Professional Documents

Culture Documents

Zincanode 402: Two Pack Zinc Rich Epoxy Primer

Uploaded by

livefreakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zincanode 402: Two Pack Zinc Rich Epoxy Primer

Uploaded by

livefreakCopyright:

Available Formats

®

ZINCANODE 402

Two Pack Zinc Rich Epoxy Primer PC 122

FEATURES • OVERCOAT WITH EPOXIES, POLYURETHANE, CHLOR RUBBERS WITHOUT SPECIAL TECHNIQUES

• ECONOMICAL AND USER FRIENDLY EPOXY ZINC COATING

• PROVIDES EXCELLENT CORROSION PROTECTION

• RAPID DRY AND OVERCOAT TIMES

• SUITABLE FOR USE IN ENVIRONMENTS UP TO 200°C

USES ZINCANODE® 402 is a two-pack epoxy zinc rich primer designed to provide exceptional corrosion resistance in harsh

exposures by sacrificial methods.

ZINCANODE® 402 is recommended for use over abrasive blast cleaned steel surfaces in most harsh environments,

especially where overcoating is required without special mist or seal coat techniques.

ZINCANODE® 402 offers ease of application, high film builds without mud-cracking and exceptional adhesion to field

weld areas cleaned by power sanding or power wire brushing. It is specified for use in power generation plants, bulk

handling equipment and oil refineries. Also in mining and chemical processes, offshore structures and exposed

pipelines.

SPECIFICATIONS Approved to APAS 2916

AS/NZS 3750-9 Type 2

RESISTANCE GUIDE

HEAT RESISTANCE Up to 200°C dry heat. ALKALIS Do not use in strongly alkaline conditions

unless suitably topcoated.

WEATHERABILITY Epoxy coatings may yellow with time.

On exterior exposure some chalking SALTS Excellent resistance to neutral and alkali

may also occur. This will not detract salts when suitably topcoated.

from the protective properties of the

coating. Use a weatherable topcoat if WATER Suitable for immersion in fresh and salt

required for appearance. water when suitably topcoated.

SOLVENTS Resists splash and spillage of ABRASION Very good when fully cured.

aromatic hydrocarbon solvents and

most common alcohols.

ACIDS Not recommended for acid conditions.

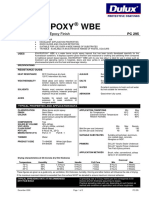

TYPICAL PROPERTIES AND APPLICATION DATA

CLASSIFICATION Zinc Rich Epoxy Primer APPLICATION CONDITIONS Min Max

FINISH Matt Air Temperature 10°C 45°C

COLOUR Grey-Green Substrate Surface Temperature 10°C 45°C

Relative Humidity 85%

COMPONENTS Two

SOLIDS BY VOLUME 48%

VOC LEVEL <460 g/L Min Max Recom.

FLASH POINT Base 32°C, Hardener 25°C Wet film per coat (microns) 125 165 155

POT LIFE 8 Hours (25°C) Dry film per coat (microns) 60 80 75

MIXING RATIO (V/V) Part A : 4 Part B : 1

THINNER 920-08925 Dulux® Epoxy Thinner SUITABLE SUBSTRATES Abrasive blast cleaned steel.

PRODUCT CODE 730-81386 Part A TOPCOATS Single and two pack products.

976-63033 Hardener

APPLICATION METHODS Conventional, airless spray or air

assisted spray. Brush and roller for

small areas.

Drying characteristics at 75 microns dry film thickness

Overcoat

Temperature Humidity Touch Handle Full Cure Min Max*

10° C 50% 2 Hours 17 Hours 7 Days 17 Hours Indefinite

15° C 50% 2 Hours 10 Hours 7 Days 10 Hours Indefinite

25° C 50% 1 Hour 5 Hours 7 Days 5 Hours Indefinite

These figures are given as a guide only, as ventilation, film thickness, humidity, thinning and other factors will influence the rate of drying.

* When used for non-immersion conditions. Refer to PRECAUTIONS section for overcoating intervals and requirements for immersion

service.

