?

a. Stab a full opening safety valve.

Close the safety valve.

Close BOP.

Open HCR valve.

Record pressure.

b. Close the BOP.

Stab full opening safety valve.

Close the safety valve.

Open choke.

Record pressure.

c. Open HCR valve and choke.

Close BOP.

Stab full opening safety valve.

Close choke.

Record pressure.

d. Stab full opening safety valve.

Open HCR valve and choke.

Close BOP.

Close safety valve.

Record pressure.

91. The well has been shut-in and the pressures are stabilizing. What is

the first step that the Driller should take?

a. Calculate Kill Weight Fluid.

b. Record the pit gain.

c. Check the drillpipe pressure to determine formation

pressure.

d. Check the BOP equipment for leaks.

e. Make up crossover to casing, make up drill pipe and run in

hole to close BOP on drill pipe.

f. Close Pipe ram and bullhead heavy mud down annulus.

92. What is the function of Blind Rams?

a. As a back-up to the Annular.

b. To seal off the open hole.

c. To cut the drillstring and seal off the hole.

d. To hang-off the drillstring during a kill.

Sample Driller-Level Questions, Rev. 0 23 March 2015

IADC’s Well Control Training & Assessment

93. Why is there a well kill ‘start-up’ procedure?

a. To compensate for Annular friction pressure during start-

up.

b. To allow the pumps to be increased slowly during start-up.

c. To allow choke operator to reach calculated Initial

Circulating Pressure.

d. To ensure correct bottom hole pressure is set for the kill.

94. What are some of the main supervisory responsibilities of the

Driller during a kill operation?

a. Instructing Mud Engineer of required mud weight.

b. Choosing kill method and slow pump rate.

c. Managing crew on manifold line-ups and raising mud

weight.

d. Operating the mud pump.

95. Where do you read Shut In Casing Pressure (SICP)?

a. At the casing shoe.

b. At the drill pipe gauge.

c. At the remote choke panel gauge.

d. At the mud pumps.

96. A well is shut-in with stabilized SICP of 500 psi and 180 psi on the

Drill Pipe gauge. The Driller pumped at 5 SPM until float was

bumped and pump shut down. The Casing gauge now reads 575 psi

and the drill pipe gauge reads 380 psi. What is the SIDPP?

a. 380 psi

b. 305 psi

c. 200 psi

d. 75 psi

Sample Driller-Level Questions, Rev. 0 24 March 2015

IADC’s Well Control Training & Assessment

97. A well is shut-in with stabilized SICP of 500psi and 0psi on the Drill

Pipe gauge. To obtain the SIDPP, the Driller pumped @ 5spm until

float was bumped and pump shut down. The gauges are now

reading the following pressures. What is the actual SIDPP?

a. 280 psi

b. 360 psi

c. 580 psi

d. 500 psi

98. The Casing pressure gauge on the Choke Control panel reads 450

psi. The Casing pressure gauge on the Choke Manifold reads 650 psi.

What action would you take?

a. Inform Supervisor and investigate difference.

b. The difference is not important, start the kill using 450 psi.

c. The difference is not important, start the kill using 650 psi.

d. Use the average pressure of 550 psi to start the kill.

99. What could happen if gas migrates after a well is shut in and

pressures have stabilized, (no float in string)?

a. Only the drill pipe pressure will increase.

b. Shut in pressures will remain constant.

c. Both drill pipe and annulus pressures will increase.

d. Only the annulus pressure will increase.

Sample Driller-Level Questions, Rev. 0 25 March 2015

IADC’s Well Control Training & Assessment

100. You are losing mud while circulating but gaining mud when the

pumps are off. The well is shut in and you suspect the well is

ballooning. It is decided to bleed-off 20 barrels of mud back to the

pits. What is the potential danger of this bleed-off?

a. Formation fluid may be bled back into the well.

b. Bleeding back too much will increase chance of losses.

c. Wellbore will become washed-out.

d. Formation will collapse into wellbore and restrict

circulation.

