Professional Documents

Culture Documents

SM - 1850K Tier3 - EN - Error - Codes

Uploaded by

Boris ZhilkinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SM - 1850K Tier3 - EN - Error - Codes

Uploaded by

Boris ZhilkinCopyright:

Available Formats

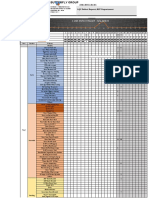

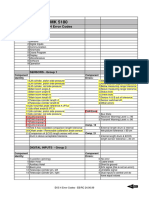

JOYSTICKS BLADE AND RIPPER ERROR CODES

6-8

EST / BB3 Cluster Cluster 1850

Error Code Description reaction of machine leading Error Code (bit coded) Description

Error object Error Description character Nr. of bit

1 Blade lowering short cut on wire to pilot valve stop blade

2 Blade lifting short cut on wire to pilot valve stop blade b 2 PWM output error on

3 Blade Lowering open load on wire to pilot valve stop blade blade axle

4 Blade lifting open load on wire to pilot valve stop blade

5 Blade open load on potentiometer (no ground) stop blade

6 Blade open load on potentiometer (no supply) stop blade b 3 sensor error

7 Blade neutral contact broken stop blade

8 Tilt left short cut on wire to pilot valve stop tilt

9 Tilt right short cut on wire to pilot valve stop tilt b 4 PWM output error on

10 Tilt left open load on wire to pilot valve stop tilt tilt axle

11 Tilt right open load on wire to pilot valve stop tilt

12 Tilt open load on potentiometer (no ground) stop tilt

13 Tilt open load on potentiometer (no supply) stop tilt b 5 sensor error

14 Tilt neutral contact broken stop tilt

15 Angle left short cut on wire to pilot valve stop angle

16 Angle right short cut on wire to pilot valve stop angle b 6 PWM output error on

17 Angle left open load on wire to pilot valve stop angle Angle axle

18 Angle right open load on wire to pilot valve stop angle

19 Angle open load on potentiometer (no ground) stop angle

20 Angle open load on potentiometer (no supply) stop angle b 7 sensor error

21 Angle neutral contact broken stop angle

22 Ripper lowering short cut on wire to pilot valve stop ripper

23 Ripper lifting short cut on wire to pilot valve stop ripper r 2 PWM output error on

24 Ripper Lowering open load on wire to pilot valve stop ripper blade axle

25 Ripper lifting open load on wire to pilot valve stop ripper

26 Ripper open load on potentiometer (no ground) stop ripper

27 Ripper open load on potentiometer (no supply) stop ripper r 3 sensor error

28 Ripper neutral contact broken stop ripper

29 Pressure Transducer wire short cut to supply function stop

30 Pressure Transducer wire open load function stop b 8 priority functionality error

31 b/w Valve wire broken function stop

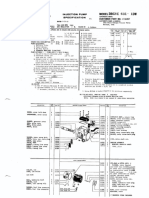

DOZING EQUIPMENT HYDRAULIC SYSTEM

32 Blade: Eeprom read Data hardware error on parameter section full stop

33 Blade: Eeprom read Data hardware error on calibration section full stop b

34 Ripper: Eeprom read Data hardware error on parameter section full stop / 0 Eeprom read data error

35 Ripper: Eeprom read Data hardware error on calibration section full stop r

36 Blade: Eeprom write Data address out of range emergency mode (On next start read the

data from the second data array.

No redundancy check possible.)

Carefully read personal and machine SAFETY PRECAUTIONS at the beginning of this Manual

37 Blade: Eeprom write Data hardware error emergency mode

(keep old data) b

38 Ripper: Eeprom write Data address out of range emergency mode (On next start read / 1 Eeprom write data error

the data from the second data array. r

No redundancy check possible.)

39 Ripper: Eeprom write Data hardware error emergency mode

(keep old data)

1850K

Copyright ©

You might also like

- Rev. Status: Customer Drawing ListDocument9 pagesRev. Status: Customer Drawing ListDebesh ChaudharyNo ratings yet

- Model 1700 Training Activity TwoDocument12 pagesModel 1700 Training Activity Twoyao nestorNo ratings yet

- 3WL10 Air Circuit Breaker: Reliable, Versatile and Perfectly IntegratedDocument2 pages3WL10 Air Circuit Breaker: Reliable, Versatile and Perfectly IntegratedDinuro DiNo ratings yet

