Professional Documents

Culture Documents

Product Realization Process:: Documentation, Clear Decisions, Incorporation Of. Collective Experience Prod

Uploaded by

Obelay SkinCareOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Realization Process:: Documentation, Clear Decisions, Incorporation Of. Collective Experience Prod

Uploaded by

Obelay SkinCareCopyright:

Available Formats

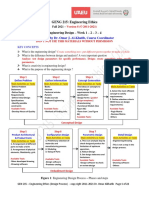

Concept Generation, 5-step process:

1. Clarify the problem (problem decomposition into simpler sub-problems)

2. Search Externally – finding existing solutions from experts, patents, benchmarking)

Product Realization Process: 3. Search Internally (Individual & group methods to adapt the team knowledge)

1. Need Statement (strategic plan) 4. Explore Systematically (Classification Tree, Combination Table to organize thinking of the team & synthesize

2. Establishment of need (examine competition, identify users, legal issues, market segments, facilitate sln fragments)

economic analysis) 5. Reflect on the solution & process (continuous improvement in subsequent iterations)

3. Concept Development (Determine Design, Design Feasibility) The Decision Matrix: systematic way to design a multifactional design while evaluating their strengths &

4. Detail Design (Define subsystems, tools, part geometry) weaknesses

5. Test & Evaluation (α&β test, reliability, training and regulations) Concept Testing Process

6. Product & Service (evaluate early product production -Define purpose of test

Changes in Competitive Envrionment Time to Market Speed Trade off: -Choose survey pop, format

- ↓ complex pod, demand trends, time2market

Evolving tech, -Communicate concept

Strategic Plan: (policy deployment and its execution.) -Measure customer response & interpret results &reflect

- Identify mission, strengths, weakness, long-term objectives, strategic/tactical issues to solve Concept Testing is used for:

- Select market segment and poducts for devlopment -Go/ no decisions, what market to be in, select/confirm concepts, benchmarking, soliciting improvement ideas,

- Project financial returns from chosen market and pdts. forecasting demands

Product Devlopmet: uses customer expect, input and Concurrent Engineering as design approach

Trad. Design process: all processes are sequential & no interaction.

àProbs: Limited communication between groups, minimal understanding of customer needs, result errors are costly Interpreting the results: Forecasting Sales

& difficult to implement. 𝑄 = 𝑁𝐴𝑃 where: Q=sales(annual) – N=number of (annual) purchases – A=awareness x availability (fractions) –

Concurrent Engineering (CE): Design approach to merge design & manufacture in

à RESULT:Any Change waste time and create delay to market entry. Staff only sees design at end. P=probability of purchase (surveyed) = 𝐶&'( 𝐹&'( + 𝐶*+,- 𝐹*+,- if no history Cdef= 0.4 andCprob0.25

- Manufacture & assemble design undertaken early in design stage

- More accurate cost estimates & well define product development Sources of Forecast error: Word-of-mouth effects, quality of concept description, pricing, level of promotion,

GOAL: ↓elapsed time required to bring a BETTER pdt to market CHEAPER & FASTER competition.

5 KEY Elem. of CE: Design for cost, performance, manufacturability/ass, serviceability & compliance Product architure Def: the arrangement of functional elements into physical chuncks which become the

Stages in CE: building blocks for the product or family of products.

1.Proj.Ident Provide a simple, clear process, define req. for approval, priorities & schedule of all tasks 3 Types of Modularity: Slot: each interface b/w chunks is of diff. type from others. Bus: common bus where all

2.Proj. Scope (confirm customer. expectation & consensus between them & execs goals) chunks have same base. Sectional: interfaces = same & attached to each other to form base.

3. Requirements & Analysis (Provide traceability cust. Needs, sys.sln &testing to enable change manag) To establish modular archit.: create schematic of pdt: decomposition of sys. Functional require. & identification

4. Sys. Design (Define metrics to predict implementation. Time& devl. efforts used for process improv.) of functional interaction.

5. Devl. Planning (define a work plan to implem. A technical sln) Cluster element of schematic to create product variety type: same as create schematic & grouping require.

Benefits of CE: Into modules.

-Better use of trade-offs in cost & design from all groups, lower dev time, less rework, prob-solving focus

Identifying interaction: same as cluster & identifying the interaction b/w modules.