101. Why is bottom hole pressure maintained constant during a well kill?

a. To prevent the influx from expanding as it is circulated up-

hole.

b. To prevent a further influx or formation breakdown during

the kill process.

c. To keep circulating pressures constant as kill mud is

pumped to the Bit.

d. To allow a high overbalance on the kicking formation.

102. You have just completed a successful pump start up and the pump is

running at kill rate. The choke gauge is stable. What gauge should

now read ICP?

a. The Drill Pipe Pressure gauge

b. The Choke Pressure gauge

c. The Kill Line Monitor Pressure gauge

d. The Accumulator Pressure gauge

103. What does the SIDPP indicate when the well is shut-in on an

underbalanced kick?

a. The difference between formation pressure and leak-off

pressure hydrostatic pressure.

b. The maximum allowable annular surface pressure (MAASP).

c. The difference between formation pressure and the

hydrostatic pressure of the mud in the drillpipe.

d. The trapped pressure caused by shutting in the well.

Sample Driller-Level Questions, Rev. 0 26 March 2015

IADC’s Well Control Training & Assessment

105. When bringing the pumps up to kill speed the casing pressure is

allowed to increase above Shut In Casing Pressure, what will happen

to bottom hole pressure?

a. No change to downhole pressure.

b. Bottom hole pressure would decrease and possibly cause

more influx to enter the wellbore.

c. Bottom hole pressure would increase and may exceed

formation fracture.

106. Which method removes the influx from the hole before pumping kill

mud?

a. The Wait and Weight Method

b. The Drillers’ Method

c. The Volumetric Method

d. The Bullheading technique

107. What is the objective of the first circulation of the Drillers Method?

a. Circulate out influx while displacing the drill string with kill

weight fluid.

b. Circulate out influx using the original fluid weight.

c. Circulate out influx using kill weight fluid.

d. Circulate out the influx using kill weight fluid with an added

safety factor.

108. Which kill method pumps kill mud at the same time as circulating

the influx up the annulus?

a. The Wait and Weight Method

b. The Drillers’ Method

c. The Volumetric Method

d. The Bullheading technique

109. If the Rotary hose split during a kill operation, what would be the

first action to take?

a. Close the Shear Rams.

b. Prepare to reverse circulate.

c. Stop pump and close the full opening safety valve on the

drill string.

d. Close the choke.

Sample Driller-Level Questions, Rev. 0 27 March 2015

IADC’s Well Control Training & Assessment

110. What should you do when stripping tool joints through the Annular

preventer?

a. Increase annular closing pressure to reduce leakage.

b. Decrease annular closing pressure to reduce stress on the

annular packer.

c. Close a pipe ram, open the annular and strip in hole till tool

joint is below the annular.

d. Open choke to reduce well pressure as tool joint passes

through the annular.

111. What is the danger of trapped gas in the BOP stack?

a. Gas can be released into Riser annulus when BOP is opened.

b. Circulating out trapped gas through choke line will overload

mud-gas separator.

c. Excess pressure in trapped gas may cause lost circulation.

d. The kill line cannot be used to during start-up procedure.

112. A well kicks with the bit off bottom and you shut it in. A decision is

made to strip back into the hole. What equipment needs to be on the

top of the drill string before stripping in the hole?

a. A full opening safety valve (closed).

b. An inside BOP.

c. A full opening safety valve (open) with an inside BOP

installed on top.

d. An inside BOP with a full opening safety valve (closed) on

top.

113. The well has been circulated to kill mud. What will happen if the

BOP is opened with old mud in the Riser?

a. Bottom hole pressure will decrease.

b. Shoe pressure will increase.

c. Bottom hole pressure will increase.

d. Maximum allowable annular surface pressure will be

exceeded.

114. What can happen to the hydrostatic pressure of a column of cement

as it sets?

a. Hydrostatic pressure increases.

b. Hydrostatic pressure decreases.

c. Hydrostatic pressure stays the same.

