Professional Documents

Culture Documents

Pei-Xue Liu and Xiao Zhang: Design of The Data Acquisition System Based On STM32, Yu-Jie Chen, Bao-Hua Jiang

Uploaded by

Anil SuhaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pei-Xue Liu and Xiao Zhang: Design of The Data Acquisition System Based On STM32, Yu-Jie Chen, Bao-Hua Jiang

Uploaded by

Anil SuhaCopyright:

Available Formats

2016 International Conference on Computational Science and Engineering (ICCSE 2016)

Design of The Data Acquisition System Based on STM32

Pei-Xue Liu1,a, Yu-jie Chen1,b, Bao-Hua Jiang1,c and Xiao Zhang1,d

1

Qingdao HuangHai College, Shandong, China

a

93987398@qq.com, 79572611@qq.com, c1073578901@qq.com,d1711301193@qq.com,

b

*Pei-Xue LIU

Keyword:Stm32f103zet6; Temperature and humidity; GSM;

Abstract. With rapid development of modern society, the requirements for high precise temperature

and humidity is growing rapidly, for example production, storage, transportation, environment etc.,

these all have strict requirements for temperature and humidity testing, so the real-time monitoring

of temperature and humidity and alarm prompt is extremely important. In this paper, a

temperature and humidity automatic alarm recorder is designed, which uses stm32 as control center,

combines the technique of sensor technology, GSM technology and serial port to finish button

control measurement of temperature and humidity or two road all the way. In the study, the system's

hardware and software design are introduced in detail and testing results show that the system can

realize the function of the temperature and humidity measurement record and alarm.

Introduction

Along with the rapid development of modern society, people are increasingly demanding on the

quality of life, production and living environment requirements need to be more and more detailed

to meet the demand of people, some storage units such as petroleum, chemical, aerospace,

pharmaceutical, food and other requirement for temperature and humidity is higher, so it is

meaningful to have temperature and humidity of the research.

In this paper, we design a data acquisition system based on STM32, data can be sent via a serial

port to the server. System not only can complete all the temperature and humidity data acquisition

or two road temperature data collection, and can be anywhere at any time to the acquisition of the

temperature and humidity data monitoring, once more than limit the buzzer alarm and send prompt

message to the mobile terminal. The high efficiency than the traditional system, the resources use

fully, and short measuring cycle, low cost, the staff don't have to site operation. Emerging

technologies used in this system, has the scientific nature can avoid the happening of the accident,

and the system has simple structure, high reliability, low cost, so the system has very important

application value of the market.

Overall design of system

The temperature and humidity automatic alarm recorder is mainly composed of: data collection

module, display module, alarm module, GPRS module, serial transmission module, memory

module, the charging module of seven parts, such as the system overall design is shown in figure 1.

Charging modules to the control center and each module power supply, control center control

key choice of temperature and humidity of the acquisition or two road all the way

temperatureacquisition, collect data and feedback to the control center for the operation of the alarm

circuit and display module, once reach the limit temperature and humidity, the control center

control SIM900A

© 2016. The authors – Published by Atlantis Press 0161

2016 International Conference on Computational Science and Engineering (ICCSE 2016)

Figure 1 overall system design

module will alarm prompt messages sent to the mobile terminal and start the buzzer, data collection

terminal through a serial port sent to the server and start the control module used AT24C02 modules

store data.

Hardware design

Temperature measurement circuit design

18 b20 temperature sensor is able to output the digital temperature sensor, it is better than the

traditional temperature sensor hardware, low cost, good stability, simple circuit connection and easy

control. First DS18B20 is negative properly connected power supply and ground, DQ and control

center MCU PD11 JiaoXiang connection for data transmission and control, because the sensor itself

cannot output high level, so the data pins DQ external pull-up resistors R5 make SCM can read "1"

signals, two temperature sensors are the same connection, the second DQ PC11 pin of MCU, to

realize the collection of two way temperature temperature sensor DS18B20 connection circuit

diagram (see figure 2).