Product Life Cycle in CE: DESIGN (60-95% overall cost here)- build-test- terminate

Modular arch.: chunks implement 1 or few functions entirely, interactions b/w chunks are defined & is simple

Ways to succeed with CE: do cross-functional teams, improve common design process concurrently, involve

supps/subcontractor early, keep low cost and simple, well done from 1st time, use evolutionary steps, 6s and reusable.

Kick-off Meetings in CE: Integral arch.: function element implemented by multiple chunks and interaction b/w them are poorly defined,

-official start with agreement on common terms, objs,indiv.tasks & proj.scope increases performance and reduces cost for any pdt model.

- Set Realistic, Measurable, Specific, Deadline-oriented goals Choosing arch.: product change, product variety, standization, performance, manufacturing. Cost, project

-Focus on beating others, faster cycle time and ↓target cost management, sys. Engr.

-Schedule completion of tasks, design review 4 risk manag. Product change: upgrade, add-ons, adaptations, wear, consumption, flexibility in use & reuse.

-Measure performance by: meet budget & sched, ↓ # of iterations, ↑effort Fundamental decisions: modular vs. integral arch., type of modularity, assign functions to modules

(manufacturability, maintainability & custom. Opportunities), assign modules to teams & which one to

Virtual Prototyping: shorten design cycle & aid rapid pdt devl. outsource.

- Advantages: Integration of multi-physical, low-cost parametric simulation/analysis tools available Conclusion: arch determines ease of pdts variety, feasibility of cust. Modif & sys level pdt cost

Growth Stage in Team:

1. Forming (discuss each abilities &weaknesses) Design for manuf. (DFM): concurrent engr & develop. Practice focusing on manuf. Issues t/o pdt dvl process.,

2. Storming (focus on tasks/team strengths before understanding complexity of task à could create lower pdt cost w/o reducing pdt quality & bring down-stream-life-cycle issues to the forefront of the new pdt

discouragement) intro process.

3. Nurturing (feeling of closeness, interdependence & unity form) Tool kit to focus on issues: QF Deployment, DFM, DFA, DF Test, DF Cost, DF Inspection, DF Maintenance, DF

4. Performing (tasks distributed and executed within members)

Repair, value analysis.

5. Adjourning (disbanding of team and goals completed)

3 methods to implement DFM: organization (cross-fct teams), firm design rules & CAD tools.

Elements of pdt manuf. Cost: Components [std & custom –> (raw material, processing & tooling)] assembly

Three Innovation Challenges: People (Want), Business (Profitable), Technical (feasible) [labor & equip and tooling], overhead [support (material handling, QA, ship and receive) & indirect allocation

Characteristic of Successful PD: Good quality, low manufacture cost, low dev cost & time, firms growth (maintenance of building and security)]

Challenges of Product Development: Assembly costs: labor, tooling and equipment. Assembly time = handling + insertion

- Tradeoffs ( b/w features & manuf. Cost) setup cost + tooling cost

- Dynamics (Evolution of technology, customer preferences, new competitors) Total unit cost = + variable cost

volume

- Details (Economic implications of choice of detailed features) DFA: key points: min part count, max ease of handling part & ease of inserting parts. Benefits: lower labor

- Time pressure (PD decisions be made quickly w/o more info) costs. Guidelines: min part count, encourage modular ass., stack ass, eliminate adjustments, eliminate cables,

- Economics (Need of large investment in development & marketing of new product) use self-fastening & self-locating parts, eliminate reorientation, facilitate part handling & specify std parts.

Product Development Process: set of steps 2 conceive, design and transform inputs into outputs Candidate for part elimination: Relative motion between part and rest of device? Different material? Separation

1. Quality Assurance (phases/checkups where process development will pass thru) b/w part and rest of device to allow assembly. If all 3 not, combine part with another part in the device.

