Professional Documents

Culture Documents

2008 12 Reprint Ion With TSV PDF

Uploaded by

BehrangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2008 12 Reprint Ion With TSV PDF

Uploaded by

BehrangCopyright:

Available Formats

SEPARATOR TECHNOLOGY

I Optimisation with TSV

by Loïc Pottier & Fives FCB’s TSV™ third generation high efficiency classifier , with more

Philippe Niel, than 210 references,is a recognised piece of equipment which has received

Fives FCB, France wide acceptance in the field of cement grinding, as well as raw meal, solid

fuel, and mineral grinding. When looking to increase production capacity,

energy cost savings and improvements in product quality, replacing an old

generation classifier with a state-of-the-art efficient model is one way to

reach these objectives while keeping the capital investment to a minimum.

and from f1.4m to f8m. Its specific

Figure 1: 3D

model of two- features are:

filter circuit • the selection basic concept with the

patented shape of rotor blades

• the patented anti-vortex system.

The blade shape ensures the

equilibrium between centrifugal force and

drag force in the whole volume located

between the blade and not only in the

selection area at the inlet. For one particle

diameter, which corresponds to the d50

(= cut size) of the selection curve of the

classifier, drag force and centrifugal force

are balanced during the transfer from the

inlet, in the selection of volume, to the

outlet of the blade.

The result is a very steep slope of the

selection curve around the d50:acuity =

d25/d75 = 0.4 to 0.6. Besides, the drastic

T

he TSV™ (Turbo Séparateur Figure 3: Chelm cement plant installation – mills N°8, N°9 and N°10

Ventilé) belongs to the third-

generation of dynamic classifiers.

Its particular design has seen it applied

and well-proven in a large range of

industrial products, from graphite to

cement, and from silicon to solid fuels,

with a cut size ranging from 8µm (TSV™

type THF) to 500µm (TSV™ type TBF),

Figure 2: 3D

model of single-

filter circuit

DECEMBER 2008 ICR

SEPARATOR TECHNOLOGY

Figure 4: TSV™ with air-and-

flash dryer is directly fed with fly ash, as

dust volute inlet

a secondary feed point. Operated in this

mode, the classifier is fed both from the

top (discharge by bucket elevator) and the

bottom. Following modification, the mill

output is able to achieve 120tph of CEM

IV with a maximum feed moisture content

of 11 per cent, which means 25 per cent

moisture content of the fly ash.

High quality cement

There is no doubt that converting an

open-circuit to closed-circuit with the

use of a classifier brought a significant

improvement in the quality of cement.

The best quality control and grinding

efficiency have been achieved with the

introduction of the third-generation

reduction of coarse particles in the final full air swept system, as commonly met classifier TSV™. The combination of the

product ensures a better early compressive when grinding solid fuels. excellent acuity and the drastic reduction

strength and consequently enables the An additional, optional feature of of coarse particles in the final product

user to lower the Blaine target value. the TSV™ is the lateral air feed which allows for a revision of the targeted

The second patented characteristic of allows considerable extension of the fineness. Figure 6 shows an example of a

the Fives FCB classifier is the inside plates classifier’s field of implementation in a comparison between grain size analysis of

of the turbine which recover the dynamic modernisation project. Even in an existing cements obtained with the first-generation

pressure of the rotating gases before building, with reduced available height dynamic classifier and TSV™.

leaving the separator. This patented and area, an efficient solution can be met. The modernisation Cementir’s Taranto

Vortex breaking system provides: This particular arrangement was chosen plant, dealing with CEMII AS (15 per

• low pressure drop in the classifier by Titan’s Kosjeric plant in Serbia, for cent slag), is a good example of a

• extremely low power consumption of modernisation of the cement mill with TSV™ industrial application. The initial

the classifier. the main production being CEM II/A-M

(P-Q). A significant hot gas generator is Figure 5: combination of flash dryer and

Installation flexibility present in the mill building, reducing the TSV™ at the Sacci Testi cement plant

In the usual configuration, material is fed possible layout for classifier gas ducts. A

from the top of the classifier and air is fed TSV™ 3600 HF with lateral gas inlet (see

in at the bottom. When operated with a Figure 4) was selected, in combination

ball mill, this arrangement corresponds to with cyclones and recirculation fan.

a two-filter circuit (see Figure 1). Furthermore, depending on the

However, the TSV™ capability goes moisture of the feed material, the TSV™

much further. A material feed on classifier can be associated with a flash

the top and bottom of the classifier, dryer. As an example, a recent project

plus an air feed means that it can be at the Sacci Testi plant in Italy involved

operated in a single-filter circuit mode. a bi-rotator mill for the production of

Dedusting of the mill is then carried out CEM IV/B-M (54 per cent clinker, 36

through the classifier (see Figure 2). per cent fly ash, five per cent limestone).