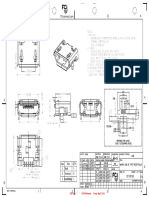

Figure 2 temperature measurement hardware circuit diagram

The humidity measuring circuit design

DHT11 is a single wire system serial mouth of temperature and humidity sensor, it combines

temperature and humidity sensor technology and dedicated digital module acquisition technology as

a whole, can directly output digital signal, its stability and reliability are high. DHT11 four pins,

feet dangling NC is not connected to any device, two power supply pins to connect power and

ground respectively, and the data pin MCU PG11 pin, control the sensor data acquisition and

transmission, but the connection to connect a 5 k on resistance, prevent microcontroller pins for low

© 2016. The authors – Published by Atlantis Press 0162

2016 International Conference on Computational Science and Engineering (ICCSE 2016)

electricity at ordinary times, the external circuit can provide current to the pins. Temperature and

humidity hardware connection diagram (see figure 3).

Figure 3 temperature and humidity measurement hardware circuit diagram

The design of display circuit

LCD12864 is a LCD screen can display the simplified Chinese character and general graphics,

the interface simple connection, software control is also very convenient, 12864 LCD module 20

pins, there are two NC is empty feet is not connect any devices, and VD foot is equivalent to

impending, R11 connected it with the slide rheostat with LEDA and LEDK control the display

backlight degrees, 1 foot and 2 feet respectively connect the power supply and to provide the power

for the whole module, DB0 DB7 12864 connecting MCU PC0 - PC7 control LCD display content,

RS, RW, EN, RSB, RES respectively connected to the microcontroller PG13, PG14, PG15, PB3,

PG4, by controlling the high and low level of each pin [16], complete LCD screen display, the port

connection (see figure 4).

The software design and test

software design

Boot after the initial configuration for equipment first and then choose between temperature and

humidity measure or measurement of the temperature of two way all the way, choose the way to

measure after enter into the state of the data collection, gathering the one sent to the control center,

has been cycle collection. Device is powered on, first on the buttons and minimum system

initialization, and then choose between temperature and humidity device initialization

fortemperature and humidityafter sampling is complete without continues to collect or output to the

control center (key)choice after temperature device initialization temperature sampling is complete

Figure 4 LCD display hardware circuit diagram

© 2016. The authors – Published by Atlantis Press 0163

2016 International Conference on Computational Science and Engineering (ICCSE 2016)

without continued to acquisition or output data to control center). Acquisition program flow chart

(see figure 5).

Figure 5 data acquisition program flow chart

system testing

This design is mainly composed of STM32F103ZET6 control the running of the whole system

and send prompt SMS with GSM technology, through a serial port for data transmission, this test

plan is to use work to make the prototype test, the design prototype (see figure 6).

Figure 6 prototypeFigure 7 SMS test results

Whole running, this design is mainly controlled by the STM32f103ZET6 equipment run time by

the first SIM900A module testing network connection, confirm that the network system run

normally, can choose all the way through the button of the temperature and humidity acquisition or

two road temperature gathering, gathering feedback data provide the basis for the control center,

control LCD display measurements, and determine whether the temperature and humidity reaches

© 2016. The authors – Published by Atlantis Press 0164

2016 International Conference on Computational Science and Engineering (ICCSE 2016)

limit, if do not conform to the requirements, the buzzer alarm and sent via GPRS module to the user

mobile phone terminal business messages (as shown in figure 7).

Summary

The purpose of this design to design temperature and humidity automatic alarm recorder under a

machine, the system hardware to complete function: can button control temperature and humidity

temperature collection or two road, all the way to collect data on the LCD screen display, alarm and

send hint to the user's phone text messages, alarm limit value can be modified by software, can

record a day's temperature and humidity measurement data and through a serial port and PC

communication, which the time intervals of the recorded data can be change by the program, the

above function through the system test run is good, has the very high application value.

Acknowledgement

This research was financially supported by the College Science and technology project of Shandong

Province The Design of Internet of things remote identification and information collection system

based on4G(J15LN59)and the design of cloud platformfor internet of thins environment based on

B/S.

References

[1] zhoubing , Ma Yingqing, Cindy. Intelligent temperature and humidity control instrument [J].

Instrument technique and sensor, 2002, 11:52-53.

[2] yu-fen Yang, ben-huazhang. Composition and development of intelligent temperature and

humidity monitoring system [J]. Journal of agricultural mechanization, 2006, 2:52-101.

[3] zhangwei, dong-fengwang. New greenhouse temperature recorder system design [J].

Mechanical and electrical product development and innovation, 2009, 5:20-31.

[4] Wang Fulu. Cold to remote monitoring system for greenhouse research [D]. The northeast

agricultural university, 2011.