TYPICAL SPREADING RATE AT RECOMMENDED A spreading rate of 6.4 sq. metres per litre corresponds to 75

DRY FILM BUILD microns dry film thickness assuming no losses.

Practical spreading rates will vary depending on such factors as

method and conditions of application and surface roughness.

December 2009 Page 1 of 2 PC 122

ZINCANODE® 402

TYPICAL SYSTEMS

(The typical systems are offered as a guide only and are not to be used as a specification. It is recommended that the specific needs of a project

be discussed with a Dulux Protective Coatings Consultant.)

SURFACE PREPARATION GUIDE SYSTEM DRY FILM THICKNESS

STEEL Abrasive blast AS1627.4 Class 2.5 1st Coat ZINCANODE® 402 75 Microns

Abrasive blast to AS1627.4 2nd Coat FERREKO® No 3 100 Microns

Class 3.0 for immersion service 3rd Coat FERREKO® No 3 100 Microns

1st Coat ZINCANODE® 402 75 Microns

2nd Coat DUREMAX® GPE 125 Microns

3rd Coat WEATHERMAX™ HBR 100 Microns

1st Coat ZINCANODE® 402 75 Microns

2nd Coat LUXATHANE® R 50 Microns

SURFACE PREPARATION Steel:

Round off all rough welds, sharp edges and remove weld spatter. Remove grease, oil and other

contaminants in accordance with AS1627.1. Rust, millscale, oxide deposits and old paint films on metal

surfaces must be removed by abrasive blast cleaning to a minimum of AS1627.4 Class 2.5. Immersed

steel must be prepared to AS1627.4 Class 3.

APPLICATION Stir each can thoroughly until the contents are uniform. Use of a power mixer is recommended. Mix the

contents of both packs together thoroughly using a power mixer and allow to stand for 10 minutes.

Ensure the clean-up solvent is available before commencing application. Remix thoroughly before using

and continue mixing during application.

BRUSH/ROLLER For small areas only. Apply even coats of the mixed material to the prepared surface. Thinning is not

normally required, however, up to 50ml/litre of Dulux® Epoxy Thinner (920-08925) can be added to ease

application. When brushing and rolling additional coats may be required to attain the specified thickness.

CONVENTIONAL SPRAY Thinning is not normally required, however, up to 50ml/litre of Dulux® Epoxy Thinner (920-08925) can be

added to ease application. Ensure paint is regularly agitated during application to prevent separation.

Typical Set-up

Graco Delta Gun: 1.8mm (239543)

Pressure at Pot: 70-105 kPa (10-15 p.s.i.)

Pressure at Gun: 380-415 kPa (55-60 p.s.i.)

AIRLESS SPRAY Standard airless spray equipment such as a Graco 33:1 Bulldog or 45:1 Xtreme with a fluid tip of 15-17

thou (0.38-0.43mm) and an air supply capable of delivering 550-690 kPa (80-100 p.s.i.) at the pump.

Ensure paint is regularly agitated during application to prevent separation. Thinning is not normally

required but up to 50 ml/litre of Dulux® Epoxy Thinner (920-08925) may be added to ease application.

PRECAUTIONS This is an industrial product designed for use by experienced Protective Coating applicators. Where

conditions may require variation from the recommendations on this Product Data Sheet contact your

nearest Dulux® representative for advice prior to painting. Do not apply in conditions outside the

parameters stated in this document without the express written consent of Dulux® Australia. Freshly

mixed material must not be added to material that has been mixed for some time. The rate of cure is

dependent upon temperature. Do not apply at temperatures below 10°C. Do not apply at relative

humidity above 85% or when the surface is less than 3°C above the dewpoint. When used for immersion

conditions the maximum overcoat interval is 3 days at 25°C. The coating MUST be fully cured and

solvent free prior to being placed under immersion conditions. For best results in water immersion

conditions replace Dulux® Epoxy Thinner (920-08925) with CR Reducer (965-63020). Topcoats of a

saponifiable nature such as alkyds must never be applied directly to ZINCANODE®402.