Sample Driller-Level Questions, Rev. 0 28 March 2015

IADC’s Well Control Training & Assessment

115. Why do you monitor flow rate and pit level change when pumping

and displacing cement?

a. To detect for gains or losses.

b. To monitor for correct displacement of the cement.

c. To indicate when to cement u-tube is balanced.

d. To indicate that the cement displacement is in ‘turbulent’

flow.

116. A well kill operation is in progress. You are coming to the end of

your shift, what instructions would you give to your crew?

a. Instruct them to write down the key points of their

handover and hand to the new crew.

b. Instruct them to write down the key points of their

handover and give to you. You will pass them on to the new

Driller.

c. Instruct them to write down the key points of their

handover and to discuss each point with their replacement.

d. Think about what you will tell your replacement at the end

of the shift.

117. What is the main function of a diverter?

a. To shut in a shallow kick.

b. To direct formation fluids a safe distance away from the rig

floor.

c. To create a back pressure sufficient to stop formation fluids

entering the wellbore.

d. To act as a backup system if the annular preventer fails.

118. Which of the following factors limit the success of diverter

operation from a floating rig?

a. Low Slip Joint air pressure

b. Diverter line valve open downwind

c. Mud pumps running, pumping mud to the bottom of the

well

d. Diverter Lock-Down Dogs in lock position

Sample Driller-Level Questions, Rev. 0 29 March 2015

IADC’s Well Control Training & Assessment

119. Which of the following statements about fixed bore ram type BOPs

is correct?

a. Ram type BOP's are designed to contain and seal Rated

Working Pressure from above the closed rams as well as

from below.

b. Fixed bore ram type BOPs can close and seal on various pipe

sizes.

c. Fixed bore ram type BOPs cannot be used to hang off the

drill string.

d. Ram type BOPs are designed to contain Rated Working

Pressure only from below the closed rams.

120. Select the correct definition of the “Closing Ratio” of a ram

preventer.

a. Operating pressure required to close the ram against

maximum wellbore pressure.

b. Operating pressure required to close the ram against a

specific wellbore pressure.

c. Operating pressure required to close the ram at BOP Rated

Working Pressure.

d. Ratio of the packer area against the piston rod area.

121. During a routine test on a surface stack rig, it is noticed that the

weep hole (drain hole/vent hole) on one of the blowout preventer

bonnets is leaking fluid. What action should be taken?

a. The weep hole only checks the closing chamber seals, leave

it till the next maintenance schedule.

b. Ram packing elements on the ram body are worn out,

replace immediately.

c. Primary ram shaft seal is leaking, secure the well and

replace immediately.

d. Energize emergency packing. If leak stops, leave it till the

next maintenance schedule.

Sample Driller-Level Questions, Rev. 0 30 March 2015

IADC’s Well Control Training & Assessment

122. Which of the following gauges on remote panel would you expect to

see a reduction in pressure when the annular preventer is being

closed?

a. Accumulator gauge and Annular pressure gauge.

b. Manifold pressure gauge and Annular pressure gauge.

c. Air pressure gauge and Annular pressure gauge.

d. Annular pressure gauge only.

123. Why are Ram locking devices fitted to subsea BOP stacks?

a. Stop the ram from closing if hydraulic pressure is lost.

b. Give extra closing force during ram closure.

c. Lock the ram in the closed position to support drillpipe

when hung off.

d. To prevent wear on the Ram Shaft packing.

124. Select the statement that is correct for pilot signals on a hydraulic

control unit?

a. Pilot signals vent at the seabed.

b. Pilot signals are used monitor fluid flow to selected

operating chambers.

c. Pilot signals operate the SPM valves.

d. Pilot signals are used to close the BOPs.

125. To what pressure must the Drill string safety valves be tested?

a. To the current bottom hole pressure.

b. 50% of the Ram test pressure.

c. To the same pressure as the BOP.

d. To the same RWP as the Kelly/top drive.

126. The well kicks when tripping. What statement is true if a non-return

valve is stabbed into the string?

a. Easier to stab if strong flow is encountered up the drill

string.

b. Must not be run in the hole in the closed position.

c. Has to be pumped open to read Shut In Drill Pipe Pressure.

d. Has potential to leak through the open/close key.