© 2016. The authors – Published by Atlantis Press 0165

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Plumbing and Fire Fighting Sample BoqDocument30 pagesPlumbing and Fire Fighting Sample BoqNajeeb Ahmad Khan100% (2)

- Gas Lift Design With Self-Well GasDocument12 pagesGas Lift Design With Self-Well GasMohanad HussienNo ratings yet

- Sandhya Vandana Ritual and PreparationDocument17 pagesSandhya Vandana Ritual and PreparationAnil SuhaNo ratings yet

- Telugu MantrasDocument28 pagesTelugu Mantraskngane8878100% (2)

- Testing and Measuring Equipment/Allowed Subcontracting IEC 61010-1, Edition 3.0Document7 pagesTesting and Measuring Equipment/Allowed Subcontracting IEC 61010-1, Edition 3.0AbbasNo ratings yet

- Testing and Measuring Equipment/Allowed Subcontracting IEC 61010-1, Edition 3.0Document7 pagesTesting and Measuring Equipment/Allowed Subcontracting IEC 61010-1, Edition 3.0AbbasNo ratings yet

- Probability of Mutually and Non Mutually Exclusive Events 1Document64 pagesProbability of Mutually and Non Mutually Exclusive Events 1syron anciadoNo ratings yet

- SAP PM T - CodesDocument4 pagesSAP PM T - CodesBujjibabu Katta0% (1)

- NARASIMHA AVATARSDocument9 pagesNARASIMHA AVATARSAnil Suha0% (1)

- ADC and DACDocument221 pagesADC and DACUtku GurcuogluNo ratings yet

- Embedded Market Io Board DatasheetDocument8 pagesEmbedded Market Io Board DatasheetAnil SuhaNo ratings yet

- Landtiger v2.0 - Manual v1.1 PDFDocument55 pagesLandtiger v2.0 - Manual v1.1 PDFAnil SuhaNo ratings yet

- Altium PCB Vids LinksDocument1 pageAltium PCB Vids LinksAnil SuhaNo ratings yet

- Ic 7404 (2) HD74LS04PDocument6 pagesIc 7404 (2) HD74LS04PBurhanudin SyamNo ratings yet

- TN 4614Document16 pagesTN 4614fet_50No ratings yet

- PDS: Rev:C STATUS:Released Printed: May 27, 2015Document1 pagePDS: Rev:C STATUS:Released Printed: May 27, 2015Anil SuhaNo ratings yet

- Godown Rental Agmt PDFDocument5 pagesGodown Rental Agmt PDFAnil SuhaNo ratings yet

- Blueboard Lpc1768 H V2Document1 pageBlueboard Lpc1768 H V2J. M.No ratings yet

- Drawing1 ModelDocument1 pageDrawing1 ModelAnil SuhaNo ratings yet

- D D D D D: A723 Precision Voltage RegulatorsDocument20 pagesD D D D D: A723 Precision Voltage RegulatorsAnil SuhaNo ratings yet

- How To Obtain The Host Name and Host ID of Your ComputerDocument4 pagesHow To Obtain The Host Name and Host ID of Your ComputerAnil SuhaNo ratings yet

- STM32F446-ARM Nucleo Board User's Manual: D.K. Blandford August, 2017 Updated November 3, 2017Document60 pagesSTM32F446-ARM Nucleo Board User's Manual: D.K. Blandford August, 2017 Updated November 3, 2017Anil SuhaNo ratings yet

- New Doc 2017-05-12 (1) - 1Document1 pageNew Doc 2017-05-12 (1) - 1Anil SuhaNo ratings yet

- Bill No 12 Rights of Persons With DisabilitiesDocument28 pagesBill No 12 Rights of Persons With DisabilitiesAnil SuhaNo ratings yet

- How To Obtain The Host Name and Host ID of Your ComputerDocument4 pagesHow To Obtain The Host Name and Host ID of Your ComputerAnil SuhaNo ratings yet

- English Notice ESE 2016 PDFDocument24 pagesEnglish Notice ESE 2016 PDFUploadingfilesNo ratings yet

- Simulink TutorialDocument4 pagesSimulink TutorialAnil SuhaNo ratings yet

- Harper Lee ArticleDocument3 pagesHarper Lee ArticleAnil SuhaNo ratings yet

- Strength Training For The MindDocument4 pagesStrength Training For The MindAnil SuhaNo ratings yet