CLEAN UP Clean all equipment with Dulux® Epoxy Thinner (920-08925) immediately after use.

OVERCOATING Aged coating should be tested for lifting by a method appropriate for the coating thickness, for example

‘X’ cut or cross-hatch methods. If it lifts, remove it. The surface must be free of oil, grease and other

contaminants. High pressure water wash at 8.3 to 10.3 MPa (1,200- 1,500 p.s.i.) to remove loosely

adhering chalk and dust.

SAFETY PRECAUTIONS Read Data Sheet, Material Safety Data Sheet and any precautionary labels on containers.

Contents of container may be under pressure. Containers should be carefully opened by first placing a

rag, then a hand, over the lid then gently easing the lid off.

STORAGE Store as required for a flammable liquid Class 3 in a bunded area under cover. Store in well-ventilated

area away from sources of heat or ignition. Keep containers closed at all times.

HANDLING As with any chemical, ingestion, inhalation and prolonged or repeated skin contact should be avoided by

good occupational work practice. Eye protection approved to AS1337 should be worn where there is a

risk of splashes entering the eyes. Always wash hands before smoking, eating, drinking or using the

toilet.

USING Use with good ventilation and avoid inhalation of spray mists and fumes. If risk of inhalation of spray

mists exists, wear combined organic vapour/particulate respirator. When spray painting, users should

comply with the provisions of the respective State Spray Painting Regulations.

FLAMMABILITY This product is flammable. All sources of ignition must be eliminated in, or near the working area. DO

NOT SMOKE. Fight fire with foam, CO2 or dry chemical powder. On burning will emit toxic fumes.

WELDING Avoid inhalation of fumes if welding surfaces coated with this paint. Grind off coating before welding.

MATERIAL SAFETY DATA SHEET is available from Customer Service (132377) or www.duluxprotectivecoatings.com.au

Dulux Protective Coatings a division of DuluxGroup (Australia) Pty Ltd PACKAGING Available in 4 litre and 10 litre packs

1956 Dandenong Road, Clayton 3168 TRANSPORTATION WEIGHT 2.12 kg/litre (Average of components)

A.B.N. 67 000 049 427 DANGEROUS GOODS Part A: Class 3 UN 1263

Dulux, Zincanode, Ferreko, Duremax, Weathermax and Luxathane are registered

Part B: Class 3 UN 1263

trademarks. DuluxGroup is a trademark.

Any advice, recommendation, information, assistance or service provided by DULUX Australia in relation to goods manufactured by it or their use and

application is given in good faith and is believed by Dulux to be appropriate and reliable. However, any advice, recommendation, information, assistance or

service provided by Dulux is provided without liability or responsibility PROVIDED THAT the foregoing shall not exclude, limit, restrict or modify the right

entitlements and remedies conferred upon any person or the liabilities imposed upon Dulux by any condition or warranty implied by Commonwealth, State or

Territory Act or ordinance void or prohibiting such exclusion limitation or modification. Products can be expected to perform as indicated in this sheet so

long as applications and application procedures are as recommended. Specific advice should be sought from Dulux for application in coastal areas and for

large projects to ensure proper performance.

December 2009 Page 2 of 2 PC 122

You might also like

- To 1-1-4 640423Document154 pagesTo 1-1-4 640423Stephen J Riordan IVNo ratings yet

- Functional Polymer Coatings: Principles, Methods, and ApplicationsFrom EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsRating: 1 out of 5 stars1/5 (1)

- WP 11 Corrosion Protection Tape CoatingDocument3 pagesWP 11 Corrosion Protection Tape CoatingKarthikNo ratings yet

- GM 4350M-2004 部件涂层性能要求Document7 pagesGM 4350M-2004 部件涂层性能要求KESAVANNo ratings yet

- B GAS Painting Multiple Choice 2Document9 pagesB GAS Painting Multiple Choice 2Muhammad NasirNo ratings yet