Sample Driller-Level Questions, Rev. 0 31 March 2015

IADC’s Well Control Training & Assessment

127. Which of the following equipment may warn of an increase in

formation pressure?

a. Pump pressure gauge

b. SPM counter

c. Mud-Gas detector

d. Return flow meter

128. If the air pressure gauge was reading zero. Which one of these

statements is correct?

a. The annular preventer can still be operated from the remote

panel.

b. Choke and kill lines can still be operated from the remote

panel.

c. No BOP functions can be operated from the remote panel.

d. All functions on the remote panel will operate normally.

129. Which gas do you use to pre-charge the accumulator bottles on a

BOP Hydraulic Control Unit?

a. Air

b. Nitrogen

c. Oxygen

d. Carbon Dioxide (CO2)

130. You close a Ram on the remote panel. The Ram close light

illuminates but you notice that the accumulator pressure has

remained static. What has happened?

a. No air pressure at the panel.

b. The 3-position Ram valve on the accumulator has not

moved.

c. Possible blockage in the line between the accumulator unit

and BOP stack.

d. Master valve not held down for 5 seconds.

131. You operate the Annular preventer and the close light does not

illuminate but the pressure drops and then returns to normal. What

has happened?

a. Master valve was not operated.

b. 3-position valve did not operate.

c. Close line is blocked.

d. Faulty light circuit or bulb.

Sample Driller-Level Questions, Rev. 0 32 March 2015

IADC’s Well Control Training & Assessment

132. If a function is made to close the hang off rams and the fluid counter

continues to register fluid movement after the correct closing

volume has been reached. What immediate action would you take?

a. Call the subsea engineer and wait.

b. Reduce manifold pressure to slow down the leak.

c. Close another set of rams.

d. Put that hang-off ram into block position.

133. If the Driller suspects the Shut In Casing Pressure (SICP) reading on

the remote choke panel is not correct what action should be taken?

a. Compare with SICP gauge reading on the Choke Manifold

and report to Supervisor.

b. Compare with SICP gauge reading on the Standpipe

Manifold and report to Supervisor.

c. Bleed SICP back by 100psi and monitor the SICP after it has

stabilized.

d. Bleed SIDPP back by 100psi and monitor the SICP after it

has stabilized.

134. What is the main function of the choke in the overall BOP system?

a. To direct hydrocarbons to the flare.

b. To direct wellbore fluids to the mud/gas separator.

c. To shut the well in softly.

d. To hold back pressure while circulating out a kick.

Sample Driller-Level Questions, Rev. 0 33 March 2015

IADC’s Well Control Training & Assessment

135. In the figure below, which dimension determines the backpressure

generated within the separator?

a. The length and the inside diameter (D3) of the inlet pipe

from the buffer tank to the choke manifold.

b. The dip tube height (H2).

c. The body height (H1) and the body inside diameter (D1).

d. The derrick vent pipe height (H4) and inside diameter (D2).

136. What is the most common use of a Vacuum Degasser?

a. It is mainly used to separate gas from liquids while testing.

b. It is used as a standby in the event of the “Mud/Gas

Separator (Poor Boy)” failing.

c. It is only used while circulating out a kick.

d. It is used to remove gas after the mud has been circulated

across the shakers.

Sample Driller-Level Questions, Rev. 0 34 March 2015

You might also like

- Cat 3406 Engine Parts ManualDocument78 pagesCat 3406 Engine Parts ManualCarlos Manzoni100% (6)

- 03 - WellSharp WC Methods and Subsea - Day 2 Pre - CourseDocument5 pages03 - WellSharp WC Methods and Subsea - Day 2 Pre - CourseAdolfo AnguloNo ratings yet

- 05 - WellSharp Workover and Completion - Day 4 Pre - Course PDFDocument6 pages05 - WellSharp Workover and Completion - Day 4 Pre - Course PDFMarkus Landington100% (1)