- Diagnostics SwitchDocument2 pagesDiagnostics SwitchGioalrizki GioalrizkiNo ratings yet

- Crane Electrical Part 2Document40 pagesCrane Electrical Part 2ruslan100% (1)

- Diagramas FBC25KDocument14 pagesDiagramas FBC25Koscar daniel saldana vegaNo ratings yet

- DT8211 Inverter Driver IC (Application Note: 2008.7.11 DMB Technology IncDocument29 pagesDT8211 Inverter Driver IC (Application Note: 2008.7.11 DMB Technology IncRony ReyesNo ratings yet

- Battery Check Report Rev.1Document2 pagesBattery Check Report Rev.1Hadian SyahrulNo ratings yet

- 11 KV HT Panel ReportDocument66 pages11 KV HT Panel ReportVishakha PandeyNo ratings yet

- MANUAL CENTURION-K-seriesDocument28 pagesMANUAL CENTURION-K-seriesJose Manuel Ramirez CruzNo ratings yet

- I200 LCD DRO Operation ManualDocument53 pagesI200 LCD DRO Operation ManualAdrian Galitianu100% (1)

- Turpial Manual EléctricoDocument62 pagesTurpial Manual EléctricoCENTRO TECNOLOGICO AUTOMOTRIZ HNo ratings yet

- Automotive Direction Indicator: Technical DataDocument6 pagesAutomotive Direction Indicator: Technical Data_gekidoNo ratings yet

- Model 1700 Training: Activity TwoDocument12 pagesModel 1700 Training: Activity Twoyao nestorNo ratings yet

- LQC Defect Report Hiatchi JulyDocument4 pagesLQC Defect Report Hiatchi JulyTahSinaNo ratings yet

- EKS4 Error CodesDocument6 pagesEKS4 Error Codesvivek kashyapNo ratings yet

- 55 50SN CompleteDocument118 pages55 50SN CompleteZafer IlhanNo ratings yet

- Lightning Connector and Port PinoutDocument2 pagesLightning Connector and Port PinoutAnonymous Cpe6vcNo ratings yet

- Infineon Bts6133d Ds v01 00 enDocument17 pagesInfineon Bts6133d Ds v01 00 enmarino246No ratings yet

- Co2 Daily Check ListDocument3 pagesCo2 Daily Check ListABHISHEK THAKURNo ratings yet

- Codigos Tijeras Gen 5Document1 pageCodigos Tijeras Gen 5fernandoNo ratings yet

- Electric 2 Suzuki VL800Document19 pagesElectric 2 Suzuki VL800Crisan SorinNo ratings yet

- Lane Departure AssistDocument3 pagesLane Departure AssistMartynas RamanauskasNo ratings yet

- Terminal Allocation Table For Robot Electric CabinetDocument4 pagesTerminal Allocation Table For Robot Electric CabinetPhươngNguyễnNo ratings yet

- Smart Servo User Guide v-01Document1 pageSmart Servo User Guide v-01kumars29No ratings yet

- Rev 15 Fut DMReg Mapfor Modbus ProtocolDocument24 pagesRev 15 Fut DMReg Mapfor Modbus ProtocolTores FinadeNo ratings yet

- Series: Direct Solenoid and Solenoid Pilot Operated ValvesDocument38 pagesSeries: Direct Solenoid and Solenoid Pilot Operated ValvesFahmi RamdaniNo ratings yet

- 1409 Instruction ManualDocument28 pages1409 Instruction ManualAjay Singh Patial100% (1)

- Ata 6140Document13 pagesAta 6140Zhan AinabekovNo ratings yet

- 6-4 Crawler TypeDocument22 pages6-4 Crawler TypeSumitomo Laos Sumitomo LaosNo ratings yet

- Yashica - Mat 124g EnglishDocument36 pagesYashica - Mat 124g EnglishKedves SzabolcsNo ratings yet

- W1000957 CompressedDocument24 pagesW1000957 CompressedCristian Neftalí Díaz V.No ratings yet

- 1.3 Pin Description P-DSO-20-5 (11 MM) : PEB/F 4065Document1 page1.3 Pin Description P-DSO-20-5 (11 MM) : PEB/F 4065Dwp BhaskaranNo ratings yet

- Laptek Form CB 11KV MVDocument1 pageLaptek Form CB 11KV MVDian PermanaNo ratings yet

- B How To Use This ManualDocument4 pagesB How To Use This ManualHoàng LêNo ratings yet