- Zincanode 304: Solvent Borne Inorganic Zinc SilicateDocument3 pagesZincanode 304: Solvent Borne Inorganic Zinc SilicatelivefreakNo ratings yet

- Luxepoxy T: Tintable Two Pack Epoxy FinishDocument2 pagesLuxepoxy T: Tintable Two Pack Epoxy FinishlivefreakNo ratings yet

- Aquagalv: Water Borne Inorganic Zinc SilicateDocument3 pagesAquagalv: Water Borne Inorganic Zinc SilicatelivefreakNo ratings yet

- Luxepoxy UHB: Ultra High Build EpoxyDocument2 pagesLuxepoxy UHB: Ultra High Build EpoxylivefreakNo ratings yet

- Durebild HSE: High Build Two Pack Epoxy CoatingDocument3 pagesDurebild HSE: High Build Two Pack Epoxy CoatinglivefreakNo ratings yet

- Zinc Rich 1p pc102Document2 pagesZinc Rich 1p pc102livefreakNo ratings yet

- Duremax Gpe ZP Aug 2018Document3 pagesDuremax Gpe ZP Aug 2018Biju_PottayilNo ratings yet

- Luxafloor ECO: Water Borne Epoxy Floor CoatingDocument2 pagesLuxafloor ECO: Water Borne Epoxy Floor CoatinglivefreakNo ratings yet

- Durebild Ste Glass Flake pc239Document3 pagesDurebild Ste Glass Flake pc239livefreakNo ratings yet

- Steel Shield 1200Document2 pagesSteel Shield 1200Moin AltafNo ratings yet

- Duremax GPE: General Purpose Epoxy CoatingDocument4 pagesDuremax GPE: General Purpose Epoxy CoatinglivefreakNo ratings yet

- Luxafloor Rollcoat: High Build High Solids Epoxy Floor CoatingDocument3 pagesLuxafloor Rollcoat: High Build High Solids Epoxy Floor CoatinglivefreakNo ratings yet

- Apexior-No 1 Aug 2018Document2 pagesApexior-No 1 Aug 2018emadsafy20002239No ratings yet

- Pds Zincanode 690 VocDocument2 pagesPds Zincanode 690 VocmuthukumarNo ratings yet

- Epilux 82: Product DescriptionDocument2 pagesEpilux 82: Product DescriptionMoin AltafNo ratings yet

- Zincanode 620 Voc v1 Jan 2018Document2 pagesZincanode 620 Voc v1 Jan 2018Moin AltafNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Apcotherm Epn 200Document2 pagesApcotherm Epn 200Moin AltafNo ratings yet

- Apcodur Ehb 500-VocDocument2 pagesApcodur Ehb 500-VocMoin AltafNo ratings yet

- High Solids Epoxy Zinc Rich Primer for Corrosion ProtectionDocument2 pagesHigh Solids Epoxy Zinc Rich Primer for Corrosion ProtectionmuthukumarNo ratings yet

- Microsoft Word - L3_Epilux82.docDocument2 pagesMicrosoft Word - L3_Epilux82.docvitharvanNo ratings yet

- Luxepoxy STL: Solventless Epoxy Tank Lining PC 246Document2 pagesLuxepoxy STL: Solventless Epoxy Tank Lining PC 246livefreakNo ratings yet

- High Solids Coal Tar Epoxy Product SpecificationsDocument2 pagesHigh Solids Coal Tar Epoxy Product SpecificationsAbuhurairah MunshiNo ratings yet

- Coaltar Epoxy - Epilux5 - 0474Document2 pagesCoaltar Epoxy - Epilux5 - 0474GautamNo ratings yet

- EPIMASTIC 5100-March 2019 Version 2Document2 pagesEPIMASTIC 5100-March 2019 Version 2PraveenNo ratings yet

- Revchem HRC 870Document3 pagesRevchem HRC 870marciobispoalmeidaNo ratings yet

- Epilux 155Document2 pagesEpilux 155Allana100% (1)