2. Coordination (master plan def roles of players)

3. Planning (natural milestones 4 completing phases)

4. Management (benchmark to get performance of current effort)

5. Improvement (document the development process helps finding points to improve)

Pdt Specification Process: 1. Set Target Specs: 1.1 Prep list of metrics (must be complete & practical) 1.2

Collect Competitive Benchmark info 1.3 Set Ideal & Acceptable Target values (5 ways: at least X, at most X,

b/w X & Y, exactly X and a set of discrete values) 1.4 Reflect on result for improvement

Product Life Cycle Stage: 2. Refine Specs (based on chosen concept & feasibility testing, technical model & trade-offs)

- Introduction (Stage market size & growth slight, marketing cost high to test & promote) 3. Reflect on result (critical for ongoing improvement)

- Growth (Rapid growth in sales/profits due to output (economies of scale), cheaper to invest in Resolve tradeoffs: 5-step process:

market share 1-Develop technical models of the poduct (tool 2 predict value of metrics for a set of design decisions)

- Maturity (where competition most intense to maintain market share, marketing &finance key 2-Develop a cost model of product (tool 2 predict if product can be produced @ target cost)

activities) 3-Refine the specs, making trade-offs when needed (competitive map)

- Decline (Market & overall profit ¯, amounts of stocks of pdt may be controlled) 4-Flow down the specs (used for complex design with many subsystems

Front-End Process: 5-Reflect on results (is the product a winner? Is there uncertainty)

-Mission StatementàIdentify customer. NeedsàEstablish target specificationàConcept GenàConcept Testà Set Target Cost:

final specàProject planningàEconomic AnalysisàBenchmark competitionà Model/prototypeàPlan -Set the value of the manuf. cost spec based on price the cie hopes the end user will pay for the pdt & on the

Product Development Organizations: profit margins that are required for each stage in the distribution channel.

Functional (specialized & deep expertise) & Project (rapid & effective coordinate in many fcts) -It is the reverse of COST-PLUS MTD: which begins with what the firm expects it manuf. Costs and then sets its

-Formed by making links b/w ppl, either aligned with fcts (ex.marketing, design), projects or both prices by adding its expected profit margin to the cost.

Reporting Relationships: give notion of supervisor/subordinate 𝑀 = (𝑃 − 𝐶)/𝑃 where : M: gross profit margin of a stage in distribution channel

Financial Arrangements: ppl linked in being part of same fin.entity. P: price this stage charges its customers

Physical Layout: links created b/w ppl in same office/floor. C: cost this stage pays for the pdt it sells

Project Matrix Organization: Lightweight (weaker project links & stronger functional links) or Heavyweight (Strong 𝐶 = 𝑃 ∏#!$%(1 − 𝑀!) where : P: price paid by the end user

project links) In function dif. department( specialization), in project organized by proj (coordination)

n: # of stages in the dist. Channel

Design 4 Manuf. & Assembly (DFMA): simplify pdt to ¯ part counts, cost of manuf. & ass, while improving assembly

Mi : margin of the ith stage

efficiency.

Types of Product Development: New Prod , Derivative of Prod, Incrementing Existing, Brand New

Product Planning Process Steps:

1. Id Opportunities (Marketing & Sales Personnel, PD Teams, Current /Pot. Cust./3dparty)

2. Evaluate/Prioritize (Competitive Strat, Market Segment, Platform Plan.)

3. Allocate Res.(Aggregate Planning to efficiently use res.) & Plan Timing(market readiness)

-Balanced portfolio has investment in breakthrough pdts, new platforms

4. Complete Pre-Pjct Planning (Poduct vision and mission statements)

5. Reflect on Results &Process (search opportunities for improvement)

Customer Needs:

1. Gather Raw Data (focus groups, interviews) 2. Interpret Data (set need statements) 3. Organize needs

(hierarchyàprimary, secondary) 4. Set importance (surveys) 5. Reflect on result for continuous improvement

Analysis Process Steps : Define Scope, Gather Info, Interpret Data, Qualify Relative Importance (trade off), Reflect

on process (continues improvement)

Need types : Primary Needs ie easy to use, Secondary Needs ie safe to bump into, latent needs prevents pipes

from freezing, importance rating thermostat is personal

Advantages of Quality Function Deployment – reduction in cost, design times and errors, early exposure to tradeoffs, written

documentation, clear decisions, incorporation of. Collective experience

Phases: Product Planning, Part Deployment Phase (components), Process Depl.. (how to manufacture) product deployment measure of critical

prod.

Each Requirement is given a rating from 1-9 then each speciation is rated in relationship to this requirement. If

there is no relationship LEAVE BLANK if there is a slight or weak correlation rate as 1, medium 3 and high 9

multiply each specification with the corresponding requirement. Ei (9x9) + (3x5)=96 the absolute rating becomes

benchmark value and is given a relative importance of 9. All other specifications are then weighted to this value.