- TS Guide 240 ElectricalDocument48 pagesTS Guide 240 ElectricalReinis GraursNo ratings yet

- Ah Yes, NOTESDocument5 pagesAh Yes, NOTESMudit AtreyNo ratings yet

- Resumen de Simbolos PIDDocument13 pagesResumen de Simbolos PIDSamuel gc333No ratings yet

- Setup & Installation Manual FOR Hitachi Zx210Lc-3 Hydraulic Excavator BYDocument26 pagesSetup & Installation Manual FOR Hitachi Zx210Lc-3 Hydraulic Excavator BYAndi KaNo ratings yet

- TPS7B4250-Q1 Pin FMEA: Application ReportDocument4 pagesTPS7B4250-Q1 Pin FMEA: Application ReportnidhiNo ratings yet

- AC5 - Blockage ListDocument2 pagesAC5 - Blockage ListPrasad DarlingNo ratings yet

- Easergy P3 - REL52009Document6 pagesEasergy P3 - REL52009Phạm Văn Chí CôngNo ratings yet

- TB6560 Mach3 CNC Stepper Motor Controller Operation InstructionDocument19 pagesTB6560 Mach3 CNC Stepper Motor Controller Operation InstructionCornel BordeiNo ratings yet

- Sistema de Encendido Honda CBF 150 UnicornDocument12 pagesSistema de Encendido Honda CBF 150 UnicornjotabanNo ratings yet

- Technical CENTURION C SeriesDocument28 pagesTechnical CENTURION C Seriesمحمدعبدالخالق العلوانيNo ratings yet

- ECUFaultsList 20160625Document12 pagesECUFaultsList 20160625George HernandezNo ratings yet

- Equipment Maintenance Schedule LatestDocument41 pagesEquipment Maintenance Schedule LatestAnandharaj .KNo ratings yet

- Chapter 12: Proportional Directional Control: ObjectivesDocument12 pagesChapter 12: Proportional Directional Control: ObjectivesSangmin KimNo ratings yet

- BMV 700 Quick Installation GuideDocument4 pagesBMV 700 Quick Installation GuidePape SonkoNo ratings yet

- Cc4800 SchematicsDocument209 pagesCc4800 Schematicspross5343No ratings yet

- 5.electrical System of B160Document19 pages5.electrical System of B160Dedi rahmat100% (1)

- Arstra 1.8 2002.ecu ConectorDocument3 pagesArstra 1.8 2002.ecu Conectorcarlos eli olveraNo ratings yet

- Group 2 Main Control Valve: 1. StructureDocument23 pagesGroup 2 Main Control Valve: 1. StructureАлексейNo ratings yet

- Rev00 - Installation Manual Capacitive Sensor PDFDocument2 pagesRev00 - Installation Manual Capacitive Sensor PDFchinck83No ratings yet

- Fuji MCB 62D1-E-0088Document20 pagesFuji MCB 62D1-E-0088006mmjNo ratings yet

- Dinoil 1 PDFDocument69 pagesDinoil 1 PDFRS Rajib sarkerNo ratings yet

- E BBOSYDocument48 pagesE BBOSYChima OsonduNo ratings yet

- Valve 2 PDFDocument2 pagesValve 2 PDFGioalrizki GioalrizkiNo ratings yet

- Op Amps: Design, Application, and TroubleshootingFrom EverandOp Amps: Design, Application, and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- Кодирование BMW F-серииDocument19 pagesКодирование BMW F-серииBoris ZhilkinNo ratings yet

- Display Panel, Operating DisplayDocument1 pageDisplay Panel, Operating DisplayBoris ZhilkinNo ratings yet

- en Failure-Codes PDFDocument706 pagesen Failure-Codes PDFtallervtNo ratings yet

- New Holland Kobelco E385 E385B Crawler Excavator Shop ManualDocument1,061 pagesNew Holland Kobelco E385 E385B Crawler Excavator Shop ManualBoris Zhilkin71% (7)

- Hidromek HMK 200W-3 Workshop ManualDocument552 pagesHidromek HMK 200W-3 Workshop ManualBAKINEC AZERSKIY64% (11)

- 1508838-Megasun 5600Document63 pages1508838-Megasun 5600Boris ZhilkinNo ratings yet

- Please Read This First : AmperesDocument27 pagesPlease Read This First : AmperesBoris ZhilkinNo ratings yet

- Hydraulic Diagram, CompleteDocument3 pagesHydraulic Diagram, CompleteBoris ZhilkinNo ratings yet