- Pds Epilux 218 VocDocument2 pagesPds Epilux 218 VocmuthukumarNo ratings yet

- k2) Luxatherm5200 5219Document2 pagesk2) Luxatherm5200 5219Syed FaridNo ratings yet

- Steelshield Ve: Product DescriptionDocument2 pagesSteelshield Ve: Product DescriptionMoin AltafNo ratings yet

- l2) Steelshield1200 3041Document2 pagesl2) Steelshield1200 3041Syed FaridNo ratings yet

- EPILUX 850 SF VOC Jan-2017Document2 pagesEPILUX 850 SF VOC Jan-2017PraveenNo ratings yet

- Carbozinc 858: Selection & Specification DataDocument4 pagesCarbozinc 858: Selection & Specification DataNico RoisnerNo ratings yet

- Metalshield Premium Aug 2018Document2 pagesMetalshield Premium Aug 2018Biju_PottayilNo ratings yet

- P3) Water Based Universal PrimerDocument2 pagesP3) Water Based Universal PrimerBrandon LimNo ratings yet

- Epoxy Primer - Epilux610 - 4079Document2 pagesEpoxy Primer - Epilux610 - 4079GautamNo ratings yet

- 19.abcolux18hs Content 237Document3 pages19.abcolux18hs Content 237MbimbikNo ratings yet

- Carbocoat 8239: Selection & Specification DataDocument4 pagesCarbocoat 8239: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- Product Data Sheet: Sikacor® Zinc RDocument4 pagesProduct Data Sheet: Sikacor® Zinc RMohammedBayrakdarNo ratings yet

- Durebild STE: Surface Tolerant High Build High Solids Epoxy CoatingDocument3 pagesDurebild STE: Surface Tolerant High Build High Solids Epoxy CoatinglivefreakNo ratings yet

- d2) Epilux218 4267Document2 pagesd2) Epilux218 4267Syed FaridNo ratings yet

- Epilux 800Document2 pagesEpilux 800anandNo ratings yet

- Carboguard 635 Thinned 50% - Sealer PDSDocument5 pagesCarboguard 635 Thinned 50% - Sealer PDSjakeNo ratings yet

- g9) Berger Apcofine 905 - 8096Document2 pagesg9) Berger Apcofine 905 - 8096Wasek SarkerNo ratings yet

- Sherwin Williams Macropoxy M262 PDS Promain 05 09 2022Document2 pagesSherwin Williams Macropoxy M262 PDS Promain 05 09 2022paNo ratings yet

- b6) Zincanode690 2886Document2 pagesb6) Zincanode690 2886Anonymous XVEucVMsENo ratings yet

- Nullifire SC601 PDSDocument4 pagesNullifire SC601 PDSPeter ThomsonNo ratings yet

- ROYALPOXY UW 410-tdsDocument3 pagesROYALPOXY UW 410-tdsSyed FaridNo ratings yet

- LUXATHERM 6200 Silicone Acrylic Heat Resisting Finish (220°CDocument2 pagesLUXATHERM 6200 Silicone Acrylic Heat Resisting Finish (220°CPraveenNo ratings yet

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 pagesB B B Berger Erger Erger Erger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Epilux 8: Product DescriptionDocument2 pagesEpilux 8: Product DescriptionMoin AltafNo ratings yet

- SigmaZinc 100 zinc primer guideDocument4 pagesSigmaZinc 100 zinc primer guideJohnson Chng Hou KiatNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- High Build Epoxy Anti-Corrosive Primer SpecsDocument2 pagesHigh Build Epoxy Anti-Corrosive Primer SpecsMuthuKumar100% (1)

- Epoxy Coating 162 PWDocument2 pagesEpoxy Coating 162 PWANIBALLOPEZVEGANo ratings yet

- Carboguard 703 GF PDSDocument4 pagesCarboguard 703 GF PDSDuongthithuydungNo ratings yet

- SikaCor SW-501 - EN - CDocument4 pagesSikaCor SW-501 - EN - CMark InnesNo ratings yet