- New OpenDocument Text (2) .Odt - 0Document4 pagesNew OpenDocument Text (2) .Odt - 0Anil SuhaNo ratings yet

- EE141 s09 Hw3 SolutionDocument6 pagesEE141 s09 Hw3 Solutionanil rajputNo ratings yet

- Date ValidationDocument9 pagesDate ValidationAnonymous 9B0VdTWiNo ratings yet

- You Can Do The CubeDocument16 pagesYou Can Do The Cubedeborahmorton100% (1)

- Course Web Page Causal Inference (Part III, Michaelmas 2020) - Qingyuan Zhao's WebsiteDocument120 pagesCourse Web Page Causal Inference (Part III, Michaelmas 2020) - Qingyuan Zhao's WebsiteMa GaNo ratings yet

- Construction and Building Materials: Weena Lokuge, Aaron Wilson, Chamila Gunasekara, David W. Law, Sujeeva SetungeDocument10 pagesConstruction and Building Materials: Weena Lokuge, Aaron Wilson, Chamila Gunasekara, David W. Law, Sujeeva SetungeAndrew PiNo ratings yet

- Review 1Document11 pagesReview 1Anonymous gfbLDQPgNo ratings yet

- Lesson 2 Matter in The Liquid PhaseDocument27 pagesLesson 2 Matter in The Liquid PhaseDarren Daniel InfanteNo ratings yet

- Solutions to Mandatory Exercises and Unit Test for Sets, Relations and FunctionsDocument34 pagesSolutions to Mandatory Exercises and Unit Test for Sets, Relations and FunctionsShashankAnilNo ratings yet

- YSCA Brochure22 York Pared Con SEER 10Document2 pagesYSCA Brochure22 York Pared Con SEER 10san cadejoNo ratings yet

- Online Shopping Survey ResultsDocument5 pagesOnline Shopping Survey ResultsAlyssa Nikki VersozaNo ratings yet

- Juju ElectricalDocument20 pagesJuju ElectricalAnkit AkashNo ratings yet

- Vacon NX OPTCP Profinet IO Board User Manual DPD00Document44 pagesVacon NX OPTCP Profinet IO Board User Manual DPD00TanuTiganuNo ratings yet

- Phys 1111 SygsuDocument4 pagesPhys 1111 SygsuLeporeNo ratings yet

- INMATEH-Agricultural Engineering Vol.42 - 2014Document175 pagesINMATEH-Agricultural Engineering Vol.42 - 2014Popa LucretiaNo ratings yet

- 1000 Startup Digital WorkshopDocument84 pages1000 Startup Digital WorkshopVicky Yoga INo ratings yet

- Activity DiagramsDocument26 pagesActivity Diagramskant.beleNo ratings yet

- J. Org. Chem. 2014, 79, 8522Document11 pagesJ. Org. Chem. 2014, 79, 8522Dianita Ruano ContrerasNo ratings yet

- Amacs LEBM0079-00Document4 pagesAmacs LEBM0079-00mustafasenbagci3693No ratings yet

- Apex Series 5000 7000 Bill Acceptor Manual PDFDocument17 pagesApex Series 5000 7000 Bill Acceptor Manual PDFFidelRomasantaNo ratings yet

- U2000 Alarm Data SynchronizationDocument1 pageU2000 Alarm Data SynchronizationleonardomarinNo ratings yet

- Log AssignmentDocument4 pagesLog AssignmentguranshsaranNo ratings yet

- First Court: Aya R N (Hag A Irene) ChurchDocument1 pageFirst Court: Aya R N (Hag A Irene) ChurchErgin KarakoyunNo ratings yet

- AOCS Annual Meeting 2020 Surfactants Detergents AbstractsDocument47 pagesAOCS Annual Meeting 2020 Surfactants Detergents AbstractsJonathan DiamondNo ratings yet

- Peter-Linz-Automata BUET Download PDFDocument2 pagesPeter-Linz-Automata BUET Download PDFmalang0% (2)

- Hostel Management SRS PDFDocument17 pagesHostel Management SRS PDFVanitha Vani64% (14)

- Mech 2 Module 1 Unit 3 (Position, Velocity and Acceleration)Document8 pagesMech 2 Module 1 Unit 3 (Position, Velocity and Acceleration)Zamantha DomingoNo ratings yet