Eg 129 is the max value so it becomes 9. And all other are weight ie 96/129 x 9

You might also like

- Agile Certified Practitioner (PMI-ACP)Document57 pagesAgile Certified Practitioner (PMI-ACP)அஜய் மேகநாதன்No ratings yet

- Automotive Design: ErgonomicsDocument56 pagesAutomotive Design: Ergonomicsravisb2958No ratings yet

- Product Design and Development: by Prashanth.P Lecturer - I.E.M S.I.TDocument57 pagesProduct Design and Development: by Prashanth.P Lecturer - I.E.M S.I.TKumar AbhishekNo ratings yet

- Business Analyst PDFDocument79 pagesBusiness Analyst PDFdommarajuuu1No ratings yet

- EDP 3 Product DevelopmentDocument15 pagesEDP 3 Product DevelopmentatulkirarNo ratings yet

- Will's Grill Case StudyDocument4 pagesWill's Grill Case Studymera indiragani75% (4)

- Value Engineering & Value Management: NTK LokuliyanaDocument32 pagesValue Engineering & Value Management: NTK LokuliyanaSujani MaarasingheNo ratings yet

- Furniture Industy in IndiaDocument9 pagesFurniture Industy in IndiaVatsal Thaker100% (1)

- Software Testing Interview Questions You'll Most Likely Be AskedFrom EverandSoftware Testing Interview Questions You'll Most Likely Be AskedNo ratings yet

- Marketing Analysis of TURKISH AIRLINEDocument7 pagesMarketing Analysis of TURKISH AIRLINEZain Chaudhry0% (1)

- Product Development Organizations - Organizational StructuesDocument1 pageProduct Development Organizations - Organizational Structuesrony16novNo ratings yet

- OPENMANDocument11 pagesOPENMANLumagui, Vanessa JoyNo ratings yet

- Computation of Demand Income Statement 1Document5 pagesComputation of Demand Income Statement 1Marianne SevillaNo ratings yet

- Value Analysis & Value Engineering: DR - Sanjay RajurkarDocument36 pagesValue Analysis & Value Engineering: DR - Sanjay Rajurkaramy goshNo ratings yet

- Project Management Process FrameworkDocument47 pagesProject Management Process Frameworkking hNo ratings yet

- Summary Operation ManagementDocument3 pagesSummary Operation ManagementStefanyNo ratings yet

- Crystal: Methods and Spiral Lifecycle ModelDocument23 pagesCrystal: Methods and Spiral Lifecycle Modelsax_loverNo ratings yet

- Product DevtDocument26 pagesProduct DevtRalph Gene Trabasas FloraNo ratings yet

- Lecture Summary DM Jan16 2011Document3 pagesLecture Summary DM Jan16 2011Sensitivelife WailNo ratings yet

- Sware Models MynotesDocument61 pagesSware Models MynotesAlbert OmondiNo ratings yet

- Product Design Specification: Chapter 3: Problem Definition and Need IdentificationDocument3 pagesProduct Design Specification: Chapter 3: Problem Definition and Need IdentificationramsastryNo ratings yet

- Notes Me 112 Concepts in Engineering Design Unit 3Document23 pagesNotes Me 112 Concepts in Engineering Design Unit 3rkNo ratings yet

- Product Design & Development: The Generic Process For Developing New ProductsDocument7 pagesProduct Design & Development: The Generic Process For Developing New ProductsRandeep DevNo ratings yet

- Prestonuniversity: Software Project ManagementDocument7 pagesPrestonuniversity: Software Project ManagementAbdul BakiNo ratings yet

- Software Lifecycle ModelsDocument38 pagesSoftware Lifecycle ModelsNithish BabuNo ratings yet

- 0002 - OM SESSION 2 (Chapter 4 - Process Design & Chapter 5 - Innovation & Design in Services & Products)Document49 pages0002 - OM SESSION 2 (Chapter 4 - Process Design & Chapter 5 - Innovation & Design in Services & Products)Tú Anh NguyễnNo ratings yet

- Chapter-2-1 Product SelectionDocument10 pagesChapter-2-1 Product SelectionAddisuNo ratings yet

- Chapter 2Document36 pagesChapter 2Abhishek SahniNo ratings yet

- Engineering Design Week 1-4 Outlines Fall 2021Document22 pagesEngineering Design Week 1-4 Outlines Fall 2021sajjad hussainNo ratings yet