- Hi Temp 400: Silicone Based High Temperature Coating PC 929Document2 pagesHi Temp 400: Silicone Based High Temperature Coating PC 929JeromeNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Durebild Ste Glass Flake pc239Document3 pagesDurebild Ste Glass Flake pc239livefreakNo ratings yet

- Zinc Rich 1p pc102Document2 pagesZinc Rich 1p pc102livefreakNo ratings yet

- Luxafloor Rollcoat: High Build High Solids Epoxy Floor CoatingDocument3 pagesLuxafloor Rollcoat: High Build High Solids Epoxy Floor CoatinglivefreakNo ratings yet

- Floor PurCem Chemical Resistance Guide PDFDocument6 pagesFloor PurCem Chemical Resistance Guide PDFlivefreakNo ratings yet

- Luxepoxy STL: Solventless Epoxy Tank Lining PC 246Document2 pagesLuxepoxy STL: Solventless Epoxy Tank Lining PC 246livefreakNo ratings yet

- Ceilcote 180 Flakeline+ds+engDocument4 pagesCeilcote 180 Flakeline+ds+englivefreakNo ratings yet

- Ceilcote 2000 Flakeline+ds+engDocument4 pagesCeilcote 2000 Flakeline+ds+englivefreakNo ratings yet

- Luxafloor ECO: Water Borne Epoxy Floor CoatingDocument2 pagesLuxafloor ECO: Water Borne Epoxy Floor CoatinglivefreakNo ratings yet

- Ceilcote 680 Primer AKZO PDFDocument4 pagesCeilcote 680 Primer AKZO PDFamitzalteNo ratings yet

- GSDGDSGSGDocument4 pagesGSDGDSGSGAnonymous fj9ypF83No ratings yet

- Zincanode 202: Two Pack Zinc Rich Epoxy PrimerDocument2 pagesZincanode 202: Two Pack Zinc Rich Epoxy PrimerlivefreakNo ratings yet

- Ceilcote 505 Coroline+ds+engDocument4 pagesCeilcote 505 Coroline+ds+englivefreakNo ratings yet

- Enviropoxy WBE: Water Borne Acrylic Epoxy FinishDocument2 pagesEnviropoxy WBE: Water Borne Acrylic Epoxy FinishlivefreakNo ratings yet

- Ceilcote 222GF Flakeline+ds+engDocument4 pagesCeilcote 222GF Flakeline+ds+englivefreakNo ratings yet

- Ceilcote 242GF Flakeline+ds+engDocument4 pagesCeilcote 242GF Flakeline+ds+englivefreakNo ratings yet

- Ceilcote 140 Flakeline+ds+engDocument4 pagesCeilcote 140 Flakeline+ds+englivefreakNo ratings yet

- Durebild STE: Surface Tolerant High Build High Solids Epoxy CoatingDocument3 pagesDurebild STE: Surface Tolerant High Build High Solids Epoxy CoatinglivefreakNo ratings yet

- Ceilcote 380 PrimerDocument4 pagesCeilcote 380 Primeryoonchankim0911No ratings yet

- Ceilcote 64 Lining: Description ApplicationDocument3 pagesCeilcote 64 Lining: Description ApplicationlivefreakNo ratings yet

- Ceilcote 262 Flakeline+ds+engDocument2 pagesCeilcote 262 Flakeline+ds+englivefreakNo ratings yet

- Duremax GPE: General Purpose Epoxy CoatingDocument4 pagesDuremax GPE: General Purpose Epoxy CoatinglivefreakNo ratings yet

- Ceilcote 6640 Ceilcrete+ds+engDocument4 pagesCeilcote 6640 Ceilcrete+ds+englivefreakNo ratings yet

- Ceilcote 74 Lining+ds+engDocument4 pagesCeilcote 74 Lining+ds+englivefreakNo ratings yet

- Ceilcote 242 FlakelineDocument4 pagesCeilcote 242 Flakelineyoonchankim0911No ratings yet

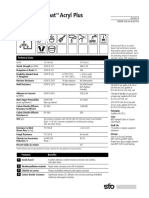

- Sto Acryl Plus crd+648+tbDocument2 pagesSto Acryl Plus crd+648+tbOgbedande Awo OrunmilaNo ratings yet