Such an arrangement was selected by The 3600kW mill measured f4m x

Cemex’s Chelm plant in Poland for the L13m (+3.2m drying chamber) and was

modernisation of cement Mill N°9 (2002) operated in a two-bag filter system, with

and subsequently cement Mill N°8 and a static classifier at the mill gas outlet and

10 (2007). The aim of this project (on top a second-generation classifier for final

of the 20-25 per cent capacity increase classification. Before modification, the

and the new production of a pure CEM I mill output was 75tph of CEM IV, with a

at 4500 Blaine) was to locate all the new fresh feed maximum moisture content of

equipment relevant to the classifier inside 9.5 per cent. The modification consists of

the existing building (see Figure 3), in a replacing the existing second-generation

shortened shutdown period (for full details classifier with a TSV™ with the addition of

of this project see ICR December 2004). its associated filter and fan, and installing

This capability of the TSV™ to be fed a flash dryer located bellow the classifier,

from the bottom is naturally applied to the in the gas stream (see Figure 5). This

ICR DECEMBER 2008

SEPARATOR TECHNOLOGY

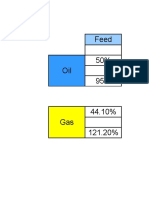

installation with ball mill plus first-

generation classifier was producing a 4100 Table 1: production of CEM II AS 42.5

Blaine cement with a R32µm sieve residue (15% slag) Cementir, Taranto, Italy

= 11.5 per cent (annual average). After

modification with TSV™, the guaranteed Before With TSV™

fineness values (Blaine ≥3800 and R32µm Mill output (tph) 49 58

≤5 per cent) gave compressive strength Mill consumption (kWh/t) 50 42.2

results higher than those recorded Blaine (cm2/g) 4100 3920

before modification (see Table 1). As a Rµ32m sieve (%) 11.5 4.9

consequence, the producer changed its Compressive strength: 2 days (MPa) 25 26.8

fineness target values from R32µm = five 7 days 37.3 39.5

per cent to 6-7 per cent, leading to final 28 days 49.3 50.5

potential capacity of around 62tph, which

meant a gain of +26 per cent.

Figure 7: model of TSV gas inlet distribution

Other possible benefits of the cement

quality improvement are the production

of new types of cement, either with wider

fineness range or higher additive content

(limestone, fly ash, pozzolan, slag etc).

Classification efficiency remains a

constant subject of investigation and

is a part of Fives FCB research and

development programme. When particular

configuration or material are met, CFD

modelling is used to anticipate the

classification parameters. Figure 7 is a

view of gas speed distribution modelling

at the classification inlet area.

A cost-effective solution

A concern when dealing with high

performing technology might be

maintenance cost and the availability of

equipment. The third-generation classifier

TSV™ is designed with particular attention

to these aspects, considering both the wear resistant base plates, up to ceramic As the bearings are calculated for a

effects of wear and the mechanical lining, including hard faced plates, or Ni- lifetime of 100,000h and operate with

reliability. Each section of the classifier hard casting. The latest improvements an efficient greasing system, this gives

is protected with regard to the type of in this deal with the protection of the complete classifier reliability. For instance,

product to be classified, ranging from rotating seal of the biggest classifiers. a bearing replacement in the frame of a

preventive maintenance programme was

Figure 6: GSD comparison recently planned after 70,000h (operating)

on a TSV™ 3600 HF dedicated to cement

grinding.

Conclusion

Fives FCB is recognised as a turnkey

equipment supplier bringing to its

customers innovative, efficient and

reliable technologies. The integration of

a TSV™ in a grinding circuit, whether

it be in a new plant or a modernisation

project, is a perfect example of

‘sustainable development’ in the cement

industry. It reduces the specific electrical

consumption, allows for higher amounts

of cement additives and consecutive

reduction of equivalent specific CO2

emission. __________________________ I

DECEMBER 2008 ICR

TSV

TM

your cement requires

a first class classifier

Get the highest quality for your raw meal, cement, solid fuels or

minerals with the Fives FCB 3rd generation separator:

• Easy installation

• High resistance to wear

• Minimal by-pass

• Tromp curve very steep

• Very low pressure drop

• Extremely low power consumption

TSV™: more than 200 machines installed worldwide To Save Value.