- Benchmarking and Engineering SpecificationsDocument21 pagesBenchmarking and Engineering SpecificationsJayesh KumavatNo ratings yet

- M20 Revision Notes NSoutputDocument8 pagesM20 Revision Notes NSoutputNam S LiewNo ratings yet

- Innovation & RND Management: Value Analysis/Value Engineering & New Product DevelopmentDocument24 pagesInnovation & RND Management: Value Analysis/Value Engineering & New Product Developmenthikam anggaNo ratings yet

- Jan 21Document5 pagesJan 21annapurn25No ratings yet

- Product Design Session3Document36 pagesProduct Design Session3Sarthak KhoslaNo ratings yet

- Cpl230-Pengembangan Perangkat Lunak (Pertemuan-2) : 5165-Kundang K Juman, Ir, MMSIDocument57 pagesCpl230-Pengembangan Perangkat Lunak (Pertemuan-2) : 5165-Kundang K Juman, Ir, MMSIAhmad SyamsudinNo ratings yet

- Identifying Customer NeedsDocument38 pagesIdentifying Customer NeedsPeriNo ratings yet

- Integrated Design of Production Strategy and Reuse Scenario For Product Line DevelopmentDocument6 pagesIntegrated Design of Production Strategy and Reuse Scenario For Product Line DevelopmentRanga RajanNo ratings yet

- 125 M527 PDFDocument5 pages125 M527 PDFElliza IshakNo ratings yet

- Operations Management Part - 2Document22 pagesOperations Management Part - 2Sai Rock SaiNo ratings yet

- Design For Quality and Product Excellence: NotesDocument11 pagesDesign For Quality and Product Excellence: NotesadnilsallyNo ratings yet

- GK NU POQ 503 Session 5 - DFSSDocument37 pagesGK NU POQ 503 Session 5 - DFSSSaurabh Kumar GautamNo ratings yet

- SPM-unit III-part IDocument6 pagesSPM-unit III-part IAnu IshNo ratings yet

- Vertical Integration Refers To The Degree A Firm Chooses To: BE BEDocument1 pageVertical Integration Refers To The Degree A Firm Chooses To: BE BETin PortuzuelaNo ratings yet

- Lecture Chap 5 - 7Document69 pagesLecture Chap 5 - 7king h100% (1)

- TQM Module 6Document3 pagesTQM Module 6Rafols AnnabelleNo ratings yet

- Agile Development: Software Engineering: A Practitioner S Approach, 7/eDocument18 pagesAgile Development: Software Engineering: A Practitioner S Approach, 7/eMohammad NomanNo ratings yet

- Chapter One (Introduction)Document25 pagesChapter One (Introduction)AbcdNo ratings yet

- Software Engineering - 2Document71 pagesSoftware Engineering - 2Yogansh KesharwaniNo ratings yet

- Lecture 5 PSEDocument29 pagesLecture 5 PSEJason RoyNo ratings yet

- Chapter 4 PPT Content UpdatedDocument18 pagesChapter 4 PPT Content UpdatedLD GentelisoNo ratings yet

- SE Lab ManualDocument36 pagesSE Lab Manualkishori shekokarNo ratings yet

- CONCURRENT ENGINEERING FinalDocument9 pagesCONCURRENT ENGINEERING Finalapi-3757722100% (1)

- Chapter One Software Engineering Practice: The Essence of PracticeDocument9 pagesChapter One Software Engineering Practice: The Essence of PracticeAbdurahmanNo ratings yet

- 4 - Ppt-HciDocument17 pages4 - Ppt-Hcirheena espirituNo ratings yet

- Lecture 4 - Concurrent Product DevelopmentDocument19 pagesLecture 4 - Concurrent Product DevelopmentHassan AttanNo ratings yet

- New Product DevelopmentDocument4 pagesNew Product DevelopmentZain Ul Abidin RanaNo ratings yet

- AMED 01a PDFDocument30 pagesAMED 01a PDFAbenesh KumaresanNo ratings yet

- Fundamentals of CADDocument10 pagesFundamentals of CADBharathi KannaNo ratings yet

- MSE7004 Assignment Brief - MSDocument7 pagesMSE7004 Assignment Brief - MSsidraNo ratings yet

- Code & Fix: Jumping Right in and Designing The: SDLC ModelsDocument7 pagesCode & Fix: Jumping Right in and Designing The: SDLC ModelsfatimaNo ratings yet