- CA - IWCF Well Control - Exp28Apr2018Document2 pagesCA - IWCF Well Control - Exp28Apr2018Milad Ebrahimi DastgerdiNo ratings yet

- 12 - WellSharp Subsea Study GuideDocument2 pages12 - WellSharp Subsea Study GuideAdolfo AnguloNo ratings yet

- Workover 1 Soal - 8 APR21.revDocument17 pagesWorkover 1 Soal - 8 APR21.revputujuliandikaNo ratings yet

- Chevron: Wellcap Plus Practice Test Surface/SubseaDocument15 pagesChevron: Wellcap Plus Practice Test Surface/SubseaBoedi SyafiqNo ratings yet

- Principles and Procedures: Rev.3 - November 2003Document144 pagesPrinciples and Procedures: Rev.3 - November 2003Ibnu Rusdi SolomammaNo ratings yet

- Exercise 4 AnswersDocument12 pagesExercise 4 AnswersadeelsnNo ratings yet

- IWCF Operations Limited: 05 July 2016Document13 pagesIWCF Operations Limited: 05 July 2016airlinemembershipNo ratings yet

- Managed Pressure Drilling Technical Report - MPD techniques, advantages, limitationsDocument19 pagesManaged Pressure Drilling Technical Report - MPD techniques, advantages, limitationseriantoelonNo ratings yet

- Stuck Pipe Nov 2011Document5 pagesStuck Pipe Nov 2011Adolfo Angulo100% (1)

- DST ConceptDocument17 pagesDST ConceptSiver AbdullahNo ratings yet

- HPHT Drill & Well ControlDocument40 pagesHPHT Drill & Well ControlanilkumarNo ratings yet

- Pressurised Mud Cap Drilling Paper (Spe-125311-By Dany)Document7 pagesPressurised Mud Cap Drilling Paper (Spe-125311-By Dany)Hammad KhalidNo ratings yet

- AC-0096 IWCF Level 5 Programme GuidanceDocument7 pagesAC-0096 IWCF Level 5 Programme Guidanceairlinemembership0% (1)

- 03 Shut-In ProcedureDocument15 pages03 Shut-In Proceduresitemaster60No ratings yet

- Egyptian Drilling Equipment GuideDocument66 pagesEgyptian Drilling Equipment GuideMohamed Kamal100% (1)

- Lubricate and BleedDocument18 pagesLubricate and BleedRoby Rido100% (1)

- 28 - IWCF Study GuideDocument7 pages28 - IWCF Study GuideBabi LakhdariNo ratings yet

- 02 Causes & Warning Signs of KicksDocument10 pages02 Causes & Warning Signs of Kickssitemaster60No ratings yet

- Stripping With Volumetric Control Steps and Example Calculations - Drilling Formulas and Drilling Calculations PDFDocument19 pagesStripping With Volumetric Control Steps and Example Calculations - Drilling Formulas and Drilling Calculations PDFAmine MimoNo ratings yet

- Rig Stuck Pipe Assessment FormDocument13 pagesRig Stuck Pipe Assessment FormBalkis FatihaNo ratings yet

- 2011 Well Servicing Practice Test KEYDocument14 pages2011 Well Servicing Practice Test KEYBoedi Syafiq100% (2)

- Iadc Drilling 1.10.20. - (77) W.outDocument14 pagesIadc Drilling 1.10.20. - (77) W.outsendi100% (1)

- 04 Circulating Well Control Methods - 2Document10 pages04 Circulating Well Control Methods - 2sitemaster60No ratings yet

- IWCF WATTAYA 2007 Rev 2Document339 pagesIWCF WATTAYA 2007 Rev 2api-3768445100% (3)

- Essential Tips For Well Control Success: Aberdeen Drilling SchoolsDocument4 pagesEssential Tips For Well Control Success: Aberdeen Drilling SchoolsCerón Niño SantiagoNo ratings yet

- Kick Tolerance Concept and Calculation For Well DesignDocument11 pagesKick Tolerance Concept and Calculation For Well DesignlakhanmukhtiarNo ratings yet