- J P G T: HapterDocument28 pagesJ P G T: HapterKali AbdennourNo ratings yet

- Kupsa Catalogue PDFDocument10 pagesKupsa Catalogue PDFPratik MehtaNo ratings yet

- Chartek 7 Application Manual 2016 (Rev 9)Document80 pagesChartek 7 Application Manual 2016 (Rev 9)Tudor MoraruNo ratings yet

- DS - 645 - Pro Anticarb HB Elastomeric CoatingDocument2 pagesDS - 645 - Pro Anticarb HB Elastomeric CoatingRay EngineeringNo ratings yet

- Florock Seamless Flooring Systems: Page 1 of 6 Florock Architectural Specification - Floroshop 8/16Document6 pagesFlorock Seamless Flooring Systems: Page 1 of 6 Florock Architectural Specification - Floroshop 8/16shashibagewadiNo ratings yet

- Create Art with SiporexDocument8 pagesCreate Art with SiporexRagaviNo ratings yet

- Mastertop Aggregate Sra 1m&3m 12-04Document2 pagesMastertop Aggregate Sra 1m&3m 12-04djrote4No ratings yet

- Tekasil Neutral Profi enDocument2 pagesTekasil Neutral Profi enEzeval GráficaNo ratings yet

- PC 2569 Apcomin Industrial Rozc PrimerDocument3 pagesPC 2569 Apcomin Industrial Rozc PrimerAshishKumar RavalNo ratings yet

- National NC Auto Lacquer ClearDocument3 pagesNational NC Auto Lacquer Clearkranti_purushNo ratings yet

- Sikafloor - 89: 2-Part Water Based Epoxy CoatingDocument4 pagesSikafloor - 89: 2-Part Water Based Epoxy CoatingEaswar KumarNo ratings yet

- Topcoat HS 420 Technical Data SheetDocument4 pagesTopcoat HS 420 Technical Data Sheetjunot880% (1)

- PDS Superlastic S600 Final v2Document5 pagesPDS Superlastic S600 Final v2sofyanNo ratings yet

- Epoxy HR: Technical Data SheetDocument5 pagesEpoxy HR: Technical Data SheetMohamed FarhanNo ratings yet

- Roush Paint Appearance Standard AS 100 1 PDFDocument6 pagesRoush Paint Appearance Standard AS 100 1 PDFBESNo ratings yet

- NAVSEA Reviewed ASTM F-718 CoatingDocument3 pagesNAVSEA Reviewed ASTM F-718 CoatinghainguyenbkvhvNo ratings yet

- Glo Construction AdhesivesDocument34 pagesGlo Construction Adhesivesİsmihan AltinNo ratings yet

- Master Exterior Wall Putty TDS 2020Document4 pagesMaster Exterior Wall Putty TDS 2020defender paintsNo ratings yet

- MasterEmaco 2525 ASEAN V1.4 0713Document2 pagesMasterEmaco 2525 ASEAN V1.4 0713Muhammad Fadhil ImansyahNo ratings yet

- Maperod C I Maperod GDocument4 pagesMaperod C I Maperod GdraganugNo ratings yet

- Carbozinc 859: Selection & Specification DataDocument5 pagesCarbozinc 859: Selection & Specification DataFrancis BautistaNo ratings yet

- SSPC PS Guide 4.00Document5 pagesSSPC PS Guide 4.00anoopkumarNo ratings yet

- Ardex Cl11: Commercial Levelling & Smoothing CompoundDocument4 pagesArdex Cl11: Commercial Levelling & Smoothing CompoundkrmchariNo ratings yet

- Interior Latex Semi-Gloss GL64XX: PremiumDocument2 pagesInterior Latex Semi-Gloss GL64XX: PremiumVenkatesh SridharanNo ratings yet

- CMM 21 26 05 81205 20151101 015Document57 pagesCMM 21 26 05 81205 20151101 015melany carolinaNo ratings yet