- Information Display Unit, Setting - 1Document2 pagesInformation Display Unit, Setting - 1Boris ZhilkinNo ratings yet

- Display Panel and Keypad, GeneralDocument3 pagesDisplay Panel and Keypad, GeneralBoris Zhilkin100% (1)

- Case New Holland Kobelco Iveco Komatsu F4CE F4DE F4GE F4HE Service Repair Manual For Engine Overhaul (Mechanical Injection and Electronic Common Rail) PDFDocument277 pagesCase New Holland Kobelco Iveco Komatsu F4CE F4DE F4GE F4HE Service Repair Manual For Engine Overhaul (Mechanical Injection and Electronic Common Rail) PDFpckey100% (46)

- Display Panel, Information DisplaysDocument5 pagesDisplay Panel, Information DisplaysBoris ZhilkinNo ratings yet

- Information Display Unit, Setting - 1Document2 pagesInformation Display Unit, Setting - 1Boris ZhilkinNo ratings yet

- Motor Kia CRDI EngDocument61 pagesMotor Kia CRDI EngHudha EdogawaNo ratings yet

- SINUMERIK 840di SL Manual: Valid ForDocument554 pagesSINUMERIK 840di SL Manual: Valid ForBoris ZhilkinNo ratings yet

- Wireless Components: FM Car Radio IC With PLL TUA 4401K V 2.1Document41 pagesWireless Components: FM Car Radio IC With PLL TUA 4401K V 2.1Boris ZhilkinNo ratings yet

- Electrical EquipmentDocument605 pagesElectrical EquipmentAlexandr DarmostukNo ratings yet

- KoneCranes Manuals 2182Document45 pagesKoneCranes Manuals 2182PatrikNo ratings yet

- Repair Manual N45 and N67 ENT Tier3 P2D32N003E Feb06Document186 pagesRepair Manual N45 and N67 ENT Tier3 P2D32N003E Feb06Michaela Wild100% (7)

- Case New Holland Kobelco Iveco Komatsu F4CE F4DE F4GE F4HE Service Repair Manual For Engine Overhaul (Mechanical Injection and Electronic Common Rail) PDFDocument277 pagesCase New Holland Kobelco Iveco Komatsu F4CE F4DE F4GE F4HE Service Repair Manual For Engine Overhaul (Mechanical Injection and Electronic Common Rail) PDFpckey100% (46)

- SERVICE MANUAL CAT RP5500 CAT RP7500e CAT RP6500EDocument138 pagesSERVICE MANUAL CAT RP5500 CAT RP7500e CAT RP6500EBoris Zhilkin100% (2)

- 11.3.2013 19:01:46 D:/work/eagle - projects/Mustang/ECU - SCH (Sheet: 1/6)Document6 pages11.3.2013 19:01:46 D:/work/eagle - projects/Mustang/ECU - SCH (Sheet: 1/6)Boris Zhilkin100% (1)

- HoistMonitor 003060-4 PDFDocument105 pagesHoistMonitor 003060-4 PDFDante Williams100% (1)

- Bomag BW213Document148 pagesBomag BW213edascribd80% (10)

- Service Manual For Frequency Control System: English 19.12.2007Document46 pagesService Manual For Frequency Control System: English 19.12.2007Rafael Linarez100% (1)

- Cat Dcs Sis ControllerDocument2 pagesCat Dcs Sis ControllerSiding BarroNo ratings yet

- Renr8038renr8038 01 SisDocument2 pagesRenr8038renr8038 01 Sisvimat vimatNo ratings yet

- Operating Instructions Maintenance InstructionsDocument148 pagesOperating Instructions Maintenance InstructionsBoris ZhilkinNo ratings yet

- BW211 212 213D 40 Service Manual E 00891163 c08 PDFDocument1,040 pagesBW211 212 213D 40 Service Manual E 00891163 c08 PDFpurnomoNo ratings yet

- 3 Input Output and Storage DevicesDocument72 pages3 Input Output and Storage DevicesRegine Lodana GueriñaNo ratings yet

- Personal Protective Equipment Matrix: General TaskDocument2 pagesPersonal Protective Equipment Matrix: General TaskBadu MalangoNo ratings yet

- Distribution Acceptable Product ListDocument30 pagesDistribution Acceptable Product ListRichard LeongNo ratings yet

- Nera Sat B MK2 Installation ManualDocument56 pagesNera Sat B MK2 Installation ManualradamNo ratings yet