- IWCF Well Control Test Paper No. 2Document36 pagesIWCF Well Control Test Paper No. 2tonyNo ratings yet

- Drilling Fluid QuestionsDocument2 pagesDrilling Fluid QuestionsMunsef AL-juroshyNo ratings yet

- Well Engineering Guidlines For Hole CleaningDocument13 pagesWell Engineering Guidlines For Hole CleaningWilliam100% (1)

- Section 05 Tripping Backreaming PracticesDocument68 pagesSection 05 Tripping Backreaming PracticesSpeculeNo ratings yet

- Iwcf Exercise STC 1Document149 pagesIwcf Exercise STC 1ali jabbarNo ratings yet

- Stuck Point WorksheetDocument5 pagesStuck Point Worksheetjose perozoNo ratings yet

- Stuck PipeDocument71 pagesStuck Pipemosli_No ratings yet

- Driller Workbook3Document4 pagesDriller Workbook3Kaleem UllahNo ratings yet

- CT Ops Exercise - No AnswersDocument9 pagesCT Ops Exercise - No AnswersMohammed Anis FortasNo ratings yet

- WC Pre Course Workbook - 1 PDFDocument242 pagesWC Pre Course Workbook - 1 PDFОлегNo ratings yet

- Pump OmDocument156 pagesPump OmandrewNo ratings yet

- Well Barriers ConceptsDocument13 pagesWell Barriers ConceptsOSCAR BUSTOSNo ratings yet

- Kick Tolerance CalculationDocument5 pagesKick Tolerance Calculationi oNo ratings yet

- IWCF by Eng. Abd El-Salam 11-2020Document166 pagesIWCF by Eng. Abd El-Salam 11-2020Mohamed Othman0% (1)

- Stuck Pipe Prevention and SolutionsDocument14 pagesStuck Pipe Prevention and SolutionsLazhar100% (1)

- Drilling OperationsDocument2 pagesDrilling Operationsharsha alapatiNo ratings yet

- WIPC Instructor PackDocument5 pagesWIPC Instructor PackMostafa ElghifaryNo ratings yet

- Drilling NotebookDocument96 pagesDrilling NotebookOmar Rosado Roldan0% (1)

- Petroleum Engineering - Well ControlDocument43 pagesPetroleum Engineering - Well ControlJeffrey100% (1)

- Well Intervention Calculations SpreadsheetDocument5 pagesWell Intervention Calculations SpreadsheetAkol MajookNo ratings yet

- Volumetric Well Control Method-Drilling FormulaeDocument19 pagesVolumetric Well Control Method-Drilling FormulaeR.GNo ratings yet

- P and P (EDC) PDFDocument62 pagesP and P (EDC) PDFAli mohammad50% (2)

- Surface Kill Sheet Exercise 2Document3 pagesSurface Kill Sheet Exercise 2adeelsnNo ratings yet

- Theory and Technology of Drilling EngineeringDocument573 pagesTheory and Technology of Drilling EngineeringKhánh Tuyền Nguyễn ThịNo ratings yet

- Drilling 16 Inch Section - Best PracticesDocument2 pagesDrilling 16 Inch Section - Best PracticesYougchu Luan100% (1)

- DAY 6 - Loss Circulation & Stuck Pipe Sharing SessionDocument27 pagesDAY 6 - Loss Circulation & Stuck Pipe Sharing SessionReza Syahputra MulyanaNo ratings yet

- Technology Transfer Volumetric StrippingDocument28 pagesTechnology Transfer Volumetric StrippingHüseyin AyazlıNo ratings yet

- Oilwell Drilling 8Document3 pagesOilwell Drilling 8chuksNo ratings yet

- Guidelines For Volumetric Stripping Rev.1 Feb.2004Document27 pagesGuidelines For Volumetric Stripping Rev.1 Feb.2004Yuri KostNo ratings yet

- 31 - Well Control Data Sheet For Vertical Wells Wt. & Wt. MethodDocument1 page31 - Well Control Data Sheet For Vertical Wells Wt. & Wt. MethodJunaid MateenNo ratings yet