Thanks to the TSV™ and to other innovative solutions, Fives FCB

designs today the cement plants of the future: more efficient,

more environnementally friendly and more economical.

www.fivesgroup.com Driving Progress

50, rue de Ticléni - B.P. 376 - 59666 VILLENEUVE D’ASCQ Cedex - France - Tél : +33 (0)3 20 43 75 01 - Fax : +33 (0)3 20 43 75 13 - E-mail : fivesfcb@fivesgroup.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Drilling Hole Opener WebDocument2 pagesDrilling Hole Opener WebBehrangNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Core-Type Junk Basket: When Ordering, Please SpecifyDocument2 pagesCore-Type Junk Basket: When Ordering, Please SpecifyBehrangNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- WorkbookDocument3 pagesWorkbookBehrangNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Basket Sub-Product SheetDocument1 pageBasket Sub-Product SheetBehrangNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 1 PDFDocument1 page1 PDFBehrangNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- FCB Horomill® Grinding Plant: FCB Horomill® Provides Solutions For Multipurpose or Specific NeedsDocument2 pagesFCB Horomill® Grinding Plant: FCB Horomill® Provides Solutions For Multipurpose or Specific NeedsBehrangNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Land Transfer FormDocument5 pagesLand Transfer FormKarma WangdiNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- SM - 1850K Tier3 - EN - Error - CodesDocument1 pageSM - 1850K Tier3 - EN - Error - CodesBoris ZhilkinNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Tadano Rough Terrain Crane GR-800EX - S - G PDFDocument16 pagesTadano Rough Terrain Crane GR-800EX - S - G PDFlesantiago100% (1)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- ReadmeDocument3 pagesReadmeJerico Merciales SalasNo ratings yet

- CISM Study NotesDocument4 pagesCISM Study NotesLa Vita Di Lusso44% (9)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- 1 2019年5月亚太语法Document16 pages1 2019年5月亚太语法lin zhuNo ratings yet

- What Is Further InvestigationDocument6 pagesWhat Is Further Investigationmohit kumarNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Ryan Higa's How To Write Good: PrologueDocument9 pagesRyan Higa's How To Write Good: PrologueIsabella Biedenharn89% (9)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Caja Automatica Suzuki Sidekick 1995Document15 pagesCaja Automatica Suzuki Sidekick 1995Glenn50% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Ericsson Minilink Spare Parts For Sale From Powerstorm 4SC01211061Document3 pagesEricsson Minilink Spare Parts For Sale From Powerstorm 4SC01211061sandro195No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- 50 Globe Mackay Cable and Radio COrporation vs. Court of AppealsDocument4 pages50 Globe Mackay Cable and Radio COrporation vs. Court of AppealsGlomarie GonayonNo ratings yet

- Multotec Trommel ScreensDocument6 pagesMultotec Trommel Screensalfredo_17110% (1)

- Invoice Template in Excel FormatDocument12 pagesInvoice Template in Excel FormatNirmal GhoshNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- DPI - Jul-Aug 16Document59 pagesDPI - Jul-Aug 16ratninp9368No ratings yet

- Prestressed Transfer Plate Design and ConstructionDocument16 pagesPrestressed Transfer Plate Design and Constructiona96lhf0% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mysore Master Plan Vol 2Document100 pagesMysore Master Plan Vol 2shahimabdu50% (2)

- Blender Annual Report 2020 v1Document32 pagesBlender Annual Report 2020 v1nallabelipavanNo ratings yet

- Roles Responsibilities A Handbook For CGST OfficersDocument64 pagesRoles Responsibilities A Handbook For CGST OfficersHr legaladviserNo ratings yet

- Afsa Form 103aDocument5 pagesAfsa Form 103alememefrog100% (1)

- Komatsu Fault Codes Listtxt PDFDocument3 pagesKomatsu Fault Codes Listtxt PDFВячеслав Шапочка100% (5)

- Marketing 3rd Quarter ReviewerDocument10 pagesMarketing 3rd Quarter ReviewerJohn Cris BuanNo ratings yet

- Spareparts Air Suspension BPW 2022 EN 31052201Document154 pagesSpareparts Air Suspension BPW 2022 EN 31052201cursor10No ratings yet

- Television and Video EngineeringDocument42 pagesTelevision and Video EngineeringGanesh ChandrasekaranNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- ARP Form NKKDocument4 pagesARP Form NKKAnthony NhanNo ratings yet

- SIP5 7SK82-85 V07.90 Manual C024-8 en PDFDocument1,750 pagesSIP5 7SK82-85 V07.90 Manual C024-8 en PDFPetre GabrielNo ratings yet

- Relaxo FootwearDocument74 pagesRelaxo FootwearKiranNo ratings yet

- Geotechnical and Hydrogeological Investigation at Dangote Cement ZambiaDocument1 pageGeotechnical and Hydrogeological Investigation at Dangote Cement ZambiaPumulo MukubeNo ratings yet

- Film Processor: Operation ManualDocument42 pagesFilm Processor: Operation ManualCamila LopezNo ratings yet

- Abhishek Intern ReportDocument44 pagesAbhishek Intern ReportAbhishek sharma100% (1)

- Simple Chemistry PBL 2.0 During PKPBDocument4 pagesSimple Chemistry PBL 2.0 During PKPBAryanaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)