- CH 06 ArtilleryDocument64 pagesCH 06 ArtilleryPGNo ratings yet

- B EIM GRADE 12 Q1M1 Learner Copy-TVL Final LayoutDocument25 pagesB EIM GRADE 12 Q1M1 Learner Copy-TVL Final LayoutMark Ragos100% (1)

- Unit 1Document90 pagesUnit 1Atul Jaysing PatilNo ratings yet

- HTSTP - List of Electrical Materials For ApprovalDocument6 pagesHTSTP - List of Electrical Materials For ApprovaljaymarNo ratings yet

- Air Cooled Package Units Roof Top Unit - AnnuallyDocument2 pagesAir Cooled Package Units Roof Top Unit - AnnuallyDreamlinerNo ratings yet

- Instructions: System MicroscopeDocument48 pagesInstructions: System MicroscopeJose Rolando Orellana RodriguezNo ratings yet

- Daikin Monobloc Domestic Hot Water Heat Pump EKHH2E - (P) AV3 Pre-Sales Package EnglishDocument31 pagesDaikin Monobloc Domestic Hot Water Heat Pump EKHH2E - (P) AV3 Pre-Sales Package EnglishzukchuNo ratings yet

- Risus in The Shell: Life On The StreetsDocument22 pagesRisus in The Shell: Life On The StreetsGarry MossNo ratings yet

- 6.7.7. Instrument Valve List (Safety Valve)Document3 pages6.7.7. Instrument Valve List (Safety Valve)hungNo ratings yet

- Wiring Guide Issue 16Document44 pagesWiring Guide Issue 16nadim_khan_12569No ratings yet

- Cooker Control SwichDocument2 pagesCooker Control SwichstarykltNo ratings yet

- Parts Reference List: MODEL: MFC-J3720/J6520DW/ J6720DW/J6920DWDocument31 pagesParts Reference List: MODEL: MFC-J3720/J6520DW/ J6720DW/J6920DWcesarNo ratings yet

- John Deere - Parts Catalog - Frame 5Document2 pagesJohn Deere - Parts Catalog - Frame 5Jorge MendozaNo ratings yet

- Monitoring Pekerjaan Dan MaterialDocument3 pagesMonitoring Pekerjaan Dan MaterialHarits Angga KusumaNo ratings yet

- Deye Inverter Hybrid Sun ManualDocument94 pagesDeye Inverter Hybrid Sun ManualAndres NavarroNo ratings yet

- Echotrac Mkiii: Model DFDocument2 pagesEchotrac Mkiii: Model DFjonathansolverNo ratings yet

- Astm A 403 Gr. WP304L-S Astm A 403 Gr. WP304L-WX Astm A 182 GR.F304LDocument2 pagesAstm A 403 Gr. WP304L-S Astm A 403 Gr. WP304L-WX Astm A 182 GR.F304LEILA545 QAQCNo ratings yet

- Modeldbgvc 63i-1DW: Injection Pump SpecificationDocument2 pagesModeldbgvc 63i-1DW: Injection Pump Specificationjohnny sabinNo ratings yet

- 1M65 Lathe UniversalDocument7 pages1M65 Lathe Universalhesam abbaszadehNo ratings yet

- EC SKILLET-CONTROLLER - RevE (2017-01-16)Document19 pagesEC SKILLET-CONTROLLER - RevE (2017-01-16)AlexandreNo ratings yet

- Faz Bindlestick's Guide To Firearms - GM BinderDocument14 pagesFaz Bindlestick's Guide To Firearms - GM Binder2ooneyNo ratings yet

- Kelvinator KD12MM1 DishwasherDocument24 pagesKelvinator KD12MM1 DishwasherkarlNo ratings yet

- Volume 5-Manoeuvring SystemDocument345 pagesVolume 5-Manoeuvring SystemJim OrfanosNo ratings yet

- ASV-ATS100: 使用說明書與零件圖 Original Instructions BookDocument18 pagesASV-ATS100: 使用說明書與零件圖 Original Instructions Bookjuan manuel sierra solisNo ratings yet

- SVC V710 2145-CG8 HW Installation GuideDocument114 pagesSVC V710 2145-CG8 HW Installation GuideMarco ErickNo ratings yet

- RX-K Rx-King SeatDocument1 pageRX-K Rx-King SeatAkbar Pontoh Hwoarang NurmagomedovNo ratings yet