- Introduction to Underbalanced Drilling Technologies (M2Document57 pagesIntroduction to Underbalanced Drilling Technologies (M2bon1ngNo ratings yet

- Highland Hotel: MR Rio Molex Butar Butar SPRTDocument6 pagesHighland Hotel: MR Rio Molex Butar Butar SPRTHendra JurbonNo ratings yet

- Perhitungan Dasar Well ControlDocument6 pagesPerhitungan Dasar Well ControlHendra JurbonNo ratings yet

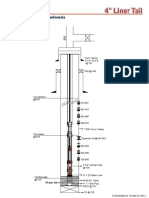

- Liner TailDocument1 pageLiner TailHendra JurbonNo ratings yet

- Kepala KudaDocument9 pagesKepala KudaHendra JurbonNo ratings yet

- Kepala KudaDocument9 pagesKepala KudaHendra JurbonNo ratings yet

- Manual TransmissionDocument31 pagesManual TransmissionHendra Jurbon100% (1)

- Manual Rod TongDocument31 pagesManual Rod TongHendra JurbonNo ratings yet

- Perhitungan Dasar Well ControlDocument6 pagesPerhitungan Dasar Well ControlHendra JurbonNo ratings yet

- Pipe Wrench Use GuideDocument4 pagesPipe Wrench Use GuideHendra JurbonNo ratings yet

- Wcbop CatalogDocument82 pagesWcbop Catalogwolfy1234100% (2)

- Drilling Progrm PDFDocument5 pagesDrilling Progrm PDFHendra JurbonNo ratings yet

- Form Pengambilan Hand GloveDocument8 pagesForm Pengambilan Hand GloveHendra JurbonNo ratings yet

- EX-0035 Drilling - English API Forumla SheetDocument4 pagesEX-0035 Drilling - English API Forumla Sheetmohamed abbasNo ratings yet

- Wcbop CatalogDocument82 pagesWcbop Catalogwolfy1234100% (2)

- Formation PressureDocument79 pagesFormation PressureRian MonterryNo ratings yet

- Pressure Traverse Galih 2 InchDocument4 pagesPressure Traverse Galih 2 InchHendra JurbonNo ratings yet

- Wcbop CatalogDocument82 pagesWcbop Catalogwolfy1234100% (2)

- Daftar PustakaDocument1 pageDaftar PustakaHendra JurbonNo ratings yet

- PT ManualDocument28 pagesPT ManualLuis Alberto IzarraNo ratings yet

- NWW BP - Spa Metric Rig 07Document3 pagesNWW BP - Spa Metric Rig 07Hendra JurbonNo ratings yet

- Blow OutDocument1 pageBlow OutHendra JurbonNo ratings yet

- Bab IiDocument601 pagesBab IiHendra JurbonNo ratings yet

- Formation PressureDocument79 pagesFormation PressureRian MonterryNo ratings yet

- 10.75” 40.5 # Casing @ 101’ and 7”20# Prod. Casing Installed in WellDocument1 page10.75” 40.5 # Casing @ 101’ and 7”20# Prod. Casing Installed in WellHendra JurbonNo ratings yet

- Nafta Gaz 2013 02 01Document9 pagesNafta Gaz 2013 02 01salomonmelcanoNo ratings yet

- Bab IiDocument601 pagesBab IiHendra JurbonNo ratings yet

- Well Head Casing DiagramsDocument2 pagesWell Head Casing DiagramsHendra JurbonNo ratings yet

- Kepala KudaDocument9 pagesKepala KudaHendra Jurbon Butar-ButarNo ratings yet

- Assignment 6ADocument2 pagesAssignment 6ADivyaraj MoolyaNo ratings yet

- B. Pharma Semester IV Pharmaceutics Engineering and Dosage DesignDocument13 pagesB. Pharma Semester IV Pharmaceutics Engineering and Dosage DesignDrAmit VermaNo ratings yet

- Wind Loading in Tall BuildingsDocument11 pagesWind Loading in Tall Buildingsrenganathank87No ratings yet