- Unit IiDocument267 pagesUnit IigaweroyNo ratings yet

- Marketing Marketing DefinitionDocument3 pagesMarketing Marketing DefinitionRenaldi WijayaNo ratings yet

- Marketing Final ReportDocument70 pagesMarketing Final Reportsatya0% (1)

- Lesson 3 Segmentation Targeting and PositioningDocument40 pagesLesson 3 Segmentation Targeting and PositioningKorine Gain MarutaNo ratings yet

- Original PDF Canadian Advertising in Action 11th Canadian Edition PDFDocument51 pagesOriginal PDF Canadian Advertising in Action 11th Canadian Edition PDFbert.roesch928100% (37)

- C H A P T E R SIX: Targeting Attractive Market SegmentsDocument18 pagesC H A P T E R SIX: Targeting Attractive Market SegmentsHrishikesh MahapatraNo ratings yet

- Marketing Course Guide BookDocument4 pagesMarketing Course Guide Booknatnael yazieNo ratings yet

- Relationship Marketing: Challenges For The Organization: Christian Gro NroosDocument9 pagesRelationship Marketing: Challenges For The Organization: Christian Gro NroosrnaganirmitaNo ratings yet

- International Marketing Management ProjectDocument38 pagesInternational Marketing Management ProjectanniekohliNo ratings yet

- M.H.R.M. MCQs T.Y. B. COM. Sem V With AnswersDocument19 pagesM.H.R.M. MCQs T.Y. B. COM. Sem V With AnswersanikethNo ratings yet

- Polo ReportDocument25 pagesPolo ReportAbid Rahim KhanNo ratings yet

- Kotler - Keller: Marketing Management - 15eDocument7 pagesKotler - Keller: Marketing Management - 15eyeasin khandaker531No ratings yet

- The Daily Drip FinalDocument31 pagesThe Daily Drip FinalJocelyn Mae CabreraNo ratings yet

- Market Segments & Consumer BehaviorDocument11 pagesMarket Segments & Consumer BehaviorGian Elixir TagimacruzNo ratings yet

- Integrated Marketing Communications Mix: Teacher: Isabelle Lanno Champlain CollegeDocument26 pagesIntegrated Marketing Communications Mix: Teacher: Isabelle Lanno Champlain CollegePaulence RaynaldNo ratings yet

- "Marketing Challenges For High-Tech Smes": AuthorsDocument10 pages"Marketing Challenges For High-Tech Smes": AuthorsTafadzwa Matthew GarikaiNo ratings yet

- Romanian Apparel Market 1Document30 pagesRomanian Apparel Market 1Organizația de Atragere a Investițiilor și Promovarea Exportului din Moldova100% (1)

- Globaldata Industry Profile: Edtech in The United Kingdom September 2022Document26 pagesGlobaldata Industry Profile: Edtech in The United Kingdom September 2022Ishika SheoranNo ratings yet

- Paper:: 12, Market Analysis and Selection 14, Marketing ManagementDocument10 pagesPaper:: 12, Market Analysis and Selection 14, Marketing ManagementMohit RanaNo ratings yet

- Porter's Generic StrategiesDocument12 pagesPorter's Generic StrategiesabNo ratings yet

- Mcom SyllabusDocument38 pagesMcom SyllabusRɩsʜʌɓʜ SɘɱwʌɭNo ratings yet

- Flexible Teaching Learning Modality: Prelim ExamDocument20 pagesFlexible Teaching Learning Modality: Prelim ExamCrystal Ann TadiamonNo ratings yet

- SMM8 Figutes PrintDocument23 pagesSMM8 Figutes PrintHongNguyenNo ratings yet

- Strategic Thinking at The Top SummaryDocument3 pagesStrategic Thinking at The Top SummaryAlessandra MontalvoNo ratings yet

- MM PPT FinalDocument20 pagesMM PPT FinalBadalNo ratings yet

- Mukiwa Strategic Managment Model AnswersDocument12 pagesMukiwa Strategic Managment Model AnswersMadalitso MukiwaNo ratings yet

- Diamond Foam - Proposed StrategyDocument34 pagesDiamond Foam - Proposed Strategyhjilani87No ratings yet

- Chapter 8: Identifying Market Segments and TargetsDocument12 pagesChapter 8: Identifying Market Segments and TargetsJewellrie Dela CruzNo ratings yet