- Da40 Poh PDFDocument300 pagesDa40 Poh PDFChris PetersenNo ratings yet

- UPCAT Math Topics Algebra Geometry Trigonometry StatisticsDocument6 pagesUPCAT Math Topics Algebra Geometry Trigonometry StatisticsAndre Mikhail SerraNo ratings yet

- CASTING PROCESS - HPDC PDFDocument14 pagesCASTING PROCESS - HPDC PDFetamil87No ratings yet

- 304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless SteelDocument2 pages304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless SteelTomy GeorgeNo ratings yet

- Probability and Statistics: Manjunath KrishnapurDocument81 pagesProbability and Statistics: Manjunath KrishnapurleeaxilNo ratings yet

- Test Results Report Rhino Wood RepairDocument10 pagesTest Results Report Rhino Wood Repairmidzi24No ratings yet

- GEM Ground Enhancement MaterialDocument2 pagesGEM Ground Enhancement Materialbrayan GcNo ratings yet

- LDR PDFDocument136 pagesLDR PDFvighneshNo ratings yet

- Experimental Investigation On Bituminous Mix Using Coconut CoirDocument8 pagesExperimental Investigation On Bituminous Mix Using Coconut CoirTJPRC PublicationsNo ratings yet

- Tpde Rejinpaul - Com Question BankDocument15 pagesTpde Rejinpaul - Com Question BankTrigger DineshNo ratings yet

- Sds Page: Objective: TheoryDocument7 pagesSds Page: Objective: TheoryMuskan BishtNo ratings yet

- ABB Softstarters2Document200 pagesABB Softstarters2mhofuNo ratings yet

- Physical Chemistry Team Chemistry Department State Univeristy of Medan 2020Document10 pagesPhysical Chemistry Team Chemistry Department State Univeristy of Medan 2020Ayulia AnnisaNo ratings yet

- 2.1.2.a Beamdeflection 2Document7 pages2.1.2.a Beamdeflection 2Bailey RodriguezNo ratings yet

- Lecture1 ALLDocument35 pagesLecture1 ALLadeelyjNo ratings yet

- Effects of Changing Climate On Weather and Human Activities PDFDocument50 pagesEffects of Changing Climate On Weather and Human Activities PDFpawlittooNo ratings yet

- I&M Lab ManualDocument20 pagesI&M Lab ManualSaad MalikNo ratings yet

- D 101363 X 012Document20 pagesD 101363 X 012AmiroucheBenlakehalNo ratings yet

- Approximation Solution of Fractional Partial Differential EquationsDocument8 pagesApproximation Solution of Fractional Partial Differential EquationsAdel AlmarashiNo ratings yet

- Chap2 Mason RuleDocument4 pagesChap2 Mason Rulegoroi90No ratings yet

- Burner Operating and Flame Momentum Calculation: InputsDocument6 pagesBurner Operating and Flame Momentum Calculation: InputsIrfan Ullah100% (1)

- Electric Field Formula QuestionsDocument3 pagesElectric Field Formula QuestionsSansen Diamante Colipano Jr.No ratings yet

- Operations Research (Me 705C) MCQS: Max Z 30x - 15x, S.T. 2x - 2x 0Document10 pagesOperations Research (Me 705C) MCQS: Max Z 30x - 15x, S.T. 2x - 2x 0aghosh704100% (2)

- Chapter 3 Humanities 412 Art AppreciationDocument6 pagesChapter 3 Humanities 412 Art AppreciationAlexis Ramirez67% (3)

- Guides Nitro Nitro Tuning GuideDocument3 pagesGuides Nitro Nitro Tuning Guideabra77No ratings yet

- Synthesis of Nanoparticles From Plant ExtractsDocument10 pagesSynthesis of Nanoparticles From Plant ExtractssitinisasyakirinaNo ratings yet

- Motion in One Dimension: Answers To QuestionsDocument30 pagesMotion in One Dimension: Answers To QuestionsLaura VanesaNo ratings yet